The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  annealing

annealingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I feel that I am ready to try annealing some brass. any suggestions on how to? what I have come up with so far is: 1. Place brass in upright positon 2. propane torch to necks 3. let cool and resize / trim how hot do i get the brass? how do i know if i did it right? Is it really that simple? | ||

|

| one of us |

whooa boy yoy may have reopened a can of worms with that question. Simple answer is, you are on the right track. Heat the necks until just red. Then quench in the water. Then prep for loading. I have a handy gaget I got from Todd Kindler at the Varmints Den in Baltic Ohio. It is a "wand" that attaches to your propane torch. Creates a circle of flame to evenly heat the neck. I then use the wand to bump the case over. I am sure there is a metallurgist some where on this forum that can enlighten us as to the proper temperature to anneal brass without ruining the case. muck | |||

|

| One of Us |

Do a youtube search on the subject. I ran across some neat and economical tricks to aid in the process. Good luck! Double Rifle Shooters Society | |||

|

| One of Us |

I use color as my indicator also. I also watch the shoulder as to not allow the dis-coloring to go below the shoulder. I use a cordless drill and my lee 3 jaw chuck but you can use a machanics socket say 7/16 I think for .308/06 size and a 1/4" adapter in a drill to spin the case to heat uniformly....I however don't water quench I air quench in front of a fan. ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

| one of us |

This is a seriously philistine approach and I'm sure I'm going to get flamed for it, but here goes anyway: I set up my blowtorch over a bowl of water and turn the case neck in the flame, holding the rim between my fingers. In some cases (220 Swift being a prime example), I feel pain before I see discolouring. In other cases (.375 etc), it's the other way round. Whichever happens first, I simply drop the case into the water. Primitive and un-scientific, but it's worked for me for years | |||

|

| one of us |

You may find a lot of useful hints here: https://forums.accuratereloading.com/eve/forums/a/tpc/f/2511043/m/712108088/p/1 I started to anneal thanks to that discussion and I see the difference at the range | |||

|

| One of Us |

Rikkie, I do exactly the same thing, with the lights off, I can see the colour change more easily. | |||

|

one of us |

I have annealed a LOT of brass since I started it. I will say, emphatically, that it not only works with aiding in consistent neck tension, it is a MUST when you are anal like me and try to achieve the very best groups with your rifles. I've gotten so efficient with my cheap-o Hornady kit that I can knock out 250 rounds in no time. I still do not drop brass in cold water and have yet to have a problem. Ted Kennedy's car has killed more people than my guns | |||

|

| One of Us |

I tried Varmint Al's dark room technique: http://www.varmintal.com/arelo.htm  http://www.6mmbr.com/annealing.html Somewhere between 1950 and 1968 William Dresser wrote an article for the NRA, "Case Neck Annealing" that shows up in "The NRA Handloader's Guide". He recomends 700 degree F crayons. http://www.centaurforge.com/700-Degree-Tempilstik/productinfo/TEMPIL700/ I tried Varmint Al's technique and since gave up. I am doing great without annealing, but if you want to, more power to ya. | |||

|

| one of us |

Norma recommendations , IIRC, are to place cases in a pan of water ,heat until red ,the immediately tip into the water. Brass starts to anneal at 450 F . | |||

|

| one of us |

It's curious; many say that hot cases must be dropped/tipped in water, while others don't. I've seen some promos of annealing machines and none of them consider the use of water..... BTW, I don't use water. | |||

|

| One of Us |

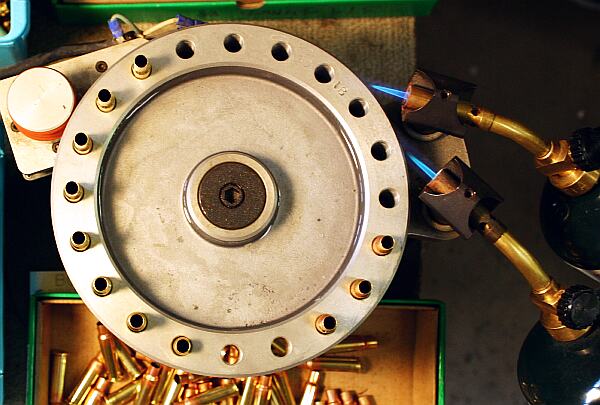

If memory serves me correctly the desired Temp. is 660 Degrees F. for case mouth and shoulder . The water pan method prevents case head and body from excessive heat . Might be useful to a beginner ?. A portable drill and chuck to hold cases with a map gas or propane torch in a holding fixture ( secured torch ). Works well enough . It's been my personal observation a red case mouth is to hot a burnt orange color is better. However observing the case shoulder color is a far better indicator IMO . Should be steel blue gray color at shoulder junction .Factory and home annealed anyone care to guess which is which .  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia