The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Annealing: Stretch out Brass Life...

Annealing: Stretch out Brass Life...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

have been playing with stretching out brass life quite a bit.. it was timely since all of this shortage and high prices of components came along... I have found that using a good neck sizing die and having a body die, instead of a full length sizing die is also helping stretch out brass life substantially...on a set of 223 brass I am now on 60 reloads! and it is going strong, although not nice and shiney.. the final thing I have learned is to Anneal... I was thinking that maybe once every 10th reload would suffice... however that still developed a few neck splits at 8 or 9 reloads... So it was actually a newbie that brought up that he anneals every 4th reload... so I thought I'd try that... needless to say, that turned out to be good advise... so for you folks that have not been annealing, it is a practice to worthwhile learn... I have reloaded for years but never annealed... brass was cheap, available etc...times change... got set up for what the cost of a bag of 100 pieces of say 17 fireball brass runs...and it has already yielded more than the return of my initial investment... especially if you are a varmint shooter who goes thru a high volume of shooting... 60 times on some 223 brass now, and just passed 40 reloads on some 22.250 brass... also just learned the joys of getting my first switch barrel for a Savage rifle I am setting up... one where I bought just the action they sell, and then got an aftermarket barrel in 7/08 and bought one on line here as a take off in 25/06, which I am having rechambered into a 257 Roberts... but that is another story! but I am also having a lot of fun doing all of this stuff... wife loves it too.. keeps me out of her hair..loL... | ||

|

| one of us |

I agree. Especially when using brass like 300 H&H that's more expensive or harder to find. I also anneal for a wildcat that's based on a shortened 300 H&H case. When I didn't anneal I got splits at the case mouth. But I annealed the next batch and no splits. I usually reload in lots of 100 for each caliber. After 4 or 5 firings, it's time to anneal. | |||

|

One of Us |

Years ago, I annealed my 303 Brit cases a few times but then forgot to and didn't shoot it for a while. Necks began splitting. I saved the rest by annealing. Those cases that have survived the last 25 years have an unknown number of reloadings. But 60 reloads is impressive! Regards 303Guy | |||

|

| One of Us |

I've never tried annealing - just seems to be too much trouble to me. Hack | |||

|

| One of Us |

Annealing about every 5 reloadings has worked very well for me for many years now. Probably don't need it quite as much if using a collet sizer like Lee's, but it sure doesn't hurt. Once I get all my ducks in a row things go quite smoothly & rather fast, considering. There are a lot of opinions & methods out there but all it really takes is a propane torch and a cotton towel. Many wildcats and Improved cartridges really need annealing before the first firing, and case life is greatly improved and extended for any cartridge. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

One of Us |

The way I do it is actually quite fun. I get the impression that annealed cases seat bullets straighter. I have a simple neck sizer and seater that does not support the case body. Regards 303Guy | |||

|

| one of us |

How do you guys anneal your cases? I am at 8 times plus on my 300 win. Thanks Windage and elevation, Mrs. Langdon, windage and elevation... | |||

|

| One of Us |

I have a variety of torches that are propane fueled by the typical bottle and by Ronson cigarette lighter propane. The small pencil & micro torches seem to permit a little better control of the heat. I would not have such a selection of torches but I wnet to a gargae sale and got 8 torches for about $6 along with about 10 lbs of solder. | |||

|

| One of Us |

I have necked sized the brass before annealing and afterwards both... where you speak of everything being concentric... they sure flow like butter when seating the bullets after annealing.. just thinking out loud, I wonder if you were loading for competition, how it would work out on neck sizing the case, seating a dummy bullet, anneal it and then using an impact hammer, pull the bullet.. then prime, charge and reseat your target bullet.... | |||

|

One of Us |

Well, how about the Lee Collet die on an annealed neck? How about using the Lee Collet die to size onto a 'dummy bullet' (ie a mandrel of bullet diameter)? Mmmm.... annealing onto a dummy bullet would be easily do-able. If I don't get laid off on Tuesday (it's the recession thing) I shall give it a try! Regards 303Guy | |||

|

| One of Us |

Hey guys, I am new to annealing but would love to try it with my .500 NE cases. These cases are VERY expensive and sure would be nice to extend their life. Can you provide the details on annealing for a newbie, please? Thanks, | |||

|

| one of us |

500 Straight, I concur, I would like to know the various loaders annealing methods. I was set to pull the trigger on the Ken Light annealer and several different size wheels for it, but pulled in the reigns when my job evaporated recently. I'm still thinking about it, but more willing to try less expensive methods for a while for sure! | |||

|

| Moderator |

i anneal to save brass, either expensive in $$ or time to make .. have for years, as its the only way to get 7+ reloads, out of all your brass.. even straight cases are improved. opinions vary band of bubbas and STC hunting Club Words aren't Murder - Political assassination is MURDER Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I have a stand built that allows a battery drill to index to the same position every time set about 30 degrees above level with the gas torch in a set position. With a deep socket ( 10mm for 221, 12mm for 7x57 and 14mm for 404 sized cases), it is as simple as putting a case in the socket and placing it on the stand for the apropriate time and tipping the case out into a ss bowl. I have worked on a count of 4, 5, or 6 sec for the different sized cases. I spent time in darkened area doing this with waste cases till I found the point BEFORE the case started to change to red hot. It does not need to get red hot to propperly anneal the neck area.This also means the heat will not be so severe that it will need to be put into water to prevent heat travel to soften the head of the case. It is quick, simple, mess free and can be done every reload. Von Gruff. | |||

|

| One of Us |

My method is very simple but isn't quite as precise as others, however it's worked well for me for many decades. I use a propane torch pointed upward at a comfortable angle, with the cartridge case pointed upwards and held at the rim with my bare fingers. I rotate the case mouth in the flame, ensuring that the entire mouth gets heated at about the same level, then drop the hot case onto a cotton towel. The neck doesn't have to get red, in fact it's much better if the color never reaches red but rather a sort of gray. As long as I hold the case in my bare fingers, the head can't get hot enough to soften it. The only caveat I've found is that the operator must operate quite rapidly when annealing short small cases such as the Hornet or Bee 'cause the operator's fingers will get pretty hot pretty fast. I've used this method on everything from K-Hornets & Mashburn Bees to 45-90s & 50-110s for decades now, with good success. The annealing wheel is much better but also is much more expensive. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

One of Us |

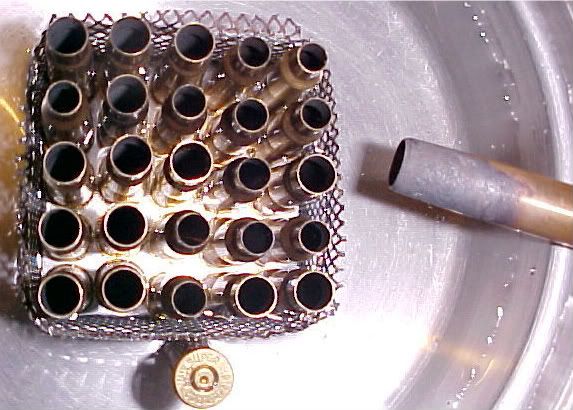

Mine evapourated too! I stand my cases in water in a basket with fired primers still in place. I use a propane torch to heat the necks until the colour changes or I can see a dull red on the neck interior. The annealing stops a way up from the water level so one has to figure out the correct standing depth. Once done, I remove the basket and that's it. No drying of cases and all that (other than an external wipe).  Regards 303Guy | |||

|

| One of Us |

I anneal my cases in order to extend the life of the brass, but more importantly to ensure that the brass is reset as near the original ductility as possible. This aids in sizing, seating, and especially for uniforming bullet release and start pressure. In order to do that each case must be heated quickly and evenly which cannot be done in batches with a single propane torch. Standing the cases in waster works at the factory where heat sources more intense than propane torches are used, since the water acts as a heat sink. For a very good idea of how to anneal properly, especially for brass used in match shooting, the archives at 6mmBR.com and benchrest.com are worth exploring. You can't really hurt a case by warming it up, but the efficacy of doing so is doubtful, at best. If the enemy is in range, so are you. - Infantry manual | |||

|

One of Us |

Yes, it is difficult. I flame them from three sides in a sequence to get as close as possible to even. I have found my case easier to size and load and they do seem to seat straighter. To compensate for uneven annealing, I do it with every reload - that way they should all remain fully annealed and reasonably even. I hope! Regards 303Guy | |||

|

| One of Us |

In a past issue of HANDLOADER magazine, John Barnsness wrote an article regarding annealing. It seems a friend of his, who is a metallurgist, was experimenting with different heat sources, and found a plumber's candle to be sufficient. Holding the case near the middle, he turned the case neck in the flame until it got too warm to hold, then dropped it onto a wet cotton towel. Cheap, simple and effective, per the scribe. | |||

|

| One of Us |

Can I ask who that noob was that got you to anneal after 4th time? Cooper .223 - Burris 8-32x50 JR Custom AR-15 - Burris 8-32x50 Mil-dot | |||

|

One of Us |

What is a 'plumbers candle'? John Barnsness has been 'flamed' for claiming case necks can be annealed using a 'candle'. Definately not a 'lighting' candle! It seems that, according to the 'metallurgist friend', I have been over doing my annealing! It's not so much my method but the heat I have been applying. As yet, I do not really know. (And, apparently, no amount of sizing will reharden the necks? They seem to work OK but are definately soft. I was able to expand a 303 Brit case neck up 375, re-anneal it, and size it down to 303 again, then back up to 375). Regards 303Guy | |||

|

| one of us |

I read in Precision Reloading about an annealing tip for my propane torch. I bought it from the Woodchuck Den in Ohio. I just checked their catalog and they still list one in their catalog. If it's the same one I use, I can say it's very easy to evenly apply heat all around the case neck. www.woodchuckden.com | |||

|

One of Us |

According to Varmint Al, in a dark room, the dull red of brass becomes visible at 750F. I have a problem with the light from the flame so I look into the dark mouth. Apparently, if the case neck remains shiny after annealing, all's good. I hope so. Also, according to Varmint Al, cooling the brass quickly after the anneal is better as slow cooled brass grows larger crystals as it cools and it's the small crystals that we want. So, that answers the question of whether to tip into water or not. Yes, do! I won't be with the hope that with my cases standing so deep in the water already, they will cool down sufficiently fast. Anyway, they are soft as can be already, so .... Regards 303Guy | |||

|

| One of Us |

For what it's worth, I anneal by the fire of a portable propane torch. I place the head of the case in an appropriate sized socket and I use a socket extension. Taking Varmint Al's suggestion for a dark room, I put the neck of the case into the hot spot of the flame, turn the extension slowly and just bring the neck to a dull read--then tip the socket to let the case fall into a container of water. I have used this method or .17AH, .223, 6.5-06, 270 and 3006. Seems to work and is really simple. Good case life, and the neck & shoulder area have the same color pattern as military brass. Now, if I'm doing something wrong, I'd appreciate a heads up! Shotgun | |||

|

One of Us |

I finally got to range test my annealed cases. (I used the dull red glow on the inside of the neck as a guage while the cases stood in water.) Well, how does .6 MAO at 207yds sound? So for me it's a case of "Don't fix it if it aint broke". Regards 303Guy | |||

|

| One of Us |

Try this link to a very educational article about annealing cartridge brass, www.6mmbr.com/annealing.html. Most of us do not reload/recondition enough cartridges to buy the machine for a single reloader, but the information is still very good. The Editor's Note toward the end of the article helped me perfect my process. I use a shisk-ka-bob skewer to hold my brass. I reduce the end of the skewer so that it will fit through the flash hole into the cartridge case about 1/4 inch. The skewer is about 6 to 8 inches long so your hand does not get close to the flame and get hot. I also do my annealing in a "low light" room. This helps me determine when the case mouth is the proper color. I stand a standard propane torch (no mapp gas, this gets too hot too quickly) on my desk/workbench. I have about 2" of water in a container (2 qt aluminum cooking pot) on the desk beneth the the torch flame. I hold the skewer in my right hand and insert the small end of it into the primer pocker/flash hole. I then move the case mouth into the flame and rotate the skewer between my fingers slowly. Rotating slowly heats the case mouth evenly and I can observe the case mouth begin to turn color. This lets me know when to remove it from the flame and drag the case off the skewer on the pot rim into the pan of water to quinch the case. This may take a little practice but you can observe the annealed case and compare it to a military case. The heat affected zone of the brass will turn a slightly brownish color. This same discoloration is observable on military cases that have not been polished. When the discoloration on your case looks very similar to the mikitary case, you are close to perfect. If the discoloration is confined to the case neck, you need to hold the case in the flame longer. When the discoloration extends down into the middle of the case, you have applied too much heat. When the discoloration is limited to the case neck and shoulder, with a VERY SMALL amount of the case body, you have it pretty close. Another indication of too much heat in some of the larger calibers is that the shoulder is so soft that the bullet will not seat without distorting the shoulder. I use this explanation because it is very difficult for me to discribe the right color of red/orange/pink/whatever. I still think orange is a fruit. Annealing brass has helped me keep a lot of brass that would have otherwise been discarded. The first thing to go on a batch of my brass is the case neck splitting. This is the result of work hardening the case neck with repeated resizing. I have had this occur on the first firing of NEW brass, so I know that the brass was brittle when I got it. After annealing this lot of brass, I have 3 or four firings and not a single case neck split. With brass at $.50 to $1.00, this is well worth learning and requires some very basic tools and techniques. I'm still learning the tricks of the trade but if anyone has question I will try to help. Sometimes my explanations arn't as clear as I think they are. Good shooting, Duckhunter | |||

|

| One of Us |

I am using a propane torch and started just holding the case neck in the flame for a total of about 12 seconds...that way I don't need a dimly lit room etc..tried that lately and it is doing quite well... instead of water to cool them down, I just put them in the frig for a few moments since I have one standing there in the garage anyway... still not noticing any difference between that, letting them air cool or using the water method.. Life Member: The American Vast Right Wing Conspiracy Jan 20, 2009.. Prisoner in Dumocrat 'Occupied America', Partisan in the 'Save America' Underground Beavis..... James Beavis..... Of Her Majesty's Secret Service..... Spell Check Division "Posterity — you will never know how much it has cost my generation to preserve your freedom. I hope you will make good use of it." John Quincy Adams A reporter did a human-interest piece on the Texas Rangers. The reporter recognized the Colt Model 1911 the Ranger was carrying and asked him "Why do you carry a 45?" The Ranger responded, "Because they don't make a 46." Duhboy....Nuttier than Squirrel Poop... | |||

|

One of Us |

Oooh Hooh! Your Spitfire is back! Interesting. I had become worried I had overdone the annealing thing. I didn't mention that the case necks were a different length and I had mixed powder types (I could see a slight shift in POI). Maybe I just got an accurate rifle? Regards 303Guy | |||

|

| one of us |

Hey 303Guy, If you do a Google on "Plumbers Candle" you will discover it is simply a Candle about 1" or so in diameter. Interesting read about using the Wax from it to drip on a Wrag so Molten Lead could be placed on the Wax and "Wiped" into Pipe Joints by Plumbers. I'd thought "maybe" Plumbers Candle was a colloquialism for some kind of Torch, Propane, MAPP, Acetylene, etc., but no it is a Candle. The problem will not be the Flame Temp, but the amount of BTUs available to do the Annealing "quickly" so the Case Head is not Annealed at the same time. If that happens, then Case Head Ruptures are a possibility. As well as extremely short Case Life due to Primer Pocket Expansion with Low Pressure Loads. ----- So, I disagree with Mr. Barsness and the MIT PHD Metalurgist. And suggest if they had "tried it" they would have discovered they either had not Annealed the Case Mouths or had ruined the Cases. Nothing tricky about it - a Candle won't work. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Annealing: Stretch out Brass Life...

Annealing: Stretch out Brass Life...

Visit our on-line store for AR Memorabilia