The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  Bareshaft testing on compound???

Bareshaft testing on compound???Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I need to figure out pretty quickly whether my shafts have enough spine for the 315 gr head, 100 gr insert and 100 grain external footing on my arrow. Nobody's' charts go that high. Arrow is an Axis ST nanotube 300, can cut them as short as 28.5" if I have to. Gives a total arrow weight 880 grains or so. I know the trad bowhunters do bareshaft testing, but I don't know how much it will help me on my compound. How can I test this? Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | ||

|

| One of Us |

That's a darned interestng question isn't it? Look at stu's arrow calculator [URL=http://heilakka.com/stumiller [/URL] You dont' say how much bow weight you have. The other thing is the external footing can stifen the arrow a bit if it's long enough so if you're arrow is weak you can fiddle with the footing length. For bare shaft testing go to the A&H archery website-they have the link for O.L. Adcocks ideas on barshafting. Keep us informed because this stuff fascinates me. | |||

|

| One of Us |

On second thought us trad guys depend on the arrow bending around the bow during the paradox and we can build up or reduce the side plate thickness to match arrow spine. You don't have anything like that but you do have adjustment for center shot. If it's a drop away rest I wouldn'g know what to do as ther is no "side pressure" If you have a plunger set up then you can tune the pressure exerted on the arrow to match the spine. I'm way out of my area of knowledge though because I haven't ever shot a compound so take my free advise as being worth what you paid for it | |||

|

| One of Us |

i can tell you how to tune with bareshaft tuning on a bowtech destroyer, as thats what i have and have done. i did it with yoke tuning by setting my rest at dead center shot and 13/16", set my nock height, and shot a bareshaft thru paper at 5 yards. i also set my cam lean (both cams) to the exact same before i started. with a tail right tear, put a half twist in each right cable (both cams)and test it again. repeat until you get either a bullet hole or a slight left tear. keep in mind to keep your ATA and BH in spec. to keep this while twisting, if you put a half twist in the right side, next time, take a half out of the left side, to keep changing the lean, but keeping your ATA in spec. but if you have a single cam bow or a hoyt cam 1/2, i dont know how to yoke tune. check out archerytalk.com and you can search around there and find lots of info | |||

|

| one of us |

Thanks for the info, guys. Lots of data on bareshaft for trad bow. Not much aimed at compounds. I have a Bowtech 101st Airborne, pulls 73#. No yokes. I guess I just suffer whatever cam lean is there? The "external footing" is one inch (100 grains) of stainless .049 wall tubing. Just enough clearance on ID for some epoxy and OD is 3/8", matching the 315 grain ABS Ashby broadheads. Last time I tested arrows on cape buffalo carcases I had several failures of the ferrule/insert/arrow where the arrow meets the BH. That was NOT with the ABS Ashby broadheads, but it's still the weakest spot.) The footing gives the best "gusseting" for the shaft/ferrule interface, and stiffens and protects the end of the arrow shaft. On these Axis ST arrows the Hidden Insert Technology means that there is normally no metal (insert) on the last 0.4" of the shaft. The external footing covers that up nicely. Some testing yesterday seemed to indicate that the spine was at least in the ballpark. I can get decent bareshaft groups at 20 yards, with the bareshafts grouping with the fletched shafts. I can rotate the nock on all the bareshafts 90 degrees at a time, and they still group together. I think that might mean the dynamic spine is both sufficient and consistent around the shafts. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

When you say you have a 100 gr insert are you referring to the arrowhead adapter? I use steel adapters rather than aluminum and they are pretty tough. I use grizzly broadheads with a single bevel they are pretty tough too. You might want to look at VPA heads they are machined out of a solid piece of steel-no adapters to fail. The VPA three blade head is bombproof and I hear they have a two blade out now too. | |||

|

| One of Us |

if your bare shafts are grouping with your field points at 20 yards, your bow is obv in tune. ive never tried to use dangerous game shafts, so i can't speak to the spine. for your cam lean, however, i think the 101st is a binary cam system. so i think you'd have to make slight adjustments to the cables, but if you're grouping b.s. and fp's, there is no need. what kind of speed and momentum numbers are you getting out of that bow with those arrows? the 101st is a fast bow. what are you going after with this setup? cape buff? | |||

|

| one of us |

Yep, Cape buff. The broadheads are Alaska Bow Supply (ABS) Ashby heads that weigh 315 grains, and are one-piece 440C stainless. I have brass inserts that weigh 100 grains. The footer adds 100 grains. Add the Asby and it's a 515 grain head. Ed Ashby's latest thing is Extreme Front OF Center (EFOC) arrows. The idea is to use the lightest shaft/fletches/nock that has enough spine for the head. It penetrates a lot better than same-weight arrows with normal/lower FOC. If I can get the FOC above 30% it will be in his Ultra EFOC group, which he says is the ultimate in penetration. The lightweight shaft is also less likely to bend/break at the insert or ferrule when the arrow has to change directions as the head breaks a bone then slides into the crack. I remember seeing the fletches slap when testing the heavy arrow/heavy head 900 grain arrows I took to TZ last time. Had some failures on scapula shots. One was a bent Grizzlie (!), two were bent/broken ferrule/adapters. I was using 125 grain steel adapers that I had case-hardened. No adapters broke, but some bent. A mature Cape Buff has some heavy and hard bones. Even the ribs are very tough and hard and likely to make a BH slide before penetrating. I was getting 220 fps from an 80# x 30" Allegiance last time. That's 96 KE, .87 momentum on an 895 grain arrow. My 73# 101st matched those numbers at 30" draw, but I dropped back to a more useable 29" draw and now get 208 fps/86 KE/0.83 momentum on an 895 grain arrow. Guess I'm getting old. Was considering an 80# Monster for this trip, but decided that it wasn't worth the hassle. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

thats awesome man. i hope to one day get to the dark continent and chase black death with my bow. it's got to be the ultimate bowhunt. i though you had to have a heavier draw weight by law though to hunt them? i guess it may depend on country, or i just heard wrong. i will try to read up on ashby's extreme foc stuff, i haven't heard of it. i just hunt north american stuff, mostly deer, so my easton a/c/c 490gr arrows at 285fps is plenty good for most stuff on this continent. how do your arrows fly with the extreme foc? and out of curiosity, what is the furthest shot distance you feel confident in when going after cape buff with your setup? | |||

|

| one of us |

I'll let you know how they fly at "long" range when I get that far. I sight my bow in from 20-50, but don't want to take an initial shot beyond 35 yds on Cape Buff. With my "light" 415 grain arrows I'm good to 60 on elk. Got a passthrough on a cow elk this year from last rib out through in front of the off shoulder, breaking bone at both ends. Something like 45 inches of penetration. The arrow stuck fairly deep in the ground afterwards, so it was still moving pretty well. 100 gr G5 Montec on a 28.5" Axis ST 340. Some countries have an 80 lb limit on DG, but my 73# 101st beats anything they were measuring when they made the rules. It beats my 80# Allegiance when both are set at 29" draw. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

your 101st ibo's pretty close to my destroyer iirc. i switched from a mathews outback to the destroyer, its a much different feel bow, but i love it. when do you plan on chasing cape buff with the 101st? | |||

|

| one of us |

Date not yet set. Hoping for 2012 season. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

I need to decide pretty quickly also whether I'm going to go with 750 grain arrows or 850 grain arrows this time. Ashby's latest 2008 reports seem to indicate that with a high FOC arrow anything more than 650-700 grains will do the job. I don't know if the improved trajectory of the 750 grain arrow is worth the loss of momentum available with the 850. Any discussion? Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I would love to discuss as this absolutely fascinates me that you get to go chase black death with a bow... however, this is beyond the realm of anything i've actually done, so it would all be theoretical. how much trajectory loss would you actually lose going to 850gr? thats a heavy arrow, but so is 750. if you get a sizable gain in momentum, i would think heavy is better. why, though, according to ashby, does the lightweight arrow shaft deflect less and break less than a heavier (like easton axis dangerous game) shaft? | |||

