The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Ackley shoulders

Ackley shouldersGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I agree that the "peak" pressure inside a case will be the same in all directions. But does that nessecarily mean that all you have is a boring little "poof" and that's that? Obviously I disagree that the shape of the case/chamber is irrelevant. What is "apparent" bolt thrust? Something that appears to exist but really doesnt? Here is an intresting little quip from Ackleys Vol I; "The design of the standard 300 Magnum (H&H) case employs a rather steep body taper and long sloping shoulder which results in case seperation just forward of the belt after the cases have been loaded a few times. This trouble is eliminated in the improved 300 OR the 300 Weatherby because of the absence of these two objectional features". That statement could be taken in a number of different directions pertaining to this discussion. And I know what I take from it, but I will just say this. If there is nothing to that statement, and/or if case shape is irrelevant and we are so much more well informed today then Ackley was back in '62. Then why are there not more cases designed like the H&H today and less newer cases that more closley resemble one of the many "Improved" designs? AK-47 The only Communist Idea that Liberals don't like. | |||

|

| one of us |

If you would read a bit more carefully (or I would write a bit more specifically) you would understand that many people judge "bolt thrust" by how hard it is to raise the bolt after firing a round (bolt stickiness or lack thereof). "Apparent bolt thrust" is having a sticky bolt. An Ackely chamber may allow higher pressures without causing the bolt lift to be sticky because the shape of the chamber allows brass springback to spring away from the bolt face, thus making it easier to lift. This is not a result of less pressure, just brass springback. Ackley was dead wrong about the case shape of the H&H leading to head separations. Head separations are caused by repeated firings of brass with excessive headspace. Many reloaders were taught that the sloping shoulders of the .300 H&H are inadequate to headspace the case (patently untrue), so they should FL size and rely on the belt to control headspace. As any shooter/reloader of belted cartridges knows, relying on the belt for headspace is very sloppy, and if such brass is full length sized repeatedly it will cause it to grow very thin at the web (the point where the brass of the case head tapers into the brass of the case walls and where the stretching occurs upon firing with loose headspace.) So why aren't more modern cases designed with the long taper of the H&H? It's because we've found it unnecessary. The slope of the H&H was to make it feed smoothly and extract easily. There was also a theory prevailing in the early Twentieth Century that long, sloping shoulders also somehow reduced pressure, a theory which has long been debunked (much as some of the Ackely theories are debunked today). The H&H cartridges also were designed for use of Cordite, the long, straw-type smokeless powder used by the British in the early part of the last century. It was easier to load Cordite in a long, tapered case. Quite clearly, near-cylindrical case walls and sharp shoulders maximize case capacity using the same length cartridge. Having long since abandoned the "pressure reducing" theory of tapered cases, cartridge designers as far back as Arthur Savage with his .300 have been using straight cases and sharp shoulders to get the most from shorter cartridges (the .300 Savage was designed to closely duplicate the performance of the original .30-06 loads, which it actually did before the .30-06 loads were boosted with better powders). MOre recent cartridge designs like the WSM and WSSM series take the cylindrical case and sharp shoulder to the extreme in attempting to wring more power out of shorter cartridges. That's why there are "not more cases designed like the H&H today". | |||

|

| one of us |

There are two very good reasons that your standard .250 will not stand the same loads as your improved .250: First, the larger chamber of the improved .250 will not allow the powder to generate as much pressure as the smaller chamber of the standard rifle (simply, if you put as much air in a 15 inch car tire as in a 22 inch truck tire the car tire is going to have a lot more pressure, okay?) Second, no two rifles behave the same, even if they have identical chambers. You can easily have one rifle show excessive pressure with the same loads that are within acceptable pressure in another rifle of identical caliber. So comparing your standard .250's performance with your Improved .250's performance is not just apples and oranges, it's apples and blueberry muffins. | |||

|

| One of Us |

Mr. Stonecreek, I with most of whats been said. I disagree on a couple of points. 1. Neck length does not always remain the same in all Ackley chambers. The 30-30/30-30AI being one example. 2. I know "back-thrust" is considered theoretical but according to the laws of physics something does exsist regardless of what we call it. 3. Again, I haven't got this one totally figured as it pertains to guns but a cylinderical chamber " not necessarily a rifle chamber" area is what determines the pressure required to move the bullet. I.E. hydralic ram effect. And for every action an opposite and equal reaction occurs. The pressure vessel or barrel must be sized to withstand that pressure. I might be all wet but thanks for the good discussion. | |||

|

| One of Us |

Thanks for clarifying that. And your right, I should have re-read your previous statement. My apologies. And so I did re-read and I find some of your statements reguarding the subject somewhat contradictory. First you said; "5. There is no difference in "bolt thrust" with an Ackley cartridge versus a regular cartridge. Bolt thrust, just like chamber capacity, is a function of how hard the expandable brass case is forced against the walls of the chamber," And then; "An Ackely chamber may allow higher pressures without causing the bolt lift to be sticky because the shape of the chamber allows brass springback to spring away from the bolt face, thus making it easier to lift. This is not a result of less pressure, just brass springback." Brass springback, or rather a lack thereof causing a sticky bolt, means that it has been stressed beyond its point of elasticity and so has remained pressed against the cylinder walls. If there is no difference in "bolt thrust" in an ackley chambering, and bolt thrust by your definition being how hard the expandable brass is pressed against the cylinder walls, then the point of a loss of elasticity would not change due to the shape of the chamber. And therefore loss of springback would be no different for the two either because the metalurgy of the brass does not alter with the chamber shape. Therefore the thing that has changed IS the amount of stress on the brass, or bolt thrust, due to the only variable there is, the shape of the chamber. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| one of us |

Wstrn: Again, you miss the point (or I failed to adequately describe it) regarding brass springback and case shape. The point I was making is that the shape of the Ackely case DOES minimize the effects of the expanded brass in bearing heavily against the bolt face after the round is fired. The best example I can cite for this is the insoluble problem that Smith and Wesson ran into with the .22 Jet in the Model 53. The Jet has a very long, sloping shoulder. When fired, the case head bears against the pressure plate (the equivalent of the bolt face). The shape of the long, sloping case after being expanded by the pressure of firing would hold the case head firmly against the pressure plate, thus freezing the cylinder. With a cylindrical revolver cartridge at the same pressures this is not a problem since there is no long slope to hold the expanded case rearward against the pressure plate. In this instance, a near-cylindrical cartridge (.357 Mag for example) exhibits no "bolt thrust" at the same pressure that a .22 Jet "freezes the bolt". The .357 is the counterpart to a near-cylindrical Ackely rifle cartridge. The difference in springback problems between a .22 Jet and a .357 magnum is much greater than between, say, a .280 Rem and a .280 AI, but the principle is the same. So, generally speaking, the more cylindrical the cartridge the less residual friction against the bolt after firing. As I said, lots of people equate sticky bolt lift with "less bolt thrust", but it is really a function of brass springback. Thus, if a cartridge case can be subjected to higher pressures without causing a sticky bolt then many people assume that it is exerting less "bolt thrust", which isn't necessarily so. | |||

|

| one of us |

There is at least one other factor which may have something to do with the belief that the Ackley series exerts less "bolt thrust". Harder brass has more springback than softer brass. Each time a brass case is fired and reloaded it gets work-hardened to some degree. Virtually all load development and formal shooting in an Ackely rifle is done with fireformed brass, and because the Ackely design provides such "good case life", Ackely brass is typically fired numerous times. It may very well be that, on average, brass for an Ackely chamber is more work-hardened and thus harder than the average for a conventional chamber (by definition it has one additional firing in fireforming.) Since harder brass has more springback then it follows that it would exhibit less friction against the bolt face upon opening -- walla!, less "bolt thrust". There are a jillion variables in cartridges and reloading. No one theory explains all of them. But with the Ackely concept, which is a good one, there have been attributed many qualities which are either illusory or simply don't exist. | |||

|

| One of Us |

The mathematics is very simple in regards to analyzing bolt thrust with a free body diagram. A free body diagram identifies forces based on the geometric form. If you have no knowledge of trig there is nothing I can do to change your mind. Had you studied trig you would be embarrassed to be making some of those statements. For a more complex study of the subject go to Varmit Al's web site and see the FEA of bolt thrust that he does with a .243 and varying surface texture in the chamber. His technique uses a tool that was never available to Ackley. All the Ackley fans can do is load and shoot and report observations. They often have no clue as to what caused the phenomena they see. Varmit Al's Analysis | |||

|

| One of Us |

Stonecreek, those were some very informative postings. I must admit that my knowledge of terms and definitions is somewhat lacking. What is the term used to describe the rearward exertion of force placed on the bolt face stemming from the applied forces developed during the firing of the case. To show my ignorance of terms, I always thought this was called bolt thrust. As I see it this rearward force should occur twice after the firing pin drops. Once as the bullet leaves the case and the case is pushed back and again as peak pressure is developed. Am I correct in my thinking? Also wouldn't you say that action design and finish play an equal role in bolt lift (thrust) as much as case design? I got to thinking about my Tikka T3 rifle I have in a 338 WM. I get case face impressions from the openings for the ejector and extractor as well as severly flattened primers using neck sized Winchester cases when I am over peak loading. I can't remember ever reaching a point where I felt a sticky bolt. The T3 action is very smooth as are some others. "The right to bear arms" insures your right to freedom, free speech, religion, your choice of doctors, etc. ....etc. ....etc.... -----------------------------------one trillion seconds = 31,709 years------------------- | |||

|

| One of Us |

I think Stonecreek was just making a funny on the bolt thrust because bolt thrust is the force put on the bolt from gas pressure in firing a cartridge. | |||

|

| One of Us |

No Chit? Why.....that dirty dog "The right to bear arms" insures your right to freedom, free speech, religion, your choice of doctors, etc. ....etc. ....etc.... -----------------------------------one trillion seconds = 31,709 years------------------- | |||

|

| One of Us |

Why am I not suprised that you are gloming onto my remark about mathematics? Thats ok, I dont mind because I know I understand things that mathmaticians dont. Your post contributes next to nothing reguarding the topic but is otherwise laden with a very condescending tone. You lay claim to a higher level of understanding and then try to back it up with a link to someone elses webbsite about fricition in various rifle chamber finishes but doesnt say a damn thing about the effects of Ackley chamberings on bolt thrust. I am not embarassed about my remarks at all. You my friend are the one who has failed to make your case. Im disapointed. Your posts are usualy better than that. Its been a fun exchange though, but it seems to be going round in circles now. If I gave someone cause to think, then Ive done my part.. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I would suggest taht you then get a spread sheet and do the maths. The increase in case life is marginal for various reasons. And the cost is ultimately higher.

In short, any Ackley cartridge is more expensive to load / use compared to the parent round. Having said that, I love my 280 Acley Imp and had great fun develping loads for it. I learned a lot about reloading and balistics while doing that. Good luck with your projects.

"When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Like I said the math is easy if you have had trigonometry but there is no way to make you understand it if you have not had trig. Your problem, not mine. Try forcing pressure against a slope. The force deflecting the pressure down the slope is the tangent of the angle of the taper of the case. Since the taper angle of the case is very small the tangent of the angle is very small and the resulting force down the slope is tiny. If you have a rough finish you just have hard extraction with very high pressure. With low pressure there is no problem because the case springs back and the taper provides the extraction clearance. In the case of minimal taper such as the typical Ackely improved if you get a tear in the chamber or the surface is rough you will have difficulty with extraction. That is because you have little self releasing clearance due to the lack of taper. You will get this issue with any common case with little body taper regardless of the shoulder angle. The only way to avoid that with an Ackley or any other near zero tapered chamber is to polish it to a nice finish so the case will release. The finish of the chamber makes a bigger difference than the chamber shape. All you get with the Ackley chambers is a good polish. If you do not get that it will not extract. If you read Varmit Al's data you will eventually figure that out. And you will figure out with a better chamber finish - your cases last much longer. | |||

|

| One of Us |

Stonecreek, I can't say for sure how the H&H 300 cases were loaded with Cordite, but know for sure the 303 military cases were loaded with the Cordite before the case was formed into a bottleneck. That is it was pretty a cylinder, then the powder was installed, then finished case forming, and finally bullet seated. Like I said I'm not sure how they loaded Cordite in commercial cartridges. Also later on didn't they chop up the Cordite to shorter lengths rather then the long spaghetti strings? I agree on the tapered case separating because they headspaced it off the belt instead if chamber fit. This is even true of modern belted magnums. I also thought the long taper was insurance to better loading such is double rifles. One tends to get very nervous when a wounded dangerous big game animal is about to maul him. | |||

|

| one of us |

SmokinJ For doubles the Brits preferred "flanged" cases (Rimmed to us Yanks) The belt was/is nothing more than a thick rim, developed to prevent rim locking (upper round with the rim behind the lower rounds rim) in magazine fed bolt guns. The original belted case, the 400/375 (I have a couple where the headstamp is simply "Hollands Patent") started as a 40cal straight wall flanged case, necked down to accept a .375 bullet and the rim thickened into a belt | |||

|

| One of Us |

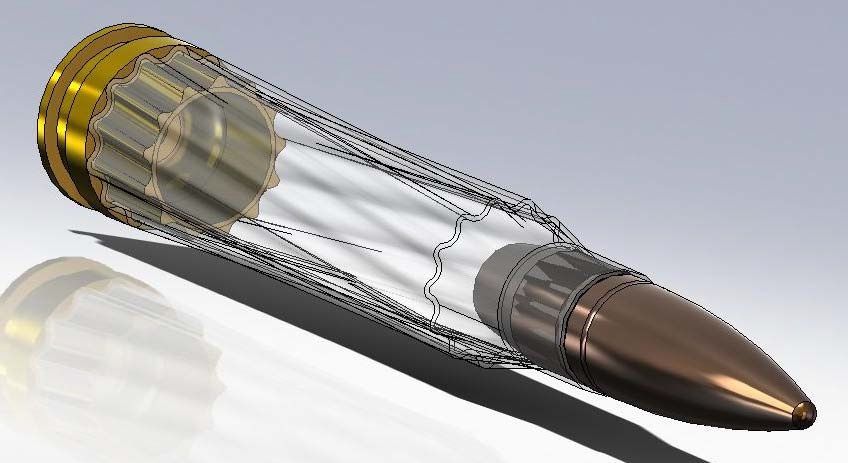

Regarding the Ackley Improved cartridges, I have found through some 45 years of use in varmint hunting, that as the years went by they became less useful. The bulk of my experience is with the .257 Roberts AI, and more recently the .22-250 Remington AI. There is one other fantasy cartridge in the collection, the .35-348 Winchester AI, in a Siamese Mauser action. This latter cartridge was only selected because I had a spare action and decided to go as weird as possible, weirdness being interesting. In truth, today there is nothing that can be accomplished with the AI case that can't be duplicated with a factory offering. When Ackley was experimenting with cartridges he did not have the incredible selection of cartridges, powders and primers we have today. The number of combinations is mind boggling. Most of the time whatever velocity gain is obtained with the AI case it is simply not a significant factor, other than some intangible belief or preference of the shooter. As for case stretch, now that I have gone to the Savage Precision Target Action and Remington actions equipped with a barrel nut, precisely controlling headspace has eliminated that variable. Cases last indefinitely. In the case of a recent .22-250 Ackley build, I used a Pac-Nor barrel with the Rem-Nut on a new bare Remington 700 action modified by Greg Tannel, set the headspace to the minimum and fire formed a series of sample cases. These went off to Hornady's Custom Shop to have a hydraulic forming die made, along with a matching F.L. sizing die - cost $300. Hornady's hydraulic forming die bumped up the cases to the Ackley profile, except that the shoulder/body junction was slightly radiused. Upon firing that slight radius sharpened up. Both the hydraulically formed cases and the once fired cases performed the same on the target. Same group size, under .5" with a Barnes 50 Grain Varmint Grenade, and same POI. That lash-up delivered 3,706 fps with a Barnes 50 grain Varmint Grenade over 37.5 grains of Varget. Increasing the powder charge, or use of other powders opened the group. The barrel cost right at $600 with a muzzle brake. Just for comparison, I bought a Bergara Remington 700 prefit varmint contour barrel in .22-250 Remington. These barrels use a smooth barrel nut and swap out like a Savage, and exchanged it for the Ackley barrel. Results were surprising. The Pac-Nor Ackley barrel was ordered in 1:9" twist expressly for the 50 grain Varmint Grenade, the Bergara barrel is a 1:12" twist for the standard .22-250 Remington. Barnes recommends a 1:10' or faster twist for the Varmint Grenade, mirroring my experience with these long for weight bullets. Both barrels are 24". A load of 36.3 grains of Varget sent the Varmint Grenade out of the Bergara barrel at 3,815 fps, shot the same >.5" groups and performed flawlessly. So the conclusion with this one rifle is that a factory made barrel, the Spanish Bergara, chambered for a standard case performed as well as, or slightly better, than the Ackley Improved version. The Bergara barrel cost about $300, with shipping. Bergara barrel quality is top notch. While the Ackley Improved barrel cost $470 exclusive of the muzzle brake. Hydraulic forming the cases is an extra expense, and very time consuming. There is no advantage to the Ackley chamber in this instance. One final word. Over the years, I have found that fire forming Ackley cases requires a fairly stout load within reason, something under maximum. If the chamber isn't cut to minimum headspace, or the cases are short to the neck/shoulder junction, the primers will protrude and the case will shorten, increasing headspace. Some seat a bullet into the lands to hold the case head against the bolt face, which may stick a bullet in the lead if forced to unload without firing, such as when a cease fire is called. I have adopted the practice of using midrange loads for fire forming to ensure that cases are completely filled out. This is caused by insufficient pressure to force the case body against the chamber keeping it against the bolt face as the firing pin blow has moved it forward. Below is a representation of what can happen with too light a load allowing gas to flow back against the case. This is a rimmed case so rather than produce excessive headspace, well it's obvious. Ackley Improved cartridges offer no advantages that I can discern, except the cool factor.  | |||

|

| One of Us |

I have spent time reviewing what documents I was able to find on DTIC concerning case design. There will be a bolt load reduction due to case friction but it is inconsistent and is not relied on in any way. No mechanism is made weaker assuming the case carries load and no cartridge is designed to operate at higher pressures based on the assumption that the case carries load. Higher pressures are dangerous as pressure increases the chance of a case head rupture. Breech mechanisms are designed to take the full thrust of the cartridge case, ignoring case friction, plus safety factors for fatigue life and manufacturing uncertainties. Everything I have found indicates case friction is undesirable. Case friction is a real concern for the military as case friction causes function issues. The first and foremost is that high enough case friction will cause failures to extract. You can look at calculations in the study “Analytic Study of Extraction Forces in the M16 Weapon”, Gordon, Frankford Arsenal Oct 1973. As I found in the report “Design and Development of a 30 mm Aluminum Cartridge Case” , Lossnitzer, 1970, the tendency for a cartridge case to stick in the chamber and cause extraction problems is primarily a function of • The material modulus of elasticity • The radial clearance between the cartridge case and chamber wall • The thickness of the chamber • The taper of the case and chamber • The coefficient of friction between the cartridge case and the chamber wall It should be obvious that sticky extraction, failure to extract is undesirable in any gun mechanism. Another issue with case friction is case separation. When a cartridge is fired , if the bolt mechanism is relatively flexible, and the case sidewall friction high, during firing, the case sidewall can be stretched beyond its elastic limit causing body splits and case separations. This is very undesirable in automatic weapons. If during extraction the cartridge leaves a case neck, upper part of the case in the chamber, this will cause a jam and the weapon will be inoperable until the interfering case part is extracted. I have had case head separations in Garands/M1a’s and probably bolt rifles. The weapon was out of commission till I found a cleaning rod and brass brush. There have been times that the brush would not knock out the case front and I had to find a cartridge case extractor. This is of little to no consequence, other than aggravation, when rock busting, but it takes time to get the rifle functional. For me, a target shooter, the relay and match can be over before I get my rifle functional, and thus I have wasted a day. If I was hunting it might mean loss of game, if hunting large and dangerous game, it might mean I am on the menu, or if in conflict with humans, a weapon down is likely to cost a life. No technical document I have reviewed is case friction anything but undesirable. Nor have I found any discussion of case shape any desire for the case shape to increase friction, in fact, the studies show that among many factors considered, case designers want to reduce case friction between the chamber and case. Page 13 of this presentation Ballistic Performance of Steels and Aluminums in FE Firing Simulations, March 2011 shows that reducing case friction with a material change is a desirable goal and also shows just how much technology has changed the sophistication of cartridge analysis since the days of P.O Ackley. Compare this analysis between the 1973 paper referenced previously, it is apparent analysis tools have really changed in the last forty years. It may very well be that the sharp shoulders of Ackley improved cartridges increase stress concentrations at the radius and increase the chance of case failure. I have not seen anything to change my opinion that the lack of case taper in Ackley cartridges is good either from a feed or extraction viewpoint. As I said before, taper allows better steering of cartridges and relaxation of material from a diagonal will create greater clearance between the case and chamber than relaxation from a line. I consider fraudulent the idea that the design of Ackley improved cartridges somehow reduce thrust, reduce load, and therefore it is safe or even smart to increase combustion pressures. Ackley's designs did not increase the thickness nor increase support of the case head. The unsupported part of the case is the weakest link in weapon design. The major selling point of AI’s is still “snake oil”. Any “advantage” of Ackley cartridges over their standard counterparts is due to increased powder capacity which, given the same pressure, will provide increased velocities. From what I have read, the 280 Ackley Improved cartridge is popular enough to justify its existence and must be good cartridge. I will stick with standard cartridges as they meet all my needs and are logistically easier to support. There is another issue that has not been touched, it is a lot easier to sell a rifle in a standard cartridge, lets say 30-06, than in an Ackley Improved cartridge, such as 30-06 AI. At guns shows I have observed just how many people walk away from rifles chambered in weird, esoteric cartridges, even though the seller was giving cases and dies away with the rifle. | |||

|

| One of Us |

Compliments to all who participated in this informative topic on Ackley type cartridges. The quote below sums up my position on them.

The so called 'improved' chambers have been clean fun for some however to get through the winter. I got one back in the 50's as I wanted a High Wall then and the used one I found was so chambered (.219I).  Get the 'power' or optic that your eye likes instead of what someone else says. When we go to the doctor they ask us what lens we like! Do that with your optics. | |||

|

| One of Us |

You are contradicting your own findings, and the report you listed states exactly what I have been saying all along..

As I said to Stonecreek. A stuck case (or lack of "springback") means that the brass has been stressed beyond its elasticity. IE; the point of excessive pressure has been reached. There is a general agreement in this thread that an AI chambering can be pushed to higher pressures then its standard, greater tapered counterpart before it results in a stuck case. My question all along has been WHY? And you just gave the same two answers within this report from Lossnitzer, 1970 that I have already given.. But then you go on to say; "I have not seen anything to change my opinion that the lack of case taper in Ackley cartridges is good either from a feed or extraction viewpoint." Perhaps you should re-read your own findings..! As I said. We are going in circles on this! You can post all the graphs and reports you want. But the one simple fact remains that an AI chambering as opposed to its standard taper counterpart DOES in fact make a difference reguarding the point of excessive pressure.. Which is re-affirmed in your report, "the taper of the case and chamber". And you can dance around the question of WHY, say it has been debunked, call it snake oil, whatever floats your boat all day long, but that doesnt change the fact! Also just to clarify. SR4759 posted a link reguarding chamber finishes and bolt thrust. Your report and post mentions coefficent of friction. These are things that can and do have an effect on bolt thrust. But they are seperate issues from the jist of the thread. Two different circumstances that have similar results and that is getting out into the weeds. The same can be said for lube or dirt on a case or in the chamber. They both will effect the coefficent of friction, and bolt thrust. But that (a clean chamber/chamber finishes) is a different subject altogether from the question of case taper. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Stonrsreek is correct and should be heard. The case thrust issur was raised in part by Ackley himself. He fired a 30/30 Imp in a Winchester 94 without a breech locking bolt. What happens is a chamber is: When firing the primer pushes back against the breech and pushes the case forward. Friction will hold the case forward until 30/40 KPSI then release coming back over the primer. When the case comes back it is with full force. That is why with headspace and lower pressures the primer will protrude, while higher pressures it will flatten. An oiled case will come back earlier and expand forward avoiding "stretch marks" and allowing case forming at lower pressure. So Ackley was wrong in this and several other matters. | |||

|

| One of Us |

Stonecreek claims: 1. Ackley necks are the same length as standard necks. It is base of the shoulder that moves forward due to the sharper angle; the point where the neck begins stays the same. Then claims: 2. Regardless, the length of the neck has absolutely nothing to do with throat erosion. Then goes on to calim: 4. Regardless of whether the brass holding the load is standard or fireformed, with identical powder charges it will perform the same. The pressure vessel is not the case, but the chamber; and it is the capacity of the chamber which determines the constriction of the powder charge. The brass case simply fills and conforms to the chamber like a plastic trash can liner conforms to the trash can when you fill it with water. Ackely necks are longer, for example, the 30/06 case neck is .446” long, the 30/06 Ackley improved neck is .419”, (think about it) with the longer neck of the 30/06 the ‘rest of the neck is sized when chambered, Meaning? By design, 30/06 cases head space on the shoulder when the case is chambered, part of the shoulder is formed when the case is chambered, the rest of the shoulder is formed when the case is fired. That should take care of one of the others claims, the one about the shoulder moving forward, reloaders, smiths and wildcatters should know before they get into a conversation, like this post, THE SHOULDER DOES NOT MOVE, except in the claims department. What does move????? & ? The shoulder/neck juncture moves back, the case body/shoulder moves forward, for those that can wrap their minds around that understanding the neck is longer on the Ackley and they can understand how it got that way. Back to gas passing the bullet, me? I want all the chamber covered, covering the neck of the chamber reduces the amount of gas that passes the bullet before the bullet gets to the rifling. Remember the gas is fluid, it flows and takes off in a hurry, the bullet is setting still there is a lag between the fast traveling gas movement and the bullet, not easy to get the mind around the sequence of events, but the neck expands and releases the bullet before the bullet moves. I am the fan of reducing gas passing the bullet, I can not stop it from happening, again, I am a fan of doing what I can to reduce the amount of hot high pressure metal cutting gas that passes the bullet. Then there is ‘TIME IS A FACTOR’ back to getting the bullet to move. When forming cases the case forms to the chamber, for that to happen it takes time, I have formed cases for the 30 Gibbs, some wildcatters got dizzy thinking I was going to hurt myself. The load and bullet I used did not create a pressure problem, because time is a factor, before the load could build and bet serious the case had to fill the chamber, by that time the bullet was up and running. However: After forming the cases the load and bullet I used became the maximum load for that bullet ‘BECAUSE! the case was formed, there was no room in the chamber for the case to expand, when I pulled the trigger things got serious. SO? I backed off a few grains, again, I was forgiven because time is a factor. Always, when wildcatting and fire forming Hatcher is left out, hatcher moved the shoulder forward .080”, he chambered 30/06 ammo and pulled the trigger, he knew the cases would not stretch .080”, After pulling the trigger, Hatcher ejected 30/06 Hatcher Modified +.080” cases, hatcher cases did not stretch, when Hatcher pulled the trigger, his shoulder was erased/flattened against the chamber and a new shoulder was formed, gain, Hatcher’s shoulder did not move, it was erased. Hatchers cases did not stretch, like fire formers and wildcatters today, he did not scribe his case, meaning he had no clue why his cases did not separate. Then there is that part about measuring before and again after, hatcher’s cases shortened from the mouth of the case to the case head, when the case filled the chamber the neck was pulled back when the new shoulder was formed. When forming: When I form 35 Whelen cases from 30/06 the case shortens .035” before I fire them. When I form 30 Gibbs my 30/06 case shorten .040”+, that is the reason I use 280 Remington cases when forming 30 Gibbs cases, the shoulder is .051” forward of the 30/06 shoulder and the case is longer by .049”. I form first then fire, everyone else fires to form. I am the fan of cutting down on all that case travel. Back to the 30 Gibbs neck, the 30 Gibbs neck is .217” long, by using 280 Remington cases I can correct that problem with an additional .040”. F. Guffey | |||

|

| one of us |

Quaint. | |||

|

| One of Us |

| |||

|

| One of Us |

So now you are asserting that an AI chamber will be MORE prone to a stuck case than a standard chamber?? I dont think so.. The finish of the chamber is by and large a product of the gunsmith and has little to nothing to do with the design of the case. Back to square one again.. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Your statement makes no sense.. Exactly what are you trying to say Ackley was wrong about??? Is this brief (and incorrect) depiction of the inner workings of a firing round supposed to prove an "absence" of bolt thrust? AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Ackley fired a 30/30 improved in a 94 Winchester without a locking bolt. The breech block stayed shut, He claimed it was the small case taper that heldthe pressure. The math involved shows this to be not true. Ackley didn't understand why bullets drifted in the wind and spent part of his books on half assed theories. With time many of his velocity pressure information has been shown to be wide of the mark. I have had respect for him for over 50 years, but he was human and had limits. | |||

|

| One of Us |

Great, more unsubstantiated claims of "esoteric math" that is supposed to have debunked an actual physical experiment and years of evidence from numerous users worldwide to the contrary.. And you say Ackley was the one with half assed theorys. And where pray tell is this mysterious math? AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Start with Trig, ask a gradeschool student to explain it to you. | |||

|

| One of Us |

Ooo. So condescending.. Thats what I thought. So your position is basically "What are you going to believe, my academic pedigree or your own eyes"? In other words you got nothin!! Gotta love it when eletists have to lean on "fuzzy math" to make their case.. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I would suggest that I've had as much experience loading AI cartridges as anyone posting here, and to very high pressures (even excessive), including a number of "blown" primers. The AI designs do not allow for more PSI than the standard designs - the brass itself is the limiting factor. The AI advantage is an increase in case capacity, which allows more "TNT" to be put behind the bullet for additional velocity performance. When pushed to the same PSIs, the AI cases wear out just as fast as their standard parent cases. The sharp angled necks may reduce length growth, but primer pocket expansion, case sticking, and case head separation occur just as frequently and at the same PSIs. Regards, AIU | |||

|

| One of Us |

I think the idea that I am contracting myself is from how one views the role of the cartridge case and action. I believe the action is strong and the case is weak. To believe Ackley’s claims as valid, you must start from the assumption that the action is weak and the case is strong. I think any confusion in terms results in which side of the looking glass one is standing. I don’t believe the case is strong at all. It is my memory that quarter hard brass has a yield of 45,000 psia. That is one inch thick of brass will start to permanently deform with 45 Kpsia of stress. As anyone can see in this picture, case sidewalls are thin brass, whereas there is close to ½” of tempered steel lugs to support the case.  Hatcher’s Notebook has the heat treatment of Remington 03 actions made from 8620 steel. This steel is a medium duty steel, picked primarily due to the low percentage of alloy content, toughness, improved yield strength over plain carbon steels, and the fact that alloy steels heat treat more evenly. Receivers and bolts of Remington 03’s were made out of 8620 steel. MatWeb has modern heat treatments for AISI 8620 that are similar to what was used in WW2: Specific conditions for property data below: Single quenched and tempered: carburized at 925°C (1700°F) for 8 hrs., pot cooled, reheated to 845°C (1550°F), quenched in agitated oil, 150°C (300°F) temper. 1.9 mm case depth. Core properties. Tensile Strength, Ultimate 189, 000 psi Tensile Strength, Yield 149, 800 psi Elongation at Break 11.5 % What is important is the yield, as once material deforms, its lifetime is severely shortened. Hopefully anyone can see that heat treated 8620 steel has a yield strength about three times higher than quarter hard brass. Therefore, any ideas that the case is strong and the action weak just do not make sense. The case will rupture long before the lugs break. The idea that the case is supposed to take load off the bolt lugs is just not supported by the material properties of the parts. Instead, it makes a lot more sense that the action supports the case, not vice versa. Viewing the action and case from such opposite viewpoints can lead to mis understandings about the role of case friction. If the case is strong and the action weak, case friction would be a good thing. But I believe the case is weak and it is a very poor action and case design that intentionally puts load on the case. Stress lines flowing through the case will cause the case material to stretch and yield. The lifetime of the case is greatly reduced because it is operating, and it is operating, above yield. The more stress the more deformation. Brass flaws will be revealed as they are weaknesses in the brass, and this will cause case body splits, and worse, case head splits. As Varmit Al’s analysis shows, when the case takes load the case head is stressed. This is bad as case heads sometimes split.  These are examples of 300 WSM cases that carried load. You can assume that case pressures were around 60,000 psia and you can assume that the pressure inside the case was equal in all directions. Case friction kept the upper walls of the cases stuck to the chamber walls, , but the case sidewalls were not strong enough to hold the load , so the case head stretched to the bolt face, causing this sidewall necking. This is bad.   To recap, it is bad for the case to carry load, it is bad design practice that requires the case to carry load, overall, it is bad on the case and for the case to carry load. Bad, bad, bad. Good case design tries to minimize friction between case and chamber, minimize the load the case carries, and maximize the support of the case in chamber. But just as there is always entropy, which causes the failure of all perpetual motion machines, there will always be case friction. I view case friction as bad, so I can see how Ackley supporters might think I am counterdicting myself when I mention case friction. The only type of actions that needs case friction are black powder cartridge rifles. BPCR shooters report that if the chamber is wet, causing a reduction in friction between the case and chamber, the case gets sucked up into the rifle throat. I think it is due to a combination of low pressures and bullet crimp, but whatever the true cause, keep your BPCR cases and chambers clean and dry. Stuck cases are bad. Case taper is important in good cartridge design but not the lack of case taper. The lack of case taper causes case sticking after the pressure is zero. That is just one of the factors resulting in a failure to extract. Case sticking cannot be considered good: we might as well go back to muzzle loading rifles. There are those who were old enough to use the first generation M16’s in combat. There a combination of a “back of an envelope case design”, no criteria for case hardness, no time displacement studies, no pressure curve studies, a powder pressure requirement that exceeded state of the art in powder manufacturing, with which a change in powder resulted in stuck cases. Many an American soldier died, many a unit was over run, because case friction lead to jammed rifles. These are Colt concept cartridges for proposed lightweight cartridges. It is obvious that good designs do not require the cases carrying any loads. I mean, if case friction is an absolute necessity, how will these caseless designs ever get to the prototype stage?

I have not agreed that cases with little to no taper can take more pressure before sticking than tapered cases. I have read opinions about “drive –in” after the pressure drops may do something to break loose cartridges with sharp shoulders, which I am not confident in, nor have I seen a credulous analysis of case and chamber that shows a lack of taper is desirable. In fact, I found one DTIC document that stated that for the material they were looking at, (aluminum) increase in taper resulted in less sticking. As for bolt loading, if someone really wants to reduce the load on the bolt there are several simple ways to do this. The first is to cut your loads. This always works. Less pressure less bolt load. A another is to use a smaller diameter cartridge. Bolt load is calculated as the area of the cartridge base times peak pressure. As the area of a circle increases by the square of the radius, increasing cartridge width increases the bolt load by the square. Therefore use small cases as they load the bolt less. Don’t use those big, bad, cases, as they will increase bolt thrust.  In conclusion, I have nothing of value to offer after this was posted:

| |||

|

| one of us |

A-MEN BROTHER Stepchild NRA Life Member | |||

|

| One of Us |

I have examined many cases that have been fired in all type and lengths of chambers, never have I found a case with skid marks, again, I fired 8mm57 ammo in an 8mm06, no stretch, I did not think for for one minute it was a miracle, and I did not declare I had an exception to case body stretch between the case head and case body. The difference in length between the two cases is .127”, ahead of the case shoulder is the case chamber, I am surprised the chamber/receiver did not stretch forward when the shoulder of the case slammed into the chamber shoulder, travel distance .127” and still? no skid marks. Difference in length: The distance from the shoulder of the case back to the head of the case when compared to the length of the chamber form the shoulder of the chamber back to the bolt face. F. Guffey | |||

|

| One of Us |

Then there is the trigger word ‘Japanese receiver’, always followed by ‘the strongest receiver in the world’, then I suggest to heck with the receiver, I want those cases. F. Guffey | |||

|

| One of Us |

Ding ding ding we have a winner! I couldn't agree more. I love shooting water-filled recyclables with new rifles... Or not new, for that matter... I can't really think af anything much more fun than sitting in a hayfield taking out targets at short, not-so-short and intermediate ranges with a recently completed firearm. When I finished my 257 AI I emptied my 'smith's supply of 25-20 75 gr FPs, loaded em w/ RL15, and blew up a bunch of vermin live and recyclable. When that summer was over I had a decade's worth of formed cases. If I considered that to be work I'd buy plaid pants, some clubs and a country club membership and give up this rifle loony stuff. | |||

|

| One of Us |

Duh - you touched upon the reason an Ackley is more likely to cause hard extraction without understanding why. Study rough finishes in a cylindrical chambers. The reason you might have less problems is not because of the design. It is because the Ackley chambering smith polished the chamber. Do you have any reasonable rationale for a tapered chamber causing difficult extraction? | |||

|

| One of Us |

Can't explain statics to you if you are essentially a non-believer in mathematics. | |||

|

| One of Us |

Yes. I have already explained it and once again the finish of the chamber has ZERO to do with the topic. There are smooth AI chambers and there are rough ones. There are smooth standard chamberings and there are rough ones. For the sake of clarity, lets assume that you have an AI chambering and a standard chambering and they are both reasonably smooth. In fact lets assume the finish is identical! The AI will be able to reach higher pressures before difficult extraction becomes a problem. Most posters on this thread with any Improved experience have pretty much consented to that, you just havent been paying attention! Which brings us back to the same round and round cunundrum yet again! WHY? Your question that I quoted is exactly what I have been asking the nay sayers to explain and they CANNOT!! Once again my take just for you. Cause your special.. A standard chambering has more bolt thrust because of the only variable, the taper. How? A couple of factors are in play. With a straight walled case the force is directed straight at the chamber walls, meaning the barrel which means the pressure is more efficently (pay attention slamfire) "contained"! The case doesnt "carry" the pressure, it contains it. Whereas with a greatly tapered chamber there is a more pronounced rearward movement of the force because of the taper placing a greater workload on the brass near the head of the case. Let me try putting it another way. We all know that "peak" pressure will be equal on all sides of the chamber walls. But where is the volumetric center of the case? With an AI chamber the volumetric center of the case is closer to the neck of the case. But with a standard chambering, the % of the pressure that is absorbed at the neck end of the case will be less then with an AI chambering because its volumetric center is closer to the case head. In other words, there is a lower % of case wall in a standard chamber at the neck end to absorb the pressure. And so a greater % of the job falls to the opposite end. I reitterate, the majority of AI users will agree that they can reach higher pressures before the usual signs become apparent, some refer to this as "masking" the pressure. You have my opinion on the matter, if anyone else can better explain it I am all ears.. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

What the H is "volumetric center" to do with anything. A new term?. You swing between boasting of your ignorance to creating new physics ??. People like you interest me; You rant about how stupid engineers are but you think nothing of traveling at high speed. Interesting. | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia