The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Induction annealing brass

Induction annealing brassGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

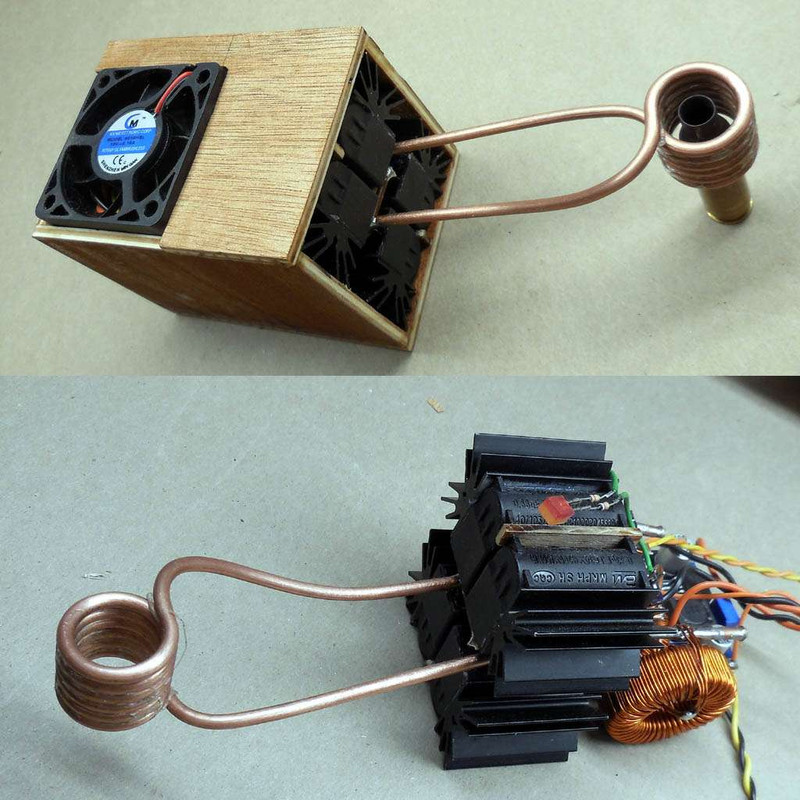

As a handloader I've annealed a lot of brass necks using a propane torch, a drill, and a bucket of water. This is a pretty tedious process as I'm sure many people here know, but it really extends the useful life of brass and can help significantly with reducing velocity variation. I've seen various induction annealers over the years, but was always put off by the price tags. Being cheap, I attempted a DIY version which has recently come to fruition. I don't have a good way to post a video, but here's a quick picture of it in action:  It took some tinkering but is now working well. It can quickly put a lot of heat into the neck without heating the case head. I can just hold a case by the head with my fingers, anneal it, and set it down before the head even gets warm. The power is adjustable so it can anneal a short fat WSSM and then be turned down to anneal a 223 or a hornet. I'm quite pleased with it! | ||

|

| one of us |

I would assume that the induction heating method heats the brass more evenly than flame heating. Looks quick and clean. How do you determine how hot to get the brass? | |||

|

| One of Us |

What's the "recipe" for the annealer? That's looks awesome. | |||

|

| One of Us |

Isn't red hot too hot? | |||

|

| one of us |

Plans would be appreciated. Dave | |||

|

| One of Us |

Lake City Army Ammunition Plant uses induction heating to anneal the four million rounds of ammo they produce every day. Brass is heated to 1100 degrees for annealing. Twice during the drawing process. | |||

|

| One of Us |

Lets face it, if Lake City uses it then at the very least it must be expeditious. Looks like nice even heat. Details on your coil material, power source and rheostat would be appreciated. I am visualizing a standard 120 volt outlet to something akin to the charcoal starter loops (modified size, etc.) and an inline rheostat to adjust heat out put. Just a quick guess. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| One of Us |

If you are really truly interested in building an induction annealer there is another reloading website that has oooodles and oooodles of info including schematics and links on what and where to buy components. I don't wish to p o moderators by naming a competing site but use your Google-Fu and find it---lots of good information. Gary | |||

|

| One of Us |

We've got an annealing service going here in NZ as per the link below. Probably good value for expensive cases such as some of the oddball and big caliber stuff. http://www.trademe.co.nz/sport...ction-1255913292.htm | |||

|

| One of Us |

I'd love to see your plans. Always wanted to explore induction. Doug Wilhelmi NRA Life Member | |||

|

| Moderator |

it's mag resonance that does this -- i don't know if a charcoal starter would work, as it only takes like a fraction of a second for induction heating to warm up a case.. i looked at building this, and the power source was like 399 back then.. no clue for today opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I tracked down the discussion of this on a another forum with a name similar to this one. Between Amazonnand eBay it looks like about $25 or less to construct it. Real straight forward for a simple one to do one cartridge at a time. Virtually plug and play. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| One of Us |

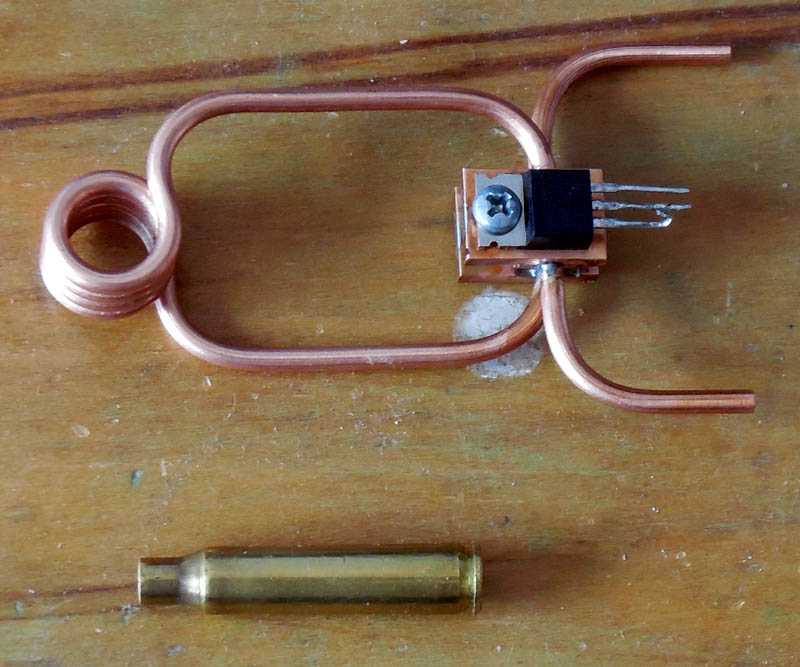

This is the basic idea: https://en.wikipedia.org/wiki/Induction_heating There are lots of ways to do it as you'll find with google. The trick to doing it on the cheap is getting various inexpensive/available/re-purposed components to work together. Here's a good description of a homebuilt setup: https://markobakula.wordpress....er-induction-heater/ Yes, the case in the picture/video is too hot. But it's just for illustration because otherwise it just looks like a case. My setup process involves repeatedly heating a scrap case in low light until it just starts to visibly glow dull red (this is about 450 degrees) in the desired area as quickly as possible. I adjust case position, power, and duration. Time and temperature are the factors in annealing brass, not just temperature. You could make a cartridge case dead soft overnight in your kitchen oven at a much lower temperature (bad idea, btw). The depth in the work coil determines how much of the case gets heated. The power level and duration can also be used to tune the process, because you don't want the case head to get hot, but a very high power for a short time will tend to overheat the mouth before the neck-shoulder area gets hot enough. So, as with torch annealing there is some tuning of the setup/process. I'm finding that inductive annealing is much quicker and more versatile though. I would not try to anneal pistol brass with a torch, for example. Water cooling is easy and makes high volume annealing sessions possible once things are set up. Air cooling could work, with suitable delays between cases for things to cool off. Generally, a low voltage high current power source is the expensive part; unless you use an old car battery perhaps. There are some threads on rewinding a transformer from a microwave oven (MOT) to build a cheap high power DC supply. | |||

|

| One of Us |

Did a little hunting. 3 main components: the induction heater/element itself, a digital timer with memory to control the duration of heat and the power supply. The power supply is the most costly if you can say any of it is costly. Between Amazon, a good source for the power supply and eBay for the other two components (3 if you count the element that is not attached to the induction unit) the total cost was just shy of $34.00. This is for a one case at a time induction unit. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| One of Us |

Now, just mount it on a progressive set up for deprime and anneal stations- with an audible beeper for timing.... | |||

|

| One of Us |

I have seen plans for an automated unit on another site, not hard to find. You set the case in, punch timer, and it drops out at the proper time. Very slick and I think the parts cost was less than a couple of hundred bucks. So far I just haven't come up with a good excuse to build one. C.G.B. | |||

|

| One of Us |

I think it's mostly for match/volume shooters who reload. Annealing 10 cases to reload for a hunting trip is simpler with a torch, or just load 10 new cases for that matter. | |||

|

| One of Us |

I think so and by quite a bit. | |||

|

| One of Us |

Great idea but I live in the USA. | |||

|

| one of us |

You can now get an induction unit for the Giraud annealer. Look on the Giraud web site. It cuts the heating time down to 1.3 - 1.4 seconds. Awesome piece of kit.  | |||

|

| Administrator |

We never object to members mentioning other websites. As far as I am concerned the more good websites we have the better. You can include links too. | |||

|

| One of Us |

I saw this auction (it's not mine) and he shares some details of the setup: http://www.ebay.com/itm/292068166797 | |||

|

| one of us |

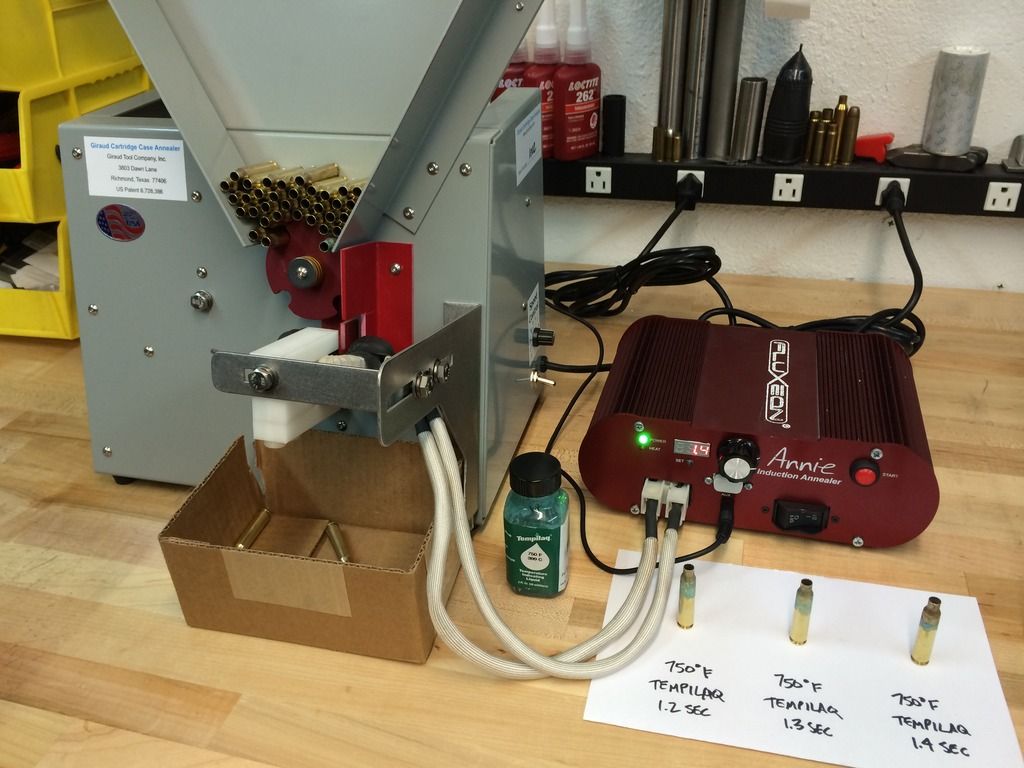

Here is the Giraud annealer set up for induction heating of the brass necks and shoulders:  Here is the heart of the induction system, called Annie:  Note: We do not sell the Fluxeon Annie induction power supply. You will need to order it directly from Fluxeon, www.fluxeon.com. When ordering, you must specify this will be used with a Giraud Annealer and requires the use of the 2-1/2" diameter iron ferrite and RS-232 to 1/8" phono plug adaptor. Without those parts, the Annie will not be able to be mated to the Giraud Annealer. The Fluxeon Annie standard configuration is not capable of working with the Giraud Annealer. I have enquired about the price of both units, and will post my results here as soon as the companies respond.  | |||

|

| One of Us |

Thanks for posting that; it looks like a nice setup! The last time I checked into something commercial like that, it was about $3k. I'm curious if they're more affordable now. | |||

|

| one of us |

I'll bug them about price tomorrow. I would like to go to a Giraud set-up.   | |||

|

| One of Us |

It looks like the prices have come down a lot on these things. From the fluxeon site it's about $500 for the annealer and maybe another $100 in cooling, coils, etc. | |||

|

| one of us |

I did some looking into that unit for quite some time, it would be a fun toy IMO, and it works with any caliber without having a set up time, basically just dump cases in and turn on the switch, but getting too long in the tooth for such toys. and my butane torch works well and I have no schedule time wise. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

one of us |

About $1000 all in $500 to Giraud $500 to Annie Hunting: Exercising dominion over creation at 2800 fps. | |||

|

| One of Us |

These guys are publishing a lot of good info on induction annealing cases. I found it to be pretty interesting: https://www.ampannealing.com/a...nder-the-microscope/  | |||

|

| Administrator |

We are using the AMP annealing machine. It works great, and we love it. Very fast and very consistent. | |||

|

| One of Us |

I've been annealing a bunch recently. It really helps with forming wildcats, like these 30cal necked down to 22:  Here is some milsurp 223 brass being annealed: https://vimeo.com/279384452 | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| one of us |

Great thread! There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

| |||

|

| One of Us |

Thanks Mr jpl. That's an interesting read and very revealing. Zeke | |||

|

| One of Us |

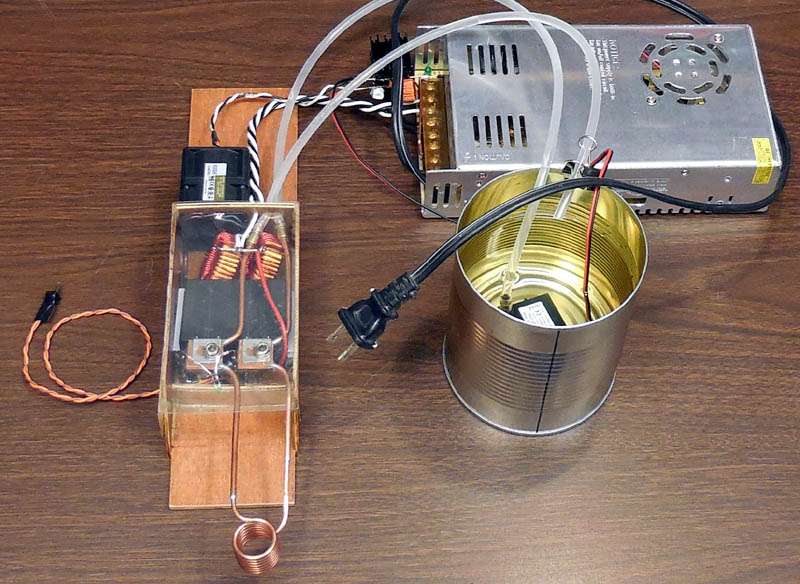

Some of my old pictures from other threads are still working, so I thought I'd put them here too. I've built a bunch of these and maybe someone would like to copy some parts of the designs. The ones with fans are cheap and easy to build, and the film caps are pretty robust. Parallel resonant is the way to go, because the voltages are low and safe for a "hand tool" type environment. The DC power supply is the most expensive part.    Testing with different size cases in large coil:    Video: https://vimeo.com/279384452 | |||

|

| One of Us |

If you want to deal with ordering from China here is an address https://www.banggood.com/searc...duction-heating.html Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | |||

|

| One of Us |

Wow. That is THE nastiest web site I've seen in a long time. Cookies and trackers and scripts from all over the planet. I need to hose out my computer now... | |||

|

| one of us |

I was told by and old guy who has annealed more brass than most ammo companies...He said"you can't get a case too hot, and the rest is BS" Any comment on that? I have no opinion on it,but did shoot a lot of brass he annealed for me at one time..Just curious.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

I guess my comment would be that not many useful things can be said with absolutes. Sure, you can overheat a case. You could melt it. You could heat it long enough that the entire case gets hot and the case head is annealed. A soft case head could fail at full pressure. If the goal is to anneal the neck, then these are two examples of "too hot" in my opinion. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia