The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  neck tension question

neck tension questionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Been reloading for many years but I'm new to this issue of importance of neck tension. Here's my current set-up: after decapping with a universal Lee decapping die, I'm running the brass (.220 Swift Winchester brand) thru a Redding neck die with expander button removed. Then I run it thru a Sinclair neck expander. The ID of the neck after that is .218", and the bullet OD is .223" (Nosler 50 gr. BT) So if I understand this tension thing right, I've got .005" neck tension, which is about .003" more than ideal according to some gurus. Question, with this set-up, I cannot get any less neck tension? Correct? Then my only option is to buy one of those expensive Redding bushing dies, correct? thanks all. | ||

|

| one of us |

I am a how does it shoot gurus if it shoots well do not worry about it. | |||

|

| One of Us |

it's running about 1-1 1/2" 3 shot groups @ 100 yds with new douglas barrel with about 50 rounds thru it to date. have not juggled bullets/powder much yet as I think neck tension and seating depth are important to get right prior to juggling. | |||

|

| One of Us |

Unless you turn the necks, a bushing neck sizer will not help. Neck tension uniformity is more important than what it actually measures in terms of pull, within reason. You don't want your bullets to fall out. Work on other variables. Seating depth, powder charge. Action bedding, scope mounting. | |||

|

| one of us |

Your overthinking your reloading IMO..Id suggest you neck size or full length re-size, keep your length correct and test several different bullets and perhaps powders, all the rest of that stuff is IMO hooey...the bench rest is your guide...I shoot the 220 Swift with several different bullets and a load of H414 or WW748 with neck sized cases and only use a set of std. RCBS dies..I do trim with a file trim die as its more accurate..I trim each case as it gets too long as opposed to all at once..My gun shoots about 1/2" with most loads, and less with some.. Your goal should be that all your neck tension should be the same rather than how tight..use the expander ball, your neck are too tight and all that does is give you more pressure. Again skip the tech stuff and let the bench rest answer all your questions. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

The best thing you can do to create uniform neck tension is anneal your cases. | |||

|

| one of us |

I just played around with neck tension on my Edge; it was accidental but noteworthy. Like you, I take out the expander and use a Sinclair mandrel die. I bought a hand held neck trimmer and accidentally turned down some cases too much. I noticed the effort required to seat bullets was much less than the other cases, but decided I would shoot them. I was at my place in CO and shooting at a gong 910 yards away; I shoot with a LabRadar, so I could see the difference in velocity. The bullets with lower neck tension definitely had lower velocity - they were from 2820 to 2840; that load averages 2870. In general, I was about 1/2 MOA low at 910 yards. I anneal using an AMP, so after shooting these bullets I annealed, resized, and ran them thru the mandrel. I notice the effort to run them thru the mandrel was markedly less, and once again, seating the bullets took a lot less effort. So I would say you could reduce your neck tension two ways: 1. Get a larger expander mandrel 2. Turn your cases But I would agree with DPCD: consistent tension in a batch of cases is more important than the tension itself. The whole exercise has me rethinking neck turning, since neck thickness from case to case is probably more important than any thickness differences within the neck of a single case. If you replace your entire batch of brass at once, then it doesn't matter - but at the same time, unless you match the thickness perfectly, your velocity might be different. | |||

|

| One of Us |

thanks all for your input. thanks especially to anotherAZ writer for that detailed description. Very interesting what you found. After my initial post I got to thinking that my post was inaccurate as stated: tell if I'm correct here: with the ID of the neck .218" and the bullet OD .223-224" the neck tension is actually half of the .005" difference: half of that per side of the case, correct? If that's the case I'm quite close to that .002-.003" ideal. | |||

|

| One of Us |

If using a standard die and you want less neck tension, turning the necks on your brass is the only way to accomplish that. Since I don't know how YOU shoot, it would be difficult to say whether you'd see improvements or not. Seating depth and neck tension adjustments are considered AFTER I've found a good load but then, after all, I can turn or change bushings easily and maybe not so for you. Zeke | |||

|

| One of Us |

Measurements show you the difference in size of your neck and bullet but only lean towards a tension amount. One would have to have a puller that measured force to have a number that represents tension. That is why annealing is a help to the issue. It makes all the brass ability to expand, thus grip, close to the same. Lots of other minutiae to worry about too but I don’t. I do anneal and use a Lee fcd to make the crimp consistent. Close enough for me and brass lasts a long time. "The liberty enjoyed by the people of these states of worshiping Almighty God agreeably to their conscience, is not only among the choicest of their blessings, but also of their rights." ~George Washington - 1789 | |||

|

| One of Us |

The only time turning necks makes a difference is in a custom chamber with a tight neck. In a factory rifle a turned neck is a waste of time... Annealing your brass is the path to consistency. | |||

|

| one of us |

That is what I found. | |||

|

| One of Us |

I'm also skeptical about turning factory brass for a SAMMI spec chamber BUT I do it anyway. I just basically scuff them 1/2 to 3/4 of the way around the neck. About 3% of the time, I find outliers that are super thick on one side and I feel like I've justified the hour spend on 100 new cases. Does it work? Of course it makes me feel better so it must be working, right? LOL Zeke | |||

|

| one of us |

I agree turning necks is anti productive and over works brass short of a custom 0 tolerance chamber such as on my 6x45 which I can reload several times in a row without resizeing, but at some point I have to resized and outsize neck ream...It shoots-.200 plus or minus, for 5 or for 10 for that matter..for general hunting I never ream, only trim. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

out of round fired factory, first firing sizes the case to the chamber, no need to neck size, its counter productive, only usefull for bench rest and perhaps varmint rifles.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Nobody on the competitive shooting circuits neck sizes any more....including bench resters. https://www.youtube.com/watch?v=vaqg4sJvg24 | |||

|

| One of Us |

My feeling is that neck tension can make a very good load a great load and more consistent but they are not going to make a mediocre load a very good load. Mike Legistine actu quod scripsi? Never under estimate the internet community's ability to reply to your post with their personal rant about their tangentially related, single occurrence issue.  What I have learned on AR, since 2001: 1. The proper answer to: Where is the best place in town to get a steak dinner? is…You should go to Mel's Diner and get the fried chicken. 2. Big game animals can tell the difference between .015 of an inch in diameter, 15 grains of bullet weight, and 150 fps. 3. There is a difference in the performance of two identical projectiles launched at the same velocity if they came from different cartridges. 4. While a double rifle is the perfect DGR, every 375HH bolt gun needs to be modified to carry at least 5 down. 5. While a floor plate and detachable box magazine both use a mechanical latch, only the floor plate latch is reliable. Disregard the fact that every modern military rifle uses a detachable box magazine. 6. The Remington 700 is unreliable regardless of the fact it is the basis of the USMC M40 sniper rifle for 40+ years with no changes to the receiver or extractor and is the choice of more military and law enforcement sniper units than any other rifle. 7. PF actions are not suitable for a DGR and it is irrelevant that the M1, M14, M16, & AK47 which were designed for hunting men that can shoot back are all PF actions. 8. 95 deg F in Africa is different than 95 deg F in TX or CA and that is why you must worry about ammunition temperature in Africa (even though most safaris take place in winter) but not in TX or in CA. 9. The size of a ding in a gun's finish doesn't matter, what matters is whether it’s a safe ding or not. 10. 1 in a row is a trend, 2 in a row is statistically significant, and 3 in a row is an irrefutable fact. 11. Never buy a WSM or RCM cartridge for a safari rifle or your go to rifle in the USA because if they lose your ammo you can't find replacement ammo but don't worry 280 Rem, 338-06, 35 Whelen, and all Weatherby cartridges abound in Africa and back country stores. 12. A well hit animal can run 75 yds. in the open and suddenly drop with no initial blood trail, but the one I shot from 200 yds. away that ran 10 yds. and disappeared into a thicket and was not found was lost because the bullet penciled thru. I am 100% certain of this even though I have no physical evidence. 13. A 300 Win Mag is a 500 yard elk cartridge but a 308 Win is not a 300 yard elk cartridge even though the same bullet is travelling at the same velocity at those respective distances. | |||

|

| Administrator |

I got some Boron Nitrate dry lubricant. I wanted to try it, so testing next tension might be a good idea too. I found some Lapua FMJ 308 caliber bullets. I have coated some. I have already prepared brass, sized in a normal Redding full length die. I will shoot a few groups with these. Then I will size the brass using different neck buttons. Any guess what might the results be? I was out of the country for a few weeks, hopefully I can start this in the next few days. | |||

|

| Administrator |

Well, someone took my BT coated bullets, because he wanted FMJ bullets. So to test this, I have decided on the following. Sako TRG Sierra 168 MK, Molly coated. 46.0 grains of Varget RWS primers RWS brass. I have already shot what I will use a standard. 3, 5-shot groups with brass sized in a Redding FL die. I measured the outside diameter of the fired cases, they measure 0.340. I am going to start with this. That is use a Redding 0.340 button to size them. Again 3, 5-shot groups with the above components. I will go 0.001 down and so on. Any suggestions would be much appreciated. | |||

|

| Administrator |

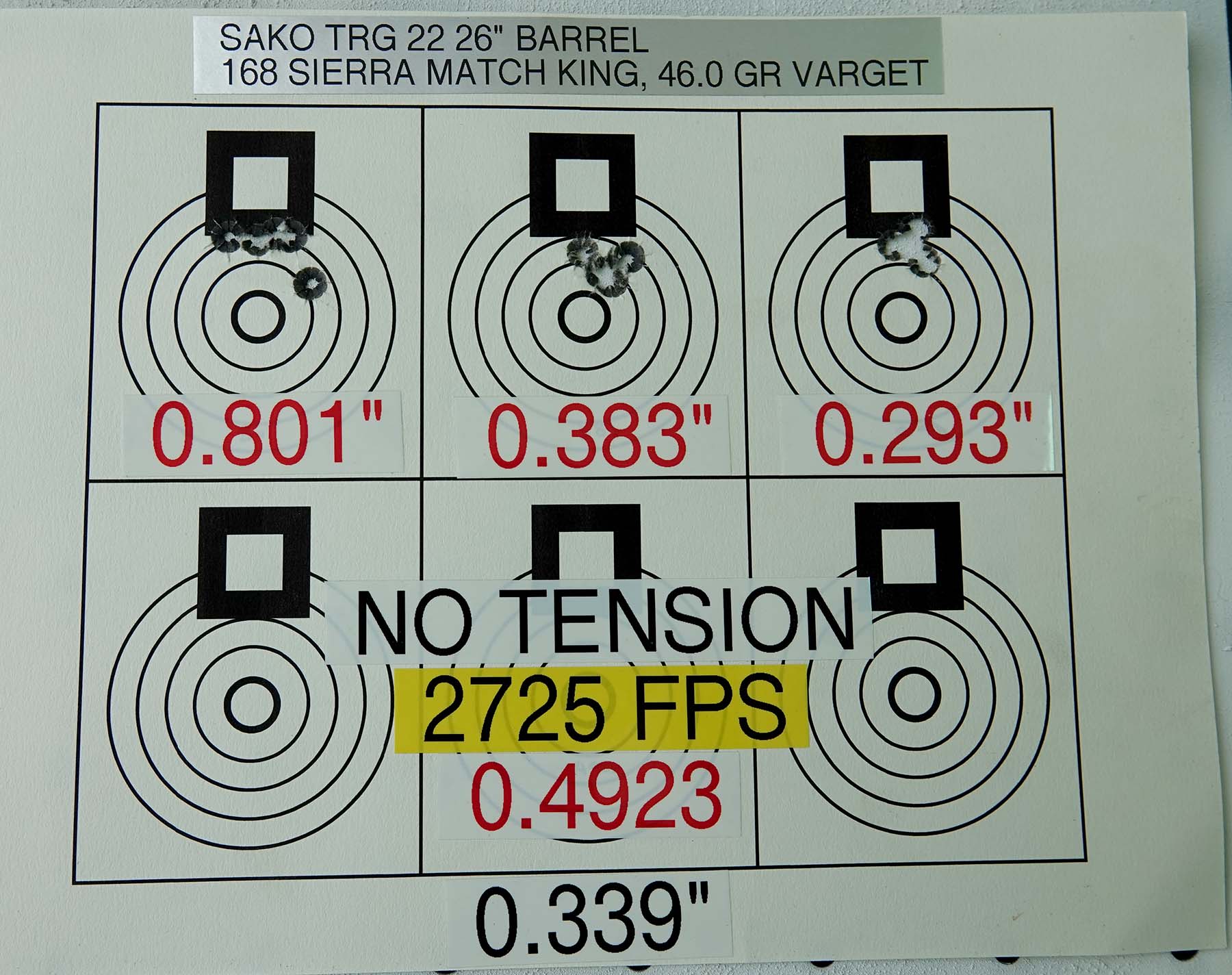

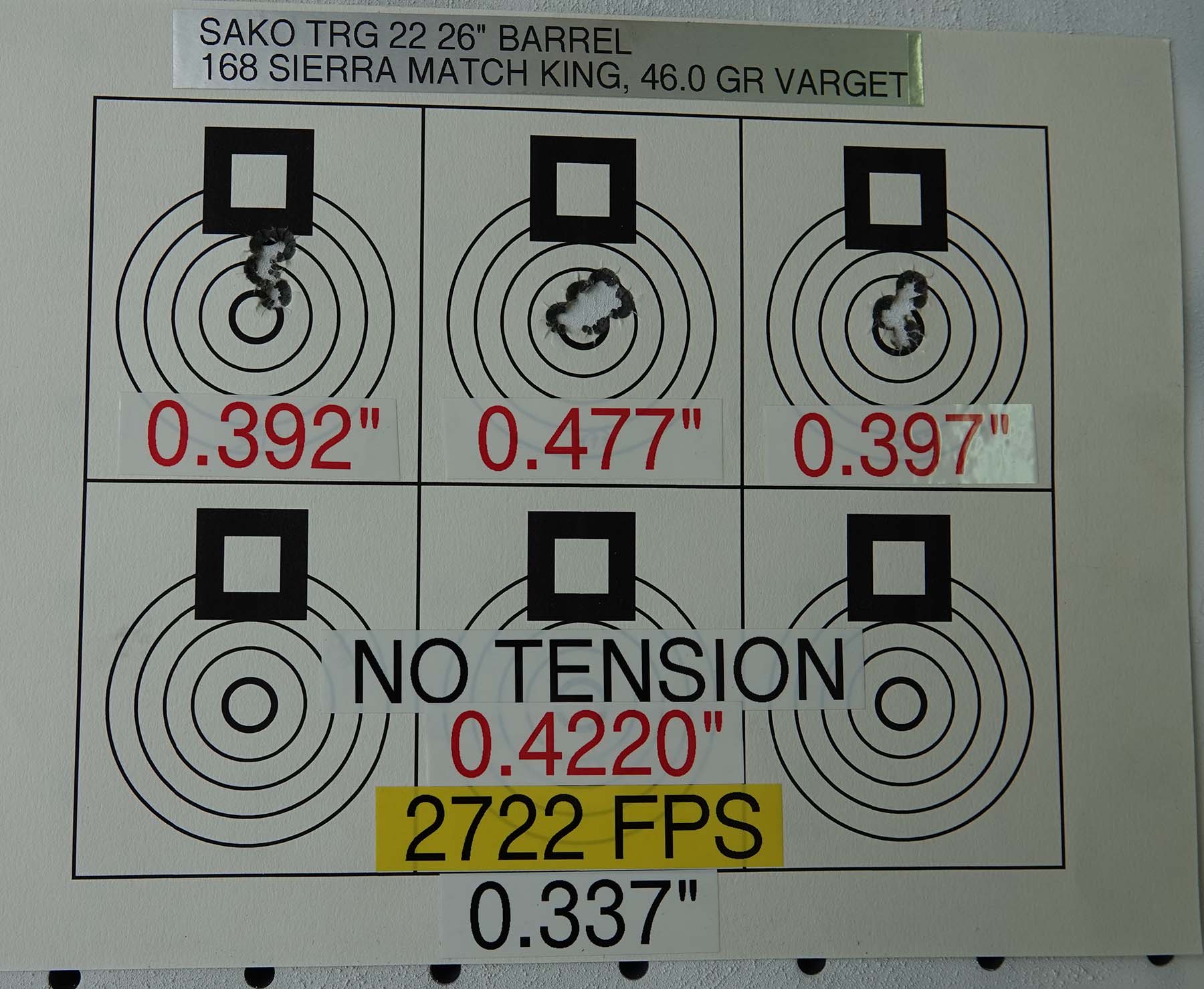

Follow up to my post above. I measured the outside diameter of the fired cases. I found the smallest sizing button that will fit it. It was 0.340" I fired 3, 5-shot groups with the loads above. Sized with Redding Full Length die. 1. 0.429" 2. 0.377" 3. 0.404 Average is 0.4033" Velocity was 2735 fps. Fired cases were sized in 0.340" sizing button. Bullets were loose, no tension at all. So bullet sticking out of the case is only governed by how they sit on the powder. 1. 0.362" 2. 0.344" 3. 0.385" Average is 0.3637" Velocity was 2705 fps. Fired cases sized in 0.339" sizing button. Bullets were still loose, no tension at all. 1. 0.801" 2. 0.383" 3. 0.293" Average is 0.4923" Velocity was 2725 fps. I will continue going down one thou at a time. I have actually shot the 0.338" sized loads, but have not measured them. Velocity was 2720, and the bullets were still loose! | |||

|

| Administrator |

Help please! I am progressing in this test. So far I have shot relatively loose bullets, and some with slight tension. Results are not very encouraging, as they are all very consistent. In both accuracy and velocity. What would you consider a major difference? In both accuracy and velocity. | |||

|

| One of Us |

Saeed, This is a very interesting study. Helpful to me as I am into single shots in which opinions vary on the crimp/tension. Thanks IHMSA BC Provincial Champion and Perfect 40 Score, Unlimited Category, AAA Class. | |||

|

| one of us |

My thought has been that its a variable with limited control Some of the results that I have read , show pressure curves of the ignition from the start to the end, and it is all around from when the bullet starts and enters the rifling and seals the barrel. Small calibers I size to try and achieve .003" under bullet diameter. Larger calibers are .002" I have pretty good groups and small deviations with my 270 140gr bullets crimped but with the 25/06 120gr bullets crimped were not so good. | |||

|

| Administrator |

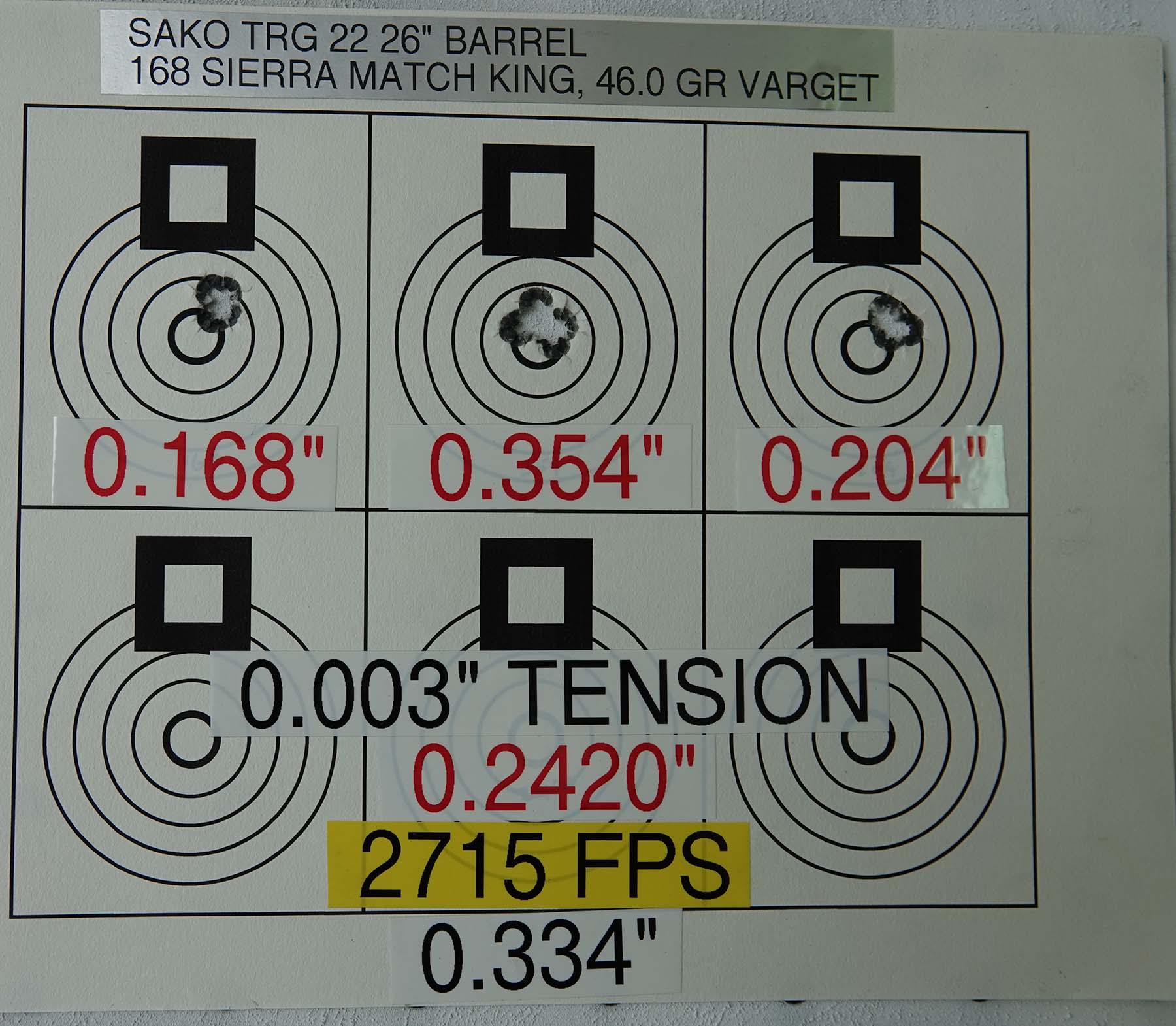

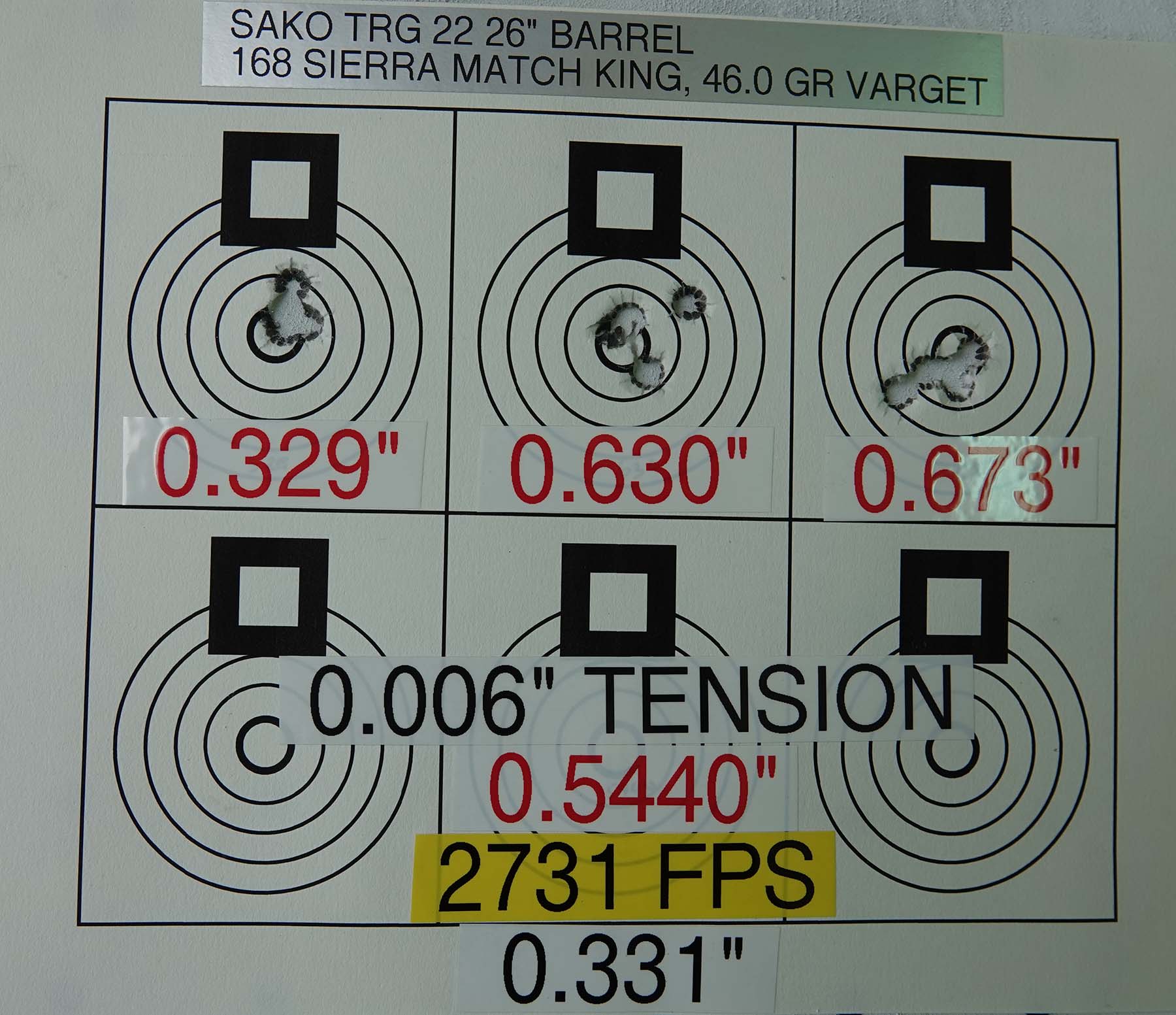

Here are my results. Frankly, I am not sure I would have gotten any different results if I had shot the same load all the time.            | |||

|

| one of us |

On neck tension, if you ever have a squib load and a bullet stuck in the throat, you don't want the next round to chamber by sliding its bullet into the case. TomP Our country, right or wrong. When right, to be kept right, when wrong to be put right. Carl Schurz (1829 - 1906) | |||

|

| One of Us |

so it sounds as if "uniform tension from shot to shot" is the key: not the amount of tension. | |||

|

| Administrator |

Here is something to think about. I am using RWS brass from factory match ammo. While full length sizing them, some cases are never even touched by the expander!!?? This means the necks on these are thinner than others. I have put these to the side, and I am not including them in my over all length test. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia