The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Pressure signs

Pressure signsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

quote:Clip taken from Speer Reloading Manual #12 on P 55. "Case head expansion [CHE] testing should be made with once-fired cases of the same make and from the same production lot... New cases can give deceptive readings. The first firing of any case will usually cause more deflection of the brass than subsequent firings. At Speer, we start with once-fired brass so the initial deflection is already accomplished." If this is truly the case, then we are not able to establish a baseline from firing factory loads. Doing so will just introduce error into the system. As is my understanding, establishing a baseline from once fired cases is only valid when using Pressure Ring Expansion (PRE). In this instance a factory round is fired, the PRE is measured at the bulge just above the case head with a micrometer, and then FLS or P-FLS. Upon loading and firing the same cases, the PRE is again measured. When the expansion of the reload equals the expansion produced by the factory round in the same case, it is believed that you have reached a similar pressure. The two are very different, and we shouldn't have a mixing of the two procedures if we want to establish the validity of the method. Unfortunately, this seems to be another problem of pressure via expansion. There is a blending of the two methods, and no real clear outline of it. For now, we are testing the method that HotCor believes to be true. Turok | |||

|

| one of us |

Turok - well, Iwanted to quote back to you two(2) passages that counter your quote from Speer, but I lost it, and am not going to retype them (sorry). In short, Developing Pet Loads by Ken Waters (which is the topic at hand) specifically uses factory components as his comparison measurements. And, In Precision Handloading by John Withers, he addresses your point directly, and states that the pressure and velocity results between factory assembled brass and once-fired brass are "close enough for the needs of the handloader when the objectives are safety and relative chamber pressure comparison." Just to keep the playing field level. Keep an eye out for the results - we are in the process of weeding the particulars out. | |||

|

| one of us |

Previously posted by Hot Core: "In my last example when measuring PRE, there is absolutely NO REASON to use New Cases if you don't want to. Take any Case you have that has been loaded "6-9 times", do either a Full Length Resize or a Partial-Full Length Resize(so the Pressure Ring is reduced from the Expanded position), reload it, fire it and measure it. In fact, since this particular one shot Test is not "Developing Loads from Below", feel free to use a case that has been fired any amount of times you desire, because you will still see PRE. (That would not always be true for CHE.) Turok, I think I may have misstated the .0005" expansion. It does only apply to CHE and does NOT apply to PRE, as you pointed out. I believe Dentons cases if fired and resized on this first round will give us no base line for PRE. We will be able to get a CHE baseline on the first round and the second round we could get the PRE baseline "for the pressure Denton is averaging" when they were fired. The second round would give the second CHE number we're looking to compare. A third round would be needed to confirm the repeatability of the PRE measurements giving us a second number to compare. For a total of one FLS measurement and two seperate fired measurements. As Hot Core indicates, he believes PRE to be a better indicator than CHE, and he may be right too. Unless Denton is willing to buy factory ammo loaded at factory pressures, the PRE benchmark will be based off of his handloads PSI. We do have PressureTrace's strain readings to give a value for this and to compare to, and I'm assuming Hot Core is saying a book max load and MV for a "cieling" works for a benchmark just as well. I'd rather start with once fired brass for the CHE test using it for a benchmark but, it sounds like 2-3-4 X-fired brass will work almost as well. | |||

