The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Detonation from NORMAL powder charges

Detonation from NORMAL powder chargesGo  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

There has been much debate on this topic and usually someone states that the phenomenon has never been reproduced in a lab. Not so! The phenomenon is real and happens more often than is realized! Take a look at this;

Look up this site; http://www.shootingsoftware.com/barrel.htm Regards 303Guy | ||

|

| one of us |

Very interesting! Do you know the 2nd load data? The first one is with 27 grains not reduced at all. Could it happen on a regular basis also with slow powders and close to 100% load density? What I always wonder is why the "secondary combustion effect" does not take place in handgun loads like .38 SPL or .45 LC with tiny amounts of Red Dot ot Unique in a huge case. Anyone has an explanation for this? Also amazing with these data is that the effect seems to be quite repeateble, very similar curves with four different tests! | |||

|

| One of Us |

The readings seem to be of barrel whip. They occur as the bullet leaves the barrel A single strain gage will measure the strain underneath it. The strain is due to pressure (hoop strain), and barrel moment (bending). To avoid this four gages must be used to cancel the barrel moment. One clue; If you shorten the barrel the spike has been reported to move back. Good Luck! | |||

|

| Moderator |

Detonation from reduced powder charges Is not what these graphs show -- they are showing the well known secondary pressure spike as recording on strain gauge pressure tools - I know, I used to use one ALOT. 303 those, and other, graphs showing a second spike are ALL OVER the rsi pressure trace, and the secondary spike happens, on every shot. The lower chart is CLEARLY labeled, "winchester ball" -- and shows the results of COMMERICALLY loaded ammo. The chart you are showing DOES NOT REFERENCE reduce loads. Charlie Sisk had a load that would blow a muzzle brake OFF due to secondary pressure. The 2nd SPIKE takes place with factory loads, as your example shows I used to have one of these things, and spent many hours examining the results and reading others results. we are talking about the FIRST spike, on this type of machine, that would be expected to be ~30k psi- IN THE CHAMBER, and on the FAR LEFT of the time scale .. in a rifle dentonation due to reduced loads, over time, there would PERHAPS be a small spike, perhaps under the 3,500psi threshold for it to be picked up, and then, a little later in the time line, a spike going off the chart, but perhaps even greater than 1second, perhaps not, The data presented shows COMMERICAL ammo, with a wicked secondary, NOT a reduced load bluing the gun. further, reduced loads blowing up cases generally are in belted or other HUGE cases . a primers brisence, even a small rifle primer, would probably fill the case all the way to the bullet, in a 223 opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

Faster powders in a revolver are finished burning about the time the bullet moves or shortly after so there is no powder left to create a secondary pressure. Slower, easy to burn and stable powders can burn the length of the barrel, and there is no problem with a slightly reduced load. Reduce a ball powder like H110 and the powder will not even light. The primer will push the bullet and powder into the barrel and the gap bleeds off the pressure so it will not light. Some of the coating will be burned off on the back side but not up into the powder column. (That shoots down the idea of primer flame going through the whole powder column.) It will just be packed against the bullet. Primer pressure forces the powder ahead and compresses it. What you want is heat and flame, not pressure, hard to get. The problem here is what happens when the powder DOES decide to light after it is out of the case???? Also be aware a magnum primer will blow the bullet farther up the bore. Then what if you are shooting fast and fire another behind it??? The condition of a secondary pressure excursion is different from the secondary explosive effect in that pressure is increased down the bore farther and can ring the barrel near the muzzle. SEE happens at the chamber with reduced loads of any slow powder in a rifle of ANY caliber. This is a condition they can't duplicate or measure because it results in either destruction of the case itself or the gun, or the gun can be shot for years without it occurring. The most likely cause is a long bullet jump from freebore or worn throats where the bullet leaves the case and stops when it engages the rifling resulting in a reverse pressure wave that detonates the powder while still in the brass. None has been proven and it still might be related to the findings of secondary pressure excursions, only happening sooner instead of after a long bullet travel. A friend and I both had SEE in our 6.5 Swede's with the long throats made for long bullets. We were using 46 gr of 4831 which is one gr over the starting load. Sub 1/2" groups were normal and we both shot a lot of that load. His happened first and I wondered if he had a short load. Not long after my rifle did it. The bolts were locked and it took a mallet to open the rifles. The rear of the cases were a mess with HUGE primer pockets and I never found my primer. Checking revealed no damage to the rifles or head space---we were lucky. I increased the powder charge but accuracy went away so I switched to Varget and am back to 1/2" groups. To question ANY findings about pressure seems to be folly. I would pay closer attention. It seems to me a lot of chambers were ringed from using a wad or a filler not touching the bullet and even BP can do it if not within very close distance to the bullet. The site had some very good data about too light of a bullet or too slippery of a bullet using moly. It makes sense to use a faster powder with a lighter bullet. | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

one of us |

Charlie Sisk, Denton and I believe another whoms name I can`t recall discussed on another forum this and claimed the event was most common when very slow powders were used with light for cartridge bullets. IE; Sisk I think found it with a 150 gr bullet in a 300 mag. They claimed a heavier bullet or faster powder usually stopped it from showing. Sisk blew a muzzle brake off the barrel of the rifle he 1st noticed it in 3X while invesigating, and claimed he could make it happen at will. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

One of Us |

Only that it was Quite so. (I've edited the title - that was to get your attention) But how would reducing the load or using a slower powder react? This was covered in the article. These traces were done with hoop strain guages which do not detect barrel whip. This is what has been identified as the cause - lighter bullets, long throats and slower powder (also moly lube, worn throats and bore and low drag bullets). The first chart is exactly that - a light bullet and slow powder. The second chart was about ball powders.

The article mentions ringing of the bore near the muzzle!

Regards 303Guy | |||

|

| One of Us |

Ask Hodgdon Powder Comapany where secondary combustion effect originated from...clue, it wasn't hand held firearms. | |||

|

| one of us |

The reason I was asking is that I shoot a lot of reduced rifle loads with very fast (for rifles) powders like Blue Dot and Vihta N110. The Vihta powder manufacturer, German DEVA ballistic institute and bullet manufacturer H&N say that this is safe practice, also with even faster powders like Unique and N320. OTOH I have read people here claiming that the SEE can also accure with these powders in rifles. It is quite obvious when looking at my fired primers and calculating tle loads in QuickLoad that under no circumstances they are low pressure loads. However, I still feel that they are safe unless I double load by mistake. OTOH | |||

|

One of Us |

I don't have the experience in this regard but I suspect this may well be the case. I also wondered whether accidental 'incorrect' powder played a role but that left too many questions. I have personally experienced 'non-linear' pressure rise with ball powder (chronographed). Regards 303Guy | |||

|

| One of Us |

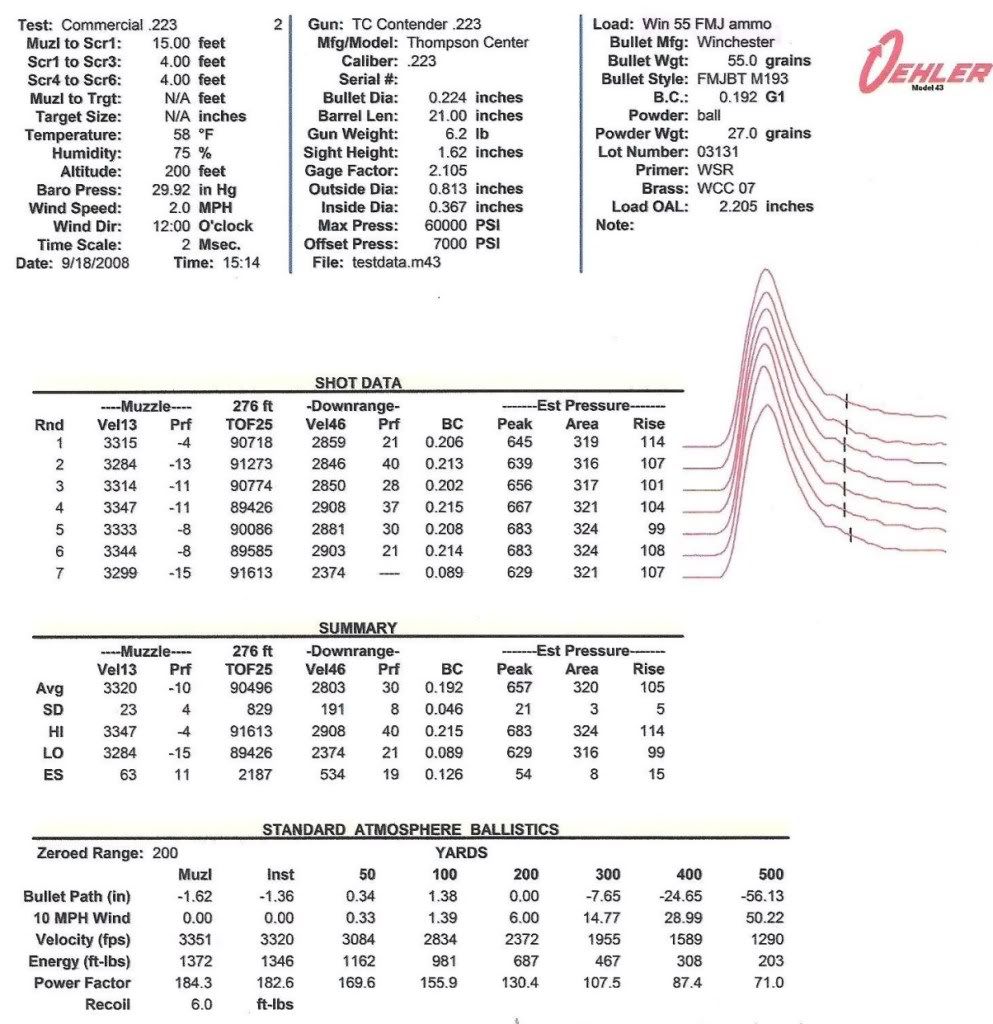

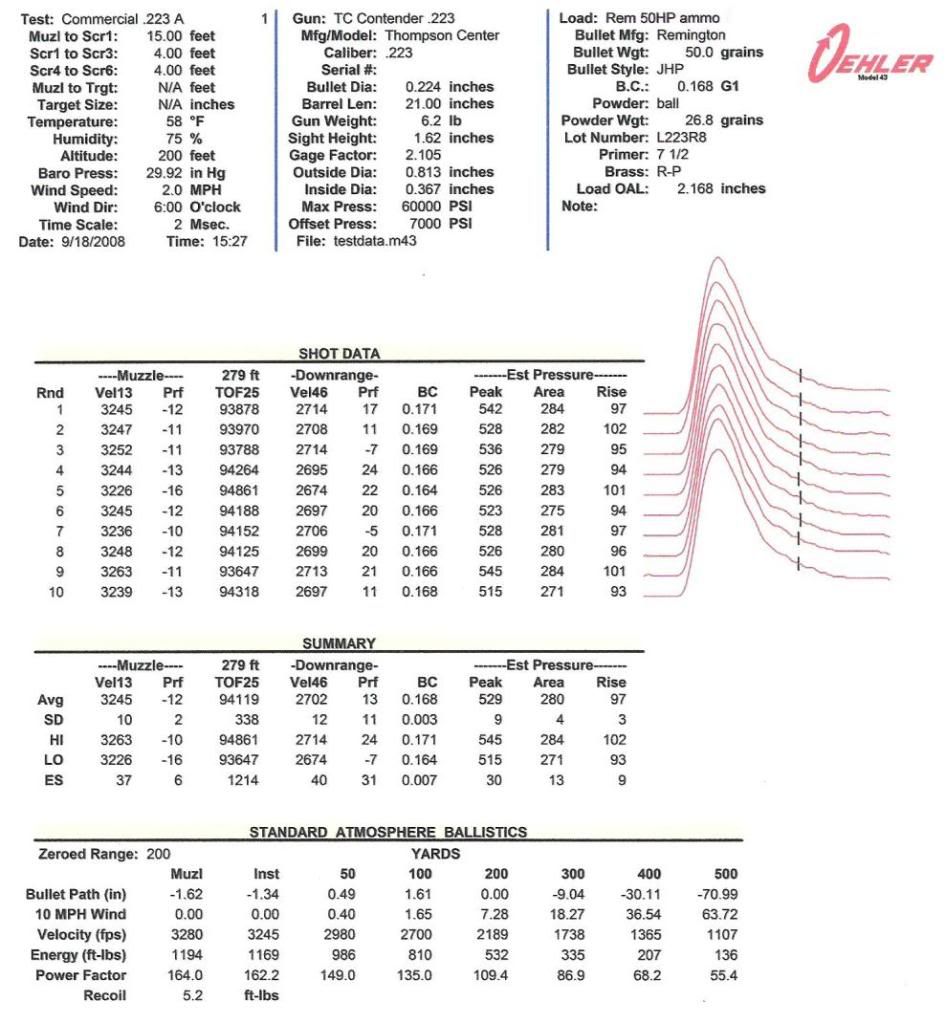

I've seen that site and quite frankly I'm not sure what they are measuring. I've duplicated the first load and test fired a box of Winchester white box FMJ M193. It contained 27 gr of ball powder over a 55 gr FMJBT in a WCC 07 case sparked by, I assume, a WSR primer. The testing was done using an Oehler M43 using a 21" TC Contender barrel with a tight chamber of .223 dimension in lieu of .5.56 dimensions. The first load (26.9 gr AA2230 over a 40 gr VM, non-molly though, in LC 2000 cases with WSR primers) produced a MAP of 53,200 fps which was on par with Remington factory 50 gr .223 HP loaded 26.8 gr of a ball powder at 52,900 psi. Both graphs of the pressure curves for 10 shots showed no anomalies. The area and rise were all very consistent. I found no indication of the reported "detonation" or SEE. The factory Winchester White Box M193 ammo was loaded quite hot but it also showed no sign of "detonation" or SEE for a 10 shot test string in the pressure graphs or area and rise. The MAP was 65,700 psiM43 and the velocity was 3351 fps. Both the pressure and velocity were much higher than 3 other lots of M193 ammo I tested during the same session. They were; LC82/3271 fps at 60,500 MAP (M43) LC91/3230 fps at 56,200 MAP (M43) LC00/3234 fps at 56,900 MAP (M43) Also during the same load my old standard .223 hunting load of a 55 gr SX over 26.5 gr H335 gave 3183 fps at 58,200 MAP (M43, right what it should have been. All 4 of these loads with 10 shot test strings had normal pressure graphs and normal area and rise readings. There was no indication of "detonation" or SEE. US M855 LC94 produced 3053 fps at 62,300 MAP (M43) and Canadian M855 88 produced 2948 fps at 60,000 MAP (M43). Again there was no indication of "detonation" or SEE on the pressure graphs or the area or rise readings. Thus we see the data of the first 2 loads (the loads under discussion) is not an anomaly nor out of line with the data of the other loads. Thus I am wondering what the problem was during the tests. Then I noticed this quote in one of 303s posts; "It is the club's "reference" ammo tested in a commercial lab to around 63,000 PSI but actually produced nearly 120,000 PSI in his old competition AR! ... In the case of this rifle, the shooter admits the throat is washed out ..." This leads me to believe perhaps there is an error in the attachment of the strain gauge to the test weapon used, an "old competition AR" in this case. The strain gauge on the M43 is supposed to be affixed on the barrel directly over the chamber. I do not use my AR because I can not put the strain gauge over the chamber on my AR because the locking lug extension, upper receiver and the barrel nut assembly do not allow access to the area of the barrel that is over the chamber. This is why I used the TC Contender barrel instead. It allows read access to the area on the barrel over the chamber to properly attach the strain gauge. This leads me to question the validity of the test as conducted by the "Midwest Highpower club". Note the graph configuration of the first load is also the same (different from the graph configurations in the rest of the article) configuration as the graph of the second test. I assume then the first test also came from the same club using the same "old competition AR". Both of those graphs are suspect due to the nature of the strain gauge attachment on an AR and by the much different results obtained from my tests. That is why I question the validity of the tests as posted. Larry Gibson | |||

|

One of Us |

The auther does say that the SPE is caused by the bullet 'running away' from the pressure in a rifle with worn throat and bore and slow powder with a light bullet of low bore friction. This is the normal pressure trace. He also says he uses loop strain guages and that the pressure trace of the 'detonation' was supplied to him, not conducted by him.  This trace shows a slight rise in pressure near the muzzle. The next trace shows a strong pressure increase near the muzzle.  What all this seems to be telling me is that underloading with a slow powder and a lighter bullet could well result in 'detonation'. On a side note, in the first graph, the different pressures were obtained by changing only the neck tension! Another quote from the same article.

Regards 303Guy | |||

|

| One of Us |

Quite simply the writer does not under strain gage installations. A transverse gage will measure Hoop Strain ,yes. However it will also measure "whip" or moment. As a metal stretches it becomes thinner. This is poissions Ratio. For steel it is somthing like 0.3. So a bending will look like a pressure to transverse gage. To isolate moment youneed four gages in a bridige arrangement. Just because you glue a gage on and get some numbers doesn't mean it is correct. Good Luck! | |||

|

| One of Us |

303guy As Hawkins states; "Just because you glue a gage on and get some numbers doesn't mean it is correct". As I stated in my first post the graph you show as the "normal pressure trace" is not the same style of graph that the following graph is. This leads me to believe the author is using graphs supplied from different sources. The graphs from my tests with the Oehler M43 are similar to the "normal pressure graph". I got no indication of "strong pressure increase near the muzzle" during any of my tests. I also have been shooting thousands of rounds of .223 in numerous rifles with 45, 50 and 55 gr bullets loaded with similar charges of AA2230 and H335. I've never experience or heard of the "rings" the author mentions near the muzzle and I've looked at numerous of those barrels with a bore scope. Consider also that if that was a "competition AR" then the likelihood of the owner using 40 gr bullets during competition is slim to none with slim being gone. It is apparent from the inconsistencies that the author made a conclusion from unrelated facts and possibly bad data from a poorly set up test. I understand you made the post starting this thread and perhaps initially bought off on the authors premise. However I'd ask you to look at the inconsistencies. Just because it is in print it does not mean it is fact. That goes for what I've printed here also. Considering I've conducted my own tests and am relying on my own data and observations. I am not making an estimate based on unrelated information as the author is. I'll stand by my tests and first hand observations. I would post the data but apparently I do not have permission to post photo's or scans. Or perhaps you could advise? Larry Gibson Guess I figured it out, will make next a little smaller  | |||

|

| One of Us |

Note on the above Oehler data printout that the black tick mark on the red graph line for each shot is exit from muzzle. The time/pressure trace for each shot is fairly normal. Here is the Oehler data for the Remington 50 gr Factory. Larry Gibson  | |||

|

One of Us |

I did mention earlier that a 'hoop' strain guage was used in this trace. I know the article is relatively long so you folks may easily have missed where the auther covers this aspect so I'll reproduce it here. (The highlighting is mine).

Regards 303Guy | |||

|

| One of Us |

303guy your sources for; "Professional ballisticians we have talked to whose job it is to formulate powder seem to be in full agreement." In agreement with what? That SEE exists? Yes, most of us are in agreement with that. However, the root cause of SEE is the bullet gets stuck in the throat and becomes a "bore obstruction". There is no "detonation", just extremely high pressure. Do they "agree" with this authors conclusions? I study balistics and have not yet seen any ballistician, "professional" or other wise, agree with this explanation. Actually other than this authors article i've not really seen it discussed. Please state your sourses. "Even if the theory is not the "entire" explanation, it is certainly useful." Useful for what? If the authors' (and apparently yours) conclusion is based on false data from a bad test then I see no use for it what so ever. Larry Gibson | |||

|

One of Us |

First off, thanks for you responses and information! This article is my source. I have no conclusions as you suggest. I am merely answering questions about the article and about what the author has written. I can neither agree or disagree with him. He could have fabricated the whole thing for all I know! The author of the article did say the last trace data was supplied to him and that the author of that data 'admitted his rifle was very worn'. This is from that article. The author does not seem to be claiming to be correct - rather, he seems to be presenting an apparent finding. If he is correct, then the significance to us reloaders -especially those of us who try reduce our loads or velocities - is significant! This whole thread is for fun, ie having a converstion with the good folks - like yourself - on this forum and to pose a question with the hope of furthering our collective knowledge. Just an interesting observation, notice on the 'normal' pressure trace graph there are several readings with different pressure rates? Those are claimed to have been achieved by only varying the neck tension! I have no reason to doubt that claim - it is in line with what has been discussed on this forum previously and I have demonstrated for myself to be valid. PS Do you folks remember that it was 'impossible' to put a man on the moon before the actual event and in the minds of some it is still impossible? Even though those of us old enough were there to whatch the whole event unfold on TV and listen to it on the radio? I tend not to dismiss anything new or different I hear nor do I dismiss the arguments against new claims. (Do you know that the universe is actually contracting and not expanding as has been believed? There are still many who can 'prove' otherwise but the evidence is mounting.) Regards 303Guy | |||

|

| One of Us |

Larry, Mike the powder engineer at Hodgdon powder company would more then likely agree with you. In fact went we were talking on the phone I mentioned that fellow that blew up his 257 Weatherby with Blue Dot. He said more then likely what happen is the primer blew the bullet into the bore before the powder ignited and BOOM...just like you said BORE obstruction. He said the original term SEE began with the Navy and big cannons and it's the accumulated powder gases OUTSIDE the barrel that have the secondary explosion. He stated it does not exist INSIDE a rifle barrel. Joe | |||

|

| One of Us |

303guy Definately interesting and if the data is correct, informational. However, my point is that if the data is incorrect, and it certainly is suspect, then the author's "apparent finding" is no longer informational in a positive context. It just adds more BS. The loads tested were not reduced loads in any stretch of the imagination. They were close to acceptable maximum charges for the cartridge/bullet combinations. The "normal" pressure traces does show the over lapping traces from the loads with different neck tensions. On another program if I over lap the taces measured by the M43 they do not overlap precisely either. Each shot is different. The author does not say whetehr the individual traces were from single rounds or from and "average" trace of several rounds. The traces, if individual rounds, fall within the +/- acceptable variation. In that case it is difficult to draw the same conclusiong the author did regarding bullet exit from the barrel. However, varying neck tension can and does have a measureable effect on the time pressure curve. If the testor, apparently not the author, was using an "average" trace then the author's conclusion may be valid on bullet exit from the muzzle only if the +/- of the loads do not overlap. If they do overlap then again the authors conlusion or premiss is wrong. Unfortuneately the article does not provide those details. I do remember the us putting men on the moon. As you state many thought it was quite possible. The technology and ability to do so was not based on faulty information. It was based on sound experiments and dat that helped us develop the technology. Mistkes were made along the way; remember the failures on the launch pads, the dead astronauts and the missed planet/moon/asteroid or whatever it was? Those were because someone made a bad decisions based on bad data. Data was collected and those that were suspect or wrong were rejected. We got to the moon because we used good scientific testing, for the most part, and used proven facts. I too do not discount any idea just because it is new. I do discount such ideas as this one that is based on suspect unproven data, especially when there is so much proven data to the contrary. Should someone come up with more convincing and sound evidence/data confirming the author's premiss then I will be glad to study it. Who know's, I might change my mind. Until then I still think the author took some unrelated data and some poorly obtained data and tried to make something of it. In the end I see nothing there. In the case of the Universe (as we know it) expanding or contracting I think the evidence is not all in and the jury is still out. Interesting discertations on the subject though. Larry Gibson | |||

|

| One of Us |

I'm certainly inclined to agree. Some years back i got involved in a discussion as to whether "explosion" was a misnomer regarding SEE. Good arguments were made in both directions. The way some rifles come unglued I guess one could rightfully refer to them as "explosions". My argument in the whole thing comes with the use of "detonation" to describe SEE. I do not think the powders used "detonate". They do progressively burn and as pressures get excessive their burning characteristics are many times altered but still they do not detonate as in the case of RDX, PETN or similar explosives. If, as in the case of a bore obstruction, where the bullet is not moving even if the powders are 'burning" the pressure gets excessive really quick because there is not expansion as when the bullet moves down the bore (the "expansion ratio" is relevant there). One time i was attempting to develop a subsonic load in the .223 using the M193 bullet. I was progressively down loading charges of Bullseye when all I got was an apparent dead primer. When I open the bolt the pressure was released. The bullet was stuck in the barrel and nothing I tried would dislodge it. Obviously the primer had forced the bullet into a gritty (primer residue is very gritty and is one of the condition along with a rough throat for SEE) throat before the powder burned. I lost 1/2" of barrel setting back, drilling out the bullet and recahmbering. Had I been using a different powder or more of the one being used I probably would have had an SEE. I agree with Mike that there is no evidence to suggest a "secondary explosion" occurs inside a barrel. I have some interesting pressure traces that appear to show the secondary explosion outside the barrel as Mike states. Larry Gibson | |||

|

| One of Us |

Larry, Listening to Mike I gathered he didn't believe in the small charges of Bullseye with a hollow base wadcutter in a 38 Special blowing up a revolver either. I tend to agree with him. He related a story to me where a reloadered managed to load two of those bullets in one case !!!!!!!!!!!!!!! Now that is amazing. He was trying to say that if the hands of time could be turned out we would find an error in loading those rounds that blow guns up. Glad we're on the same page. Joe | |||

|

One of Us |

Quite so! But it is an interesting concept! Larry, are you able in any way to test this theory? This guy, the author, claims that his results (or those supplied to him) are being caused by a special set of circumstances and those seem to tie in with bfrshooter's experience with his 6.5 Swede. Much of what was said in the article did not strike me as a jarring inconsistancy or contradiction of previously held ideas. In fact, it seems to tie in with described reduced load 'detonations'. The auther called them "Secondary Pressure Events", not SEE nor did he call them detonations - that was me and was a deliberate 'misnomer'. That's why I used the 'inverted comma' things. This I can accept, yes! But again, special conditions need to exist. I have had similar effects but I was using a 'reduced' load, not a full pressure load of reduced volume using a faster pistol type powder. In my case, the bullet failed to enter the bore (for one reason or the other), but because it was a 'special purpose' bullet, it lodged in the leade and sealed the bore completely. I let the pressure 'release' for a few minutes before opening the bolt. (I knew there had been ignition by the rise in temperature of the chamber area). There was still pressure in the chamber even after it had cooled! There were no pressure signs, only slight squaring of the primer - a pistol primer. Quite simply, there never was enough powder to produce enough pressure to be in any way dangerous. The reason for the bullet not engaging the rifling in the first place. I have had other bullets in a different rifle stop near the muzzle due to jacket expansion. Once or twice the bullet stopped then shot out. Those that stayed stopped in the bore came out with no resistance with a cleaning rod. Again, not enough powder to develop any kind of real pressure. Regarding the primer pushing the bullet into the bore, it is said that these 'detonations' occure with large magnum cases with light bullets and slow powders, but, I have tried to drive a bullet out of my small capacity 303 Brit with only a primer and it doesn't even dislodge from the case neck! Well, most of the time. Usually the event occurs when a case has no powder and nothing happens. However, once, a bullet remained in the throat and I was unable to chamber the next round. That was with a freshly annealed neck. Yup! I made up a drill bit and guide to hollow out the bullets so they could be bumped out. (Three times until I figured out what was causing the jam!) A detonation is an event in which the explosive reacts chemically at the speed of the pressure wave passing through the material. If a propellant were to actually detonate in the chamber or barrel, the whole gun would simply disintegrate into fragments. Brass would not 'flow' under pressure - it would break. I would be inclined to say most of the time but there could be more than one cause of destructive or damaging pressure in a gun and that possibility could be clouding the issue by posing contradictory results and supposed causes. (One of the contradictions could stem from some folks denying what they really did!) Just one more point - if one takes a look at the trace showing the extreme pressure, one sees a marked drop in pressure immediately prior to the 'pressure event'. This would tie in with the authors "catch up" theory.

Regards 303Guy | |||

|

One of Us |

Actually, Larry, I think he does. Those are individual traces. This is what he said; (The emphasis is mine). Here's what I think; if there is any possibility of truth in the article, we need to confirm (or disprove) it. It may be sales talk - the auther does seem to 'own' the product he is writing about. That being PressureTrace. This could mean that someone will have to buy one and use it alongside an 'older' one that the author says is now 'outdated'. It cannot be me - I face redundancy in a few days time! (Besides, I never had the money for one in the first place). Regards 303Guy | |||

|

| One of Us |

If anyone is interested; "Rifle Accuracy Facts" by Vaughn gives an excellent description of strain gage pressure measurements. He shows Barrel moments ("whips") that he corrects with proper gage installations. This is a most excellent book. Strain gages are not new, we were using them in the Aerospace industry over 50 years ago. The proper measurement of strain with them has been established for quite a while. Good Luck! PS I think it was Pressure Trace that reported that the firing pin impact caused 10,000 PSI of chamber pressure. | |||

|

| One of Us |

303Guy "Actually, Larry, I think he does. Those are individual traces. This is what he said; (The emphasis is mine)." Okay, I will go into more depth on poorly set up hardware. During a previous test the M43 recorded pressure traces showing that same secondary pressure spike. This was with a very popular load combination that has been in use since the inception of the cartridge it was used in. I called and discussed this with Dr. Oehler. He knew exactly what the problem was. First the M43 console was on the bench pretty much even with the muzzle, the solution to that was to move it back. Additional he correctly assessed I had the wires that were attached to the strain gauge running along side the barrel (I did). He said to simply move the wires back away from the barrel. The bullet when moving apparently also produces some sort of electro magnetic wave. When I retested the same load there was no secondary spike in the pressure plate. In this case I was using the Contender in Pistol form and had taped the wire alongside the barrel to keep it out of the site's way. The computer "filtered out" the "noise"...no. It was simply a case of improper set up of the equipment. One thing you also learn when dealing with these (or chronographs for that matter) is to keep the set up and use as consistent as possible. If you do not do that then your results vary, sometimes to the extreme. "Here's what I think; if there is any possibility of truth in the article, we need to confirm (or disprove) it. It may be sales talk - the author does seem to 'own' the product he is writing about. That being Pressure Trace. This could mean that someone will have to buy one and use it alongside an 'older' one that the author says is now 'outdated'. It cannot be me - I face redundancy in a few days time! (Besides, I never had the money for one in the first place). I believe you are correct and I agree with you. I already have the Oehler M43 and am quite satisfied with it's results. I have ran tests on numerous factory cartridges of which I have contacted the manufacture. I have provided them with the lot # and they were very kind enough to provide me with the Pressure they recorded for that lot of ammo in their SAAMI spec pressure testing machines. The results with the Oehler M43 always were within the expected variation considering my tests were with commercial rifle barrels and chambering. One of the ballisticians also provided me with the accepted variation they expect when they also test the ammunition in commercial rifles with a like strain gauge instrument. My results concur with theirs. Dr. Oehler has written a very detailed article of an experiment where he hooked up several pressure measuring methods (3 different strain gauges and 3 different piezo electric gauges plus the CUP method) to the same industry accepted pressure gun. The pressure of each test shot was recorded by all the instruments simultaneously. I can not report more than that because of my word to Dr. Oehler. I really do wish Handloader or perhaps the Rifleman would publish Dr. Oehler's article. One important thing I have learned with the M43 is time management. If in a hurry you can get away with a quick set up of a chronograph, shoot a few rounds and have fairly reliable results. You can not do that with the M43. Also if the Shooting Software machine and program is similar (appears to be) then the same time management would apply. There is so much information to input into the computer (I always try to load the tests the night before conducting the test. Then at the range care must be taken to set up correctly and consistently. I use the same bench and place the target in the same place in the target holders. Careful measurements are taken of the atmospheric conditions with reliable instruments. Careful and consistent placement of the screens is also done. And now I have learned that careful, proper and consistent placement of the wires and computer is also necessary. If I am pressured by a time crunch I don't even bother testing. It is too easy to input wrong data, fail to double check everything and thus get faulty results. I have done this several times and have just had to throw the results away and repeat the tests under more "controlled" conditions. As the saying goes; "garbage in, garbage out. I don't have any qualms with someone "selling" their product via an article as under discussion. However if the author does own the company/product he certainly could have presented much better scientifically valid data to support his premise. I might add that before I bought the Oehler M43 I had attempted several different ways and numerous times to get additional information from Shooting Software concerning their product. There were always "technical" difficulties and I never got any additional information from them other than "our product is cheaper than Oehler's", it works better than Oehler's (couldn't tell me how though)" and "we'll gladly sell you one but we haven't got any strain gauges right now". When I talked with Oehler Research I not only talked with the technician building the M43 but also with Dr. Oehler himself. They offered no criticism of the other product and gave complete information on the M43, what it would do and what it wouldn't do. I have had numerous informative and helpful conversations with Dr. Oehler since. Actually I have been talking with Dr. Oehler since '75 when I bought my first chronograph, an Oehler M10 which I still have and which still works very well. I also have an Oehler M35P. Back to the article; I'm not saying there is any mistruth in the article. What I am saying is the author's premise, conclusion or "hype" is drawn on incomplete data that appears to be faulty and there for is suspect. If anyone has a Shooting Software machine I would gladly attempt to get together with them for a side by side comparison against the Oehler M43 PBL. If we can get together for some shooting that would be great also, I'll buy the beer Larry Gibson | |||

|

One of Us |

Thanks for that Larry. That is indeed interesting! Mmmm.... There were one or two 'things' about the trace in the article, those being the source of the energy to produce such a massive pressure rise and the fact that much of that pressure seemed to be past the muzzle! (The latter would indicate a delayed recovery time meaning the trace itself does not indicate a true pressure in at least one of the trace charts. For starters, it could indicate a small but sudden signal which gives a false spike ie a muzzle blast or elecro-magnetic pulse). Well, I'm glad I started the thread as now I can sleep again! (With the BS having been cleared up!) Without the internet I would have been pondering this and perhaps even believing it for a long while! A beer sounds good! PS It seems Dr Oehler has truly earned his title! Regards 303Guy | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Detonation from NORMAL powder charges

Detonation from NORMAL powder charges

Visit our on-line store for AR Memorabilia