The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Ackley shoulders

Ackley shouldersGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have been messing with a 280 Ackley a friend of mine built and it's been great. I have decided that I want into this on my own. Here are a list of cartridges I'd like to try to Ackley. Your thoughts would be appreciated. Not doing this so much for a gain of velocity, but for the gains in reloading ease, and case life. 8x68S 9.3x64 338-06 (thinking about a 338-280 Ackley) 280 Ackely 6mm Rem Ackley | ||

|

| One of Us |

I have a 257 AI and in a way I wish I would have left it a standard 257 simply because I think the Standard 257 is adequate and fireforming can be a bit of a pita. On the other hand, AI's do have their perks. The straight walled case significantly reduces bolt thrust which in turn will mask pressure signs. Personaly I see this as a plus because I like to load close to Max but not to rediculously high pressures and an AI makes it easy to do. And as you said they also reduce case stretch. With bullet prices being what they are today I am looking at alternative methods for fireforming. I have considered using a heavy for caliber cast slug for fireforming but am not sure if that would be enough. I also have some inexpensive Varmint bullets loaded up for fireforming with fairly fast burning powder, but havent got out to try it yet. Then there is the Cream of wheat method. If you need to fireform for multipule calibers then you could spent $100 bucks on bullets for case forming alone pretty easy nowadays. For the most part I am sticking with standard calibers anymore. But I would like my 7X57 to have been an AI. Do which ever pleases you. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

My friend uses kind of a strange method. Most of his rifles are AI'd of one sort or another, but he just shoots them and doesn't worry about fireforming. His reloads are the AI. He used to use crayola crayons to fireform. Now he buys 1/8th inch thick beeswax and uses that, but mostly he just shoots them as normal cartridges then round 2 is AI. | |||

|

| one of us |

I no longer fire form AI cases as a separate step. I find a load with a powder fast enough to form the case and that shoots well. I load them up and go to the range or go hunting. When they're used up, I have fire formed cases. Mark Pursell | |||

|

| One of Us |

BWW...I have 2 AI'd rifles. A 6mm REM AI and a 260 REM AI. For both I load a stout load with a fast powder and fire at targets as I would if they weren't AI'd. For the most part, I do add a little extra powder after fire forming to gain a little velocity, and therefore a little flatter trajectory, but ultimately the reason I went AI is extended brass life with less stretching. One other bonus is the longer necks which is supposed to reduce throat erosion. I was out on Sunday fire forming some of the 260 brass and was putting rounds through the same hole. Mind you I was only shooting @ 50yds due to the amount of snow we have (was too lazy to move the target out further), but this rifle chambered in 260 AI looks promising!! My 6mmAI is also a tack driver and I regularly ring steel @ 1/2 a mile and put rounds into about 3/4 MOA at that distance! | |||

|

| one of us |

My first AI I had barrel set back and new chamber just to see if any gain (velocity) and if I liked it that was appr 30yrs ago. Every one done since then has been with new barrel so I do see a gain (velocity) and accuracy is on par with my other builds in standard cases. I see no difference in case life vs other standard builds. My varmint AI rifles I fire form shooting PD other rifles use COW method and I can get sharp shoulders doing it that way. I have good supply of Nosler brass that I use for the 280AI and 30x280AI I tried and no longer have. Besides the 280AI I have 35 WhelenAI,243AI,223AI and 222AI also have Kreiger barrel 243,223 and Chanlynn barrel 222. I've had these build in the past 7x57AI,(2)6RemAI,(2)22-250AI,6x222magAI,6x250AI plus few others. I like the AI same as standard case so have no prefers on what I have build if you find something you like have it build. VFW | |||

|

| one of us |

I have the, 250 Sav Ack Imp (1910 Mexican Mauser action) 257 Robt. Ack Imp (1910 Mexican Mauser action) 280 Rem Ack Imp (1909 Argentine Mauser action) And that is listed in the order of being my favorite. Fireforming is super easy and fun most of the time. Steve E............ NRA Patron Life Member GOA Life Member North American Hunting Club Life Member USAF Veteran | |||

|

| One of Us |

I am a odd one. I like the ackleys and enjoy the oddity of them. I load a hundred or so up and shoot them like the standard cartridge and reload the fireformed brass. | |||

|

| one of us |

Not to argue with anyone, but it is only fair to disabuse the uninitated of ancient canards in regard to the Ackley Improved concept: 1. Ackley necks are the same length as standard necks. It is base of the shoulder that moves forward due to the sharper angle; the point where the neck begins stays the same. 2. Regardless, the length of the neck has absolutely nothing to do with throat erosion. 3. Case life and case stretching of most standard cartridges are not impacted by the Ackley treatment. The 17 degree shoulder of the .30-06 family is adequate to prevent excessive stretching. Some Ackley proponents, who invariably neck-size only, attribute the lack of case stretch to the Ackely shape rather than the real factor responsible, which is neck sizing rather than FL sizing. 4. Regardless of whether the brass holding the load is standard or fireformed, with identical powder charges it will perform the same. The pressure vessel is not the case, but the chamber; and it is the capacity of the chamber which determines the constriction of the powder charge. The brass case simply fills and conforms to the chamber like a plastic trash can liner conforms to the trash can when you fill it with water. 5. There is no difference in "bolt thrust" with an Ackley cartridge versus a regular cartridge. Bolt thrust, just like chamber capacity, is a function of how hard the expandable brass case is forced against the walls of the chamber, the bolt being the rear wall. If there were no bolt face there, the rear of the case would be blown right off of the case body, wouldn't you agree? The tensile strength of the case body is hardly sufficient to reduce bolt thrust simply because the case body "clings" to the chamber walls "more tightly". I like the Ackley concept and own a couple of them myself. But many of the justifications for them are pure fantasy. I know this is heresy to thousands of Ackley enthusiasts, but it's not appropriate that the superstitions of yesteryear go without debunking. | |||

|

| one of us |

Me too. Mauser built 270 ICL, built by Vern Junke in the late 50's early 60's. Unbelievably accurate rifle, I still have some original "Peters" Bullets he loaded for it. With those 50-60 yr old bullets, you can still shoot .5" groups. Amazing how we have not come very far ... Still trying to get .5" out of our guns after 60 yrs! | |||

|

| One of Us |

Well I haven't used hundreds of Ack cartridges, but in the few that I have seen it seems to give less problems with brass. | |||

|

| One of Us |

I think the Ackley Improved series of cases are 98% total fantasy. Yes you get slightly greater powder capacity. All the rest of the so called benefits do not exist and just placebos. Analyze the changes one by one and there is zero basis in physics for all the silly claims. | |||

|

| one of us |

Why don't you tell us which AI you own and reason for building them. I know few that own AI and they are a wildcat rd and only one is SAAMI. VFW | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

I agree with Stonecreeks comments. I went with AI cartridges because of curiosity and the potential improved performance without discarding the many standard cases I already owned. I own and have reloaded the following extensivley: 257 AI - significant increase in case capacity with increasted performance over the standard 257 Roberts. Performance approaches that of the standard 25-06. It's been accurate for me. 25-06 AI - I do not recommend this cartridge - neither did Ackley. IMO, way overbore and hard on barrels. Not inherently accurate - I found it hard to get 1/2 MOA groups even with Lilja and Krieger barrels. I don't use it anymore and converted the gun to a 375 AI and 280 AI. 280 AI - significant increase in case capacity and performance, which approaches that of the 7 mm Remington Mag. There are other believers as well, such as Nosler, Jarett, etc. Also, accurate. 30-06 AI - minor and controversial increase in performance, but I've had great luck using Re25 with 180 gr. bullets - performance that I was unable to achieve with the standard 30-06. Others, but not all, have had similar experiences - check out GSP's posts. Also, accurate. 338-06 AI - I really like this cartridge, but I would also likely like the 338-06 and 338 Gibbs. If I had it to do over, I'd go with the Gibbs. This group is very efficient. With the AI I'm getting ~2840 fps with 225 gr bullets, Re17, and a 26" barrel - and with good case life. Also, very accurate. 375 H&H AI - essentially the 375 Weatherby (actually ~2 grs H2O larger case capacity) and a substantial increase in performance over the standard 375 H&H. If you lose you ammon, it'll shoot standard 375 H&H and 375 Weatherby ammo. AIU | |||

|

| One of Us |

I don't care about the increase in performance, I am doing it for a increase in cartridge life. | |||

|

| One of Us |

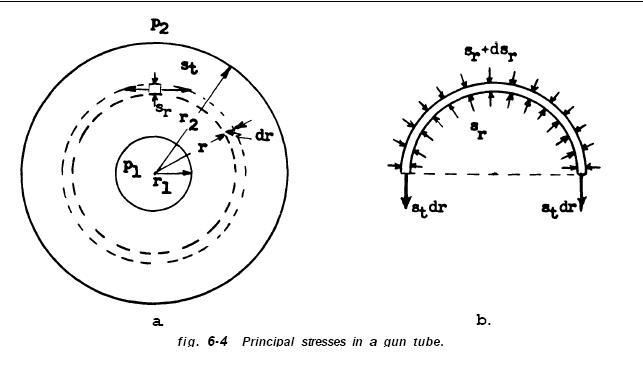

P.O Ackley was selling snake oil. The section in his handbook about Ackley Improved cartridges, and his “proof” that straight taper cartridges reduce bolt thrust is totally useless and potentially dangerous. Cases don’t act as wedges or inclines. Given enough load they stretch. They don’t carry load, or should not carry load, when they are expected to carry load, as in the weak Lee Enfield, (the British NRA has warned its members not to shoot Lee Enfields in the rain!) they inevitably fail; cases are simply gas seals. At the time ole PO was selling his Ackley improved (AI) cartridges, he was blowing out the shoulders, straightening the case, to increase powder capacity and raising pressures. It is obvious that ole PO was taking flak from folks who were claiming that his high pressure cartridges were overstressing the action. Savants on other forums give out a rule of thumb that a 40% increase in case volume provides a 10% velocity increase, implicit is the assumption that this is isobaric. This may be a crude rule of thumb, and I have done nothing to verify this. Below are comparisons of Ackley's published data compared to pressure tested data. 49th edition of Lyman Handbook, the max load of a standard 30-30 with a 150 grain bullet and using 28 grs IMR 3031, the velocity is 2145 with a pressure of 38,000 cup. In Ackley’s own handbook, the maximum load for a 30-30 AI for a 150 grain bullet using IMR 3031 is 38 grains for a velocity of 2700 fps. From web data, the case capacity of the 30-30 Ackley vs the unImproved Winchester parent differ by 5% http://www.gmdr.com/lever/3030atext.htm yet here you have Ackley stuffing in 10 additional grains of powder and claiming a velocity increase of 125% over the standard 30-30. The only way to get those sort of velocities through incredibly high pressures. If you go to your 1957 Gun Digest, factory ballistics for the Winchester 180 grain Super Speed 30-06 is 2700 fps. Modern reloading data shows you can push a 180 Barnes with 55.7 grs IMR 4350 to 2685 fps, in close agreement with older factory data. Ackley’s handbook gives reloading data of 61 grains IMR 4350 with a 180 grain bullet for a velocity of 3053 fps. Noslers shows a max load for the 30-06AI of 56.5 grs IMR 4350 with a 180 gr bullet at 2835. For the 30-06AI Ackley is putting 5.3 additional grains of powder in the case and claiming a velocity increase of 113% over the parent cartridge. His data is pushing bullets 218 fps faster than modern pressure tested ammunition of the same case. The only way to do this is through incredibly high pressures. Clearly anyone now, or then, who had access to a ballistic lab or even crude rules of thumb would be able to say that the only way Ackley was able to achieve those high velocities was through extremely high pressures. Ackley was getting high velocities from his improved cartridges, cartridges which were being used in actions not designed for those levels of pressures. P.O. wanted to show that his high pressure cartridges did not increase bolt thrust so he ran a rigged experiment to protect his reputation and prove a bogus point, that is straight walled cases reduce bolt thrust and therefore his overpressure cases are safe to use in standard actions. With perfectly clean chambers and clean cases there is parasitic friction between the case and chamber and that will lower bolt thrust disguising evidence of pressure. This does not mean you can just add more powder to the case as radial stresses on the barrel have not changed. Ackley totally ignores radial stresses on barrels. Barrels have their pressure, fatique limits and they don’t go away because of case taper.  When a barrel spilts in half at the chamber, the results are not pretty: http://thegunzone.com/m1akb.html When you read his M1894 Ackley Improved test, Ackley starts off by claiming that no one knows the design limits of actions, which is a lie. What is certain he did not know, but that does not mean someone does not know. Designers are not going to provide that information to the general public, and it shows the limits of a skilled machinist when it comes to matters of mechanical engineering design. Ackley does not know, does not know how to calculate such things, does not know that increasing pressures above design limits reduces the fatique life of parts, therefore he goes off in the direction if the action holds it for a couple of shots, the pressures must be safe. P.O Ackley cartridges are very interesting and P.O’s test of a straight sided cartridge holding pressure without a breech block has been duplicated. The tester swabbed the chamber out with alcohol swabs between shots. The Ackley cartridge held. However the other cartridges, such as the 30-30, 35 Remington, blew out of the breech at 1900 fps. A 150 grain cartridge case flying at 1900 fps will go through both sides of most people's skulls. Read carefully Boatright’s papers one of which he shows how a 308 case, in a clean chamber, can lock in and hold pressures by itself up to 25K psia. Go to Jim Boatright’s web page. http://www.thewellguidedbullet.com/ Look for yielding of the brass case in these studies http://www.thewellguidedbullet.com/m...al_studies.htm However once pressures go above 25K psia, Boatwright shows the brass case stretches and if not supported, the case head will blow off. Regardless of taper, cases are made out of brass and will stretch. There may be bolt load reduction due to friction and stretching but it is inconsistent and not to be relied on in any way. If you notice, P.O. Ackley never printed experiments conducted with a 30-06 or a similar high pressure cartridge. I am certain if he had reported the results, it would have been a litany of case heads blowing out the back of his lug less rifles at lethal velocities. It is likely he did, given all the actions and barrels he had around, I believe it is more credible that he ran tests in a number of Ackley Improved cartridges but only published the test that supported his theory. We see this all the time when reputations and money are at stake. If he did not, then he should have bought a lottery ticket because he was very lucky. We do know that Ackley and others did not conduct sensitivity tests, varying chamber finish, (chrome for example), powders, primers, or much of anything else. There are axial loads which must be taken into account and case taper does nothing to reduce them, in fact his straight taper reamers reduce barrel thickness when used in a standard barrel. I totally disagree with the conclusion that Ackley and others have drawn, that his cartridges reduce bolt thrust and therefore a user can just pour the coal into the cartridge and let fly. Cases that are designed to maximize function and reliability have plenty of taper. Taper allows the cartridge to feed better and extract better. Straight walled cases don’t steer worth a flip and they tend to stick on extraction because the case retracts on a line, not a diagonal. As for case life, I took a set of 308 cases 22 firings in a M1a. If you know what you are doing, you can reload cases for a long time. | |||

|

| One of Us |

I own one AI cartridge and that is the .257AI. Never again is all I can say. I built it because I had an intermediate length action and could not build the 6.5-06 I wanted to build without seating bullets extremely deep. Also every one I knew who had a .257AI loved theirs. I built mine with a 26 inch barrel hoping to get near 25-06 velocities. What I got was a finicky rifle that don't feed as well as if it was a standard caliber and even though it will shoot the original case as accurate as after it has been improved I still hate fire forming for no real advantage! As far as case life I have not had problems with case life on any cartridge. In my opinion it just is not worth it. Molon Labe New account for Jacobite | |||

|

| One of Us |

Although I agree with much of what you said it is still one persons opinion to which I would take exception on a couple issues. First of all. One of the main reasons for having an AI case at all is for a slightly increased capacity. While it may be true that the chamber is the vessel reguardless of wether the case is fireformed or not, I dont know of anyone using an AI load in an un-fireformed case. I dont! So your assertion that accuracy will not be effected is either based on the assumption that one IS using their AI load in an unfireformed case, or that one is going to invest the time to work up two loads for the same rifle, one for fireformed cases and another for standard cases. I dont do either. Secondly. The bolt thrust issue. No, I dont agree that if there were no bolt face there that the rear would be blown off the case. If there were no bolt there, the entire case would shoot out of the chamber before the bullet ever left the breech. The seal of the brass against the chamber would not exceed the force of the pressure. Your assertion suggests that body taper has no effect on bolt thrust. If that were true then how does an AI chambering "mask" excessive pressure? It is really not that complicated to understand the reality of bolt thrust and the lessening of its effects with a straight walled case. If you strike a nail on an angle it is going to bend, but if you strike it straight the force is directed at the strength of the nail. With a straight walled case the pressure is directed toward the walls of the chamber, but with a greatly tapered case the pressure will follow the path of least resistance toward the end of the case/chamber with the most volume. Toward the head of the case. Bolt thrust is real. And Mr. Ackley was much more than a "snake oil salseman". He was highly educated, one of the most noted authoritys in the nation, and had a reputation for speaking honesty. And on the subject of firearms which he lived and breathed, I would take his word over that of a bakers dozen of "Modern Internet experts" any day. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Overbore and hard on barrels OK, I can see that in some sense. Inherently in-accurate???? How in hell can that be? A 25 Gibbs, and a 257 wthby wouldnt be able to hit a barn door I guess? | |||

|

| One of Us |

I have noticed that many folks equate a barrel burner to also being inaccurate. We had a 7.82 Warbird that was a 1/3rd of an inch rifle. Saying that, the barrel was shot out in 450 rounds. Load development was a bastard, by the time we really got it shooting well it would have a shift due to wear. | |||

|

| One of Us |

\ Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

I just love revisionary history. You compare Ackleys book which was published in 1962 to modern day data. You call him a snake oil salesman, a "liar" and talk all about what he didint know. Ackley was one of a handfull of pioneers in the field at a time when the GP knew much less about firearms than they do today. What is your claim to fame? I find your post not informative, but repugnant and hatefull. Much of what IS known in the firearms industry today, especialy reguarding wildcat development and the strength of actions, can be attributed directly to Ackleys research. And if he was so full of bull, then why are so many of his designs and theorys still so popular to this day? AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Most of the cases I load for need to be trimmed @ about every 3 firings. Not so with my 257. After numerous firings I have only trimmed those cases once. YMMV. And with the price and availability of brass being what it is today that is a nice perk. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Whether or not the case head blows off or the case blows out depends on the friction force between the case and the pressure inside the case. In low pressure blowbacks, gas pressure is not high enough to rupture the case sidewalls (when the action opens) and the gas pressure is not high enough to fix the case in place. In high pressure blowbacks, if oilers were not installed on the early mechanisms the case heads would have blown off. The friction between case and chamber was so high the case was fixed in place and the internal pressure exceeded the yield and ultimate of the brass sidewalls. There have been unsuccessful low pressure blowback designs that used cartridge friction in an attempt to lower reciprocating mass. I believe they were unsuccessful because it is impossible to control the amount of friction between case and chamber once the firearm reaches the field. I challenge you all to find some. I had never heard about any of them till recently.

These are the basic requirements of a cartridge case: It must retain pressure. obdurate, and extract without rupturing or sticking. It holds the primer, bullet and propellant. It protects these components from physical damage and adverse environments and it protects the user from hazards of handling propellants. It protects the gun chamber from hot burning gases and absorbs a little heat. It seals the chamber against gas leakage. As the brass case is weaker than the steel action, the case does not carry load. The cartridge case is a gas seal and will rupture if not supported by the action. I understand why Americans think the cartridge is a structural member, there to protect the action from load, that concept comes from a 1921 Army coverup and it is totally wrong. Modeling the system as a hammer and nail is inappropriate. It would be better to model it as a thin walled pressure vessel. Instead of a hammer, the forces inside are gas. The forces are equally distributed though out the system, not concentrated. There are lots of pretty picture books on guns, there are very, very few on gun design. I have not found any on cartridge design, though are snippets in AMC Pamphlets and on DTIC. The only “controversy” about calculating cartridge thrust on the bolt is where to take the diameters. Some design agencies have used the inner diameter, which they claim represents the column of gas against the bolt face. Others use the outside diameter of the case, or the point of maximum case head separation. This is a better way and more conservative in my opinion. No one “weakens” an action assuming the cartridge case takes any of the load. So, just how much thrust does a tapered cartridge take off the bolt? Assume a high pressure system where the internal pressures exceed the yield strength of the brass.

You must understand, I don’t give a rats about your outrage. He published that data. He published the results of his test. His AI cartridges gave high velocities because they were overpressure not because of some magic about cartridge taper. He built on the work of others, who lied, but right now, instead of writing a lot about that, I have other things to do. | |||

|

| One of Us |

Nor do I give a rodents rump about your sour grapes, axe to grind or whatever your problem is. Ackley himself acknowleged that the lionshare of velocity gains in improved cartridges was generaly accompanied by an increase in pressure, but that it didnt matter as long as the brunt of the pressure was born not by the action but the barrel/chamber and as long as it was within safe limitations. He never claimed them to be "magic" as your fraudlent, lying disposition suggests. Ackley himself was a critic of the term "Improved", calling them "so called improved" cases a number of times in his own book. He wasnt a "Liar". He was a straight shooter in a different time. You attack him for his work but fail to explain how a straight walled case will exibit no excessive pressure signs where an otherwise tapered one does. And anyone who has reloaded both a standard chambering vs an AI chambering knows that is true in spite of what you and your favorite critics claim to the contrary. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

But a stronger case does carry more load doesnt it? When I built a 25/35 imp, before I blued it I had access to an Ohler strain guage system. The original 25/35 brass blown out would cause sticky lever extraction at less then 38,000 psi. The imp cases made from .375 win brass at 42,000 psi ( my self imposed max) still showed no extraction issues at all. | |||

|

| One of Us |

The case doesnt "carry" the load, but it must "contain" the load. And all factors are relevant. A weaker action will be able to bear less of a load reguardless of the strength of the brass, but stronger brass will allow slightly higher limitations as the brass is the weakest link in the chain. Your 25/35 was able to attain higher pressures because the strongest part of a chamber is the barrel. And with less taper, more pressure is directed toward the chamber walls as opposed to the case head. In other words, the explosion is more efficently "contained". AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I'll buy that. | |||

|

| One of Us |

Yes it would. If pressures were the same a thicker piece of brass will carry more load than a thinner piece. The typical problem is that a reloader uses the same powder charge in heavier brass and can’t figure out why his old maximum loads are now blowing primers. Which is one of the reasons solid head cases will hold pressure that will blow through the head of a balloon case. Another is that with less material, it takes less stretch to rupture a balloon head case.

You were prudent to measure pressures. Rifle brass varies in weight, thickness and hardness. Case hardness has a surprising effect on case wall retraction. So does thickness.

I have no idea of what test articles and media you used which lead you to this conclusion. Reminds me of a fellow shooter who put on a Krieger barrel on his rifle. He took known loads that were safe in old barrel, but changed the primer brand. When fired in his Krieger barrel his loads blew primers. He then claimed it was due to the primer. I know Krieger barrels are tight, I have blown primers in them with loads that were perfectly fine in Douglas or Wilson barrels, but that did not change his opinion. Another guy told me that the pressure within an auto tire is higher at the bottom of the tire than at the top. As proof he pointed out that the bottom sidewalls are budging and the tread has flattened to the ground, whereas the tire top is round. When I suggested that if that was true, then the best way to measure tire pressure was to rotate the tire so the stem was half way between top and bottom, to get an average. He agreed.

This is the pressure curve of a 7.62 Nato cartridge.  I take the position that at any moment in time, the pressure within the barrel, all the way back from the base of the bullet to the base of the cartridge, the pressure is the same. Of course the pressure changes with time, but at each moment in time, the pressure through out the system is the same. As an example, the highest pressure is 50 Kpsia at 0.55 milliseconds. In that time the bullet has traveled less than five inches. And your claim is that the pressure at any point in time, varies within the case, and varies by the shape of the case? So what is your predicted case pressure at the shoulders, of a 308 case, versus, lets say, the base, at 0.55 milliseconds? And how did you come up with that? | |||

|

| One of Us |

Your story about the guy who claims tire pressure is higher @ the bottom than the top gave me a good laugh. But you seem to misunderstand what I am trying to say. It is not that there is a pressure "Variation" perse. But rather that there will be a rearward movement of pressure (see bolt thrust) from the narrow end of the vessel toward the wider end of the vessel because once again the pressure will follow the path of least resistance. The movement of pressure toward the rear of the case is precisley because of the taper and the fact that the pressure will peak at the smaller end of the case before it will peak in the larger end. And to claim otherwise is like saying that it would require the same "volume" of air pressure to put 10 lbs of pressure into a bicycle tire as it would to put 10 lbs of pressure into a semi tire. Which just isnt so. Unlike tire pressure @ the bottom and top of a tire, the ignition and detonation of pressure in a case is very much a fluid set of circumstances and not stagnant pressure. Also, if you shoot a bullet at a plate of steel that is set at lets say a 30* angle, the bullet will not ricochet directly back toward you at at 180 degrees. It will ricochet at the angle that the steel plate is set on. But if the plate is at a precise 45* angle to the trajectory of the bullet then the plate will be forced to absorb more of the impact from the bullet. The truth is that all rifles have bolt thrust, wether they are straight walled or not. This is due to a little thing called headspace. An older Hornady manual gives a detailed depiction of the sequence of events that take place during ignition of a rifle case. Id like to tell you which manual has it but I seem to have misplaced it. Anyway it tells us that at the onset of the ignition the first thing that happens is that the firing pin drives the case forward as it is driven toward the primer, then as pressure builds the primer is actualy partialy unseated toward the bolt, then as the pressure builds further it eventualy drives the case rearward toward the bolt face re-seating the primer. So from this we can see that bolt thrust is in fact a real phenomenon. And I still maintain that a straight walled case as opposed to a strong taper will serve to minimize its effect in reguards to what is "maximum safe" for a given action. Have a nice day. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

Well I agree on what is in the Hornady manual and I guess we disagree on how the gas pressure manifests itself and what values are used in calculating the loads on the bolt. At least we are back to amicable | |||

|

| One of Us |

You can maintain it or theorize it or refer to a Hornady manual to illustrate it but you have not done the math to analyze it. Do the math, resolve the thrust component due to the angle of the case taper. When you complete that little exercise you will find you are talking about a percentage difference that very nearly approximates zero. | |||

|

| One of Us |

Experience with more than 25,000 rounds of 223 AI leads me to disagree with you vehemently. The AI cases exhibit SIGNIFICANTLY less case stretching and standard 223 Rem. I'm seeing the same thing with a 257 AI and 280 AI, but haven't yet gotten to nearly the same volume.

Again, with more than 25,000 rounds of 223 AI under my belt, I would vehemently disagree with you. Unformed brass has always run slightly slower than formed brass with the same loads in the same barrels.

I agree with you. Ackleys are not magic, but they can provide some real benefits. I build them for the benefit of significantly less case stretching and the ability to match or slightly exceed standard case velocities with lower pressure while maintaining the same magazine capacity. | |||

|

| One of Us |

The case is a gasket to seal the breech end of the barrel. Part of it is a container to hold the powder charge, the primer, and the bullet. The primer body is also a gasket. With different thicknesses of cases there will be different pressures because the internal capacity is different. Thicker will increase the pressure...this is with the same type and lot of powder and the same charge weight or volume. Adding a filler or wad to cartridge will increase the pressure because of a few things like reducing the volume of the case, adding more mass for the powder to move, and adding friction especial traversing through a bottleneck constriction. Putting a thinner or thicker gasket on an internal combustion car engine, for example, will lower/raise the compression pressure simply because it changes cylinder volume. | |||

|

| One of Us |

Sorry mate, but Algebra was as far as I got in math and I hated it too.. But none of you nay sayers have explained how an ackley case is able to so effectivley "mask" excessive pressure. I have. And the fact that they do contradics your idea of a near zero approximation. Besides, as I have shown there are many things going on during the couple of milliseconds of detonation of powder within a case. Im not so sure a simple mathematical equation would cover all of it. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I didn't see my post as nay saying. | |||

|

| one of us |

Well, theoretically, I suppose that the weight of the extra two-foot high column of air would make the pressure at the bottom of the tire higher by some calculable amount. Ironically, this story has more to do with internal ballistics than one might initially think: The pressure inside of a cartridge case (chamber) is equal in all directions. If it exerts 50K psi on the sidewalls, it also exerts the same on the bullet base and ON THE BOLT FACE. The shape of the chamber is irrelavent. Now, it is true that a chamber with less taper will allow a brass case to be exposed to more pressure than a case with more taper and still allow the bolt to open and extract more easily. This is because of the mechanics of the springback of the brass. The same amount of springback in a near-cylindrical case takes more static pressure off of the bolt than if the case is much more tapered. Since most shooters in part judge pressure by the lack of bolt stickiness on opening, this may be one way in which an Ackely case "masks" pressure. As to case stretch, no one has yet denied that their experience with an Ackely cartridge is with anything other than neck sizing. If you neck size one case and full length size another, the FL-sized case will always exhibit more stretch than the neck-sized case. Besides, Ackely fireformed cases ALWAYS start out somewhat shorter than standard cases since blowing the brass out at the shoulder shortens the case (I was amazed at how much shorter my .22 K-Hornet was able to make a standard Hornet case upon firing). When you start with a shorter case it takes more firing to reach maximum case length than when you start with a longer case. Does anyone disagree? Action strength (or stress): Again, regardless of the shape of the case, the thick STEEL barrel and action of any gun has many times the ability to contain pressure than the thin BRASS case. The cartridge case will always fail before the action fails (although the failure of the case can precipitate the failure of the action). Changing the shape of the case, even if it results in less apparent bolt thrust, less apparent case stretch, etc., etc., won't in any way make the case stronger at the unsupported web: Give it enough pressure and it will blow, and long before the steel action would otherwise give up. | |||

|

| one of us |

ANY minimum chamber (not just HS length but diameters) will mask pressure. IF straight"er" walls grip better, than why do revolvers have a recoil shield as part of the frame? Ever tie up a revolver, with hot loads? | |||

|

| One of Us |

I have 2 of the ai chamberings and i will tell you that it is worth it if you load them to their potential. They are the 250AI and the 257AI. if someone was just looking for longer case life they will get the job done. I also own a rifle in 250 sav and when loaded to the same loading the factory brass is toast,while the improved is not hurt at all. Some will call snakeoil on what he tried to do way back then,before all of the new fangled stuff came into being. That said if you do not like the chamberings with a 40 degree shoulder ....Don't get one. Some of the newer chamberings that have come onto being do not have the desired effect of some of his original ones. Your views are yours and mine are from shooting them. Have a nice night. | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia