The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Primers backing out - problem solved.

Primers backing out - problem solved.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I started testing handloads in a new rifle. I had shot 4 factory loads in it and they looked fine, so I used that brass (Norma) to start load development. On the handloads, the bolt lift is normal, and the primers are not flat, but they are backing out slightly when fired. I full length sized the brass the first time, but the second time I backed the die off the shell holder enough to size about 3/4 way down the neck, to avoid bumping the shoulder back. When seating the primers, they offer the usual resistance on the hand-held priming tool. This is a bit unusual, because the cartridge is 9.3x57, and I don't have good load data for it. The rifle is a FN Mauser 98. The only time I can remember this issue happening before, is in low pressure loads, but it's been a long time, and I want to proceed with caution. So, I'm using RL 15 powder and CCI 200 primers, and 250 Nosler BT bullets. The first batch of four was 44 grs to 47grs. I couldn't tell any difference between the first and the last. So, I tried one round with 48 grs, and the primer backed out a little more than the previous lighter loads. The last one was supposedly neck sized. Again, bolt lift was normal feeling, and no skuffs on the case head, and the primer is not flat, just backed out slightly. I probably wouldn't be having this issue, if I was familiar with this rifle, and especially if I had some good book load data to go by. I know about the Norma data out there on the net, but it doesn't do me any good since I have no Norma powder. I found some info on RL 15, and decided to proceed, but now I hesitate. Any suggestions? This may not be the best powder for this cartridge, because at 48 grs, it's a little compressed. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | ||

|

| One of Us |

You check the headspace on the bolt? | |||

|

| One of Us |

I have no tools to check headspace. Instead I did this: I tried some 8x57 Norma factory ammo in the chamber, and the bolt closed easily. I tried some fired cases from the same box, and the bolt wouldn't close on the empty fired cases. I tried some 8x57 cases fired in another rifle - handloads - and the bolt will not close. I tried some FL sized 8x57 cases from the same batch, and the bolt closed with resistance. I tried putting several layers of tape on the head of the 9.3x57 Norma factory ammo, pulling the bolt and fitting the cartridge and tape under the extractor, then feeding it into the chamber, but felt no resistance with maybe 10 layers of tape between the bolt face and the case head. What else should I do? Seems that based on 8x57 factory ammo, compared to 8x57 cases fired in two of my 8x57s, the head space on the 9.3 is tight, since the bolt won't close on cases presumably fired to fit a correct 8x57 chamber. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Hi there, Don't know if it's any help but I put your info into quickload and it comes back as max pressure for your 47 grain load. | |||

|

| One of Us |

Haggis, That's helpful to know. I think OXO's right. This head space issue is probably what the trouble is. If I'm correct that the headspace is the same as the 8x57, then I'm thinking it's not the chamber. I'm thinking it's the factory ammo, and brass. So, to get to the bottom of it, I'm thinking of making some loads with the bullet seated out enough to contact the lands, and thus push the case all the way back tight against the bolt face. That will fire form the shoulder for sure. Then I'll test load development in those true fire formed cases, and see if the problem vanishes. There are two problems with that solution. One - I hope it isn't a constant problem, because I hate to waste a bullet on a mild load just to fire form. Two - what's the fire form load? It has to be mild. So, check your quick load software - what's a mild load using IMR 4895 or H4895 - that will be safe with the bullet touching the lands? KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Kabluewy, I read somewhere that 10% of max was a good place to start a fireform load with the bullet touching the lands so based on a 250 grain bullet and H4895, I'd guess at 40 grains to err on the conservative side. Quickload gives this as approx 68% of max pressure but don't take my word for it, I'd wait for one of the fellas on the site with actual fireforming experience to pitch in first as I've never done it before... | |||

|

| One of Us |

Excess head space caused case head separations and not backed out primers. I'd say the pressure is too low. | |||

|

| one of us |

I'm not an expert, but I would consider an excessive headspace. | |||

|

| One of Us |

Sounds like excessive head space to me. I don't know anything about the load limits for your cartridge but if it's as much as it seems, it may take a couple of firings even with the case neck sized to correct the problem. I don't know that I'd go to the trouble of fire forming the cases. I think I'd just go ahead with my load developement and see if your problem doesn't correct itself. Aim for the exit hole | |||

|

| Moderator |

headspace or lug setback .. grumpkin, excessive headspace and and will case primers to push out, without being flattened.. it could be overly resized brass, which is effectively the same thing. opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| one of us |

