The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Seating Depth's effect on Velocity

Seating Depth's effect on VelocityGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Inquiring minds want to know.... | ||

|

| one of us |

It is a marginal change, but velocity typically increases very slightly as seating depth increases with a given powder charge. For one thing, you're effectively making the barrel longer | |||

|

| One of Us |

IIRC, within reason, on the chamberings that I've seated way over the SAAMI oal specs, the velocity decreased. GWB | |||

|

| Moderator |

When load for long and the shortened, pressure goes up opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I did some searching in the mean time and off of the Hornady website found this:

| |||

|

| one of us |

I did this for my 300 Win Mag and the velocity decreased about 60-70 fps. Graybird "Make no mistake, it's not revenge he's after ... it's the reckoning." | |||

|

One of Us |

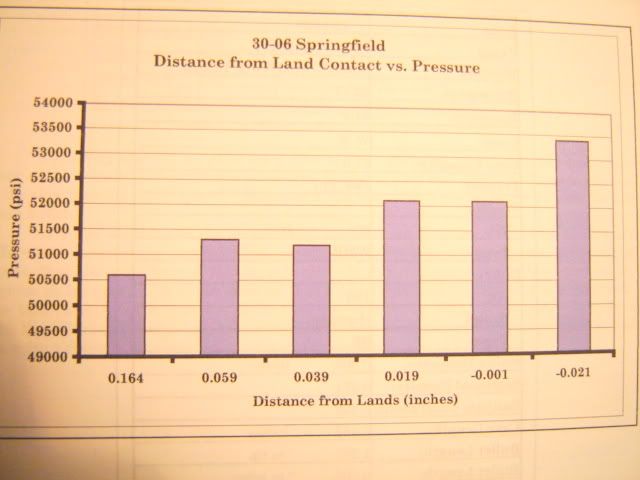

Barnes: Once our cartridge selection was made we worked up loads which were below SAAMI maximum pressure, but within a few thousand pounds of the maximum pressure to account for variation and drop-off within a given sample. We set our first distance at 0.025” off the lands, then continued to move the distance out at 0.025” intervals for five separate groups. Our one exception was the .300 Weatherby Magnum. We started at SAAMI maximum length for the cartridge and moved back in 0.050” increments. We divided the powders into two groups, ball and extruded, for which we worked up loads and shot groups. We thought there could be a significant difference in how the different types of powders reacted. We used the same primers for both powders — if magnum primers were used for one powder type they were also used for the other. We used Federal GM215M for the magnum cartridges and Federal GM210M for the others. To begin our experiment, we established some basic parameters in which we would operate. These parameters included case length, distance from the lands, powder type, primer type, and what information we would record from the shooting tests. We decided at the onset to perform two tests within the experimental parameters. The first test would utilize ball powders only, while in the second test we would use extruded powders. All other parts of the test remained the same for both data collections. The one other exception was with the Weatherby data. We did not start at 0.025” off the lands since Weatherby rifles have very long throats. For the Weatherby rifle, we began at SAAMI maximum length and worked back in increments of 0.050” until we had fired five separate groups. Cartridge loads were worked up by one of our diligent Ballistic Technicians (Shooter is his nickname) until they reached an approximate pressure of 60,000 to 65,000 psi, dependent upon the SAAMI map. The barrels were first calibrated using SAAMI calibration ammunition to ensure the pressure readings were accurate. Then the five different groups were shot in order from closest to the lands to farthest from the lands. After each group a break was taken so the barrel could cool off. We decided to use well-known cartridges featuring a variety of case capacities. We felt this would allow for a wider spectrum of differences not only within the cartridge, but also between cartridges. PRESSURE CHANGE The pressure seems to fluctuate between highs and lows as distance from the lands becomes larger. For example, as the distance moved to 0.100,” pressure increased with some of the cartridges, particularly the .300 WSM and the .30-06 Springfield. Some of the cartridges had pressure increases with either the ball or extruded powders but not both. This was true with the .300 RUM and the .300 Win. Mag. As can be seen in the chart below, pressure change was not a constant for this experiment and results were highly surprising for several of the cartridges. Keep in mind, this was not an average of tests, but the result of a single test per cartridge. We tried to work up loads that would be within the 96% range of the SAAMI maximum pressure rating for each cartridge. This proved to be somewhat tenuous, as the pressures would drop off differently for each cartridge. *Note: beginning on the left with shot No. 1, distance is closest to the lands, and ends with shot No. 5 on the right, which was seated at the greatest distance from the lands. This applies to all charts.  Hornady, click the link and go to bottom of page to see the illustrations: To illustrate the effects of variations in bullet travel before the bullet enters the rifling, we'll compare a standard load with adjustments made only in the bullet's seating depth. In a "normal" load with the bullet seated to allow about one 32nd of an inch gap (A) between the bullet and the initial contact with the rifling, pressure builds very smoothly and steadily even as the bullet takes the rifling. Pressure remains safe throughout the powder burning period (B), and the velocity obtained - 3500 fps - is "normal" for this load in this rifle. Seating the bullet deeper to allow more travel before it takes the rifling, as in these next two illustrations, permits the bullet to get a good running start (C). Powder gases quickly have more room in which to expand without resistance, and their pressure thus never reaches the "normal" level. Nor does the velocity; with the same powder charge it only comes to 3400 fps (D). When the bullet is seated to touch the rifling, as in the accompanying illustrations, it does not move when the pressure is low (E); and not having a good run at the rifling as did the other bullets, it takes greatly increased pressure to force it into the rifling. As the rapidly expanding gases now find less room than they should have at this time in their burning, the pressure rise under these conditions is both rapid and excessive (F). Velocity is high at 3650 fps - but at the expense of rather dangerous pressure. Many rifles deliver their best groups when bullets are seated just touching the rifling. Seating bullets thus can be done quite safely if the reloader will reduce his charge by a few grains. The lighter load will still produce the "normal" velocity without excessive pressure. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

It seems this will serve as a learning experience for many of us here! Really interesting how pressure increases with some cartridges using extruded powder as the bullet is backed off the rifling but with ball powder, it decreases! | |||

|

| One of Us |

obviously a deeply seated bullet goes faster, cause it gets a running start | |||

|

| One of Us |

Hey, I got it right! Red C. Everything I say is fully substantiated by my own opinion. | |||

|

One of Us |

Velocity will follow pressure and seating deeper will decrease velocity. I have seen it happen with magazine length restricted loads. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Just finished shooting a Ladder named for the beautiful offspring of Mr. Audette with the .338 Lapua at 1000 yards. The loads at mag length with 104 grains of powder which were .100" off the lands chrono'd at 2875 fps. Cartridges loaded to an OAL that was .030" off of the lands with 101.5 grains of the same powder chrono'd at 2860 fps. The .030" off loads had a vertical dispersion of only 2.5" at 1000 yards! less than .25 MOA! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Seating Depth's effect on Velocity

Seating Depth's effect on Velocity

Visit our on-line store for AR Memorabilia