|

| one of us |

sometimes these discussions get completely out of hand. The goal of making a safe handload to me is that it will work in the hottest weather, with easy extraction, primer pockets won't loosen up in 7-10 firings, etc. Whether another method is 5000 psi closer to being exact doesn't matter to me. You won't damage a rifle by following the CHE method, I don't have to have anyone explain why it doesn't work, I've done it too long. I thought about buying the M43 Oehler machine once, until I found out the pressure was based on the estimated pressure of a factory round that no one really knows what the pressure is in my rifle. I sure wouldn't want to base my handloads on the pressure of current .243 factory ammo which often chronographs 2750 with 100- grain bullets, quite a bit underloaded. If you dig out an old Hornady manual, I believe a 1973 model, where they describe the CHE expansion method they used. I was using it several years before that, as I started loading when I was 13 years old. I have a deep suspicion that I've fired more rounds than some people, and I have also had exactly 0 rifles that had the locking lugs set back and some of these have worn out three barrels. All this reminds me of a friend that was trying to mark the timing marks on the balancer of a race engine. I told him how to do it by running no. 1 to TDC while on the compression stroke( by watching the piston come up as the intake closed) and locating it with a dial indicator. While I was doing it and old timer came up behind me and said it didn't really matter, just get it close and put a mark on it for reference, since what you're going to do is change it until the car runs the fastest, all you need is to know what mark to set it on. Who cares if it says 40 degrees, 50 degrees, or 60 degrees. The whole purpose is to make a safe load and establish a reference point. Basing it on a factory load that hasn't been pressure tested in your gun just makes no sense to me. If the method produces 65000 psi and it's safe in 110 degree weather, case life is good, extraction is easy, that's OK with me. If they come up with pressure testing equipment that will measure it, not base it on an unknown I'd be the first in line to buy it, just as I was one of the first to buy a chronograph, which I still have and it still works after 31 years. | |||

|

One of Us |

In my reloads I've used the loading manuals (and several of them for verification of suggested loads) I've used a Chronograph, I've visually scrutinized primer appearance after the shot, and I've miked cases looking for growth. On rare occasions I have no data (such as loads for my .204-.223) and am relying on purely primer appearance, case growth and velocity. Now I'm hearing that this is inadequate...Hey guys, it's all I had to work with!!! Someone said something about a strain gage and an electronic readout. Will someone tell me more about this technique?...Who markets it?..Is it really good?...cost? | |||

|

| one of us |

Oehler makes the most common one I know of, the M43. the M43 does a number of other things, but includes a strain guage that is glued to the receiver of your rifle and will give you a relative pressure as it is compared to a factory load. My understanding is if you assume (I hate to hear that word) that factory ammo for a .30-06 is 55000 psi, it will give you a very accurate reading of the pressure in your rifle. I was only using the .30-06 as an example, it will do a number of other functions as well, look up the Oehler web page and have a look. | |||

|

| one of us |

quote:I have Ken Waters Pet Loads and in looking through his method I have found: quote:Yes he does use factory loads, but he is also using a Pressure Ring Expansion, not Case Head Expansion. The two measurements are taken in different locations of the case as I previously mentioned. He is not recommending using factory loads for a comparison when performing Case Head Expansion. This does not go against the quote from Speer. According to them you will get erroneous readings when you take your Case Head Expansion measurements off of the first firing of any case. I don�t have Precision Handloading, so I can�t say, or know what was stated there. Just to clear things up, Case Head Expansion, measures on the solid portion of the case. The best example to use for CHE is on a magnum case. Here you would measure ON the belt. For Pressure Ring Expansion, you measure just in Front of the belt. Vapodog PressureTrace can be found at the following link: http://www.shootingsoftware.com/pressure.htm Denton is the man to talk to about how good it is. He did the stats check on it. It is $189 US, BUT you also need a laptop to run it on. Anything that will run W98 will run the software. Turok | |||

|

| one of us |

Turok - making sure I am on the same process as you. The pressure ring being the point on a case where the sizing stops , usually directly at the top of the web in a case. And case head being the point on a case just above the web, where the brass begins to thin. How close am I? Maybe I don't fully understand the location of the pressure ring? (the visual ring at the web section of a case) | |||

|

| one of us |

You can normally see the pressure ring as a brighter ring around the case. It will be where the brass in the case head thins down, say about where the belt would end on a magnum case. You also should be able to feel it with your fingers easily. | |||

|

| one of us |

jstevens - you seem interested for a topic that got out of hand. Really, we are all just interested in going a farther into our handloading process - call it complete understanding of the process. I agree with you, as I've been reloading for 17 plus years now, and haven't had any guns come apart from my handloads. The difference is I am now getting to the point where I am actually understanding what goes on - this discussion is part of a learning curve (which no one person is ever above). Where is trg (original poster) - I hope you're learning something through all this. I have, and still will. Alot of different views have been stated. | |||

|

| one of us |

Alright, we can solve this methodology quandary very simply by using once fired brass. None of the authors mentioned argue AGAINST using once fired brass from factory loads. If that's what we use, no one can argue that part of the experimental design. JMO, Dutch. | |||

|

| one of us |

Turok and Dutch win the day on this one. I'm going to go get some factory ammo and shoot it. I will then add that to the experiment. We will have PRE data off 2-4x fired brass, which everyone agrees is OK, CHE off 2-4X fired brass, which some people say is OK, and CHE off 1X fired brass, which everyone says is OK. I'll run the stats for all these variations, and we can report on all of them. Ahhhh! Wait a minute! Wait a minute! I just remembered where I have a stash of exactly once-fired brass. T/C, if it is still there, I'll number it and get it on its way today. The calibration of the strain gauge system is NOT based on a factory round of unknown pressure. Factory rounds are used as a sanity check on your calibration, which is derived from the dimensions of the barrel, the properties of steel, and the gauge factor of the strain gauge. I've looked at the lab procedure at Hodgdon, and I consider it to be excellent. However, I don't find anything in their procedure that traces pressure to fundamental physical quantities any better than the strain gauge system does. They do have the advantage of a "cross check" with other systems, using special "calibration ammo", which we do not. Almost any measurement system is better than no measurement system. My issue is that before I rely on a measurement system, I want to know how repeatable it is. Besides being fun, this exercise will tell us that about PRE and CHE. | |||

|

| one of us |

Well, either we lost everybody or those interested in what's going down are in agreement with the process. Dutch,denton, Brent, and myself are posting our thoughts as we go along here. So, if anybody on the board has any disagreements and/or different ways, please jump in. | |||

|

| one of us |

I'm getting things together and walking out the door to go shoot for the day, no time to type. You send as many cases as you like my way and I'll get them back to you measured right away, the more the better... Once fired sounds good too. I believe you guys are on the right track on where to take the measurements but I've got no time to comment now, I just got the emails this morning too. | |||

|

| one of us |

First batch of cases are in my possesion. Geez, with rims like these little buggers have, I may not even need a jig...... | |||

|

| One of Us |

What happened to this? | |||

|

| one of us |

I know pressure signs when i see them. Some photos here.> Photobucket pics Old Thread but a good one. | |||

|

One of Us |

Hey, this looks like it was an interesting thread! (But I haven't read it from the beginning!) Regards 303Guy | |||

|

| One of Us |

Very interesting. What happened? | |||

|

| One of Us |

I have been using the CHE method for more than 20 years, it's easy to find the solid section of any case. It's the section just above the extraction cannelure, and the expansion ring is where the case walls and solid web meet. It's easy to recognise because it's larger in diameter than the soild web section. You will normally see a dull section below it, and chamber marks above it. Some cases show very little expansion, which really negates them from this due to low pressure. Hot Cor, I am of the opinion that the PRE method is not as accurate as the CHE method. I use CHE to tell me when I have reached my MAX, which is ANY expansion of the solid web, once this is noted, I back off to the load that showed no expansion. Quite a few years ago, I took factory ammo and fired it, pulled the bullets and powder from several others, and reloaded the once fired factory cases with the exact same components, fired them and measured the CHE. There was NONE! This was in factory loaded 300WM 180gr loads from Winchester, when the advertised velocity was 3090fps. Rifle brass these days seems to be harder than that of even 10 years ago, so who knows what pressures we're getting, as long as the brass lasts and there is no primer pocket expansion all's good IMHO. I do keep an eye on velocities, but I also load for several cases that there isn't good info for, and have to develop my own loads. I even develop my own loads with powders that have little info on, and I have only ever blown one primer in all this time, but that was due to very high temps at the time and the ammo had been in direct sunlight for some time. Cheers. | |||

|

| one of us |

Hey 416, Nothing wrong with your Method at all. It is what all Reloaders should be doing instead of fretting over all the other insignificant Pressure Indicators. I like PRE because it also works well for me. But, it also has it's Tricks. When you are using CHE you might occasionally notice the "After Firing " measurement is a bit smaller than the "Before Firing" measurment. That is due to the Case Head expending in a slightly Ovate shape rather than completely Round. So by using PRE and CHE at the same time, I can still watch the Pressure as it is Increasing. Works well for me, but you should always use what works the best for you. And as I mentioned way back on page 1 of this fiasco, PRE is the "Only Method" that will work properly on the old Low Pressure cartridges. Best of luck to you. ----- I can't say for sure, but this is either a thread where the "Results" proved the fools wrong, or where the main fool "Bogied the Info(not Data)" and proceeded to make all kinds of Bogus Charts and Phoney Reports based on his ignorance. You still occasionally see links to the Phoney Bologna by people who don't have the proper education and experience to know any better. As you well know, - if - you do not perform the measurements properly, then the results will be as worthless as those coming from a Haphazard SGS. | |||

|

one of us |

HC I problem with this line of thought. How does a solid case head expand in a "ovate shape" from pressure that is applied from one direction only on brass that is supported on only the opposite end? I understand PRE expansion being somewhat oval due to variation in the case wall thickness. Case heads however shouldn`t do this IMO. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| one of us |

Hey Ol` Joe, Good questions. I believe it is due to the Case Head thickness being ever so slightly "thinner" on one side. As you know, nothing man-made is perfect, and when the Forming Dies are making the Cases, even though they try their best, things are not always aligned to 0.000,001", plus wear and perhaps dropping. I'd be interested in learning from anyone that knows better than that. I do agree CHE would be even better than it's current "near perfection ability" Try it and you will see. Then tell me what's happening. Best of luck to you. | |||

|

| One of Us |

Seems like it (ovate CHE)would be due to inconsistencies in the case wall thickness or alloying. I do not think that the expansion of the cylinder can occur 100% equal along the entire length and circumference of every case, every time. I would bet that the smaller sides of the ovate would also measure a touch longer in length. My calipers don't measure to the .00001ths so I can't confirm. | |||

|

| one of us |

What Kelbro described - Case Wall Thickness Variance - can easily be seen on 99% of all Cases when you measure PRE. As you "rotate" the Case between the anvils, it is easy to locate the wider spots. And of course, the Widest Diameter is the PRE that you are seeking. Over five decades of doing these measurements, I've only had a coule of rifles and Case combinations where there was not a Wider Spot when measuring PRE. Have one right now which is a 243Win M7 with R-P Cases. My guess is this specific Lot of Cases has extremely low variance in the Case Wall Thickness. And of course being in the "Round" Receiver of the M7 there is no reason for the Chamber to be forced into an out-of-round condition like you will find on M70s and Mousers. | |||

|

| one of us |

Hot Core wrote:

Wrong, wrong...wrong. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

Hot Core wrote:

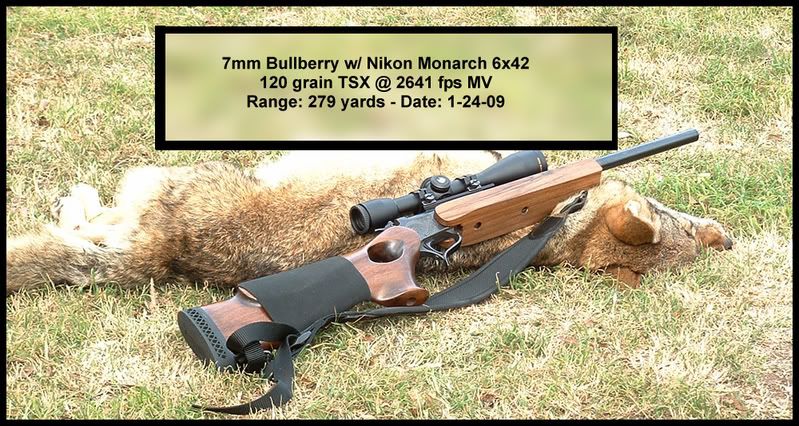

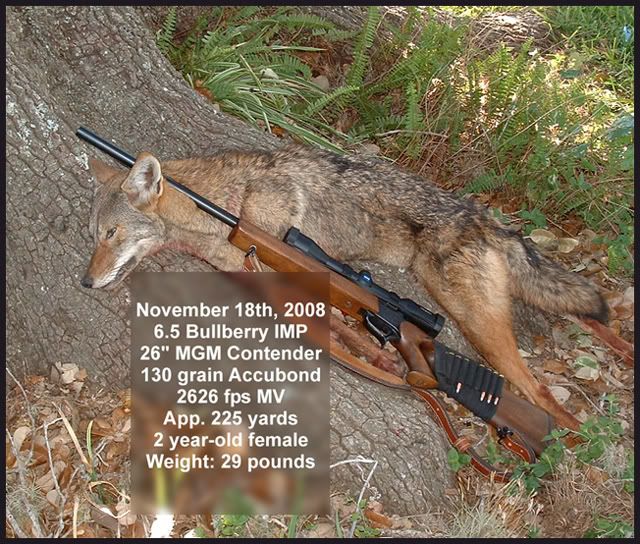

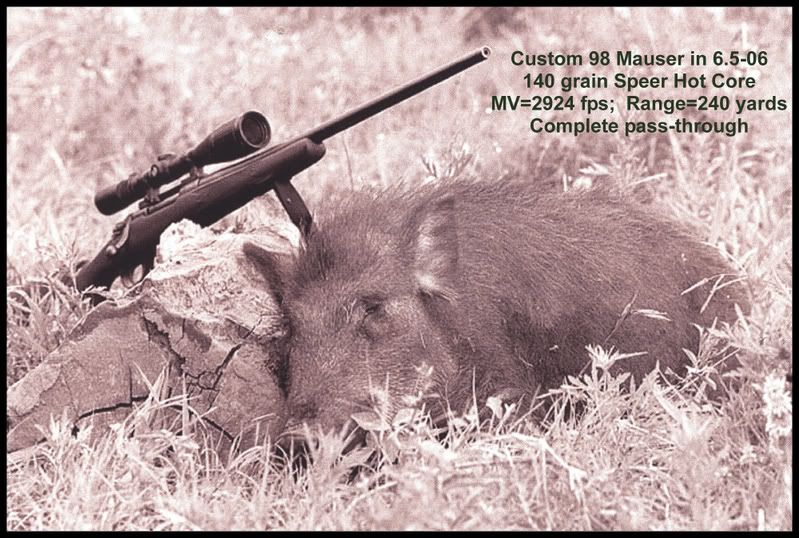

Hmmm...the only "Mousers" I have seen in this area of the state are always "out-of-round" but generally do respond to proper varmint calling techniques. This is what the "mousers" around here generally look like:    But if they've become the target of my attention, they may look more like this:     Of course, for sake of measurement purposes, perhaps below is the kind of "Mouser" you meant. Is so, that one is actually a "Mauser."  Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

one of us |

Wall thickness is evident when neasuring "PRE". This is taken at the point the case wall meets the solid case head. "CHE" is measured on the solid case head. There is no wall involved just a solid cylinder of brass with a flash hole/primer pocket at the core. I am in agreement with HC that a ovate expansion is very common when measuring PRE, I just don`t get the reasons for a similar finding when pressure is applied evenly to the top and bottom of the solid cylindrical head. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| one of us |

Yup, that is a Mouser to me. | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia