The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Anyone bring the 8x57 up to 60,000 psi?

Anyone bring the 8x57 up to 60,000 psi?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Most listings are sedate, 51,000 is the closest. | ||

|

| One of Us |

PM Wildcat Junkie. He has done a lot of modern load development with the 8x57. | |||

|

| One of Us |

The CIP max. pressure is about 3900bar (~57.000psi). European reloading datas are listed about this pressure. | |||

|

| One of Us |

Begs the question: why would you want to? | |||

|

| one of us |

IN a good mod. 98 MAUSER I see no reason not to, its perfectly acceptable and many of the loading books show more PSI than that from good modern or strong Mauser actions and Mauser take offs such as the mod 70 win.... Most of my hunting rifles are MAUSERS, and loaded at about that pressure. I only had one 8x57 a few years ago and I max loaded the 160 gr. Barnes X at about that pressure as that's where it shot best..It was a hammer on deer with that combo and the fellow that I sold the gun to has shot more than a few big mature bull elk at various ranges, all one shot kills. As to why would you want to? because I like to get peak performance out of a caliber, otherwise I would drop down to a lesser caliber. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

There are very good reasons for that. Specifically, most of the 8 X 57 rifles out in civilian hands are military rifles. These rifles were not designed or built, for heavier loads. I have not found an explicit statement to the design loads that Paul Mauser used. SAAMI and CIP standards were established well after his death. However there is information about the proof pressures used in M98 actions. Rifle Magazine Issue 159 May 1995 Dear Editor pg 10 http://www.riflemagazine.com/m...PDF/ri159partial.pdf

Kunhausen shows similar numbers in his book : “The Mauser Bolt Actions, A Shop Manual” Rifle & Carbine 98: M98 Firearms of the German Army from 1898 to 1918 Dieter M98 Mauser service rifles underwent a 2 round proof at 4,000 atm gas pressure, 1 atm = 14.6 psi, 4000 atm = 58, 784 psia. Page 103. A comment on the metallurgy and process technology of the era, Dieter found records that indicated that the bolt lugs broke on 1:1000 of GEW98 service rifles used by the Bavarian Army Corp! Gun Digest 1975 has an excellent article, “A History of Proof Marks, Gun Proof in German” by Lee Kennett.

The article indicates it was applied to the 1898. The 1939 German proof law called for proof at 130% of service load pressure. From Mauser Bolt Rifles by Ludwig Olsen, page 134, the maximum working pressure of the German 7.9 sS cartridge was 46, 926 psi. According to sources, this round was used in machine guns after WW1 and then shortly before WW2, became a universal issue round. Use in the K98 action had to have been examined, and I expect the decision to use in the K98 would have been based on the improvement of metal quality and process technology. A proof pressure 7.9sS would be 61k psi. Unless someone can produce credible data as to the proof standards of later 98 actions, and the design limits used by Paul Mauser, I am going to state that it is reasonable that the action was designed to support cartridges of 43, 371 psia with a case head diameter of 0.470”. Later higher pressure ammunition was probably considered an acceptable risk, but even then, the 7.9 sS cartridge pressure was 46,926 psi. I believe that a pressure standard for these rifles of 43, 371 lbs/ in ² is reasonable based on the SAAMI spec pressure of 35, 000 lbs/ in ². Obviously SAAMI researched this issue, probably determined original pressure standards, then used wise judgment about the age, uncertain previous history, unknown storage, usage, the known limited strength of period plain carbon steel actions, and as an industry, they were are not willing to accept the liability involved with selling new ammunition of a higher pressure. Even pressures of 51,000 psia are high for 1930's and 1940's actions, given the 46,926 psi loading of the sS 7.9 service rifle load. Military Mauser actions were made out plain carbon steels, the older the action, the worse the quality of the steel. This is a real limitation for action strength and fatigue lifetime. Due to the material technology of the era, pushing the pressures on old actions is not advisable. It is your face, your rifle, you crack the lugs, a catastrophic event can happen. However, there have been a few modern actions, made out of modern alloy steels, chambered in 8 X 57 mm. A typical alloy steel has a 20% higher yield than older plain carbon steels, so just by the material technology, a modern action made with modern alloy steels, can take the 60,000 psia pressures you see for other cartridges. So, if you have one of those Rem 700's chambered in 8 X 57 Mauser, there is no particular reason not to load the cartridge above the 51,000 psia limit you see in manuals. | |||

|

| one of us |

Over the years I have heard it suggested that Mausers develop headspace..I have never experienced that and I have owned many mausers..I would any day prefer a Mauser over a mod. 70 for strength in that a Mauser is only case hardened on the outside so that it will not fragment like a mod. 70. The Mauser might split a barrel, and puff up, but it won't fragment, as far as I know.. I know of some 96, 95, and one FN that developed headspace or so I was told, but the fellow telling me that was reliable.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

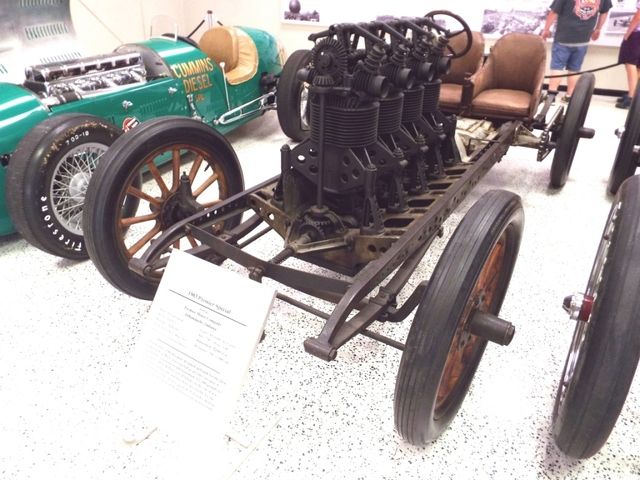

This is worth looking at for an idea of the risks of these old receivers: 1895 Chilean Mauser http://dutchman.rebooty.com/1895Chile.html The shooting community has been saturated by decades of gunwriter nonsense on old actions and gunsmithing articles, which were nothing more than advertizing by the authors. Gunsmiths want to drum up business by extolling the advantages of "sporterizing", gunwriters are paid to shill for importers, and as such, the shooting community is sold on the romance of these old actions. I think the M98 Mauser action design is one of the best, if not the best, action every designed. The Japanese Arisaka is also a extremely well designed action. However I am not a fan of the materials used in pre Vacuum tube technology actions, or even of the materials in a Vacuum tube technology military actions. I would be a fan of these exact same actions built out of modern materials, under modern process controls, in modern factories. I am not a fan of the 03 action as it is inferior in every aspect of departure from the M98. The WW2 M1903A3 actions and the nickel steel actions are probably the strongest, but they are certainly not the safest as the action vents gases straight into the shooter's face. The 03 action also breaks parts, particularly the firing pin, firing pin collar, and cocking piece. For an idea of the manufacturing technology used in old actions, examine the technology of the finished products that are still around. As an example, here is the 1903 Premier Special. This car is at the Indy 500 Museum, and this car is in its race configuration. Notice the wooden spokes, chain drive, the “hey Ma!, no front brakes!”. For that matter, there is no brake pedal, the driver grabbed the brake lever on the right of the car. Take a look at the horse and buggy suspension, solid axle, huge leaf springs. No safety belts, there were no safety belts till the early 1950 Indy cars. Some other points, you had two people in the cockpit. The riding mechanic https://en.wikipedia.org/wiki/Riding_mechanic pumped the oil and fuel. These early engines did not have an engine driven oil pump. From what I understand, the riding mechanic pumped oil into the engine and it dripped out on the track, or went out the exhaust, but it was not recycled back into the oil tank! Spark advance was done manually, usually you see sticks or balls on the steering wheel by which the driver manually advanced or retarded the spark. Younger people probably don’t know what a distributor was so this probably won’t make an impression on them.     The technology of the day had its risks. This car could be pulled out and raced, but it was a death trap then, and it remains a death trap today. Back then, someone would inevitably be killed in each automobile race, sometimes spectators and drivers. Spanish Mausers have a poor reputation, primarily due to inferior metals and soft receivers: Small Ring Mauser Question. http://www.thehighroad.org/showthread.php?t=756353

