The Accurate Reloading Forums

Here is my reloading pic to share

11 February 2009, 04:11

ted thornHere is my reloading pic to share

6" of ice was all she could take my 1200 sq. ft shop came down to the floor.

Just before the crash you can see the bow.

and after

Now the cleanup and rebuilt starts.

________________________________________________

Maker of The Frankenstud Sling Keeper

Proudly made in the USA

Acepting all forms of payment

11 February 2009, 04:49

bartsche

Man, that is sad.

roger

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone..

11 February 2009, 05:44

craigsterWhat a bummer!

11 February 2009, 07:18

SnellstromSorry to see that Ted.

Look on the bright side, looks like you still got a building you just need a roof.

Best of luck rebuilding, if I lived closer I would come give a hand.

11 February 2009, 07:23

ted thornThanks guys the silver lineing is now I can fix it up a litle bit different than before. Its all down to just the concreat pad now....the rebuild will start soon. Waiting on the insurance check.

________________________________________________

Maker of The Frankenstud Sling Keeper

Proudly made in the USA

Acepting all forms of payment

11 February 2009, 07:26

James Kainquote:

Originally posted by Snellstrom:

Sorry to see that Ted.

Look on the bright side, looks like you still got a building you just need a roof.

Best of luck rebuilding, if I lived closer I would come give a hand.

Man that sucks! But yet I see this all the time in my home state of Maine. You think contractors would take in consideration that we do get a lot of snow and ice....Best of luck rebuilding and good thing they were in the safe

I agree I would help if I lived near by too

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

11 February 2009, 07:32

Fish30114Ted, good luck going forward! I always TRY and look at events like this a shot at doing it up a little better--but it's hard to do that sometimes!

Heavier trusses eh!? Or the electric tape---does that stuff really work??

Best--Don

11 February 2009, 07:41

ted thornWithout a doubt I will be beefing up the truss system maybee overkill but going with 24" this time and maybee an intierior room or two.

________________________________________________

Maker of The Frankenstud Sling Keeper

Proudly made in the USA

Acepting all forms of payment

11 February 2009, 14:16

Steel SlingerThat sucks, I know that lots of people over in my neck of the woods didn't fare so well either. Good friend of mine had 3 trees collapse on his house. He got pretty lucky though, very minimal damage... just the vent pipes and some of the shingles were damaged. Hell, there's still people out in the country with no power. I even heard that the power companies were being attacked with rotten food from peoples freezers cause they didn't have power.

FiSTers... Running is useless.

11 February 2009, 16:28

jeffeossoSorry to hear this..

11 February 2009, 17:31

adamhunterquote:

Originally posted by ted thorn:

Without a doubt I will be beefing up the truss system maybee overkill but going with 24" this time and maybee an intierior room or two.

Sorry to see that Ted. Not telling you how to build your shop, but as a builder myself, I would go 16" with your trusses and up the member sizes.

30+ years experience tells me that perfection hit at .264. Others are adequate but anything before or after is wishful thinking.

11 February 2009, 19:00

James Kainquote:

Originally posted by adamhunter:

quote:

Originally posted by ted thorn:

Without a doubt I will be beefing up the truss system maybee overkill but going with 24" this time and maybee an intierior room or two.

Sorry to see that Ted. Not telling you how to build your shop, but as a builder myself, I would go 16" with your trusses and up the member sizes.

No offense to you bub, but we have had people from GA and other places from down south come up to Maine to do some building. Most of them have fallen down due to the weight and stress of the snow and ice. They may not go down the first year but most do go down with in 5. People down sound, and you may not be included, have a tendency to forget about how winters affect building out this way. But then again you said you build them not design them.

(after seeing all these places fall from people down south, I think I can poke a little fun at them)

But that's not bad if you compare that to the "engineers" who design parking lots! The ALWAYS forget about the snow! So it may look good but where do we put the snow? Also they turn the parking lot into a night mare for the guy(s) plowing it!

Best of luck!

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

12 February 2009, 04:26

James Kainquote:

Originally posted by Steel Slinger:

That sucks, I know that lots of people over in my neck of the woods didn't fare so well either. Good friend of mine had 3 trees collapse on his house. He got pretty lucky though, very minimal damage... just the vent pipes and some of the shingles were damaged. Hell, there's still people out in the country with no power. I even heard that the power companies were being attacked with rotten food from peoples freezers cause they didn't have power.

Why didnt they put the food outside in the snow to keep it frozen?

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

12 February 2009, 04:35

p dog shooterI am sure that in MO. They didn't figure much for snow load. We figure for up to 4 feet here a 5/12 pitch on the roof helps. The house Iam at now has 2x6 truss's with 16 inch centers a 5/12 pitch no worrys about snow load here.

12 February 2009, 08:31

Doc224/375Ted Thorn ; may I ask what the spacing was on your gable roof trusses ?. What size where the Truss cords 2X4

or 2X6 ?. They appear to be 2X4's but pictures can deceive the eye .

When viewed from Front ? the shop doors , there is a space between the two doors in the center .

I would suggest if you like your shop open with out walls and rooms built inside to explore this possibility .

In that center section between the doors put a Post and then a beam above and resting on plate line , now

span the entire depth too the back wall ; post under where the beam rest on the plate line there also .

If you give me the measurement from front too back I can calculate the size needed to span that distance .

Either a Gluelam or Engineered Beam . It needs to be STOUT if necessary you can either have the contractor

check into it or building Dept. regulations if required ?.

Any way I would be confident by having the ridge beam or ridge rafter actually if it's a 2X material

being used . That's the one which runs under the peak the length of your shop wall too wall or beyond if

you have overhang . These are made by scarf cutting say 2X8 2X10's .

Now what I propose is a PROVEN DESIGN . In the middle of that Beam span you need to put a post up under

your Roof Ridge line . Sometimes " Welded Metal Saddles " are used for this purpose other times simply

place two blocks on either side for nailers . You end up with a Ridge beam rafter a much Larger

mid span Beam , with a post up too the ridge . Now at 45 degree angles brace the ridge rafter from the base

or up higher of your center post support . You can actually brace all four directions , but will need

mid span purling supports under your truss spans in order for them to be effective .

It just sounds complicated but is Easier to do for a competent carpenter . From each gable end of your shops

wall on top of the plate line angle back at 45 degrees Ridge line supports . In essence you have

trussed your Roof Ridge to bear weight down on too the Wall and Concrete rather than just trusses .

I'll try and find some drawings so You will be able to visualize it .

Most truss systems are by design Floating so no matter if you had interior rooms or walls they don't support

any more or less Roof Loads !. That's the down side too trusses over conventional stacked roofs which

bear weight down at all points .

12 February 2009, 09:52

Steel Slingerquote:

Originally posted by James Kain:

quote:

Originally posted by Steel Slinger:

That sucks, I know that lots of people over in my neck of the woods didn't fare so well either. Good friend of mine had 3 trees collapse on his house. He got pretty lucky though, very minimal damage... just the vent pipes and some of the shingles were damaged. Hell, there's still people out in the country with no power. I even heard that the power companies were being attacked with rotten food from peoples freezers cause they didn't have power.

Why didnt they put the food outside in the snow to keep it frozen?

That would have worked for the first couple of days, but temps quickly went back up to the 50's and 60's.

FiSTers... Running is useless.

12 February 2009, 11:14

James Kainquote:

Originally posted by Doc224/375:

Ted Thorn ; may I ask what the spacing was on your gable roof trusses ?. What size where the Truss cords 2X4

or 2X6 ?. They appear to be 2X4's but pictures can deceive the eye .

When viewed from Front ? the shop doors , there is a space between the two doors in the center .

I would suggest if you like your shop open with out walls and rooms built inside to explore this possibility .

In that center section between the doors put a Post and then a beam above and resting on plate line , now

span the entire depth too the back wall ; post under where the beam rest on the plate line there also .

If you give me the measurement from front too back I can calculate the size needed to span that distance .

Either a Gluelam or Engineered Beam . It needs to be STOUT if necessary you can either have the contractor

check into it or building Dept. regulations if required ?.

Any way I would be confident by having the ridge beam or ridge rafter actually if it's a 2X material

being used . That's the one which runs under the peak the length of your shop wall too wall or beyond if

you have overhang . These are made by scarf cutting say 2X8 2X10's .

Now what I propose is a PROVEN DESIGN . In the middle of that Beam span you need to put a post up under

your Roof Ridge line . Sometimes " Welded Metal Saddles " are used for this purpose other times simply

place two blocks on either side for nailers . You end up with a Ridge beam rafter a much Larger

mid span Beam , with a post up too the ridge . Now at 45 degree angles brace the ridge rafter from the base

or up higher of your center post support . You can actually brace all four directions , but will need

mid span purling supports under your truss spans in order for them to be effective .

It just sounds complicated but is Easier to do for a competent carpenter . From each gable end of your shops

wall on top of the plate line angle back at 45 degrees Ridge line supports . In essence you have

trussed your Roof Ridge to bear weight down on too the Wall and Concrete rather than just trusses .

I'll try and find some drawings so You will be able to visualize it .

Most truss systems are by design Floating so no matter if you had interior rooms or walls they don't support

any more or less Roof Loads !. That's the down side too trusses over conventional stacked roofs which

bear weight down at all points .

I like this Guy!

Now for the food and tossing thing! Man I m really sorry you guys had to deal with that. Back in the Ice Storm of 98 we had people helping the CMP(Central Maine Power) guys and bringing them hot food and drink. Some friends tell me who work for CMP, when the power guys came up from out of state they would string the lines on the wrong part of the pole and have to do it all over again. They also had to redo the power boxes and supports. I guess down south and out west they dont have to do the same regulation crap we need to do for such weather.....live and learn.

Hell in 98 I was a sophomore in high school. Graduated in 2000. Then off to the army! 9-11 was one hell of a day. I had a 24hour "staff duty" shift the 12th. Many phone calls...many....and beer...:P

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

12 February 2009, 11:31

James Kainif there are more posts like what I just said, my pc was giving me a hard time, and sent it a few times. I think I got them all...sorry

I also ramble when I m wicked tired. I should be sleeping.....

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

12 February 2009, 19:22

adamhunterquote:

Originally posted by James Kain:

quote:

Originally posted by adamhunter:

quote:

Originally posted by ted thorn:

Without a doubt I will be beefing up the truss system maybee overkill but going with 24" this time and maybee an intierior room or two.

Sorry to see that Ted. Not telling you how to build your shop, but as a builder myself, I would go 16" with your trusses and up the member sizes.

No offense to you bub, but we have had people from GA and other places from down south come up to Maine to do some building. Most of them have fallen down due to the weight and stress of the snow and ice. They may not go down the first year but most do go down with in 5. People down sound, and you may not be included, have a tendency to forget about how winters affect building out this way. But then again you said you build them not design them.

(after seeing all these places fall from people down south, I think I can poke a little fun at them)

But that's not bad if you compare that to the "engineers" who design parking lots! The ALWAYS forget about the snow! So it may look good but where do we put the snow? Also they turn the parking lot into a night mare for the guy(s) plowing it!

Best of luck!

No offense taken James. That's why I said up the size and space his roofing members at 16" OC in lieu of 24".(increasing the amount of trusses/rafters). Snow load is a bitch to figure no matter where. By the way, I got my start in New Hampshire, plenty snow up there!

30+ years experience tells me that perfection hit at .264. Others are adequate but anything before or after is wishful thinking.

12 February 2009, 19:39

James Kainquote:

Originally posted by adamhunter:

quote:

Originally posted by James Kain:

quote:

Originally posted by adamhunter:

quote:

Originally posted by ted thorn:

Without a doubt I will be beefing up the truss system maybee overkill but going with 24" this time and maybee an intierior room or two.

Sorry to see that Ted. Not telling you how to build your shop, but as a builder myself, I would go 16" with your trusses and up the member sizes.

No offense to you bub, but we have had people from GA and other places from down south come up to Maine to do some building. Most of them have fallen down due to the weight and stress of the snow and ice. They may not go down the first year but most do go down with in 5. People down sound, and you may not be included, have a tendency to forget about how winters affect building out this way. But then again you said you build them not design them.

(after seeing all these places fall from people down south, I think I can poke a little fun at them)

But that's not bad if you compare that to the "engineers" who design parking lots! The ALWAYS forget about the snow! So it may look good but where do we put the snow? Also they turn the parking lot into a night mare for the guy(s) plowing it!

Best of luck!

No offense taken James. That's why I said up the size and space his roofing members at 16" OC in lieu of 24".(increasing the amount of trusses/rafters). Snow load is a bitch to figure no matter where. By the way, I got my start in New Hampshire, plenty snow up there!

Then you got started only a few hours from myself

Disabled Vet(non-combat) - US Army

NRA LIFE MEMBER

Hunter, trapper, machinest, gamer, angler, and all around do it your selfer.

Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight.....

12 February 2009, 21:35

temmiBoy do I understand… Ike came through and dropped a tree through the roof in Houston and put 4 feet of water in the House in Galveston…. Just starting to rebuild / repair Galveston…

It will get better

T

13 February 2009, 00:20

Doc224/375I didn't want to step on anyone's suggestions only to offer a proven design method of construction .

As per Snow loading calculations are a given Std. . Yet as most of us know standards are fine for

almost any storm ALMOST being the key word . Then comes that 25-65 year mother of all storms and

Standards go right out the window along with all of your stuff being either ruined or lost .

Even the potential for loss of life !. My Idea I was attempting to convey was a kings Post truss

or actually modified Kings Post Truss . My design calls for a Ridge Rafter to support under

under the Peak of the Roof framing or Truss system if using one . By placing a Single large Beam

from wall too wall ( In Ted Thorns Case front too back ) thus tying those two wall together

in the center of the building span . Now by placing a post on the top in the center of that Beam

and having it go up under the Ridge Rafter under the Truss or Conventional Roof framing or stacking

as we used to refer to it . You have essentially spread the entire roof load too the walls as well

as split the building load in two so to speak . Looking at the Modified King Post Trusses picture

in this link . Picture the Rafter under the center of that center post , now picture that bottom

cord or modified collar tie down on top of plate line with everything else pretty much as pictured .

That distributes weight evenly too all bearing surfaces involved . In Snow areas a Minimum 5/12

pitch is advisable . Further North increased pitch angle becomes necessary . 12/12 = 45 degrees .

Ted FYI ; All trusses need not be of this design only the center one of the length of your shop .

larger shops require placing more of these as length increases . A engineered Beam is the way

to go and needs to be stout say a 6X 14 or 16 to bear that center roof load on ?.

24" center too center rafters or Trusses are adequate 5/12 pitch 2X4 Truss system only 2X6 cords

NOT Conventional stacking by any means that would require 2X8 Minimum with collar ties .

The second link shows a Standard King Truss substitute bottom cord with that Beam and You

got the perfect Idea !.

http://www.harmonyexchange.com...rials/timberroof.php http://www.vermonttimberworks.com/truss.html More info for you to digest .

http://www.trusssystemsinc.com/prod02.htmLast but certainly not least are Metal Buildings which are pre engineered for your specific needs and COST

Effective also .

13 February 2009, 04:01

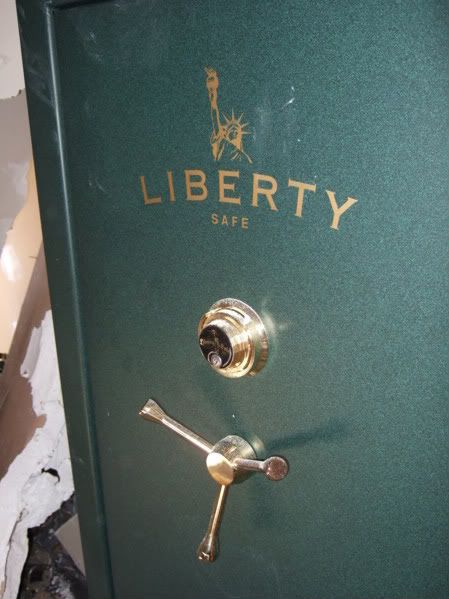

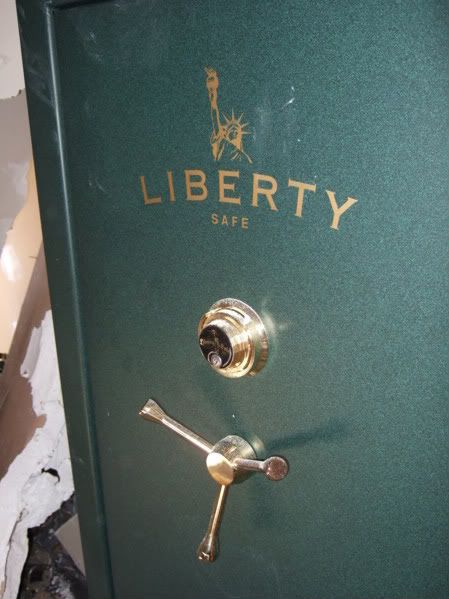

RustyDamn good looking Liberty Safe! I like mine too!

Rusty

We Band of Brothers!

DRSS, NRA & SCI Life Member

"I am rejoiced at my fate. Do not be uneasy about me, for I am with my friends."

----- David Crockett in his last letter (to his children), January 9th, 1836

"I will never forsake Texas and her cause. I am her son." ----- Jose Antonio Navarro, from Mexican Prison in 1841

"for I have sworn upon the altar of god eternal hostility against every form of tyranny over the mind of man." Thomas Jefferson

Declaration of Arbroath April 6, 1320-“. . .It is not for glory, nor riches, nor honours that we are fighting, but for freedom - for that alone, which no honest man gives up but with life itself.”