The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  donut, no donut, inside neck ream???

donut, no donut, inside neck ream???Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

OK, here's what I did. Us ing a standard 260 Rem RCBS FL sizer, I removed the resizer button and decapping rod and replaced it with a RCBS .257 resizer/decapping rod and necked up my .243 lapua brass. Next, I used the standard 260 Rem sesizer/decapping rod and neck up to .264. I then fireformed the brass in my rifle with standard 260 Rem chamber. In the fired unsized cases, I inserted a 6.5 Berger VLD and it would not slip all the way in. There's a donut, right? I then necked sized the fired cases in a Redding Type 'S' neck bushing die. It does NOT neck all the way down to the neck/shoulder junction. Futhermore, when I attepmt to ream the donut with my RCBS inside neck reamer, there is NO resistance thus leading me to believe there is no donut of consequence. Should I continue neck sizing and loading or should I tackle the donut from a different approach? Bobby B. | ||

|

One of Us |

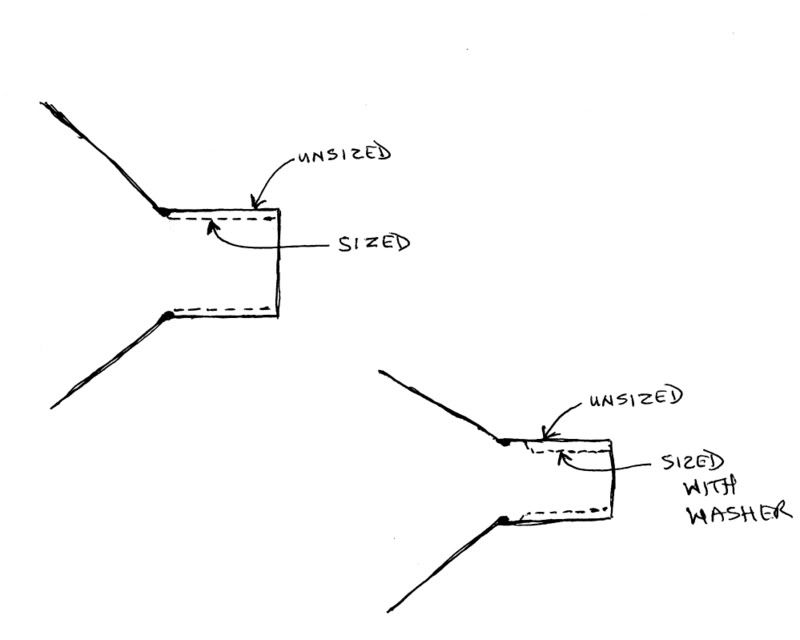

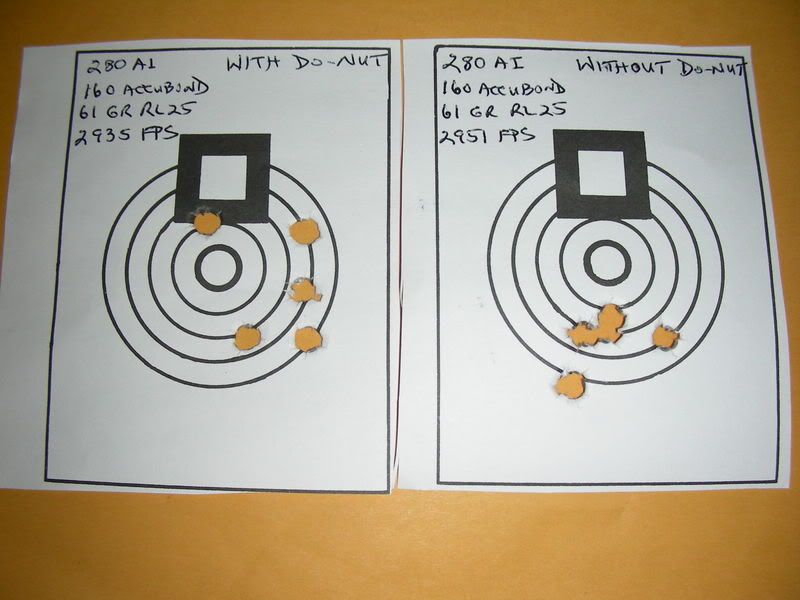

Well, one thing for sure is that if the do-nut is hitting the bullet before sizing and the do-nut is not sized or eliminated, then it will hit the bullet after sizing. It may be that the ID of the neck is sized as small or smaller than the do-nut like this sketch I did a long time ago  One of the problems with a do-nut is that it may not be consistant. IMO it could be lopsided if there is inconsistant shoulder thickness. IOW if the brass is thicker on one side of the shoulder than the other then there may be more brass flowing on that side when forming the do-nut. Best to get rid of it. I get rid of mine with a Forster reamer but in order to use it you need to have a custom tight necked chamber where you can outside neck turn your brass so that when fired it will be .003" over caliber. Then the Forster reamer, which is .0025" to .003" over caliber, will cut out the do-nut when reaming. The only other way I know to get rid of a do-nut is with the K & M outside neck turner and one of their cutting mandrels. But you normally have to use one of their neck mandrels to prep the neck for the outside neck turning mandrel, so that may have some effect on the do-nut as well. Anyway, do-nuts make a large difference in my 280AI  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I think had you done your resizing by going from a .243 to a .260 with a F/L die with the ball in place, you wouldn't have a problem now. I've taken .243 brass up to 7-08 w/o any problems. I did take the resizing ball out and ground more of a taper on the nose. (very high tech, I chucked it in a drill motor and used some of my wife's emory boads: course side, fine side and then finished up with a little 0000# steel wool) But I'm not sure that was needed. That said, I think if you were to F/L resize the brass now, it might do away with the donut. If not, it'll push it to the outside where it'll do no harm. Aim for the exit hole | |||

|

| one of us |

The donut is only a problem if your seating the bullets base into it. Bergers can have a pressure ring on the base of the bullet as much as .0008" larger then bullet diameter. Your bushing die may not even size into the donut, leaving the excess metal on the outside of the case.If to large, chambering might be hard if seating into the donut. . Sizing a few case in the standard die using the expanded should move any donut outside on the neck when you can measure it. A loaded rounds maximum neck diameter should not be larger than .2969" I have seen 2 different measurement on the neck diameter, so, not sure what is correct. The fired case neck should measure .002" or more, larger than a loaded round. | |||

|

| One of Us |

The Redding die does not size the full length of the neck but comes down to within 1/8-3/16" of the shoulder/neck junction. However, the Berger VLD is seated deep enough that the bullet itself lies inside where the donut would be. I'll play it safe and FL resize with the standard RCBS FL die, then ream and load. Bobby B. | |||

|

| One of Us |

I doubt that you'll have to ream. Aim for the exit hole | |||

|

| one of us |

I am not sure how the RCBS reamer works.Looks like it might outside turn and ream at the same time. RBCS Instructions Outside neck turning would be better then using a reamer, unless the case neck is held in a die when its reamed to center the cutter. Keep in mind that the donut can return later after a few firing. | |||

|

| One of Us |

There must be 2 different types of donuts, if I trim the outside of the neck to remove a donut THE NECK FALLS OFF, then there was the time a friend, smith, reloader swore off of wildcatting, he lost the necks of 6 cases, the only one he found was the last one fired, he came for a visit, I set up a few projects to avoid wasting his time then took him on a tour that included smiths, parts source, builders and machinist. I did not change his mind but he did leave with a better understanding his attempt did not work, most of his information came from the Internet. The dreaded donut when left in the base of the neck is a restriction, 55,000+ psi escaping gas tries to flatten it or cut it out with hot high pressure metal cutting gas, and the restriction has a tendency to raise pressure, partial neck sizing gives the neck 2 different diameters, when fired the smaller diameter flattens. Then it gets down to brass stretch and or flow and the brass making the turn at the shoulder/neck juncture. F, Guffey | |||

|

| One of Us |

Ain't but 2 ways to get rid of the donut and one of them is dangerous, see the lost case necks cited above. You can either keep the outside parallel and cut away the inside, or keep the inside parallel and cut away the outside. First and IMO best but most expensive way is to get an RCBS or similar inside-neck-ream die and use it on fired but unsized cases. Another variation of this method is to get a special inside cutter, available from Sinclair's among other places, made with teeth especially shaped to cut the donut from the inside of a fired but unsized/expanded case. Please note that when cutting the inside, it's ALWAYS necessary to start with fired but unsized or at least unexpanded cases. The second method, less expensive but also more subject to FUBARs, is to cut the outside of the neck down at its juncture with the shoulder. In order to do this properly it's necessary to start with sized cases having necks tight enough to ride tightly on the mandrel of the cutter, to support the inside of the neck firmly. The cutter should have a perceptible shoulder joining its 2 cutting edges, roughly corresponding to the the shoulder angle of the case, and the operator should run the cutter's shoulder back fully into the angle formed by the juncture of the case's neck with its shoulder. But not TOO deep! The idea of using sized/expanded brass is to move the donut to the outside of the case and then cut it away without making the remaining neck walls too thin at their base. This is apparently what happened to the fellow mentioned above, he cut the outside too far back into the beginning of the case shoulder and it eventually separated. It's a ticklish operation and so is somewhat subject to case loss if not monitored closely. To recap: either keep the outside parallel and cut away the inside, or keep the inside parallel and cut away the outside. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

I'm confused about this donut thing. I guess it forms as brass is fired and flows. I outside neck turn my brass for most of my rifles but not all. According to Varmint Al, once brass is neck turned, it will not need it again for the life of the brass. | |||

|

One of Us |

Hey rc, yeah once you outside neck turn you don't have to do it again. Do-nuts are rare and I only get them in that one rifle when using one type of brass. And I have 2 other tight necked chambers. Supposedly if you outside neck turn into the shoulder a little then that will give an area for the brass to flow into and the case expansion from the pressure will alleviate do-nuts. I do that  but it does not prevent the do-nut on the one case I get them in. Just keep sticking a bullet down a fired unsized case neck and checking for one. Chances are you will never find one. If you do, get back to us. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

rcamuglia , after reading through the responses I can understand why, nothing about Woods illustration has anything to do with donuts. I have formed 22/6mm improved cases from 30/06 and 25/06 cases, about the time the case was sized down to .243 the DREADED DONUT had to be removed and that was before any on the cases had ever been fired and the dreaded donut problem is exaggerated with an improved shoulder, as you said many cases never form a donut, by design and or accident the old folks got it right, as with the 7mm57, 8mm57 and later the 30/06. The long tapper of the 303 British, 30/40 Krag, 300 H&H and the 30/30, all with belts and or rims created problems for reloaders because of the lack of concern for what happened to the body of the case when fired after full length sizing, P O Ackle corrected the problem by increasing the diameter of the body of the case and changing the angle of the shoulder, Not easy to wrap the mind around but the "Then it gets down to brass stretch and or flow and the brass making the turn at the shoulder/neck juncture". Bench resters claim they fire a case 50+ times without measuring or weighing the for loss of brass or for diameter and thickness and claim the case stops growing after 3 to 5 firing. Back to stretch and or flow, as with train axles with fixed wheels, there is no differential between the two wheels when making a curve, one wheel slips and or slides because one wheel travels further than the other. When sizing a case the outside has further to go than the inside of the case and the outside, because of resistance to flow, is against the wall of the die and or chamber, so when someone says the case stretches I ask "If the case stretches where are the skid marks?", that leaves flow, Then it gets down to brass stretch and or flow and the brass making the turn at the shoulder/neck juncture. "Not easy to wrap the mind around" and when the case is pushed into the die from the bottom it is compressed, this causes the case to get longer (Unless a Colet is used in the die, in that case I suppose the case is compressed from both ends rcamuglia the dreaded donut is something we have created, and you are not confused, some of the information available on the Internet IS CONFUSING. There is no logical reason necking up a a 243 Winchester to 260 Remington would cause a donut, the most versatile die available is the full length sizer die if adjusted correctly, all the donuts I have created came while forming, after that I expect donuts to form when the brass makes the turn at the shoulder neck juncture on cases with sharp shoulder, and I never play games or try to out think the process, I ream the inside of the neck. | |||

|

| One of Us |

I adjusted my RCBS resizing die so it 'just barely' contacts the shoulder of a smoked case. In other words, it's adjusted tp 'partially' size ceses for my rifle's chamber. Inserting my RCBS reamer/turner into the resized case, there's NO resistance to the reamer/turner. So where did the donut go? I'm going to seat a bullet deep enough into a fireformed and resized case that the bullet won't be even close to touching the lands. I should feel some difficulty chambering the round if there's a donut. Right? BTW, the chamber neck is .299. Bobby B. | |||

|

| one of us |

| |||

|

| one of us |

Donuts happen when forming brass from a different parent case. Necking down 308 GI brass to 243 makes donuts for me. And donuts do return after a few firing, but not always. | |||

|

| One of Us |

"I should feel some difficulty chambering the round if there's a donut. Right?" NO, I have no clue as to what "just barley" is, the term has no value when measuring, similar to' a tad' smidgen and a quarter turn' I adjust my dies with the companion to the press, the feeler gage in thousands. When you full length sized the case the first part of the die assembly that could touch the die is the sizer ball on a fired case, if you have a DONUT at the bottom of the neck on the inside of the case the sizer ball hits the donut, then everything stops until enough pressure is applied to the handle to force the sizer ball through, and there lies the problem, the donut should be removed before the sizer ball passes through it, BECAUSE the sizer ball is not designed to size on the way down, it is designed to size on the way up after the die has reduced the diameter of the neck. Again with all the confusion: a hand loader sizes a case, the sizer ball hits the DREADED RESTRICTION IN THE NECK, THE DREADED DONUT and says "WHAT THE HECK" and continues applying pressure, then suddenly the donut is no longer a restriction ON THE INSIDE and the case is full length sized THEN and the restriction is reinstated, after that the ram is lowered and the sizer ball, again, is restricted until it moves the well traveled donut, then if the old saying is applied about not working your brass one has to wonder if all that travel could be considered 'WORKING YOUR BRASS. Somewhere in the events of sizing the case there was a good time to remove the donut, in my opinion the good time is not after full length sizing, save the integrity of the outside of the neck and shoulder and remove the wadded up brass on the inside with out working it back and forth. Stretch and or flow and brass yield pressure, does 60,000 psi hammer the inside of the case against the chamber wall and make it thinner, if the brass is hammered and the brass gets thinner, where does it go? Does the 60,000 psi hammer the brass against the shoulder of the chamber? Resistance to chambering, I would seat a bullet and shove it through the neck of the case until it fell inside, then size the neck up to remove it, when sizing I would check the cases for a bulge at the neck/shoulder juncture after full length sizing, if the bulge was not there before sizing then appeared after sizing I would not trim the bulge, I would hit the case with a hammer and save it in a can and wait for the price of brass to go up, do not hit the case when a primer and or powder is installed. or you can trim the outside and take a chance your neck will fall off. F. Guffey | |||

|

| One of Us |

So, how to determine if there is a donut, for those that have never seen one, use the sizer ball as a hole gage, the sizer ball should slide through the neck without effort, if it stops at the shoulder/neck juncture, find out why it stopped, there are other reason for the sizer ball to have resistance when inserted in the neck, stopping at the bottom should suggest a donut unless the neck are partially neck sized. F. Guffey | |||

|

One of Us |

Mr. Guffey, if the diameter of the do-nut is .255" (on his 257 caliber gun) and the expander ball is .254" (common for expanders to be .003" below caliber size), then the expander ball will not hit the do-nut going or coming. Then if he only sizes part of the case neck, then when seating the bullet will push the ID of the sized portion of the case back to .257" and then contact the do-nut which has remained at .255" because it was not contacted by the expander. I would suspect that very seldom would a do-nut be so large as to contact he expander ball but it is still enough to contact the bullet diameter. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

F. Guffey, Other than utilizing the expander button, how does one go about necking the .243 Winchester case up to .264"? Bobby B. | |||

|

| One of Us |

Bobby B. said he necked the 243 Winchester case up to 257 then installed the 6.5. .264, 260 primer punch assembly in the 260 Remington full length sizer die, sized a case then fired the it, then sized the case again. Then you posted the illustration of a partially sized neck without the hint of a donut. I do not know what dies you use, on the dies I use when the ram is raised the neck is sized and the inside diameter of the neck is reduced, the only way to get the sizer ball out from inside the case is to lower the ram, when the ram is lowered the sizer ball sizes/expands the neck, then I wonder what is a DREADED DONUT, as I have said I have created donuts when forming cases, a good way to bend the primer punch/sizer ball assembly is to attempt forcing the assembly through the donut/wadded up ring of brass, again I do not know what dies your are using, I get all the use possible out of the versatile full length sizer die, very seldom is it necessary to to use a specialty die. I thought you were the one with all the hole gages, there are tools foreign to reloaders, I have hole micrometers and ball micrometers and blind end hole micrometers, as I have said, for those that have never seen a donut, finding on is a matter of taking a bent all and slid it sown the neck, a small bump is a small donut or a case that has been squatted, a big bump is THE DREADED DONUT, or as you suggest, it can not be done. F. Guffey | |||

|

| One of Us |

Bobby B. you did good, Hunington and RCBS says the only additional tool necessary for necking up 243 Winchester to 260 Remington is a tapered sizer ball, the foot note for the required tool has to do with dies make before a certain date, after that date all neck sizer balls are tapered, going from 243 to 257 and then to 260 (.264) is more practical if you have the dies. I use case forming/trim dies, I do not have one for the 260, I do have one for the 7mm57. Order a special order catalog from RCBS 1 800 533 5000 RCBS part number 09824 $8.95 F. Guffey | |||

|

One of Us |

Mr Guffey, the original poster (Bobby B) said this in his post

That is why I posted the sketches to show what may happen when sized this way. The sketches clearly show a knob or projection at the shoulder/neck junction, perhaps if I had labeled it for you it might have been clearer.

Yes I am the one with the pin gauges and find them very useful  and on the do-nuts I had and reamed out they were not detectable by sliding anything other than a bullet or a pin gauges down the neck. But please answer the previous question of why you would say to run an expander ball down the neck and that would show if you had a do-nut

____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Yesterday, I FL resized my cases and the donut was clearly visible on the outside of the neck, and it could be readily measured as well. I took my Sinclair Neck Turner and carefully removed the donut, all the while be very careful not to cut into the shoulder too deeply. If the wind stays calm this afternoon, I'll test some loads for accuracy then examine the cases again for donuts. Thanks guys for all your input. Bobby B. | |||

|

| One of Us |

I'm gonna throw the Bull Shit flag on this supposed need to have an intermediate step when resizing from .243 to .260!! I have never reformed .243 to .260 but I've resized a whole bunch from .243 to 284 back when the 7-08 was still a wildcat. My neck was cut so close that if I reduced .308 brass, I had to neck turn; if I expanded .243 brass, I didn't. Lube the case and lube the inside of the neck. One pass thru a .260 full length die with the resizer ball in place and wa la, .260 brass. NO doughnuts. There's no need to over think this thing nor make it a lot more complicated than need be. One simple question: If we are expanding .243 brass to .260, even using the pointless method that the poster used, where is this extra metal that is forming the doughnut coming from??? Aim for the exit hole | |||

|

| One of Us |

Bobby B. Get ready for a bunch of case seperations at the neck. What you were looking at was a part of the neck that just hadn't been besized. In other words, there was no extra metal on the outside of the neck so by you removing what you're calling a doughnut, you are cutting the neck thickness in half at that point. If you P/FL resize brass the case will shortly form this doughnut around the outside of the neck at the shoulder. This does no harm and in fact, IMO, helps to align the cartridge in the chamber. Aim for the exit hole | |||

|

| One of Us |

Wasbeeman, if you're calling BS on me, it's misgiven. I didn't say one has to neck up the .25 before necking up to .26, I'm simply stating that's what I did. IF I recall correctly, somewhere on AR someone wrote that donuts are formed during the fireforming process and not the sizing process. I'll check some of my sized cases for donuts, the cases which have not been fireformed. I'll reserve comment on the neck separation possibility. Obviously, it has happened to others and, so, could happen to me. However, it would seem that turning off the donut is no different than turning a neck for use in a tightneck chamber. Bobby B. | |||

|

One of Us |

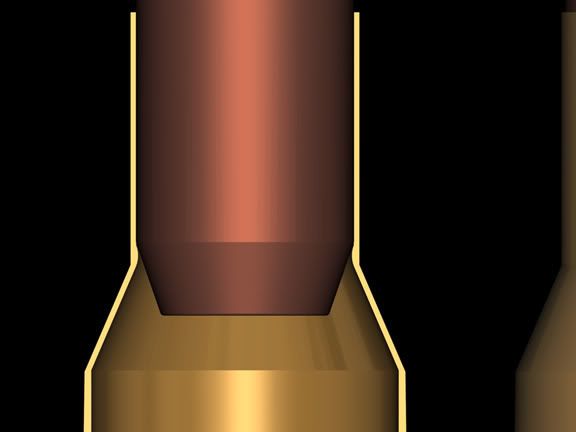

I guess first of all we have to define whether you are talking about an interior do-nut or an exterior do-nut. Normally when do-nuts are mentioned they are interior   and not exterior  never outside turn an exterior do-nut off and outside neck turning into the shoulder will help prevent interior do-nuts before they develop. Hey LB, what happened to your excellent post? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Just checked my cases; the virgin sized cases do have an outside donut, the virgin loaded cases have an outside donut, the fired cases have an outside donut plus there's a restriction inside preventing a bullet from sliding in all the way, and the full length resized cases have an outside donut. I believe it's safe to assume that the donut was not a problem when I fireformed the virgin sized brass. As Wasbeeman stated, perhaps it simply aided in aligning the case in the chamber. Certainly there was no excessive pressures generated by this donut as I was pushing 130 Berger VLD's in excess of 3000 fps out of a 24" barrel with no pressure signs; no extractor mark, no sticky bolt, (I did not mike the case heads before and after). I've taken some photos but cannot post them here due to undeveloped computor skills. However, I'd be willing to e-mail them to anyone who is interested in posting them. The cases appear much like in Woods' drawing. When I sized up the cases, the case shoulder did contact the resizer die. Since the 260 case measures 1.776" from head to shoulder/neck junction, and the .243 measures 1.804", and both cases have a 20 degree shoulder, it stands to reason that full length resizing a .243 case to .260 would resize the entire neck portion of the case being resized. I'm only wanting to understand what is occuring, and have no interest in arguing with anyone. If I can benefit from someone's knowledge and experience, or they can from mine, then we're all better for it. Bobby B. | |||

|

One of Us |

Hey Bobby B No problem, so far this has been a civilized thread by AR standards. IMO, an exterior do-nut does no harm and may even be beneficial, is has been in my guns. But an interior do-nut will be a problem in that it is an inconsistant rear crimp on your bullet. Try to figure out a way to get rid of it, what works for me may not work for you. I use a Forster reamer which is .003" over caliber but you have to set your cases up so that the fired ID of the neck is .003" over caliber so the reamer will work on it. If you have a factory chamber that has more neck clearance than .003" then this is not possible. What is the ID of your fired unsize neck? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

An exterior donuts diameter on a loaded round has to be smaller than his chambers neck @ .299" When sizing with the standard RCBS FL die after outside neck turning, you will still get a small amount of donut on the inside of the neck. This is due to brass spring back. But , he is going to be using bushing dies after the neck have been turned. Sizing only 1/2 of the neck will not be in the area of the donut. So any remaining donut will not be a problem. Woods is correct, the only way to get fully rid of a donut is inside neck reaming, as the case is held in a special die. We are talking at most .001"(spring back) that is not removed by outside turning. | |||

|

| One of Us |

Woods, Measuring the ID close to the mouth, I get .265-.266". Measuring deeper in where the donut would be, I get .259-.260". After turning the donut off the cases, I necked sized the same cases with my Redding Type "S" Neck Bushing Die. It's still windy outside so I won't be testing loads for accuracy today. I don't have an explanation for where the extra brass is coming from as it is there after I've necked up the cases. It's there BEFORE I fireformed the cases. The only experience I have that's related, is necking down 7x57 cases to 6mm, establishing a secondary shoulder, loading with Blue Dot and cornmeal, and fireforming. Never knew about donuts back then and experienced no problems with accuracy or pressure spikes with the formed cases. Bobby B. | |||

|

| One of Us |

Just primed 33 cases in preparation for loading. These are 33 ONCE fired cases. Of the 33, 11 had very loose primer pockets and the remaining 22, although no too loose to use, were as loose as what I generally get after 4-5 full power reloads in my 7 Rem Mag. Of course all original 260 loads generated much greater velocities than their book counterpart in the Nosler Manual. That's afirst for me and I've been doing this for about 30 years. Bobby B. | |||

|

One of Us |

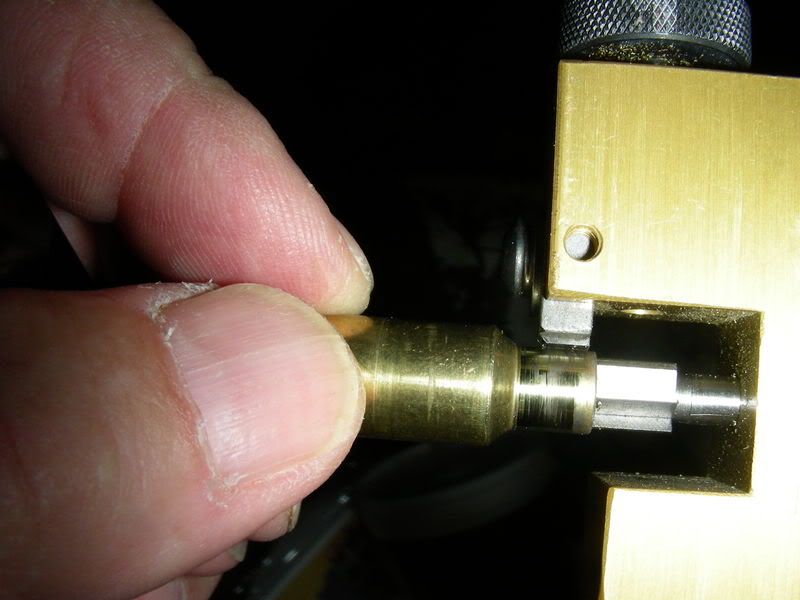

Then your cases in that gun are a candidate for reaming the way I do it. Not saying it is the best, just the way I do it. The primary requirement is that the ID of a fired case not be any larger than .267", which yours isn't. I use a Forster hand held outside neck turner  with a 264 mandrel if I am outside neck turning  If I want to ream I use a 264 reamer  The reaming mandrel has the same size shank on it as the outside turning mandrel it fits in the hand held turner   I use the reamer on once fired brass where I have previously set the new brass neck thickness so that I have .003" clearance around the neck in the chamber. Once the case is fired I now have .003" over caliber diameter so the reamer will fit in and I lightly clean up the outside at the same time  By trapping the neck between the outside blade and the inside reamer blades (which span the entire neck unlike the K & M) I am assured that the neck thickness will be exactly what I want it to be from the mouth to the shoulder. Your brass is thick enough so that you could use the same equipment. Personally I don't form any brass from one caliber to another but I have heard that it will make neck thickness vary considerably because of the brass moving from one place to another. If I did I would be sure and use something like this in order to make the neck consistant. I guess the reason you are going through all this is so you can use Lapua brass. Otherwise it would be simpler to just get 260 rem brass. The main advantage of the Lapua is the consistancy of the neck thickness but it sounds like you are negating that benefit by necking it up. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Woods, you're right, the reason I'm going through these extra steps is to use the Lapua brass. The reason I was necking up in 2 stages was to minimize neck thickness variation resulting from necking up. At this point, it appears all I've really accomplished is to learn something rather than my original goal of achieving something. Live and learn, right? Bobby B. | |||

|

| One of Us |

Bobby B. I thought you deserved betters answers, now I believe you finally got them, the first should have been 'NO' the rational should have been 'there is no way you can form a donut by necking up a 243 W to 260 (.264) Remington, and as I said if you used a collet die all bets are off. Partial neck sizing does not create a donut, getting better answers requires exercising the right to disagree, as to the part about learning something from me? I do not count on it nor do I expect it. Bad habits acquired on the Internet: Fire forming, it is not necessary to fire form your 260 Remington cases after necking them up, the case is formed , the shoulder is forward and the diameter of the case did not change. Fire forming with reduced loads is an option, I choose to fire form once but that is with cases that require blowing out the case body and forming the shoulder as with the 30 Gibbs, I have the full length sizer die and no cases that are long enough from the head of the case to the shoulder, the shoulder of the Gibbs is .202 ahead of the shoulder of the 30/06. I do not use reduced loads, as I said if I fire form a case I do it once, if you used the reduced load formula it is possible there was not enough pressure to completely blow the neck out. http://www.z-hat.com/Cylinder.htm The Remington cylinder brass is a 'can not miss' when adjusting the length of the case from the head of the case to the shoulder, the cylinder brass is 2.650, it would be nice to have, problem I will never use the brass I have. So I form first then fire as opposed to sizing first then fire. This method works when head space is determined before sizing. I am a big fan of necking up a case to create a second shoulder, on the Gibbs I have used an 8mm sizer ball then necked the neck back to 'ZERO' the head space, I have use the 338 sizer ball and the 35 Whelen sizer ball, all three worked, but forgotten is Hatchers experiment into modified chambers, he tthought excessive head space was tearing up the 03s, so he moved the shoulder forward .125 on the 30/06 chamber and test fired his new 03 creation, the cases held together, the rifle did not blow up, when the cases were ejected they were 30/06 + .125 Hatcher modified cases, had he increased the diameter of the chamber and increased the shoulder angle the cases could have been called the Hatcher 30 Cal Wildcat. His cases head spaced on the extractor, meaning the case did not move forward and bounce of of the shoulder, just a coincidence, the 8/06 shoulder is forward of the 8mm57 by.129. As to Hatcher' creation, once the case blew out to fill the chamber it should be left out, full length sizing the fired case is guarenteed to cause the case to fail. F, Guffey | |||

