The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Cleaning brass, what is the best...

Cleaning brass, what is the best...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Good day everyone, I've just been reading an old article on brass cleaning and its pitfalls, namely 'Handloader' # 136, an article written by Steve Timm. Now, I use a vibratory tumbler with dry tumbling media. I've decided to get back into .223 reloading. This article states that the tumbling media might collect(read agglutinate) in cases of low capacity, mainly due to other-than-bone-dry conditions. I've never given a second thought to this, and I've never gotten into a situation that indicated an overpressure of unknown origins. But then, Ive never reloaded small cases before. To those of you that do not have the article as written in 'Handloader', the gist is that a handloader got indications of severe overpressure in cases he had handloaded(.17 mach IV). His rifle was sent to the parent company and it was determined(by Mr. Timm, company resident gun nut) that tumbling residue had accumulated in the cases, thus reducing case capacity and increasing pressure. The solution, as described by Mr. Timm, was to de-prime/size, tumble and then soak in a light grease-cutting detergent solution, shake through a colander and drying through heated forced-air(I'm not even going to try explaining this, northern vs. southern climes) Has anyone in this forum been in a similar situation? Mr. Timm's article does raise a few questions, namely: Is dry-media tumbling as safe as it purports to be? Is the inclusion of a wet-cleaning step in case prep a worthy one? Hoping that the aficionados of reloading(that's most of you, I hope) have a worthwhile comment to this topic. Tazzman | ||

|

| One of Us |

I have the Lemi Shine and some distilled white vinegar, ultrasonic cleaner per the 6mmBR article. I also have lots of vibrators. This guy, Kombayotch, is the best science nerd in internet reloading forums: http://www.snipershide.com/for...owflat&Number=933264 | |||

|

| one of us |

And here I thought you didn't have a sense of humor . . . that's TFF!!! And I duly note you giving UUUseful advice to someone from Kanada. | |||

|

| One of Us |

I've changed the way I prep cases the last year. Main reason was to speed up cleaning but I think the change has a few pluses. I used to tumble brass in walnut shell media with brass polish for hours, prep cases and then tumble again for hours in treated corn media to remove the resize lube which left a film of resize lube and brass polish. Some times I would try to remove film with a cloth but was again time consuming. Rifle 1. Deprime cases 2.Clean brass in Birchwood case cleaner http://www.birchwoodcasey.com/...&subcat=3&prodcat=57 I mixe it 1 1/2 times stronger and leave a little longer in solution. Rise good in fresh water and and air dry. wearing rubber gloves (brass should be deprimmed before putting in solution) 3. resize rifle brass 4. clean off resizing lube in lacure thinner wearing rubber gloves let air dry OUTSIDE. 10-15 minutes 5. dedur and clean primmer pocket,trim to lenght and neck turn as needed( debur and neck turn first time only and check lenght after shooting if crimped ammo) 6.tumble in untreated corn media leaving no film 7. load to specs. Pistol most I just tumble and run thru progressive reloader with carbide dies , brass could be cleaned in Birchwood cleaner if primmers are removed 41 mag & 44 mag I trim them all to minimum lenght to assure even crimp, hunting ammo I add deprime and clean primmer pocket | |||

|

| One of Us |

Lacquer Thinner is a generic name for a petroleum based solvent blend. Toluene (Toluol), Xylene (Xylol), Methyl Ethyl Keytone What does it all mean? When you see the word "Toluene", you want to avoid it, or wear lots of protective gear. | |||

|

| one of us |

I can not see the soaking then drying then shaking thing sounds like it would be even more likely to have media left in the case. With rifle cases I have gotten into the habit of wiping them after the shot right out of the chamber then when loading, size deprime, trim if necesssary then vibrate the lube off with almost dry media NRA Life member | |||

|

| One of Us |

MEK is also known as Methyl Ethyl Death. Use 90% Isopropyl Alcohol (IPA) instead. It is cheaper and you can use it indoors. You can buy a bottle on sale at a discount store for less than $.40 so buy 4 or 5 and lable thme so they do not get used for something inappropriate. In fact you can skip a lot of that case cleaning agony by just keeping the brass clean. Rinse in soapy water and then re-rinse in hot water. After the hot water drain and wipe off, rinse in IPA just to absorb the water in the interior. Roll on a towel then turn upside down in a loading block. Place in front of a fan for 30 min and they are ready to load. If you need to protect your hands a box of black nitrile gloves is about $7 at harbor freight. The IPA can also be used to removed case lube. If you do get cruddy brass you can still use the other methods. Rinse any garbage that will come off with soap and water and permit to air dry. Start out with the Birchwood Casey cleaner mixed per spec. Add your cases to a large pyrex pan then add the Birchwood. Warm on a hot plate to a little over 100 F. The heat will make the acid react with the oxides faster. Drain out the acid and rinse in hot water. If they are clean enough, dry and load if not tumbling may be required. The pretreatment with the acid will make the tumbling more effective. | |||

|

| One of Us |

I just de-prime them then in the vib cleaner for a while,then re-size.When done back in they go for a little while.I have enough brass that i don't have to have them done in 20 min.Good Luck | |||

|

One of Us |

I guess it's time for my usual post on how I clean brass. I don't own a tumbler anymore, gave it to a kid starting out in reloading. I can trim, chamfer, clean the outside of the case, clean the inside of the neck and apply mica to 50 cases in about 45 minutes  the outside can be made a matte finish or a slick shiny one  no liquids, no chemicals, no dust, no waiting ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I don't own a tumbler either. After sizing, I wipe cases clean with a degreaser. That's as clean as they get. I'm not interested in getting lead dust in my lungs, so no tumblers in my shop. Don | |||

|

| One of Us |

Too much information dude. I use either treated corn cob or treated walnut shells in the vibrator. This takes about 15 to 20 mins max depending on how many I'm doing. I use denatured alcohol to clean off any residue. I resize, trim to length, debur, etc. and then run them through the vibrator with treated walnut shell media. Again, maybe 15 or 20 mins. I then remove the residue with denatured alcohol and finish loading them. Nice, clean, reasonably shiney reloads are done. Takes me about 1.5 to 2 hours to do 50 338-378 Wby reloads from beginning to end on my single stage press. My smaller stuff is a little bit quicker. Ken.... "The trouble with our liberal friends is not that they are ignorant, but that they know so much that isn't so. " - Ronald Reagan | |||

|

| One of Us |

Woods your brass looks great. Now we need the details. Von Gruff. | |||

|

One of Us |

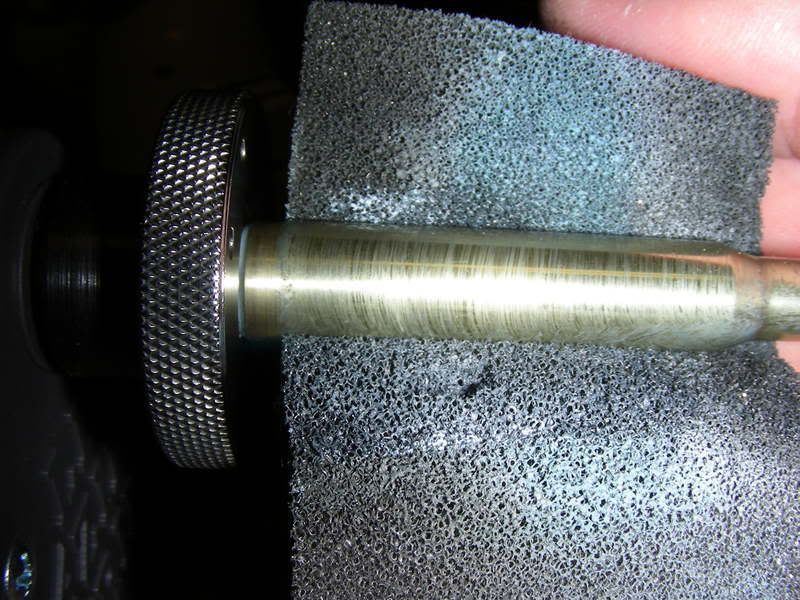

After sizing, put case in a Zip Trim screwed to a piece of 2x4 and held in a vise, trim and chamfer  then spread a line of Flitz on the case and spread with one of those sponges that come in the top of a box of TSX's   hold a rag against it and spin again  clean the inside of the necks with some steel wool wrapped around a 22 brush  and dip in mica. Substitute a piece of Scotchbrite for the Flitz for a brushed finish  But I like the Flitz finish. It chambers easier and tarnishes less. I don't Flitz new cases so they can grab the chamber walls during the initial expansion. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Seems alot of work compared to tumbling. | |||

|

| One of Us |

Just how challenging is it to hold a case up to the light to see if the light shines all the way thru. | |||

|

| One of Us |

I was wondering that too, but wasn't going to say anything. Anyone use a reshaped paperclip to check for any internal signs of beginning separation? Picked up that habit from Bob Milek. I use a variation of the "woods" method but with 0000 steel wool instead of flitz, and RCBS caseslick on a cotton swab instead of mica. It's also amazing to me that people who pay top dollar for customized guns and top line scopes will go as cheaply as possible when reloading their ammo? Great guns deserve great ammunition! | |||

|

| One of Us |

Brass Cleaning Thread Rusty We Band of Brothers! DRSS, NRA & SCI Life Member "I am rejoiced at my fate. Do not be uneasy about me, for I am with my friends." ----- David Crockett in his last letter (to his children), January 9th, 1836 "I will never forsake Texas and her cause. I am her son." ----- Jose Antonio Navarro, from Mexican Prison in 1841 "for I have sworn upon the altar of god eternal hostility against every form of tyranny over the mind of man." Thomas Jefferson Declaration of Arbroath April 6, 1320-“. . .It is not for glory, nor riches, nor honours that we are fighting, but for freedom - for that alone, which no honest man gives up but with life itself.” | |||

|

| One of Us |

When I first started reloading I tried the paperclip check for case head seperation a few times but the real answer is no. In @ 45 years of reloading I can recall maybe 2 or, at most, 3 case head seperations. And that includes partials. I don't like to run my ammo at top end on the one hand and I usually find some other signs that warn me off such as primer pockets getting loose or necks getting thick, that sort of thing first, and then I pitch it. I only neck size or what they now call partial full length resize. I use a F/L die but only work the case enough to ensure positive chambering so the case body works very little. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Cleaning brass, what is the best...

Cleaning brass, what is the best...

Visit our on-line store for AR Memorabilia