|

| one of us |

Ashby says (and my experience upholds it) that it's a matter of how much inertia is in the broadhead and how much is in the shaft. Basically weight at the back of the shaft provides the inertia that makes the back of the arrow flop sideways when the head changes direction, stressing the ferrule area. In his testing on water buffalo carcases (almost Cape Buff from a bone standpoint) when he used heavy shafts/heavy arrows with "normal" FOC of about 15% he typically had a 16% failure rate of the shaft/insert/ferrule/adapter. When he made arrows of the same total weight, but put the weight up front (25-30% FOC) he had ZERO shaft/insert/adapter failures at the shaft/insert/ferrule/adapter on the same broadside shots that had previously caused the 16% failure rate. He said in his 2008 report that he'd test angled shots in a future test, but that has not been published yet if it has been done. Both the 750 and 850 grain arrows are slow "rainbows" so I'm kinda leaning towards the heavier shafts, too. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

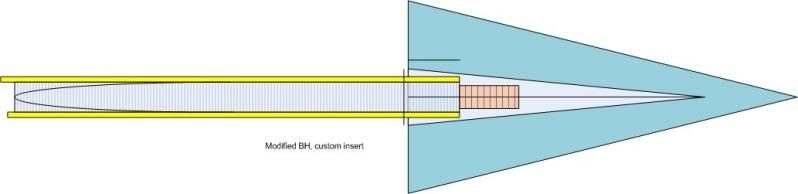

Here's a photo of the Asbhy BH with external footer. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Here's a sketch of what I think would be the best broadhead/shaft interface design for the skinny Axis ST shafts. No bending motion can ever get applied to the threads, and the bending motion is applied to the shaft only where the insert is full diameter metal. Should be unbreakable. The head is the Alaska Bow Supply (ABS) Ashby. It would require a custom insert as shown, or a piece of all-thread and a standard HIT insert, glued in forward in the shaft. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I had an insert made like that but the machinist against my wishes made if of aluminum and it bends easily. I think made of steel it would be the bomb. Combine that insert with a sleeve and you have the ability to tune your FOC exactly how you want along with an indestructable arrow. Don have you read Ashby's stuff on shaft diameter? He really stresses thin diameter shafts. I'd look strongly at your sleeve and come up with something thinner. I use a piece of aluminum arrow shafting (2216?) for sleeves and haven't broken one yet even though it's thin stuff. I spent a whole afternoon shooting gophers with 2 arrows made with sleeves. I shot over 60 gophers with my longbow, so you know how many misses were involved. The most dramatic miss was when I mistook a rock for a gopher and scored a direct hit. The judo point was demolished but the arrow was in perfect shape. All I'm saying with this is that the thin sleeve held out just fine and you could get away with less "meat" on yours. | |||

|

| one of us |

cc1, The problem is the difference in energy on your trad bow and an edgy compound like mine. I footed some Axis arrows with 2216/2218 and broke one the first day, intentionally shooting at angled steel surfaces at glancing angles. I have not tried the fat footer yet - it does get expensive! When the tip skids you get some bending moment at the junction. Don't know how to effectively mimic what happens when a BH splits a bone at an angle and is forced to change direction, though. The modified broadhead approach fixes all the poblems, but I can't find anyone to do the mods for me. It is tough to figure out how to hold the broadhead in perfect alignment to do the drilling. That one inch long fat section is exactly what I worry about with the tubing external footer. I know Ashby stresses small diameter shafts, but don't know the tradeoff between the probability of a junction failure (which prevents penetration completely) and the consistent penetration loss invoked by the short fat section. Thanks for the discussion. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

cc1, Next time tell your machinist to try 7075-T5 aluminum stock. Stronger than most mild steels. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

makes sense now with the heavy back end of the arrow still wanting to drive the arrow and putting unnecessary bending forces when the bh deflects. thanks for explaning. that is a wicked looking setup.. have you chrono'd your 750/850 gr arrows to check what fps you're getting? what targets do you shoot into? i would imagine your setup would blow through a "normal" archery target like the block | |||

|

| One of Us |

Fair enough about the aluminum sleeves being broken with the compound. What about using shafts that don't use the HIT system? The insert you show could have an end machined like the tapered end of a broadhead adapter, So there would be no screwing the broadhead into the insert but glueing the adapter directly into the back of the broadhead. You'd have two pieces, the machined insert and the broadhead. I've not seen a failure of the broadhead and broadhead adapter, usually it's the end of the arrow breaking behind the insert or the broadhead adapter breaking in the threaded section. | |||

|

| one of us |

cc1, With the arrows I tested in 2006 there were definite failures of all three components -shaft, insert and adapter. It was hard tell what failed first sometimes, but no doubt that all three failed - and I was using case-hardened steel adapters on the Grizzlies. No adapter broke in half so I do not think they were over-hardened. Those shafts were Carbon Tech Rhino Safaris - the biggest, heaviest carbon shafts I have ever seen. They were .335 diameter with heavy traditional-style aluminum inserts. The shaft and the insert both broke and bent, too. That's why I want to try these small diameter lightweight shafts. I've shot the Axis ST three years now, and they are as tough as anything I've ever used. I am more afraid of the ferrule bending than anything else. Once it bends/fails it all tends to come apart. Cooper, the 752 grain arrow is at 225 fps, the 836 grain arrow was 214 fps. One thing I forgot when I ordered the Ashbys is that the RH bevel tends to unscrew when it hits. I think that it is important to keep the threads tight so that the face of the arrow/insert/footer stays tight against the face of ferrule to help reduce bending moments on the ferrule shaft. I've already ordered the RH feathers to go with the RH Ashbys, so I guess I'll just use a wrench and maybe some loctite on them. Next time I will go LH feathers and bevels, since the direction of spin does not matter much on a compound. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I think some glue on the threads is a good idea no matter what spin you have, it's just gotta be better to have everything glued as one solid unit. Especially for a special hunt you won't mind having a handful of arrows that you will have glued the heads into. I'm thinking poor arrow flight really is the main culprit in your arrow breakage. If the arrow hits even a bit off of kilter it imparts huge lateral forces, obviously you know this already. I've got my target butt set up in front of a brick wall I had one arrow that just wasn't happy and always flew badly out of the four that I've been using lately. Three fly nicely and one didn't however I've missed the butt with all four arrows while trying some different shooting positions. The arrow that broke was the poorly flying one the other three have all had direct hits into solid brick and no damage at all. Interesting and anecdotal for sure. By the way have you looked at the KME broadhead sharpener? It's the bomb for that kind of head. Dang! What an exciting hunt to go on, I can't wait to hear the outcome. | |||

|

| one of us |

I concentrate on getting good flight on every arrow. Each tested many times before I take it hunting. What breaks the arrow is the tip of the BH sliding sideways before it bites, or breaking the bone with the crack at a slant to the line of flight. Even the sharpest tip will sometimes slide a bit on hard bone, especially if the bone is slanted to the line of flight - and they all are! The arrows hit the hide square, but then are forced off line by the above events. The back of the arrow will then tend to slap sideways as it whips beyond the new *forced* line of travel. The lighter arrows are supposed to reduce the slapping effect and retain momentum better, since all the weight is in the head. That's why I test by intentionally firing some of the arrows onto a slanted steel plate. I think I need to pad the steel plate, though - I am wondering if some of the breakage is due to the side of the bare shaft hitting the edge of the plate. Hard to simulate a cape buffalo realistically! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don I saw your post on Tradgang, go back there and take a look at the skeleton pictures that were posted. Pretty cool stuff. I'm thinking that something like a Cape buffalo shouldn't be shot at a quartering angle and you'll prevent lots of potential problems. I guess that's where it's best to have a PH that has extensive experience with bowhunting so he understands what you need to get a shot off. | |||

|

| one of us |

I'm having trouble finding a machinist to taper the SS tubing, so I decided to try 3 layers of external aluminum footing. So I put a section of 2.4"x2016, 1"x 2215, .25"x 2413. The 2413 is a press fit on the 2215, so I'm not sure if enough glue stays in to hold it.  This gives one layer of support .2" past the 3 rivers 100 grain brass insert, 2 layers past the threaded section of the insert and a full 3/8" diameter end section that matches the OD of the Alaska Bowhunting Suppply Ashby broadhead. Footing adds 40 grains total. Edited to change to picture with broadhead. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  Bareshaft testing on compound???

Bareshaft testing on compound???

Visit our on-line store for AR Memorabilia