The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Actual CHE & PRE Data + Fabricated M43 info.

Actual CHE & PRE Data + Fabricated M43 info.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Looks like the PMs and emails were correct about Dave Shining me on. Hate to see it go that way, but hopefully there is a way around it. If any of you who have totally wasted money on a M43 or Pressure Trace and would like to replace Dave in the Test, let me know and we will run it. I have a buddy who tossed away some money on a Pressure Trace and I'll see if he is interested in doing this. He and I are both addressing some health problems with our families, so it might take awhile, but I'll guess he will be interested. Meanwhile, I've decided to share some CHE & PRE data with the Board so you all can see how they work. And since I can't get any M43 data, I'll just fabricate some for it, which will probably be as close as it would get anyhow. Since I have a good bit of 223Rem data and that is what you all were expecting, I'll use some of it. I did not measure Groove Expansion on these Cases but will if my buddy gets to run the Test. It would have been nice to have seen how well GE tracks with CHE. But, I can do it the next time I get a chance to go run some Tests. Won't be telling you all the actual Load Data, cause I learned long ago not to give that out on the net. But, I can give you incremental Powder changes. I'll use the 223Rem since that is what we all thought we would get from Dave. 223Rem CHE & PRE Data, plus Pre-CHE measurement, Post-CHE measurement, actual CHE, actual PRE, and fabricated M43 data First four at 27.0gr 28....29....1.....49.....0psi 29....29....0.....49.....0psi 29....29....0.....51.....0psi 25....25....0.....55.....0psi We got no M43 data because the battery was dead. Second four at 27.25gr 29...29+...0.5.....52.....0psi 28+..29....0.5.....58.....0psi 28...30.......2.......57.....0psi 30...30.......0.......52.....0psi We got no M43 data because a wire was ripped loose. Third four at 27.5gr 28...28....0.....57.....22psi 28...28....0.....60.....4psi 25...25....0.....59.....59psi 28...28....0.....61.....88psi We got "normal" M43 data because the Strain Gauge was not glued on properly. Fourth four at 27.75gr 25...25+...0.5.....63.....50,689psi 30...30.......0.......59.....49,253psi 27...28.......1.......59.....00,000psi (NOTE: Slightly Blown Primer) 27...28.......1.......58.....147,934.687psi We got strange M43 data because the wind blew it over on shot #3 and goofed something up. Fifth four at 28.0gr 27...28+...1.5.....63.....56,230psi 27...28+...1.5.....61.....57,447psi 24...25.......1.......66.....No Reading 30...30+...0.5.....56.....No Reading We got No Reading with the M43 on the last two shots because the $2500 Laptop fell to the concrete and became Land Fill. ----- If you go back through the above "Actual Data", you might notice what appears to be a CHE Problem. I picked this one specifically to answer a question Dave had raised. Anyone care to guess what is WRONG with the CHE values and why it happened??? ----- Find Key: findactualchedata | ||

|

One of Us |

Let me guess! Let me guess! (picture hand raised and jumping up and down in a school desk Because.................

because they don't make any sense

because you have too much time on your hands How come the third set didn't have any CHE even though the previous lower loads did? I would think that it would be because that load did not develop any pressures. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Hey Woods, That is a completely 100% accurate answer. There is an excellent possibility that could have been True when that Data was originally collected. It does indeed look that way. However, if you look at the PRE Data, you will notice the Pressure is Increasing. I went ahead and Averaged the PRE Values to help with the Astute "Guesses" Group #1 PRE = 0.375100" Group #2 PRE = 0.375475" Group #3 PRE = 0.375925" Group #4 PRE = 0.375975" Group #5 PRE = 0.376150" So the CHE is indicating something that Dave asked about. And PRE is indicating the Pressure is Increasing as well as a Second Issue. ----- Want to try again Woods? You are doing fine so far. Anybody else? Don't feel like you will embarrass yourself, it is not intended to make anyone look foolish. But it does require some Thinking if you are not familiar with CHE & PRE. ----- Bytheway, I heard back from my Califoney buddy who has the Pressure Trace System. He said he has not bought Centerfire Ammo in at least 50 years, but would be glad to do so for the Test. But, it will be the Fall before he can run the Test due to the Family Health issues he is dealing with. No problem for me either. But it will just take awhile to get'er done, since no one on the Board trusts their (totally worthless) HSGSs to be able to compete (Case)Head-to-(Case)Head with the never improved upon, always reliable, never fail, totally dependable, relatively inexpensive, completely repeatable, CHE & PRE. | |||

|

| one of us |

I do appreciate you taking your "Dumb & Dumber" laughing stock, comic act on the road. I belly laughed when I first read it and I'm still laughing now.  | |||

|

| one of us |

Glad you enjoyed it. It was indeed meant for fun. | |||

|

| one of us |

There could be no other use for it.  | |||

|

| one of us |

I feel sure you realize the thing that makes each of them funny is how close to reality they are. | |||

|

| one of us |

None of these tasks is rocket science, yet we're to believe you're capable of measuring a tapered brass case to within one ten thousandth of an inch? You manage to bungle all the above, yet your measuring capabilities are spot on? Really dude, you're embarrassing yourself. | |||

|

| One of Us |

Strain gauges on the strong rifles of handloaders remind me of two jokes: 1)Q: Why can't Baptists make love standing up? A: Because it looks too much they're dancing. 2) Q: When approaching an intersection, what is the goal? A: To proceed through the intersection without collision. If we wanted to construct analogs of these jokes for this application, they might be: 1) Q: Why can't strain gauge handloaders just work up until the brass expands? A: Because that pressure might be too high. 2) Q: What is the goal of working up a load? A: To find the hottest load that still has long brass life. ------------------------ My father got a contract for one of his gun designs from Detroit Arsenal [US Army] that included a strain gauge on the barrel right over the throat. It was there to detect "Fall Back" when the gun was pointed up. That was the M107 that I have seen on the History Channel "The Story of the Gun" with footage of it in the Viet Nam conflict. He got that contract single bidder, because they liked his M55 and M110 designs so much. | |||

|

| one of us |

The only joke here is the CHE one Hotcore keeps pontificating about...old, useless and out of touch with reality. I know I'm laughing! | |||

|

| one of us |

Will this ever end? Seems like every time I look, there's a new post touting CHE and PRE as the greatest thing since sliced bread -- and of course, the endless refrain is written by the very same poster. There are far too many variables that CHE and PRE can't account for and thus will not always give one a true indication of pressures. And that IS science. These measurements are tools -- nothing more, nothing less -- and should not be regarded as gospel. Use them as you wish but understand that many of us do not share the same enthusiasm, have our own methods and have enjoyed perfectly safe reloading for a long time (myself for nearly 30 years). Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

It would if the great pontificator would present us with comparative evidence not of his own making. But he can't because there isn't any. He even said it himself. CHE does not give results that can be compared with any reloading manual ever published...not in psi or CUP. | |||

|

| One of Us |

Since when did cup or psi have direct meaning for the advanced hand loader with a strong rifle? The effect on the brass is the driving issue in load development. There are 100 other handloading forums with less sophistication, where cup or psi have a consensus of support as a driver. PSI or cup have should have some use in reality in making load books, where SAAMI registered average peak pressures should be the driver, if those books were written better. How to write a mediocre load book.. revision 2 PSI or cup have some use in reality in making commercial ammo, where SAAMI registered average peak pressures are the driver. What does it all mean? Hot Core, Barshe, SR4759, and I are all engineers who can develop our loads from pressure signs on our brass. There are lots of other forums with dumber posters. | |||

|

| one of us |

tnekkcc wrote:

Really??? Perhaps it is for those who live on the edge, but I don't. For me, the driving factor is accuracy at safe pressures and using common sense, experience and logic along with typical technical indicators. And while CHE and PRE qualify as useful indicators, they are by no means the final word in pressure readings. And it doesn't require an engineering degree to realize as much. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| One of Us |

| |||

|

| one of us |

OK, since your intelligence level far exceeds anyone else here, try this: In a 7mm Bullberry, 33 grains of H335 shows no measurable CHE and PRE over new brass. Neither does 34.5 grains. So, in your experience, all would definitely be well at 33 and 34.5 grains -- and even somewhat beyond -- right? Based on the CHE and PRE method, you would be DEAD WRONG. The 34.5 grain load is beyond what a Contender can safely handle as a steady diet and would ultimately stretch the frame. The brass can handle more, but the firearm cannot. In this instance, then, PRE and CHE are absolutely useless. You have to be both intelligent enough and not so narrow-minded that you can read and understand all indicators, not just a set of numbers from two measurements that any 5th grader could extract. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| One of Us |

| |||

|

| One of Us |

Bobby, how do you know what a Contender can "safely" handle? Regards, AIU | |||

|

| one of us |

Without going into great detail, I will first point out that case head size, case shape/taper and subsequent backthrust against the frame are major factors. For these reasons alone, one can run cartridges with small case head size such as the .223 or those based on the improved 5.6x50R full throttle in the Contender. You can't do so with cartridges based on the .225 Win., 30-30, .444 and others. Therefore, a factory-loaded .223 at upper-level SAAMI specs is just fine. A factory-loaded .308 WCF is NOT. Even a factory-loaded .300 Savage round, which operates at lower pressure than the .223, is not a good idea and therefore is why most custom makers will not chamber for it. In fact, I doubt any reputable maker would chamber a .225 Win for you in the Contender format, but a .225 Win AI (aka .226 JDJ) is fine as long as you don't exceed standard .225 Win data. Again, I won't get into lengthy discussions of such, but I'll add that simply gauging CHE and PRE will not suffice in determining safe or max loads. One must consider all facets and all indicators and then rely upon common sense and experience to arrive at a logical conclusion. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

One of Us |

Bobby makes a valid point. The qualifyer of rifle type and strength needs to be highlighted. I have stated on a related thread that CHE and maybe even PRE does not apply to my Lee Enfields as I cannot safely load close enough to the brass strength. I have to keep case elongation in mind. Regards 303Guy | |||

|

| one of us |

Hey Bobby, I had no idea anyone was forcing you to have to read these threads. Must be difficult indeed to have to endure the posts you don't agree with and are FORCED to read. Bytheway, who is the person forcing you to read them? Yes a Spirited view of something anyone believes in(that you don't) should be avoided by all means. I'll have to get my Dual Log Pickett and calculate how much your concern bothers me with what I post. I'll speculate, in the Spirit of the Thread, that the nominal value would be less than could possibly be read with a 0.0001" capable Micrometer. I am so glad to get your "APPROVAL". I've been holding my breath for a long time hoping and HOPING that you would find it in your heart to allow me to continue using the never improved upon, always reliable, never fail, totally dependable, relatively inexpensive, completely repeatable, CHE & PRE. Aaaahhhh..., I'll sure sleep better tonight now that it is OK. ----- Hey Bobby, What did the above factual Data tell you about those Loads? Or does "your Method" keep you from being able to read what is happening? I'm not running a Scam like Dave, just showing how the Greatest Pressure Detection Method of ALL TIMES works. Oh yes, Thank You for showing major interest in the thread, by keeping it alive. | |||

|

| One of Us |

Bobby, thanks for the comeback, but I still don't know why the Contender will not handle cartridges based on the .225, .444, etc. Does the manufacturer specifically state that the Contender cannot handle these rounds? Or, maybe the manufacturer has published upper limits on PSI for the Contender? I apologize for not knowing much about the Contender, but I'm curious how these precautions are arrived at. Morever, why is the 225 AI OK, but not the standard 225? Has the manufacturer specifically tested these two rounds? Regards, AIU | |||

|

| one of us |

Ackley Improved User- Case shape is first and foremost a problem with rounds such as the .225, 22-250, etc. as it lends to the backthrust issue. Cartridges based on the improved .225 do remarkably well in the Contender as the minimal taper, for one, allows the case to better grip the chamber walls during firing, all of which factors in to minimized backthrust against the frame. That case shape also lends itself to minimal brass stretching -- and, ultimately, less frequent case trimming. One must also be certain to never leave any oil in the chamber of a Contender or similar single shot as you will be flirting with erratic and spiked pressures. As to the .444, the Contender thrives on a number of wildcats based on this brass. The 375 JDJ and 309 JDJ are the best known of the bunch and afford the shooter about as much firepower as one can safely enjoy on the Contender format. I could go on rambling forever, but if you want any specifics, there are a number of articles on the www.bellmtcs.com website and also on the specialty pistols forum (both on the opening page and posted within various forums). Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

Hot Core wrote:

Coming straight from the pulpit of the self-professed reloading god Hot Core himself, I guess we all better believe it, right? Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

Hot Core wrote:

I didn't bother to look at your data as I don't trust anything second-hand and have no way of knowing if you may have erred in measuring or fabricated or fudged on any of the numbers. Thus, it's not worth my time. Hot Core also wrote:

Don't flatter yourself. I rarely read your posts when certain acronyms appear (your other posts are interesting, I will add). But when I see CHE and PRE, I can generally predict what the content and tone will be. ---- One last thing: Since you claim your method to be " the never improved upon, always reliable, never fail, totally dependable, relatively inexpensive, completely repeatable, CHE & PRE," I must ask why all ammo, bullet and powder manufacturers don't use it exclusively??? Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| One of Us |

Well, I've made many, many trips to the range to use my M43 Oheler PBL. I've never had a single problem with it as Hot Core describes. Obviously his own incompetancy is what triggers his imaginatation. As I have mentioned in previous posts I have taken pressure and velocity measurements and CHE measurements with Several .223 reloads and factory ammuntion both commercial and milsurp. The classic example of what's wrong with CHE is when a new box of Winchester White Box 55 gr FMJ M193 5.56 ammuntion (just recently purchased at Cabela's) was tested. There was No, let me say that again, there was no increase in CHE measurement of any of the fires cases. The velocity out of the 21" Contender barrel was 3351 fps. Any one familiar with chronographing normal .223/5.56 55 gr loads out of 20-21" barrels would know that velocity was high and something was amiss. What was "amiss" was the pressure. The MAP of that Winchester ammo was 65,700 psi(M43)! Now before Hot Core and tnekkcc get all worked up and cliam the m43 was amiss let me say that the loads test before and after The Winchester ammo test were quite normal. Actually the ammo tested right after was Remington factory 50 gr HP. It gave 3280 fps (just about what should be expected for a .223 with 50 gr bullets out of a 21" barrel) at 52,900 psi(m43). The load tested befor the Winchester ammo was my standard load of 26.5 gr H335 under a 55 gr Hornady SX in LC cases with a WSR primer. Velocity was 3183 (again just what should be expected from a 21" barrel) at 58,200 psi(M43). Thus we see there was nothing "wrong" with the M43 when the Winchester ammo was tested. What is wrong is a belief that CHE is a reliable indicator of pressure, Hot Core's hallucinations withstanding. Larry Gibson | |||

|

One of Us |

Mmmmm... might I ask how oil in the chamber influences pressure? Do you mean a flooded chamber - that would constitute a physical obstruction. (Ummmm... this is relevant, right?) Regards 303Guy | |||

|

| One of Us |

Larry, I don't see how this is doing you any good. ------------------------------------------------------- Hodgdon website: 223 Rem, H335, 25.3 GR. 55 GR. SPR SP, 2.200", 24" barrel, 3203 fps, 49,300 CUP My Test: Ruger #1, CCI 400 small rifle primers, LC brass once fired processed from Scharch and prepped by me, 55 gr Vmax moly, H335 25 gr, did not load 25 gr. 26 gr, did not load 26 gr. 27 gr, unfired, extractor groove .3290" 28 gr, extractor groove .3290" 29 gr, extractor groove .3290" 30 gr, extractor groove .3295" 31 gr, extractor groove .3320" The threshold of brass yield is then between 29 gr and 30 gr. If it is 29.5 gr, then backing off 6%, the correct max load is 27.7 gr per Vernon Speer's 1956 technique. ------------------------------------------------------------- Likewise for H335 168 gr 308: Hodgdon max book load: 308 WINCHESTER, CASE: WINCHESTER, BBL: 24", PR: FEDERAL 210M, 168 GR. SIE HPBT COL: 2.800" H335, 42.0 gr., 2631 fps, 49,300 CUP My test: Pacific .308 Win reamer, VZ24 trued action, A&B fluted stainless 24" F54 barrel, H335, CCI200 primer, 2.9" OAL, Speer 168 gr. HPBT Gold Match, brass: Win308Win: 0) 42 gr. did not load 42 gr. 1) 43 gr. extractor groove growth = .0000" 2) 44 gr. extractor groove growth = .0000" 3) 45 gr. extractor groove growth = .0000" 4) 46 gr. extractor groove growth = .0000" 5) 47 gr. extractor groove growth = .0000" 6) 48 gr. extractor groove growth = .0000" 7) 49 gr. extractor groove growth = .0000" 8) 50 gr. extractor groove growth = .0020" 9) 51 gr. extractor groove growth = .0020" 10) 52 gr. extractor groove growth = .0110", primer fell out The threshold is then between 49 gr and 50 gr. If it is 49.5 gr, then backing off 6%, the correct max load is 47.5 gr per Vernon Speer's 1956 technique. ---------------------- What does it all mean? When the brass strength is the driver, you measure the brass yield threshold. Anything else introduces error trying to infer the brass yield threshold. Why did Hodgdon back off 10% on 223 and 13% on 308, when 6% is the correct amount? Read my essay by Googling ""How to write a mediocre load book" second revision" | |||

|

| One of Us |

Larry, what's wrong with 65,700 PSI? Maybe that's within the elastic limits of your brass? AIU | |||

|

| one of us |

Ouuuuuch, fabricated and fudged? I already told everyone I was indeed fabricating the M43 info. But, no doubt it is close to the truth - outside a Lab. For all the rest of you following this thread, I'll run Bobby's "not worth my time" through the old ancient Translator. Ah yes, it means, "Bobby dosen't have a clue!" OK. I'm so easy to get along with. Excellent! That means you are still able to retain valuable information. Maybe we can Train you yet. ---- I've never seen nor heard anyone from the Ammo Manufacturers say they do not use CHE or PRE. When a person understands what it is actually being measured, my well educated, Math, Physics, and first-hand experienced based "guess" would be that there are folks in both Manufacturing and Quality doing just that. Otherwise, they really do not know if the Case has a proper Temper. Huuumm, I suppose they also run a Hardness Test for Brass which is "similar to" but uses a different Scale than a Rockwell hardness Test for Steel. And I'd "guess" they do the Hardness Testing as the Case Lot moves through the Forming Process so the Temper can be "tweaked"(a high tech term None of this accounts for Doughnut-Dust on the Cases. | |||

|

| one of us |

I don't think I've seen such convoluted crap since Bill Clintoon asked us to define the word 'is.' Must be drugs or alcohol causing a short in his brain waves to type such useless tripe. Hotcore, you truly are embarrassing yourself.  | |||

|

| One of Us |

The weak link in 223 and 308 type case heads is the primer pocket getting loose.* I don't know if brass manufacturers are simply controlling brass strength by specifying "H06 tempered C26000 cartridge brass" [ extra hard tempered 83 ksi to 92 ksi tensile strength, 68.1% to 71.5% Copper and the remaining % is Zinc]. But I do know that there is very good uniformity of brass from brand to brand in load work up testing the threshold of extractor groove growth. There is much better than +/- 5% [like the H06 spec] on the predicted pressure with Quickload for different brands threshold loads. This would suggest that some spec tighter than H06 is being used throughout the industry. Quickload is only a prediction, but based on the extreme accuracy of velocity predictions, we may assume it is useful for relative pressure comparisons. *Unlike the more solidly built 6mmBR case head design where the primer piercing is the limit. The load is worked up with CCI450 magnum small rifle primers, and if the crater caused piercing threshold is too low, firing pin bushing is often done. Gre-Tan is a well known provider of this service. | |||

|

| one of us |

Hey tnekkcc, You are talking so far over a few peoples heads that they will have no Reference Point. There are folks that really believe there is a device which provides "unquestionally reliable data" and all you have to do is shoot a Bullet near it. Then the device Magically Deciphers the most minute Ballistic details(while using non-calibrated Bogey Set-Up Data, with guessed at dimensions and Fudge Factors). I'm sure their teachers are proud of them. Your accurate insight is falling into uneducatable eyes. Nice Graph! | |||

|

| One of Us |

tnekkcc, Have you tried the Remington 7 1/2 or the CCI mil spec SR primer in the 6mmBR case to see how they handle perforations. | |||

|

| one of us |

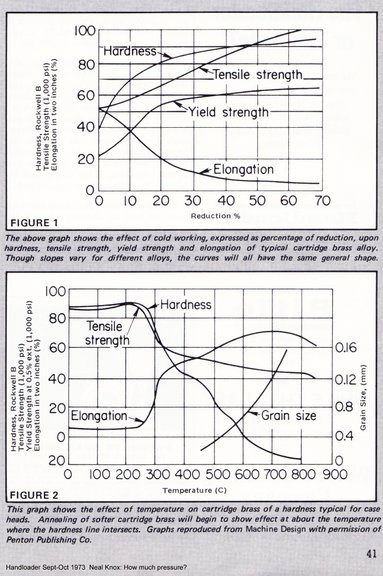

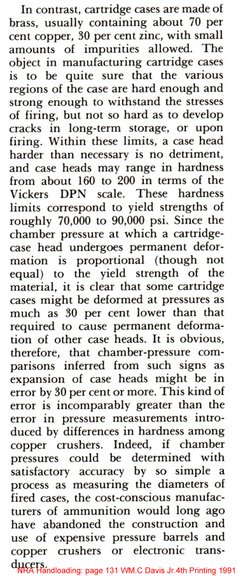

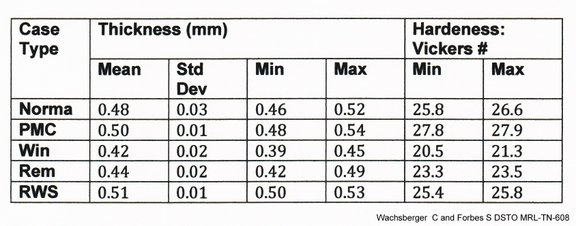

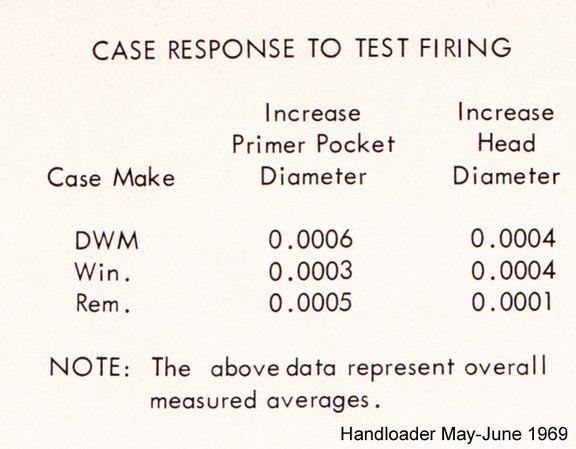

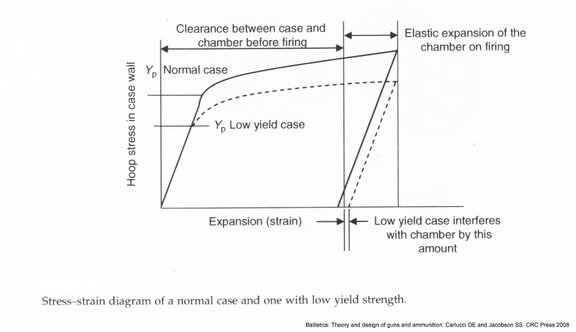

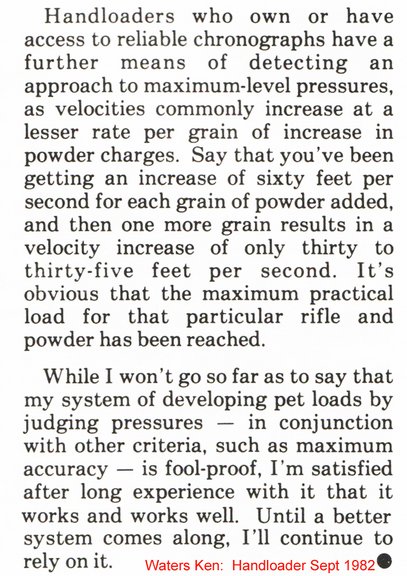

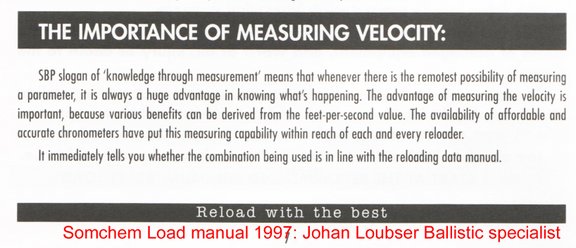

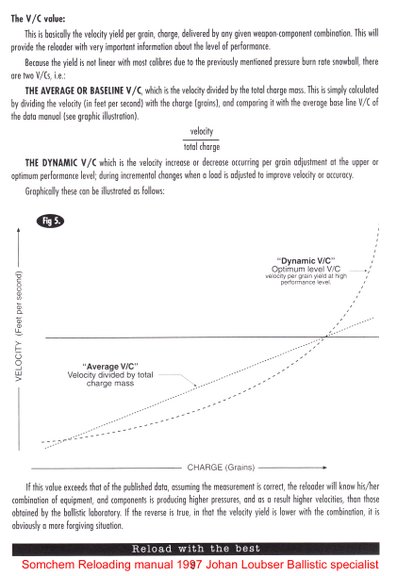

CHE/PRE vs Strain gauge pressure testing The following claim has been made: “allow me to continue using the never improved upon, always reliable, never fail, totally dependable, relatively inexpensive, completely repeatable, CHE & PRE” For a test in measuring, this is a pretty powerful claim! For what we are measuring is the amount of strain ( deformation ) after application of a stressor in the form of pressure of a brass cartridge casing after firing. A claim like this should raise red flags, because out of hand such a claim would be suspect given that an infinite number of variables could creep into this seemingly simple exercise of measuring the outside diameter of a case, even more more so when the method is to be correlated to a parameter such as pressure; and this then compared to another method. The act of measuring in small values, 0.0001 of an inch on a imaginary point on a tapered cylinder in itself poses logistical problems. If this task were given to 10 people in a room and each were asked to repeat the task 10 times without the aid of a jig that forces measurement at a specific point I bet any number of variabililty in data would result. For starters we have to acknowledge that CHE/PRE is a static representation of deformation against an applied amount of pressure whilst the strain gauge gives a dynamic representation of the rate of strain in the gun chamber steel to applied pressure over time. two very different concepts ! The conformal piezo transducer measures rate of deformation of the case wall to applied pressure over time, the In-chamber Piezo transducer as used by CIP measures direct in- chamber rate of pressure change against time, the Crusher gage measures static deformation of a slug of copper, or in original form lead to pressure aplied to the wall of a case. The "strain cage" measures rate of strain of a slug of metal against pressure over time. The spring cage measures rate of deformation of a spring in a cage caused by pressure on the case wall in response to pressure over time. The proponents of the CHE/PRE method are: 1. Ken Waters 2. Bob Hagel 3. The Speer manual. ( the Speer manual is basically a combination of the above with important provisions regarding the amount of case firings allowable before measurement. Giving credence to the effect of work hardening of the case) Just to be sure that we understand what each proposes one can find the detaille in the following: 1. Developing Pet Loads: Ken Waters’ methods for judging pressure: Handloader magazine September 1982: 2. Facts every reloader should know: Points on pressure Bob Hagel: Handloader Nov-dec 1973 3. How to detect and control pressure: Bob Hagel: Handloader 90 March -April 1981 4. How to detect and control pressure: Bob Hagel: Handloader 91 May –June 1981 5. Pressure points how to measure head expansion: Bob Hagel: Handloader magazine Jan -Feb 1978 On cursery scrutiny of the above we see a number of differences between citations that are important. 1. There appears to be no consensus regarding the absolute number in terms of expansion of the case which is deemed a positive test. This fact is noted by those who have studied the method against more accurate systems such as Piezo transducer measurements This is important if this test is to be used as a measure of a pressure value; it has to have a cut off point where the test becomes positive. Because of the imherent nature of the test as defined by Ken Waters as not an indication of an absloute pressure number this point is also not defined but seems to be assigned as an arbitrary value. Ie the deformation value is not correlated to a pressure value. in a article: How much Pressure by Neal Knox Handloader Sept-october 1973 the author shows that one can by virtue of knowledge of brass quality calculate what the PSI would be that would give deformations in the brass. The only problem is that all brass is not created equal, in fact on face value it would appear that brass suffers from mass production flaws in terms of quality and dimension.  2. Waters and Hagel do not mandate measurement after one firing only, their original discriptions allowed for measuring after multiple firings of the same case, in fact Hagel goes on to show how the bright marking of the PRE "grows" and moves down the case after each firing. This poses a problem because when a pre and after firng measurement is to be taken off a tapered cilinder how are we to know where to measure. Speer's manual madates a single firing only then measurement but again no mandate as to point of measurement. 3. There is reference to variables in cases but nowhere are allownances made for the variables. Issues such as Out of round dimensions etc. Hagel proposes sinning the case around untill the biggest measurement is obtained? Hardly a basis for repeatability? Having pointed these points out we can look at the method as it should in framework of a statistical exercise. John Barsness examined the meaurement of CHE/PRE as originally proposed by Hagel and Waters against a proven absolute pressure testing standard using lab verified, regulated conformal transducers in test barrels at the Western Powder companies facility at Miles city. Reference: Pressure guessing John Barsness: Handloader 219 Oct- Nov 2002: The results of this comparison given the statitstics treatment exposes the following: 1. CHE/PRE is not sensitive: This is in part due to an abnormally high rate of false positive results. For the most the measuring done in this series of tests showed false positve results before the SAAMI pressure cieling value was reached. The micromter readings were poistive before peak pressure was reached. For the handloader this is not bad because false positives leaves the handloader with a safety margin! this is likely why both Waters and Hagel could lay claim that the method in combination with other signs are sufficient to keep the loader safe?.... But not always !!!!! 2. PRE/CHE is not specific: Again because of a high rate of false positives 3. Error: CHE/PRE showed both high rates of Type 1 and type 2 error Type 1 error due to the high rate of false positives but also high type 2 error rate, because of the occurrence of false negatives. this is the achilles heel of the CHE/PRE method, this is where the cases do not deform and yet the pressure approaches dangerous levels or is abve the SAAAMI standard. Barsness points out in another article that Hagel and others have had to recant on their stance on CHE/PRE, Hagel in fact does so in his book Ballistics for the Hunter. 4. Precision: ( positive predictive value ) this is the indication of a tests value in that that the test will be positive if pressure is high ! Precision of this test is low based on the high rate of false positive tests. This is what William C Davis has to say about these methods:  WM.C Davis was the chief Engineer at Colt, he played a major role in the development of amongst other the AR16 and was a consultant in Ballistics Engineering for the US DOD. He had 60 years of ballistics experience and published numerous defence related bulletins on the subject of ballistics. Source: NRA: Handloading 4th Printing 1991 Measurments of chamber pressure by WM.C Davis jr. pages 127-132  This statement basically the same as that of Davis by York and Brownell. Source: Ballistic breakthrough: A new means of determining true pressure Brownell LE and York MW Prof LE Brownell. Professor of Chemical and Nuclear Engineering, Supervisor Du Pont Ballistic Grant, University of Mich. Ann Arbor Mich. MW York: Engineering consultant and research consultant to the Du pont Ballistic Grant. Masters degree in Engineering University of Michigan, West Point graduate 1958. Also from Gun digest: 22 ed 1968 Author Michael W York Title: Ballisitics research Breech Pressure Breakthrough Pages 17: “ At present most handloaders have to rely upon unreliable secondary indications of pressure. Shooters have used blown and flattened primers. Difficult extraction, and cartridge case expansion as indications of high pressures. These indications do in most cases result from high pressures………. However the lack of such indications does not mean the load is safe” This is confirmation of the high rate of false negatives in the test. One of the points made by all the propnents of CHE/PRE is that all cases are not created equal. Not between brands, not between lots of the same brand and not between cases from the same lot and brand. In an effort to validate the efficacy of the conformal piezo pressure gauge the following data was published on cases used in the 308 and 223. For purposes of this discussion all military sourced cases were omitted and only sporting cases are included.  The authors of this defence bulletin correctly measured diameters of the cases using a specially contructed jig ensuring that measuring was done at 4 equidistant points on each case, this ensured consistancy in point of measurement eliminatiing some variability in the process. These differences in case quality manifest when testing pressure with the conformal piezo gage and what was unexpected was an apparent anomaly in response based on case diameter when comparing the 7.62mm to 5.56mm cases; in that the response to pressure differed between the smaller diameter cases and the large diameter cases and the difference being attributed to case diameter This finding was not further explored as it fell outside the parameters of the of the study. What this does do however, is it brings suspicion to Hagel's position on the strength of cases based on design. Hagel proposed based on CHE/PRE measurement that all cases responded equally to pressure irrespective of design, this appears not to be so. A study done comparing the charcteristics of DWM 30-06 brass vs Winchester and Remington that various brands respond differently to applied pressure. Source: Technical evaluation of DWM brass Dick Ceremsak Handloader May – June 1969  The response of brass to pressure as a stressor is summed up in this graph, the graph shows why on brass quality differences alone a static measurement after application of stress would differ if brass quality differed.  The Source of this data appears on the picture. Many here have critisized the use of the chrono in assessing pressure, can't be done said many ! Lets see what the gurus of the shooting world so oft quoted have to say: 1. Ken Waters, from that very same oft quoted article in Handloader: This is the very source of the whole CHE/PRE Debacle, so part is accepted and part discarded ? which is true and which is false? Developing Pet Loads: Ken Waters’ methods for judging pressure: Handloader magazine September 1982:  and Gun digest: 22 ed 1968 Author Micheal W York: Masters degree in engineering university of Michigan west point graoduate 1958 Ballisitics research Breech Pressure Breakthrough page 18: also John Barsness: Velocity and Pressure: Handloader Magazine: August sept 2005 Chamber pressures can also be calculated with a chronograph using ballistic efficiency as a gauge from the Sochem Reloading manual, Author Johan Loubser who now is the ballisitc consultant for Western Powder.   and so we can continue.... on and on | |||

|

| one of us |

Hot Core wrote: "You are talking so far over a few peoples heads that they will have no Reference Point. I'm sure their teachers are proud of them." The egos of a few here never cease to amaze me. But since HC feels it is appropriate to take cheap shots, I'll momentarily stoop to Hot Core's condescending level and fire back: Hot Core, I am quite certain YOUR English and/or writing instructors would be ever-so proud of you since you've somehow decided it is appropriate to capitalize every word in a sentence you deem to be important. Did you even pass high school English??? (Maybe it was by a small margin, say .000105 point?) Or maybe some other reason -- anatomical, perhaps --- piqued your interest in such small numbers. Thanks to a couple of chest-pounding egotists, one could find more mature behavior on a pre-school playground than on this thread. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| One of Us |

Denying that CHE can't be used is mainly based around use of inadequate statistical data. Test a statistically valid number of cases and you will have valid results. Sure it will never be 100% perfect. You have to test all your brass to destruction for that. In the same way the use of the chronograph is never going to be 100% certain. What a most of those arguments do is assume linearity of pressure vs charge weight. At very small charge increments you might believe that is true. However the use of some null point in the data where velocity no longer increases linearly as a indicator that maximum allowable pressure has been reached has no basis in logic. Smokeless powder is not calibrated to lose linearity at some magic point. Would anyone expect that 3031 would have the same loss of linearity at the same pressure in a .222 with a 50 grain bullet as it does in a .458 Win with a 500 grain bullet? | |||

|

| One of Us |

Alf, I would like to send you a bill for causing me to read all of that The two layered problem remains: 1) The strain gauge set up will not accurately measure the absolute pressure. 2) Even if the absolute pressure could be known, it would be of limited importance to the hand loader in a strong rifle [unlike ammo manufacturers and load book writers]. What does it all mean? What the prudent advanced hand loader wants to know is the threshold of short brass life. If the pressure could be known, that would not the best predictor of the short brass threshold.... sampling the brass life is the best. If the brass life of a cartridge is a function of primer pocket growth, measuring the extractor groove growth [what I call EGG] with calipers is easier than measuring the primer pocket with pin gauges. There. You can't send ME an invoice for engineering hours | |||

|

| one of us |

Had a guy named Fred Whitaker who was my HS English teacher. He told me to hang on for a moment after class one day. Next thing He said was, "You REALLY HATE this Class don't you?" I replied that I did. He said that was Good, because he figured I HATED it enough that I'd not want to REPEAT it. He also said the folks who are between the Lovin' it and Hatin' it were the ones he worried about. As AMAzinG as it SeEmS, I PASSED!!!!! I don't Need any STINKIN' English!!! As a side note, Mr. Whitaker had a Canon that he had made. It fired concrete filled Soda Pop cans and was a real Hoot. It is really amazing that we never Killed anyone with that thing. He'd invite a bunch of us English HATERS over and we'd all have a Blast with the canon. ----- Tnekkcc, you ought to be ashamed of yourself for bothering to read alf's bologna. I did a quick scan, noted some egregious errors and moved on - as usual. However, if you want a few Quoting barsness is on the same level as quoting teanscum. | |||

|

| one of us |

Hot Core wrote:

I seriously doubt the level could go any lower. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Actual CHE & PRE Data + Fabricated M43 info.

Actual CHE & PRE Data + Fabricated M43 info.

Visit our on-line store for AR Memorabilia