|

| One of Us |

When necking a case up the neck gets shorter, that is another concept to get the mind around because no one measure the thickness of the brass. Again when necking a case down the neck gets longer, another concept that is difficult to get the mind around most believe it the neck gets thicker. Then it gets to case forming, some believe the shoulder is moved back, this does not happen, when I form 8mm57 cases from 30/06 cases part of the shoulder becomes part of the neck abd part of the case body becomes part of the shoulder on the newly formed 8mm 57. The shoulder did not move back, is more like the shoulder was erased and redrawn further back, in this situation the neck can get thicker and the case gets longer. F. Guffey | |||

|

| One of Us |

The consensus seems to be that a donut cannot be formed by necking up the .243 brass to .260. Maybe we need to clarify what a donut is because there is a very obvious lump on the neck of my cases where the shoulder/neck junction is. It is there after necking up the brass and before firing the brass. It is there after the cases have been fired plus there is a restriction inside the case neck which prevents a bullet from slipping into the case past the shoulder/neck junction. Finally, it is still there after the case has been full length resized. For the sake of knowledge, I have turned off the lump on some sized but unfired cases. It will be interesting to discover whether or not this lump will be present or not after firing. I realize it's very difficult for you all to decide whether or not I know what I'm describing. If I knew how, I'd post the photos I took, but since I don't, I'd be happy to e-mail anyone interested in viewing them and they might better understand what I'm describing. Something is occuring and I'm at a loss to explain it. If anyone is able to shed some light on this, it's be much appreciated. Bobby B. | |||

|

| One of Us |

"I then fire formed the brass in my rifle with standard 260 Rem chamber. In the fired unsized cases, I inserted a 6.5 Berger VLD and it would not slip all the way in. There's a donut, right?" Again, are you using reduced loads, I do not use reduced loads, I fire form cases once. To get predictable results use standard loading when fire forming??? Again I do not use reduced loads, are you using oatmeal, cream of wheat, a filler of some kind? I think that technique creates problems, as I said I fire wildcat loads once, when the case is extracted it is a mirror copy of the chamber, reduced loads are cute, friends have complained fire forming is a waste because the case requires 3 firings to complete the process, then there is sudden shock that is created with fast burning powder, the practice of using reduced loads in WW 1 was abandoned because the 1903 Springfield was at best a marginally safe rifle, the 03 with it's weak receiver could not tolerate the sudden shock created with the use of pistol powder.Then there was the reloader that fired reduced loads in his Weatherby 300 Win Mag, his rifle was rendered scrap and he did not understand why, he claimed reduced loads were the only loads he used in the rifle, it was nothing, then, all of a sudden the rifle fell apart? No, the rifle absorbed all the sudden shocks it could stand. He felt better when he was lead to believe he double charged one load. I do not use bushing or collet dies, again I use the versatile full length sizer die for everything, I have neck dies, small base dies? and BAR dies, if I used anything else I would accept the results by comparing the case to a standard, the standard would be a case that was sized with a full length sizer die with the expander ball installed. When testing a rifle at the range the first case fired and ejected is tested with the bullet protruding from the next round to be fired, I place the bullet into the neck of the fired case, it should slide in with room, with 30 cal test I use the neck of a 270 case, on a sized 30/06 case the 270 fits, on a fired 30 cal case the 270 neck is loose, | |||

|

| One of Us |

Woods, your setup is the neatest thing I've seen since sliced bread! Here are a few rules/truisms I've discovered over the years: A donut can form any time brass is moved whether necking up or down, shooting or sizing. 'Can' and 'any time' are the operative words here. Donuts can and do sometimes return. A donut cannot be fully removed unless the portion of the neck adjacent to the cutter is fully supported during the cutting see Woods' setup. A good inexpensive check for the presence of a large and VERY unsafe donut is to insert the base of an unfired bullet into the neck of a fired case. If the bullet will fall all the way down into the case body then things are at least fairly safe even if maybe not perfect. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

The cases were necked up with a RCBS FL resizer. The cases were loaded with standard powder charges for the 260 Rem and then topped with Berger 130 VLD's. As I mentioned in previous posts, I'd be happy to e-mail photos of the cases. Bobby B. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  donut, no donut, inside neck ream???

donut, no donut, inside neck ream???

Visit our on-line store for AR Memorabilia