Excessive Headspace in M1916 Mauser http://www.thehighroad.org/sho...6707989&postcount=10

http://www.thehighroad.org/showthread.php?t=530130

http://www.jouster.com/forums/...93-in-.308#post41975

http://www.thehighroad.org/showthread.php?t=632782

Regardless of the “reputation” of Swedish steel, old Swedish small ring actions are variable in quality and also fail: Variation in M96 Swede Actions

One only has to go through the magazines of the 1920's and 1930's to see just how rapid was the improvement in metals, metallurgy, process controls, etc. I am going to say that things were still pretty wild and woolly in the 1920's, but rapidly improving. By the time you get into the 1930's, metallurgy is getting mature. All the basic alloy steels used in today's firearms were developed by the time you get to WW2. However, even now, in this time of endless prosperity and peak of human civilization (sarcasm intended) there is room for improvement. As recently as 1987, wheel bearing lifetime was increasing due to process improvements that produced cleaner steels. Improvements in Bearing Steel, Cleanliness and the Effect on Integral Wheel Bearing Systems Ghassan S. Tayeh and Helmut R. Woehrle 1987

| |||

|

| one of us |

Very good points on the small rings you mention.. If I use a small ring Mauser it will be a G33-40. a mod. 35 (German Customs G33-40 without the cut) or a Brno mod. 21 or 22 all of which are G33-40s.. A commercial Mauser L.R. with small thread medium action (used by Rigby for the 275 Rigbys dated about 1903 to 1905..These when available will bring about $700 to $800. The Chilean 98. 1908s or the Puruvians will stand the test for sure. I have had good luck with the 1935 FNs with thumb cut also. Some later FNs seem to have trouble but only with high intensity cartridges such as the Wby's etc. There are others and I use them from time to time, but the above are my favorites. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

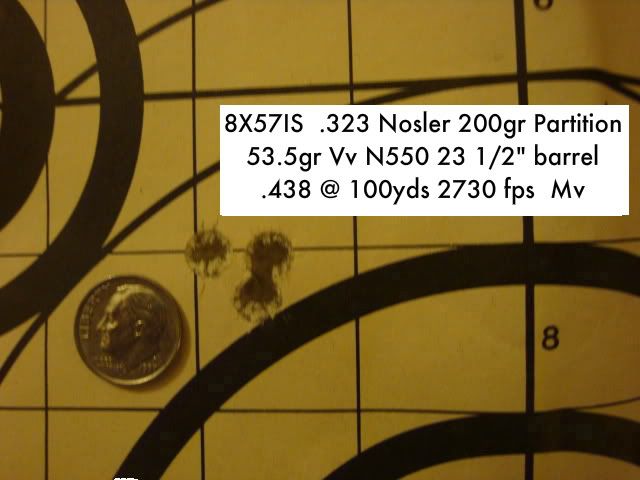

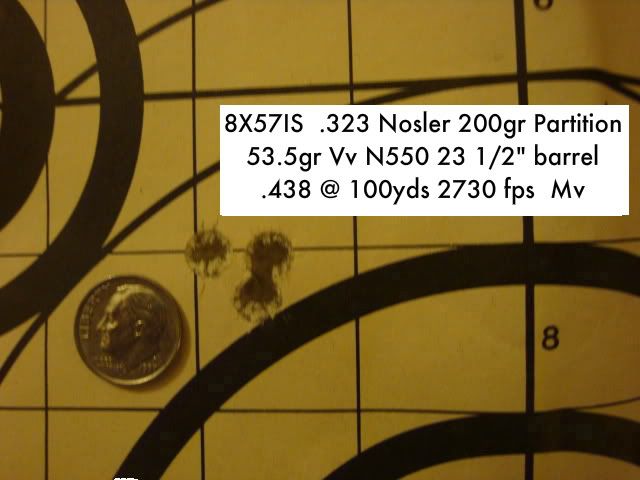

These loads are being used in a circa 1960s vintage Vz 500 (commercial) Yugoslavian LR intermediate length M98 action. I get nearly identical POI, Mv & accuracy with RL17 & 200gr Speer Hotcore bullets.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Some past mortem pics from a large Whitetail buck hit straight on @ 100yds with a 200 gr Speer Hotcore leaving the muzzle @ 2700 FPS. No blood trail due to catastrophic pump failure, but the animal only went about 50 yds  About 1/3 of the liver was destroyed.  The lungs were shredded. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

That's what I'm looking for!! Great stuff and thanks for posting!! | |||

|

| one of us |

I have 1943 vintage J P Sauer & Sohn as well as 1939 Oberndorf K98 actions. The J P Sauer has had 100s of rounds of full house 8mm-06 Ackley Improved round through it W/OI an signs of set back. I am contemplating doing an 8X68S on the Oberndorf. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

Darn if i only knew that those Mauser actions were junk,i would not have built that 3oo WSM on that Polish action. Now what to do. With the small ring types 95-96 i can see not hotrodding but with the 98,nope not a problem as long as one uses their head and don't lose it. | |||

|

| One of Us |

Reshot the 56.5gr with the 180gr AB and 2,650fps. Will drop to 56gr which gave the group below and call it quits.  20150911_191853 by adshools, on Flickr 20150911_191853 by adshools, on Flickr | |||

|

| One of Us |

The No.1 British Enfield rifles were made of the softer steels of their day and had replaceable bolt heads to compensate for wear and bolt and lug setback. Later the No.4 Enfield rifles were made of higher grade steels and improved heat treating methods and the last No.4 Enfield rifles were chambered in .308/7.62. If and I say "IF" your Mauser has softer steel in its manufacture, and if you are over stressing the rifle the first indication will be increased headspace. Also European proof testing requires "TWO" proof test cartridges to be fired and if the headspace increases over a given amount the rifle fails proof testing. The American SAAMI maximum allowable chamber pressure for the 8x57 is 35,000 psi "BUT" the European CIP is 57,000 psi. And the CIP standards are much higher than American pressure standards and when converted to our American pressure would be approximately 52,000 psi. Bottom line our American ammunition manufactures are loading the ammunition to the lowest pressures the oldest firearms in that caliber can operate at without problems. I also find it strange after having so many heated discussions with slamfire about lubing cases and increased bolt thrust, that he has said the things he did here. Bottom line, after spending half a lifetime collecting and shooting the British Enfield rifle that did use softer steels. The first sign of over pressure will be increased headspace. And the 1929 British Textbook of Small Arms tells you to keep the chamber free of oil and grease or the action will be strained. And I find it amusing the British used softer and cheaper steels in the construction of the Enfield rifle and used replaceable bolt heads to compensate for the increased headspace with wear and use. | |||

|

| one of us |

This group was shot out of a K98 "take off" barrel I bought for about $40 from Numrich. It has had only a re-contour & crown done to it, proving that not only are the actions rubbish, but the military barrels are junk too.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Wildcat Junkie, Mercy I love those J.P. Sauers..Just sold my mint and engraved 30-06 JP Sauer for a small fortune, hated to see it go. It shot one inch all day long with the receiver sight on it..makes me sick thinking about its leaving my hands, I'm just a gun whore, dammit. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ed Horton, interesting to see you back again. I know what loads and how the loads were assumed and sized by those who designed firearms. You don't, this was something the Government did not put into your Quality Assurance manuals, now did they? Instead, you believed a lie told to you by Remington. | |||

|

| One of Us |

The 30-30 is rated at 42,000 psi and the .303 British is rated at 49,000 psi. So your saying the Mauser action is weaker than the Enfield action. The Enfield action was later chambered in .308/7,62 at 52,000 psi and your saying the Mauser action is weaker. It looks like you know more about old cars than the Mauser action and European testing methods. | |||

|

| One of Us |

I just checked the Lyman and Hornady manuals for the 8x57 Mauser and Quickload. All figures base on the Hornady 150 grain bullet and IMR-4064 Lyman 51 grains 48,700 psi Hornady 51.1 grains Max Quickload CIP 56,565 psi 53 grains 4064 54,662 psi Quickload SAAMI 35,000 psi 45.4 grains 4064 34,892 psi From the above the SAMMI downloads the rated pressure to a max pressure of 35,000 psi. Lyman and Hornady manuals raise this to approximately 49,000 psi. And CIP adds two more grains of 4064 but their pressure of 56,662 is measured at a different point on the case than the SAAMI and reads differently. But 53 grains of 4064 under Quickload SAAMI is 54,563 psi. So the European CIP loads the 8x57 to approximately 55,000 psi (American SAAMI pressure method reading) Two American reloading manuals load to 49,000 psi (American SAAMI pressure method reading) And the SAAMI wimps out at 35,000 psi due to the older 8x57 rifles still being used today. | |||

|

| One of Us |

If your point is that there is a mix and match of units, that is the pressures I am quoting for the Mauser are CUP not PSIA then that would reconcile the logical absurdity you have presented. So, are the proof standards I quoted CUP or PSIA? What was the actual pressures the Germans were measuring , in PSIA, for proof rounds and standard rounds? What is your source as the authorities I quoted did not differentiate between CUP or PSIA. And then, reconcile the 35,000 psia standard, as the SAAMI standard is 35,000 psia, not CUP, at least from the web sources I have read. If the SAAMI is CUP, where is your source? Then what loads did Paul Mauser use in designing his rifles? Where is your source? | |||

|

| one of us |

Buy modern actions and don't worry about the Mauser nonsense. I'll take a Ruger MKII 77 over a old 98 any day. Gun smiths love them because it cost a lot of money to ring them up to modern standards. | |||

|

| One of Us |

[QUOTE]Originally posted by SlamFire: What is your source as the authorities I quoted did not differentiate between CUP or PSIA. {QUOTE] All the pressure figures I listed were in psi and not cup, and these figures clearly show that the Europeans do not download the 8x57. And the Lyman and Hornady manuals load the 8x57 hotter than the SAAMI recomended max pressure. And my "absurdities" came from the Hornady and Lyman reloading manuals and Quickload. So make sure you contact these three sources of reloading data and let them know that the great SlamFire has pronounced their data to be "absurdities". In closing SlamFire it is always a great pleasure discussing firearms and reloading with you. And that is because your always the only one who knows what he is talking about and everyone else is wrong. Just like you telling everyone its OK to lube your cases. You must not have read the Sierra manual and missed what they said about lubing cases.  And forgot to read the Lyman manual.  And my all time favorite the 1929 British Textbook of Small Arms.  Its always amazing the "absurdities" published in manuals that the great SlamFire ignores. Have a nice day. | |||

|

| One of Us |

I am of the opinion that CIP pressure standards, that is European pressure standards, are higher for certain cartridges, such as the 8mm Mauser, is primarily due to the fact that sellers must submit their firearms to proof before sale. I am basing my information on the book The Standard Directory of Proof Marks by Gerhard Wirnsberger. I am ashamed to admit that I bought this book in 1988 only for the proof mark pictures, so I could date firearms by proof marks, and I did not read the test until recently. The text was quite interesting in its own right, the author really knew German proof laws, and from the book, there are reciprocal agreements between EU Nations. That is, all these Nations had to raise their proof standards to an equivalent standard, for Germany to recognize Finnish proof marks, for the French to recognize Germany proof marks, for Austrian proof tests to be recognized as valid by the Finns, French, Germans, etc, etc, etc. I knew that firearms regulation was different in European countries, I sort of knew of Proof Houses, but that was about it. While I hardly know anything about individual EU country firearm laws, but according to this book, all European firearms have to be proofed before sale. In the US the manufacturer proofs the firearm once. The firearm may be out on the American civilian market for 150 years, pass through a hundred owners, bought, sold, stolen, but the firearm is only inspected for soundness by the manufacturer once. In Europe, every time that firearm is sold, it has to pass through a proof house. So if the firearm had 100 owners, it would have been proof tested 100 times. The book states that the proof marks of various American manufacturers are not accepted as valid in Europe, so newly made American firearms have to be proof tested before they can be sold in Europe. If I am wrong about this, if the laws have changes since 1988, I would like to know. Anyway, what is ignored by those touting CIP pressure standards is what a Proof House does. American’s believe that some sort of an overpressure round is fired in the firearm. We actually don’t know that, American manufacturers may not be firing overpressure rounds at all. I do know that some manufacturers function test their firearms. But that is all I know about it. I actually don’t know for certain what any American manufacturer does. I assume they function test, I assume they fire an overpressure round, and I assume that a Quality Assurance Specialist gages the chamber, barrel, etc for compliance to standard. But, there is no proof law in the US and some manufacturers may be doing nothing more than boxing the guns with a warranty card. It could be like the bad old days of General Motors. Back in the 1970’s a General Motors Executive said “Marketing sells it, manufacturing makes it, and customer service makes it work” As for what a Proof House does, based on what I have read a Proof House does more than just fire a round in the firearm. They gage the firearm. I recall reading they gage the chamber, barrel dimensions, and probably conduct a number of extra inspections. I assume they function test every feature, such as safety and trigger. This is conducted before the live fire test. What I have read is that proof testing with a cartridge is conducted with a cartridge that produces 30% more pressure than a standard cartridge. For the test to be valid, they lubricate the cartridge. Parasitic friction results when a dry cartridge is fired in a dry chamber. This parasitic friction between case and chamber reduces the load on the locking mechanism. (It also stretches the case) Lubricating the cartridge fully loads the locking mechanism. This is important, the Proof House is the one certifying that the mechanism is safe, they don’t have a financial interest in selling the firearm, they do have a financial interest in protecting their reputation. If they did not lubricate the cartridge they would be rightly criticized, perhaps sued, for an inadequate test of the locking mechanism. They would not be able to certify that they loaded the mechanism 30% over standard loads. American’s just assume Proof Tests are free or ignore the issue. Based on what I found on the web, the British proof house charges today it costs ₤30 for a shotgun, ₤25 for a centerfire, ₤15 for a rimfire rifle or barrel to be proofed. http://www.thefirearmblog.com/...sthash.xKe1BcBu.dpuf I thought it would be more. What is not mentioned is what happens to a firearm that does not pass proof. For one thing, it can’t be sold. According to my book, in Germany, prior to 1968, guns which failed proof, for whatever reason, were destroyed by smashing or cutting. This must have been fun for the Proof House workers, smashing an otherwise perfectly good firearm because the safety failed. After 1968, only the bad part are given a rejection mark. It is clear that one intended effect of European proof laws is to reduce the number of old, antique firearms in civilian hands. Old firearms are tested against current standards, current proof pressure cartridges. Old firearms, worn out firearms, that do not meet proof cannot be sold. I don’t know what the owner does, maybe he can sell parts off it. This is a financial risk to the owner, I am very certain the buyer expects the owner to pay for the cost of proofing. In time, old, structurally insufficient firearms will be weeded out of the system, either by rejection by the Proof House, or by owners deciding that the risk of failure is such that owning or modifying an antique is just not worth the financial risk. For cartridge manufacturers, for countries with aggressive and universal proof test systems, they know that the population of firearms out in the market have been tested to the latest pressure standards and are therefore can handle full power loads. In America, with all those ancient, substandard, unknown condition rifles sloshing around, the financial risk of a lawsuit to an ammunition manufacturer is substantial. Therefore, pressures for certain cartridges, like the 8mm Mauser are quite low. Now what I need, for a real Proof expert, such as Ed Horton, is to find out just how many firearms are submitted for Proof in Europe, pick a couple of countries, like the UK and Germany, and find out how many fail. Then to really dig down, just how many old military rifles (particularly Mausers) are submitted, and how many of those fail proof. To get a real representative idea, the data needs to go back to at least the 1960’s when it is probable that old military Mausers were still commonly in use. So a year by year accounting of the total number of firearms submitted to Proof Houses, how many failed, by year. And then of those, how many were old military Mausers, and how many of those failed. So Eddy, get cracking. This data will be of use to everyone and actually add to human knowledge. | |||

|

| One of Us |

Eddy, you did not answer the primary question, what were the design loads that Paul Mauser used, and for the proof testing I referenced, what were the units. Did the Germans proof test in PSI or CUP, or what? You are the self proclaimed CIP expert, this ought to be simple. | |||

|

| One of Us |

SlamFire I don't have to prove anything, the max rated pressure for European 8x57 ammunition is 55,000 psi American pressure taking methods. I don't care what the pressure taking methods were before 1900 by Paul Mauser. All that matters is what these pressures equate to today and its 55,000 psi the same as the .223/5.56 chamber pressure. And your the one proclaiming to be the pressure expert, all I did was quote the reloading manuals and Quickload. And if these figures are wrong then Lyman, Hornady and Quickload are all wrong. So excuse me if I and many others here think your wrong. BUT here is what we do know in your own words above. Any surplus military 8x57 shipped from Europe to the U.S. was proof tested and passed a much tougher Europiean inspection requirment before coming to the U.S. Just like all my surplus Enfield rifles I collected and stamped 18.5 tsi. So tell me again its OK to lube the cases on surplus military rifles. But we should not load the 8x57 Mauser over 35,000 psi. So it boils down to this SlamFire, who do we believe about the 8x57 Mauser the European CIP or SlamFire who is "never" wrong. (yeah right) I think you need more quotes from the High Road postings and even more about ball bearings to fool the younger kids in the audience. Have a nice day | |||

|

| one of us |

I'd much rather use modern brass in an old Mauser than 1920's brass in a modern action. ______________________________ "Truth is the daughter of time." Francis Bacon | |||

|

| one of us |

Correct but I really prefer to use modern brass in a modern action. That said I do have a 95 in 7x57 that I load a 139 at 2450 a nice mild load that puts them into one hole. Kills very well. I several 98s in various calibers I do not load them hot. They do get the job done. I really do not see the reason to push a cartrige/action past design specs when it is so easy to buy another rifle in cartridge/action in a hotter combination. At least here in the US. I really don't expect my 30-30 to be a 308 or my 308 to be a 06 or my 06 to be a 300 mag. There is a reason they make big gun safes. | |||

|

| one of us |

What was the rational for +P loads in 257 Roberts then? I could also be argued that any cartridge with a .473 head diameter is merely a loaded up or down versions of the 8X57. All of those cartridges started out as the 8X57 case that was either lengthened, shortened, necked up, necked down, or a combination, etc. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

wildcat junkie From collecting milsurp rifles these rifles have to function under combat conditions and keep working in combat. Meaning they are made two to five times stronger than off the shelf civilian factory rifles. On top of this European inspection standards are much higher than we have in the U.S. yHere in the U.S. you can buy the components to build a AR15 rifle and the rifle will never be proof tested. BUT in Europe it is a requirement that the rifle fire two proof test cartridges and be inspected. Bottom line, the ammunition pressure requirement set by our American SAAMI is set to the lowest pressure level used in the oldest firearms using this cartridge. And in Europe these firearms are inspected and proofed and if they are not up to modern standards they become wall hangers to keep their owners safe from injury. And all anyone needs to do is go into a British firearms forum in the U.K. and ask about proofing and inspections standards. To find out the truth on proofing and inspection standards, and also ask about the older British base crusher method where actual pressure/bolt thrust was measured. | |||

|

| One of Us |

I really don’t recommend feeding this troll. Edward Horton has a number of alias, bigedp51 for one, but he is a well known troll. If you notice, he has dropped into this thread to berate me, attack me, not to really add any content. He is an angry intolerant person, holds a grudge for years. He is positively pathological about lubricated cases. He was been told by entire forums that his beliefs are at best pseudo science, but that does not make a dent in his delusions. I have debated Edward enough times at other forums to find out that he ignores anything that is against his preconceived notions. It is a total waste of time to either address him, contradict him, or even agree with him. http://www.milsurps.com/showthread.php?p=109323 Thread Closed !

I don’t know why he was banned at any one particular site, but he was banned at www.milsurps.com and many other sites. One possible reason has been the posting of copyrighted material. In flagrant disregard for the rules of forums, he has put them in risk of lawsuits by posting copyrighted material, and links for free down loads of copyrighted material. Ed knows better than any of us what he has done, but I remember threads in which Ed was warned that the material he copied/linked to was copyrighted material, and the copyright owner had protested the posting. Edward Horton is an unwanted and disruptive element in any forum, in time, he goes nut case and so strongly attacks posters that forum moderators find that the only solution is to ban him. Do you know Ed Horton? http://forums.gunboards.com/sh...o-you-know-Ed-Horton

Testing the PRIVI 168g fmjbt https://www.gunandgame.com/thr...i-168g-fmjbt.128017/

If does not take much effort to find the forums where bigedp51 or Ed Horton was banned. A quick search finds for example, banned at this one: http://forum.pafoa.org/member.php?u=40113 bigedp51 Banned You feed this troll at your own risk. At some point in the future, you will say something that offends him, and then, he will be attacking, berating you. | |||

|

| one of us |

Makes me think of the guy who taught me carpentry. . What's 3mm in a big house like this. Grizz Indeed, no human being has yet lived under conditions which, considering the prevailing climates of the past, can be regarded as normal. John E Pfeiffer, The Emergence of Man Those who can't skin, can hold a leg. Abraham Lincoln Only one war at a time. Abe Again. | |||

|

| One of Us |

Dear SlamFire So you spend two days digging looking for anything to attack me. BUT what you left out was the fact I "HAD" a Enfield manual sticky at Gunboards and the owner of Milsurps ended up sucking my sticky dry and then my sticky being shut down at Gunboards. And all this was over greed, money and increasing membership at Milsurps. I could go on and explain more but who cares, all that matters is you hate loosing any form of debate in any forum. So you resort to misinformation ans lies. In the last forum we were in your reported me for the pictures I posted as being copyrighted. When I took the photos myself with my own camera. On top of this under the fair use and educational proposes section of the copyright law you are allowed to use illustrations and short sections. Or did you forget the handouts your school teachers copied from the very books you used in school. Bottom line SlamFire you just hate loosing any debate on any subject. So you revert to the crap above to distract the readers from the fact you loosing the the debate on 8x57 chamber pressures. Bottom line I was banned from Gunboards for telling the owner to go "F" himself for selling ten years of work down the drain. And I was banned at Milsurps for telling the Enfield community how the owner Badger screwed me. And whats really funny SlamFire is your not the owner or the moderator here. And you turned a discussion into a personal attack simply because I posted information counter to yours. So SlamFire show me and everyone else here what is outrageous about the information I posted. Or better yet explain your personal attack and actions here in response to a discussion on SAAMI and CIP chamber pressures. | |||

|

| One of Us |

SlamFire you tell people its perfectly OK to lube their cases but you come here and say you shouldn't load your 8x57 Mauser over 35,000 psi' Is that because you lube your cases and if you load higher than that the increased bolt thrust will increase the headspace on the older Mausers. So please tell us what is pathological about posting printed warnings by people with far more knowledge on the subject than you have.     As usual SlamFire I expect you will PM the owners of this site and tell them I breaking copyright laws by posting these images. Lets hope the owner understands the educational proposes and fair use section of the copyright laws. | |||

|

| One of Us |

So SlamFire you tell us these military 8x57 Mauser's are not designed for higher pressures. And yet the Europiean CIP tells us they are rated at 55,000 psi American SAAMI pressure equivalent. I post data from two reloading manuals and Quickload. And then you decide to tell everyone I'm a troll. So tell us SlamFire you were wrong about greasing/lubing cases and wrong about the Mauser action. So tell us SlamFire how the reloading industry, the reloading manuals and Quickload became trolls or post outrageous information. | |||

|

| one of us |

I said cartridges and actions a modern action can be loaded to higher pressure. | |||

|

| Administrator |

If the rifle is built on a modern action, there is no reason why you should not load it to higher pressure than original. | |||

|

| One of Us |

Another voice of reason!

| |||

|

| one of us |

I would consider a M98 action made during or after the mid '30s a "modern action". My 1942 vintage J. P. Sauer & Sohn action had excellent fit & finish despite the well executed sheet metal rigger guard with milled floor plate. The Rugar M77 is nothing more than a poorly executed copy of the M98. The CRF M70 is perhaps the best copy, the 3-pos wing safety a vast improvement & is a much desired modification to the M98 action. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Anyone bring the 8x57 up to 60,000 psi?

Anyone bring the 8x57 up to 60,000 psi?

Visit our on-line store for AR Memorabilia