No, no. You can't use masking tape to check headspace on a bolt action - the camming force is too great. That only works for autoloaders like the FAL. For bolt actions you have to use steel shim stock. Cut up cans, etc work fine. I tried the tape thing once on a Mauser and was able to put about 10 layers on the head too. Then I tried shim stock stuck on with a dab of grease. I was only able to put .003" worth on the same factory cartridge. I think the problem is too mild of loads. If you want perfect headspace, gradually screw down your sizing die until the cases chamber with the desired effort. | |||

|

| one of us |

I show the 8x57 and 9.3x57 have the same headspace. As to the 47grs of RL15 behind a 250gr being max. QL does show that however that a max is 37710. So even if your headspace is just to the long side of acceptable you might just be getting to a pressure point high enough to back the primer out. As usual just my $.02 Paul K | |||

|

| One of Us |

rr340, that's what I'm thinking too. I think it is both headspace and low pressure. The headspace caused by the shoulder too far back, and the chamber OK. The reason I don't want to just increase the charge is in case I'm right. If so, the case will probably stretch at the web, and at the least shorten its life. I measured the case length before and after firing, and there isn't much difference. So, I'm still thinking that I need to fire form the shoulder to the right place, not by increasing the load, but by seating the bullet out to the lands. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| one of us |

If you are concerned about your headspace then take a couple cases neck the up to 375 and then adjust your die to get a snug fit and compare. If you are going to reload anyway just go from there. As usual just my $.02 Paul K | |||

|

| One of Us |

FWIW, I may be more of a chicken than the rest of you, but if I suspected excessive headspace, which seems likely here, I'd want it checked with go/no go gauges to be damn sure and safe. If I didn't have any, I doubt what the gunsmith would charge to check it would be unreasonable. I certainly doubt it would seem a high price at all just after the worst case scenario (puns are fun) occurred. | |||

|

| one of us |

I couldn't find 250gr BT's in Nosler's 8mm section. I did find load data in Accurate, Speer, Nosler, Hodgdon and Sierra, but none offered data for that heavy a bullet. Forster has chamber gauge info. | |||

|

| One of Us |

I'm talking about 250 gr 9.3mm Nosler bullets. Not 8mm KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

I don't have a .375 expander. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

I don't have go/no go gauges. It would cost me $70 - $90 to ship the rifle both ways to a gunsmith, since I live on an island, in the middle of nowhere. As I said, my go / no go gauge was fired 8x57 cases, (in two different 8x57 rifles) and factory 8x57 ammo. The first was a no go, and the latter is go. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| one of us |

If you are curious. Go to the PO get a small flat rate box fill it with brass and $5 and send it to me I'll expand it to .375 and return. The flat rate is $4.95 I believe. As usual just my $.02 Paul K | |||

|

| Moderator |

use aluminimum foil or a gum wraper for shims... or even cut one out of a can opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

I may take you up on that. Thanks. BTW, I've never done that. I'm trying to envision how that's done. Say, if I had some 375 H&H dies, could I just run the 9.3x57 brass over the expander, and that would do it? I have a set of 375 H&H dies in storage, but I won't be able to get to them until this summer. However, that could be the long term solution to this issue. I may be able to borrow some .375 dies. In the meantime, do you see cause for alarm in me proceeding with the fire forming idea on a small scale, maybe 3 or 4 cases. You know - seating the bullets to touch the lands ahead of a light load of 4895? Thanks, KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

I'll try that. Thanks. I'm pretty satisfied that the chamber is not excessive head space. There are several reasons for that starting with the barrel is a fresh new one from PacNor. It was a pre-chambered & threaded barrel when I bought it. My old-time gunsmith installed it, and I know for sure he knows what he's doing. Besides it would be pretty hard to mess that up. Second, he and I discussed it, and he said he was headspacing off some 8x57 gauges he had, and he asked me if I knew any reason that wouldn't work, since he had never done a 9.3x57 before. I told him that I didn't know for absolute sure, but I was 99% sure the headspace is the same as the 8x57. I'm sure he didn't guess. Third, this action is in really good shape. It's like a good as new commercial FN 98. So, all that and the above cause me to think the shoulder on this brass ain't right. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| one of us |

I see no problem at all. The bullet should be firm in the lands not just touching. When I use a bullet to form I seat it long and keep seating it a little deeper until I can just close the bolt. Now I move shoulders forward .2"+. Going by 9.3x57 loads that are light I go to med heavy to heavy 4895 Loads. As to necking it up. lub the inside of the neck and run it in a 375 H&H die would be fine. The more tapered the better. I've taken 280 brass up to 416. Yet SEVERAL steps and anneal in the middle. But the step from .366 to .375 isn't much. Your idea of checking with the 8x57 brass isn't bad but like Jeffe and others said use foil or at least something stronger than masking tape. It is also way easier to feel if you remove the firing pin and shroud so you don't have to compress the springs. Last even new factory brass to spec and a chamber cut to spec with a light load can give you room for the primer to back out enough to feel. The firing pin moves everything forward the pressure moves the primer back and there is not enough pressure to stretch the case back to hit the bolt. As usual just my $.02 Paul K | |||

|

| One of Us |

Very good. Thanks ramrod. I'll post results. Incidentally, once I had a problem with a Ruger 77 MKII action/bolt, and I bought another complete bolt assembly off GB, as a wild card fix. So, the bolt fit really well, but the question of head space loomed. So, I tried the tape method mentioned, using that clear kind of tape used in offices everywhere. I took some cases fired in the rifle with the original bolt, and tried closing the replacment bolt with 2 and 3 layers of that thin tape between the case head and bolt face. I could easily feel resistance, and noticably less with two layers and one, compared to three, and of course no resistance with no tape. This was so reassuring that I went ahead and test fired the rifle with the replacment bolt. So far it has worked perfectly, and I sold the original bolt already. I know that's unusual, but it happened to me - twice. I also tried the same thing one time in a Mark X Mauser action - comparing two different bolts for head space. Same scenerio. Fired case. Three layers = noticable resistance, less with two, and none with no tape. In the Mauser, I tried a third bolt, but didn't get the same results, so I concluded that bolt would not be good to swap. I didn't actually swap the bolts in the MK X, and fire it, but I just tried it to see if it was close. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Well, I found out some things. First the chamber has a long throat. I had to seat the bullets way out there to touch the lands. Also, the bolt closes rather easily on a cartridge with the bullet seated too long. It simply completes the seating by pushing the bullet deeper into the case. I partially pulled a factory cartridge, and it seated back enough to allow the bolt to close simply by closing it over the resistance. So, the seated to the lands resolved the primer backing out issue. The fired primers look normal now, flush with the head of the cartridge. Not flat but with nice round edges and good solid center firing pin strike. I found a set of 375 dies to borrow, and expanding the case necks is the method I'll use in the future. It's too expensive to waste a bullet fire forming. The rifle is fun to shoot. Mild recoil. Now I need a good load. The powders I have are varget, IMR 4895, H 4895, IMR 4064, H 335, Win 760 (same as H414) RL 15, 3031, H4198. Plus some slower powder. Anyone have any load suggestions? Thanks, KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

If the primers protrude after fifing two conditions are present; The case is short for that chamber, and the pressure is low. A higher pressure would have pushed the case back over the primer. If you lightly oil a case it will come bach ovrt the primer and fill the chamber forward. This is now your correct size for that chamber. If you set your sizing die to it your concerns go away. By the way using a headspace gage or "Scotcj" tape look for a slight touch for a valid measurement. Good luck! | |||

|

| One of Us |

I'm very nervous about oiling the case and firing that way, and will find another way to resolve the problem. The reason for this is because a long time ago I had what may be an unusual experience, and then maybe it isn't unusual. I fire formed some brass for a wildcat that way, and I wasn't using a bullet, and later discovered setback of the lugs. It may have happened anyway, but I just don't know for sure. It was a 1909 action which sets back sometimes anyway. But I do know that such a method will drastically increase the back thrust on the bolt. Anyway, I vowed to myself to never do that again. I think you are right about the combination of two factors - the shoulder on the case being too far back, and low pressure. So, I borrowed a set of 375 dies, to expand the necks to .375, and then size in 9.3x57 dies until they squeeze fit. Also a fellow has PM me some data from his software, which will allow me to develope some standard pressure loads. Thanks, KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Kabluewy, I have been working up loads for the 9.3x57 for a while. Ive had some backed out primers also. Husqvarna 9.3s have varying chambers. I have 2 m146s. They have real long throats too, Im supprized you could even get the bullet to reach the lands. Anyway, I think R15 might be a bit to slow a powder, I like imr 4895 and imr 3031. With a 285gr bullet Ive loaded as high as 48gr imr4895/285gr bullet 46gr imr3031/285gr bullet with no pressure signs then backed both down 2 grains Neck size your brass only Go here too, for 9.3x57 load info http://forums.gunboards.com/fo...an-Sporting-Firearms Hope this helps | |||

|

| one of us |

It worked for me a couple of times; of course, it's somewhat empirical, but I could never apply 10 layers of tape on the head of the brass without feeling resistance; IIRC 3 or 4 were the max. I agree that there are better ways to check the headspace. | |||

|

| One of Us |

After a certain pressure is reached the case comes back with the same force oiled or not. This has been verified by measurement and finite element analysis. Good Luck! | |||

|

| One of Us |

In that case - damn and double damn 1909 Argentine actions. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

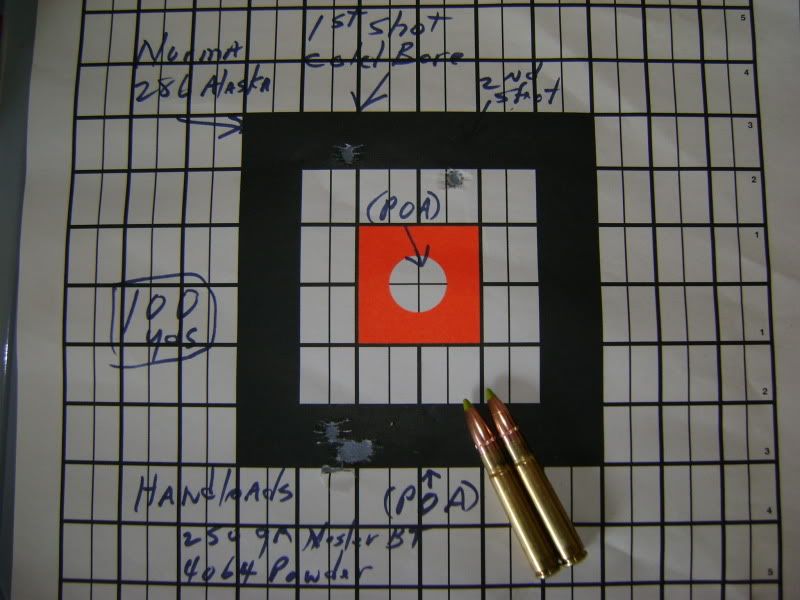

Ok, with a little help from ramrod, by PM, I think I'm on the right track now. Still using the same five cases, which haven't needed triming yet, tonight I settled on 4064 powder, and the same 250 gr Nosler ballistic tips. I loaded four rounds, increasing in one gr incriments, and went out the road, and blasted them at the mountainside. I won't give the weight of the powder, because the specification is max of 50,000 psi, which may not be a good idea in some other rifles out there. According to QL software, the top load I used is below the max as stated. I sized the brass this time only partially, avoiding set back on the shoulder, and when I chambered the round, I could feel slight resistance as the shoulder of the brass met the shoulder in the chamber. Anyway, short story, the primer backout problem has dissapeared, and I can't tell any difference in the least load to the most. They all look safe, with no indications of excess pressure. All the loads were slightly compressed, and I seated the bullet a little long, basically even with where the neck meets the shoulder, not counting the boat tail. So, now it's time to go to the range and test for accuracy and hopefully run a few across a cronograph. This has been fun and a little more of a challange than usual. Sort of took me back to basics somewhat. I had forgotten what FL sizing can do to a shoulder, and it probably wouldn't have been noticed had I not started with such low pressure loads. Normal pressure would have jsut stretched the case to fit the chamber, and probably the case life would have suffered. This has been a good reminder. Thanks for all your feedback. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Enjoy, that is a pretty hairy combination. Good luck! | |||

|

| One of Us |

What do you mean? Please be specific. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

With a full power load you are very similar to a 35 Whelen. If it won't kill somthing you shouldn't be hunting T-Rex's to begin with. Enjoy! | |||

|

| One of Us |

I noticed that my 35 whelen had sort of become boreing. This 9.3x57 is not my t-rex rifle. I have a 458 for that. Instead I'll use the 9.3 for velociraptors. Incidentally, I increased the charge two more grains, one at a time, and shot the two cartridges yesterday. Still no bad things happened. Hopefully this weekend I'll get to the range. Maybe I'll have a bragging target to post. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Andrew, I appreciate your concern. Yes I agree that it seems that the shoulder will set back on this case just from the camming pressure alone. I think that's because there isn't much shoulder there, as it is with similar cartridges such as the 35 Whelen. I do have another box of factory ammo, but I just haven't used it yet. I used the term "nothing bad happened" perhaps because I'm lazy about words sometimes. I just didn't want to be specific. "Bad" in this situation would be significant signs of excess pressure, such as sticky bolt lift, very flat primers, skuffing on the face of the cartridge head, excessive stretch, loose primer pocket, etc. In my case, something really bad happening isn't likely, because increases have been one gr at a time, so I should be able to see when to stop. And to answer your question - at some point, I absolutely expect to see some degree of the signs listed above as an indicator of too much powder. My point of course is that I haven't seen it yet, but I know if that was my goal, all I have to do is keep increasing the powder charge, and sure enough my goal will be achieved. However, that is not my goal. My goal is to reach a reasonable full charge load, test it for accuracy, and go hunting. I increased the charge because I had reason to believe that I had not yet reached the potential of this load/rifle combination. At this time, I think I'm getting pretty close, without exceeding anything. I might as well try to use the potential of the cartridge & rifle combo. Those factory loads are apparantly in the 30-30 class of pressure. I figured I might as well bump it up to modern cartridge preasure, for a strong bolt action, and use a 250sgr bullet. I'm curious what the cronograph will say. If I get 2300 fps, I'll be happy with that. But whatever it's doing will be ok. I have a 35 Whelen with a short barrel, and all I could get out of a 250 gr bullet is 2300 fps. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

I just got back from the range, so here's the picture. I'm happy with the results. Looks like a shooter to me, with the handloads. The factory loads didn't do well. It's encouraging that it shot well in the Hogue stock. I was worried that it wouldn't. I'll pull the rest of the factory loads, because they just won't do, and use the bullets elsewhere, and load a full box using the Nosler ballistic tips. I have a few of the Accubonds, sne I'll try them too. Hopefully they shoot to the same point. That's a leupold 2x7 VXII shotgun scope, with the heavy retical.    ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Primers backing out - problem solved.

Primers backing out - problem solved.

Visit our on-line store for AR Memorabilia