The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Regarding Headspace, what is the

Regarding Headspace, what is theGo  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

Maximum permissible amount that would not cause detrimental results? Not what is ideal, but rather what becomes the threshold of dangerous. .003", .005", .008" etc.  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | ||

|

| One of Us |

Just went through this with my Savage 110 7mm RM. I was getting insipient case head separations on only the 2nd. or 3rd. reload. Vapodog had suggested that it was headspace so I took it to a gunsmith. He used a No-Go gauge which he said was .008". The bolt closed easily on this (it should not have). He then used a .012" and the bolt would not close (thankfully). Anyway, at .008" and above the headspace is considered excessive from what I was told. I was getting many insipient case head separations, enlarged primer pockets and extractor markings on the case head face. I sent it back to Savage (under warranty) and they corrected the headspace problem by replacing the entire receiver and making the appropriate adjustments and now I have not had any further problems with the brass. ********************** > I'd rather be a CONSERVATIVE NUTJOB than a Liberal with no NUTS & No JOB > | |||

|

One of Us |

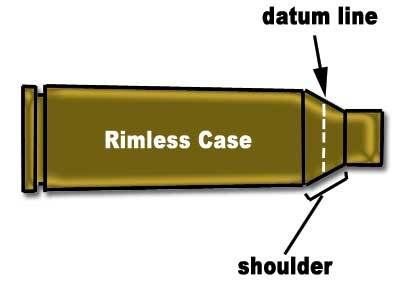

Hey 308sako I measure the gap between the case shoulder and the chamber shoulder (headspace in an unbelted case but not headspace in a belted one) with the Hornady Headspace Gauge which attaches to your caliper and takes a relative measurement close to or at the datum line on the case shoulder   I reload for over 40 guns and document this measurement on most of them. The headspace on new cases is determined as much by the brass manufacturer as it is the gun manufacturer. On belted magnums the brass manufacturers know that the case will headspace on the belt and they usually put a generous amount of gap at the shoulder. It is not unusual at all to have a measurement of over .020" in a belted magnum gun. I had a pre-64 Model 70 in 264 win mag that had .0295" and a 338 win mag that had .027" which was excessive and led to burn throughs on the 264  and a case head separation on the 338 win mag  On a regular case like a 30-06 the gap is much smaller and varies between .007" to .017" with most around .010". Once you get past the initial firing and the case has expanded then you can headspace on the shoulder and it becomes a moot point. But to answer your question I would be cautious of any measurement over .020". If you use a go-no-go gauge then you're on your own cause they don't give as much information. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

If you form a false shoulder, none of the brass will stretch due to dimensions. The problem occurs with weak actions, like the 303 British, that are subject to compression with powerful loads. ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

| One of Us |

Woods: It seems that if that is true then all No-Go gauges would seat and allow the bolt to close unless different calibers have different tolerances? I know that in my 7RM it was between .008 and .012 and it was excessive. Perhaps I misunderstood the gunsmith - are you saying that different calibers have different headspace tolerances and that the 7RM should not be more than .008? Thanks, Wayne ********************** > I'd rather be a CONSERVATIVE NUTJOB than a Liberal with no NUTS & No JOB > | |||

|

One of Us |

Aerostarp & Woods, It is these type of responses which make AR such an excellent reasource. The cartridge which I am specifically inquiring about is the .308. Now I would confess to using a BuBBa gauge (.44 Special case) and the fact that it measures the shoulder just above the case's sidewall... but the difference in a fired case to a loaded round was as much as .010" This of course would equate to excessive headspace in my opinion. I lost several cases to partial seperation upon firing. I have since broken down the remaining rounds and Using my BuBBa methods used a .270 die to stretch the HS back to within .004" Scary isn't it?  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | |||

|

| Moderator |

headspace is datum to breechface, and having .005 is considered max new, .008 might pass a field gauge, and .000 or .001 is considered optimal in MY opinion, and at no means being rude to woods, woods is measuring a clearence at the datum, which is not the technical and specific term "headspace". it is therefore not "headspace" rather datum clearence, in SOME cases (no pun intended) opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

You question is somewhat loaded. If you are talking about a rifle that is fired only with tough new brass (factory ammo only no reloads) it will withstand a greater ammount of heaspace without causing a problem with safety. Accuracy will suffer some though. If you have brass that is of lesser quality and is subjected to a lot of reloading the headspace required to be safe is smaller. | |||

|

One of Us |

The rifle is a Rem 700 VSSF, cal. .308 Win and the brass is Lapua and fired many times.  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | |||

|

| one of us |

Ahha, then you should have ZERO Headspace(resize so it is actually 0.0010" to 0.0020" too long) so you have a slight crush fit. It is refered to as P-FLRing the Case. An exception to this would be if you are Hunting in Dangerous Game country and then it is proper to create a bit of Headspace by doing a normal FLR. This helps avoid jams if a bit of trash gets into the chamber during the Hunt. I'd not responded before because I thought you were talking about the semi-auto you have pictured. With the semi-auto, in order to get reliable feeding(so the Bolt closes all the time) then you do need some amount of Headspace. This can be determined by Trial and Error as well as uing the inconsistent "Thingys". Best of luck to you. | |||

|

| One of Us |

Think of headspace this way: Headspace is the space for the cartridge to sit in the chamber. If there is too little, you can't close the action. If there is excess head space, there is excess slop in the fit. And that's about all it means or should mean to any reloader. There is NO reason any handloader should have "excess" headspace. Back the size die off so your cases fit with a small amount of resistance to bolt closure, and that's effectively ZERO excess headspace. Works every time it's tried. Jamming any case as far into a sizer as it will go almost gurarentees the loader WILL generate excess headspace. The effect on cases is cumulative and the number of times it can safely occur depends on just how much the cases are being over sized. There's NO "rule of thumb" about it. Again, the actual headspace in any rifle should be irrelivant to a reloader; adjust the sizer to accomidate whatever it is. We can use the chamber itself as a gage. Easier perhaps is to use a RCBS Precision Case Mic or Hornady LnL case checker and dial indicator as Wood's photo shows. or even the Bubba gage to find the fired location of shoulders and adjust the sizer to move it back only one or two thousants. There is no reason to consider, or size, rimmed or belted cases any differently from rimless cases. In fact, it is MUCH safer and better for case life if we DO NOT size them any differently! Just make your cases fit your rifle, your ammo will work well and your cases will last much longer. That's a good thing! | |||

|

| One of Us |

Now I am not advocating doing this or saying it is even safe, but I once owned a 257 Roberts with .055" headspace. The gun never blew a case, but I never reloaded a case from it either. I am not a complete idiot. For the record I did eventually set the barrel back to respectable specs, but figured I may as well do some experimentation with the huge chamber. Excess headspace is a definite concern but there is a lot of room between NoGo and unsafe. You can make an unsafe condition by oversizing cases in an inspec chamber. A NoGo gauge is used for new chambering. A field gage is more for testing serviceability of used guns. PA Bear Hunter, NRA Benefactor | |||

|

One of Us |

Wayne, I really can't say because I don't know which measurement the gunsmith is quoting, how he is getting the measurements on his go-no-go and whether he is even correct. I would say that the headspace on a belted magnum should not be more than .008" but you have to realize that means the case can only move .008" or less before the belt stops the forward movement and that the case could still have .020" of datum clearance as jeffeosso calls it. That datum clearance is what leads to case stretching at the web and leads to case head separations. With a go-no-go you are not measuring this at all. Like Jim C. <>< says, there should never be a reason to size so that you have excessive headspace but I would add one caveat: you can not control headspace on new cases, only after firing and then sizing. IOW, headspace should be of no concern after firing and sizing because you should be setting your dies to size sufficiently but minimally. On cases without a belt like the 30-06 the datum clearance I measure with my "thingy" is headspace as defined on the SAAMI site

and I think of it as the distance the case can move forward from the bolt face before it is stopped by some part of the chamber. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Certainly a workable definition. I consider that to be "excess headspace" in that it is excess to what's needed to chamber the round. I don't want any such excess, it ONLY permits case stretch. Evenentually a head seperation WILL occur! | |||

|

| One of Us |

308 Sako, I'm sorry, but I don't understand what you are trying to measure with the .44 Spl. case. And I also don't understand why you would use a .270 sizing die to "stretch the HS". I would suggest you get a RCBS case mic.  Measure your fired case. The case mic will will show you the head space dimensions of your rifle. Once you determine that dimension, you can carefully adjust your sizing die to match your rifle's chamber by using the mic to check your resized cases. Generally speaking, the closer to zero HS is best for accuracy..... but you'll probably want to move the shoulder of the case back a couple thousandths of an inch for reliable feeding. | |||

|

One of Us |

What woulkd be dangerous would depend on the brass being used. Some brass stretches better than other lots of brass. "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| Moderator |

Woods, With respect, i do not consider what you are measuring to be the same headspace that a headspace gauge measures. In the case of belted mags, this is without a doubt the case. opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

To Winchester 69. You posted the following,

This is not quite correct and illustrates one of the problems of headspace with RIMMED cases and not being familiar with the Lee Enfield action. First, Headspace for a Rimmed case is that between the face of the bolt and the face of the chamber - what is in the rest of the chamber is immaterial. On firing, the case fireforms to the chamber. The Lee Enfield chamber was deliberately made 'overlarge' - after all, it was a military rifle whose users did not reload and who often had to use wet, dusty, muddy and out of spec ammo made by brand new employees. If your ammo does not chamber on your deer hunt is disappointing but not to compare with being at Passchaendale on a wet October day in 1917. What happens next is the real problem for the Lee Enfield. A user takes the fired case and full length sizes it - a real squashing down to bring to min tolerance - no wonder the case separates, it is over sized, just like a 30/06 case that has the shoulder pushed back 20 thou each time - Point ONE : NECK SIZE only for Lee Enfields. I should also add that some cases are thinner than other and made to the LOW tolerance - I don't use Winchester cases for that reason. Second Point : Powerful and action compression loads are mentioned for the Lee Enfield. The SAAMI max loads surely should not be exceeded but I do load to the max appropriate. I do have .303 cases - Neck sized - which have been fired 10 or more times with max loads and they are still fireable. Its not action compression, its FL sizing instead of Neck sizing. Last Point: "The problem occurs with weak actions, like the 303 British, that are subject to compression with powerful loads." A gunsmith friend, in over 50 years of dealing with Lee Enfields in NZ, has never found one where the action has failed; plenty with split barrels and where the case has failed but not the action. The most spectacular was a No4 where the owner confused Nobels No1 PISTOL powder with Nobels No1 RIFLE powder and fired 40 gr of the pistol powder behind a 180gr projectile. The case failed, and the bolt reared up "like a striking Cobra" but the lugs held. Not too bad for a "weak action'. Yes, I do currently own 44 Lee Enfields and have been using them since 1965. Arte et Marte | |||

|

One of Us |

I need to bring my "thingies" and come by your shop one day. That way I can watch you use the go-no-go gauge and show you the measurements I get. Of course the belted cases headspace on the belt for the first firing and your nomenclature of "datum clearance" is good. However for an unbelted and unrimmed case the data I get is headspace in that it measures how far the case could travel from contact at the bolt face until it stops forward movement with contact at the shoulder. The "thingy" just gives a definite measurement in thousanths of an inch. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Moderator |

so, our discussion would be settled with a simple experiment of a go gauge, a no-go gauge and measurement of fired brass? as one can clearly understand, a gun that closes on a go, but not on a no go, would be within saami specs, generally 0.0 to .005 headspace. Any measurement beyond that range would measure "something else" agreed? opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| Moderator |

ah, i have read up on this RELOADING tool .. that allows one to set their dies to their chamber. it allows for variance in brass, pressure, and bolts. In other words, it does allow one to set their dies perfectly to not overly size their brass. a perfectly worthy pursuit, as it allows for negative and positive headspace, because it is a tool to measure fired brass and sized brass. it's okay, i'll call hornady tomorrow and inquire if a "lnl headspace gauge" should be used to determine if a rifle is in or out of go/nogo range.. or if it is entirely a reloading tool for setting dies opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

One of Us |

It might be excess headspace but it would still be headspace according to the definition of the term. IMO I posted while you were posting and would not say that the gauge should not be used to determine if a rifle is in or out of a go-no-go range, but rather to set your dies to not oversize the brass. Which IMO is a more useful task than determining if a rifle's chamber is within a range of set values that the go-no-go gauge tell you. I'm not saying that you should buy one to set chambers with, just to learn the exact dimensions of the rifle you have in hand. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Moderator |

i think we agree, a very useful tool for setting dies. a perfect companion to the OAL tool .. but it is not a 1:1 measurement of a rifles "saami" headspace opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

One of Us |

I'm not sure excess headspace is actually "dangerous".....a lot of folks have experienced head separation without injury or damage to their rifle.....there was a thread here a while back where a good many folks told of head separation but no damage to anything.....other than a lost brass casing. I've seen headspace so severe that case head separations happened on the very first reloading.....meaning a factory load was fired and reloaded and that reload separated the case! IIRC the headspace was exceeding .020" ..... and still no damage done except for extreme poor case life. IMO anytime headspace exceeds .008 over the "GO gage" the situation should be corrected..... Better yet....one should never take a gun home NIB until the shop owner prooves the headspace to be correct day-1.......and if it grows....then one might wonder what is causing it! /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

One of Us |

Okay, here's another example. I recently had a rebarrel done by a very good gunsmith (who posts here). The original gun was a Browning BBR in 300 win mag with a short magazine that was made into a 6.5 rem mag with a Douglas barrel. I forget what he said but it was "just inside the go-gauge" or something that meant he used minimal headspace on that belted case. I'm sorry but I really don't understand the go-no-go "thingy" since I have never felt the need for one. Anyway, I did develop a method to determine the headspace on a belted case. On this case I determined that there was no forward movement allowed by the chamber after closing the bolt which to me means the front of the belt was against the chamber and there was no headspace (with that particular type of brass). Now with my "thingy" I measured the "datum clearance" at the shoulder on new cases and it measured 1.768". After the first firing the measurement was 1.782" and after 3 firings when it developed a crush fit the measurment was 1.785". So the datum clearance was 1.785"-1.768"=.017" (with zero headspace). So the chamber does not have a headspace problem but there is substantial expansion of the brass of .017" which is a very useful piece of information. That measurement is what causes case stretch and possible case head separations or other problems. So why would I need a go-no-go gauge and what else could it tell me or could it even tell me the amount of "datum clearance"? Now when you are reaming a chamber I would suspect that they would be very useful and even essential for setting the chamber dimensions. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Moderator |

we are obviously talking about different things when we say headspace I have extended the hand of compromise on this. Unless that is accepted, this one will be my last post in this thread on the matter opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

One of Us |

When discussions of headspace is referencing belted magnums the issue often gets clouded.....and rightfully so. Headspace is officially measured at the foreward end of the belt as that's what the headspace gauges measure, Clearance of the foreward end of the shoulder is another matter and is often confused with headspace. I have encountered this problem in a .257 Weatherby and the problem was compounded because I had two .257 Weatherbys at the same time.....and the ammo wasn't interchangeable.....even after FL resizing.....it drove me up a wall..... /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

One of Us |

Hey jeffe, you can bug out anytime you want. Throughout this thread I have been very careful not to call the "datum clearance" on a belted mag headspace. We agree on that. If you don't want to talk about the gap at the shoulder since you can't measure it and haven't measured it and don't want to deal with it - OK - but that is what this thread is about. You have extended the hand of compromise and I have gone out of my way to carefully explain time and time again that we do agree on headspace but there is another issue out there and I'm not going to stop talking about it because you can't measure it or understand it. This thread is about the clearance at the shoulder on a 308 which is measured by the Hornady Headspace Gauge (to the thousandth, not just within a range) and you keep getting upset over the front of the belt thing. And the gap on an unbelted or unrimmed case between the case shoulder and the chamber shoulder when the case head is against the bolt face IS HEADSPACE! It doesn't matter whether that gap is zero, .002", .020" or .2" it is headspace, sometimes EXCESS headspace, but headspace nevertheless. So you extended the hand of compromise, I shook it, and because I won't forget about what I know to be true, you're going to bug out? Adios ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Well, I have only seen one rifle fail due to excess headspace. That was a Lee Enfield. It did not break - they are not week actions, just very flexible - but rather, the locking lug recesses peened to the point where the bolt began to bind in the receiver. Excess headspace causes a hammering effect which can double (or worse) the load effect against the bolt face and since the older L E actions were not made from modern steel, they set back. This same effect could conceivably break a mauser type locking lug. I have seen a broken P14 locking lug - one of the strongest out there. (But I have no idea what broke it - I'm just saying they can break). Regards 303Guy | |||

|

| One of Us |

303 guy: I think you saw a case of chicken vs the egg! I suspect the receiver was soft and already peened and finally got peened back far enough to blow a case and also bind. In regards to the lug failure on the P14, the bolt(assuming it was the bolt's lug???) may have been over stressed in another gun due to an overload or bore obstruction; if it was the lug in the receiver, the same is my suspicion, an overload somewhere along the line. Still you can't rule out bad QC on the parts. PA Bear Hunter, NRA Benefactor | |||

|

| One of Us |

In the mid 80's, a elderly target shooter complained to me that his .308 ammo was "no good", the cases were separating on the second reload. His chamber was spot on, that is within 0.001' of zero headspace, so I had a look at his cases, and he was right. I would not fire the cases a third time. Why ?, his technique was wrong, the FL die was screwed HARD down on the shellholder and on resizing, the shoulder was pushed back over 20 thou. Excessive headspace all right but in a perfect chamber. Arte et Marte | |||

|

| One of Us |

A good general primer on .303 British headspace and case problems is here; http://www.milsurps.com/showthread.php?t=9026&page=2 Arte et Marte | |||

|

One of Us |

You are quite right, airgun1. The rifle in question had an excess headspace problem to start with (I dismantled some of the loaded rounds that came with that rifle and it was scary!) I did warn the owner but he chose to ignore me. The case did not blow. It was just the peening that eventually jammed the bolt. That P14 lug really surprized me. It must have some flaw. A gunsmith showed it to me. Thanks for the link KimW9. Very interesting! I am beginning to understand the disfavour the Lee Enfield has 'earned' itself. Pity really, it is actually a fine rifle and an excellent bush rifle. I have recently learned that it also makes a very good cast bullet rifle! Ideal maybe, since it does best with lower pressure loads and heavy bullets. Regards 303Guy | |||

|

| One of Us |

One major problem in these discussions developes over various datum lines, belts and rims. Bah, humbug! All that's for engineers and, occasionally, gunsmiths. For shooters/reloaders all that headspace means is the space for the loaded cartridge to fit into. I think it can be demostrated that most rimmed and belted cases actually stop forward movement on the shoulders and reloadeers can control that, at least after the first firing. If the case fits the chamber snugly there is no excess headspace and that should be our goal. Attempts to measure headspace in thousanths is difficult and really irelivant to our needs. Do we measure from the SAMMI max? Or minimum? Or at midpoint between the two? Then, if/when we get that precise measurement, what do we do with it? I just size my cases to fit the chamber it will be used in and forget it! | |||

|

| one of us |

.005" Here is a must read from Brownell's Brownell's | |||

|

| One of Us |

Actually, according to the SAAMI site: HEAD CLEARANCE The distance between the head of a fully seated cartridge or shell and the face of the breech bolt when the action is in the closed position. Commonly confused with headspace. HEADSPACE The distance from the face of the closed breech of a firearm to the surface in the chamber on which the cartridge case seats. http://www.saami.org/Glossary/display.cfm?letter=H | |||

|

One of Us |

Good point pisces What we are talking about when we talk of dimensions like .002" or .008" is head clearance. Head clearance is part of the larger dimension of headspace which is from the bolt face to the seating surface. Headspace will always only vary by the dimension of head clearance so that is why the topic is usually discussed referencing the abbreviated dimension of head clearance. I will be careful in the future to use the terms appropriately. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Fired some of the cases which were failing at a 100% rate today. After sizing them in a .270 Winchester die to 'lengthen" them. Result was no visalbe case failures, but I will still toss the brass. I am confident that oversizing, and many usages of the brass are the factors most involved. Thanks for the replies and knowledge.  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | |||

|

| one of us |

As far as I'm concerned, the difference between head clearance and headspace is simply one of semantics but if we use these terms correctly it does make the discussion easier. If the question is about headspace on a belted magnum, the minimum is .220" and this is what a "go" gauge should measure. In most situations, this will rsult in a head clearance of about .005" or more since this head-to-belt measurement on most brass will be around .214-216. If a cartridge is reloaded with a head clearance of .005 the result will be a case head separation inside of five loadings. The "no-go" headspace measurment on a belted mag is .223". This would yield a head clearance of roughly .008" with most brass. I have seen belted brass where the measurement from head to belt was as low as .212". Up until today, I had never seen a belted case which measured over .218 (except the 450 marlin, of course). Today, I ran into a factory cartridge which would not chamber in a rifle in which the headspace was precisely .220". Mystified, I measured the cartridge from head to belt when I got back to the shop. It measured .2215" on the higher side and .220" on the lower (wasn't even). All the other cartridges in the box were the more typical .215-.216". In over thirty five years of messing with belted cases, this was the first I had seen which was over-spec. A good reason to cycle even factory cartridges through the rifle before heading out. I had the feeling that I could have forced the bolt closed but this would almost certainly have galled the lugs on the stainless bolt. If the rifle was chambered for a rimmed case with negative clearance (otherwise known as interference) of .0015, there would be no way one would close the bolt without causing some damage. Rims don't compress. 308Sako, I understand how you are using the 44 Special case and, while it won't give you a true "headspace" measurment, it is a valid means of comparison. If you sized that 44 Special case so the mouth had an ID of .375, you could actually get a true measurement to the datum line which could then be compared to a spec sheet for the cartridge. Of course, this would tell you little regarding "head clearance" in your rifle. As far as determining head clearance is concerned, the "shim behind a case or gauge" method is as good as any. 50 pieces of 308 brass should be enough to wear out a barrel if they are reloaded corectly. Regards, Bill | |||

|

| one of us |

A long time ago I changed the barrel on my 6.5 Swede with a take off I bought for $20. I made my own barrel wrench and receiver wrench. Not having a lathe at the time or any gages, I used a new unfired case and masking tape. I put one piece of tape on the shell head and it would chamber. Two pieces had a little drag and three pieces would not allow the bolt to close. The only way for me to adjust head space was to carefully stone the front of the receiver so the barrel would screw in farther. It took a little thought with the thread pitch but it came out perfect after the barrel was locked in tight. From then on the brass was sized so the bolt would just close with a little "feel". Even though this barrel still has pits in it, it holds 1/2" groups all day and has taken a lot of deer. Brass lasts forever. It shot so good I customized the rifle with a piece of cherry out of my woods. Now when it comes to belted cases, it is not a good idea to depend on the belt for head space because of all the variation in brass. The shoulder should be used once the brass is fired. I can see a problem with new brass having too high of a belt but most are too short and create more head space then you need. Your size die settings are more important then what the head space is. All of those measurements to a half thousandths are not needed, just let the rifle tell you what you need to do. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Regarding Headspace, what is the

Regarding Headspace, what is the

Visit our on-line store for AR Memorabilia