The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  Cape Buffalo Arrow for 2012

Cape Buffalo Arrow for 2012Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Overall the results seem to indicate once again that single-bevel BHs tend to out-penetrate double bevel heads in non-homogenous media. I make no claim that this is test mimics an animal carcase, but it is more indicative of penetration in bone than a foam target. Don, why do you think that is? | |||

|

| one of us |

Ashby and others who have done a lot more thinking and testing than I have seem to think that it's due to the twisting action that results from the changing diameter of the wedge causing a splitting action. Me, I believe it works, but I don't know why. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

You are correct in your assumption that a single bevel will penetrate better on game Don. Not much but it does. Especially where bone is in contact. I have spoken to Frank from German-K and asked him to make me a few single bevel GK's. He was not to fond of the idea but he said that he will have a look. The Ashby is a great broad head and will do the job on any animal but I have seen them fail a few times on heavy game like Giraffe etc and when I commented on it some people said that I am dreaming. It still stays a great head but it can fail like any other broad head. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

Copied verbatim from my similar thread on ArcheryTalk.com: [QUOTE=piggy;1063160697]I Used Ashby's Broadheads on a recent water Buffalo hunt and had the same issues with the broadhead snapping, infact of the 6 shots into water buffalo 5 of the 6 broadheads failed when impacting the entrance rib! I changed to the 250grn VPA broadhead on the same shaft and same bow and took a buff. Here are some of the broadheads which snapped the shaft is where one snapped at the ferule  [/QUOTE] [/QUOTE]Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don, when did you buy your Ashby's? Another recent report on Bow Site with hunters taking water buffalo in Aus involved an Ashby failure. I'm concerned as I plan to hunt elephant in August and the plan was to have Ashby's on the sharp end. Do you think it's possible that one batch was bad but the others are generally good? JCHB | |||

|

| One of Us |

Have I just been BS lucky to take 2 Asian and 1 Cape buffalo and a giraffe with one arrow each tipped with a Razorcap? My elephant took 3. No failures, full penetration (one went through both ribs of a water buff!) My one obsession is that the bh's are polished sharp on a 1600 diamond stone. Dave | |||

|

| One of Us |

Hey another Calgarian!! Dal what bow did you use for those animals? | |||

|

| One of Us |

Hoyt 90# for most, PSE 74# for the Cape buff. Most arrows were 1000 gr +/-. d | |||

|

| one of us |

Mine were shipped Oct 19, 2011. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Did some more testing today, but got interrupted before I was through.  It was a bad day for blow-throughs. I was explaining the superiority of the single bevel to a guy at the range, when the single-bevel 300 grain SteelForce failed to blow through the 5/8" OSB. I then fired an ABS Ashby and an Abowyer Brown Bear at the OSB. These heads had blown through easily before, but were stopped today. The best explanation I can come up with is that the OSB was damp from the leaking camp on my truck. The Abowyer was the only one that made it to the arrow. It looked like the Abowyer penetration was stopped by the oversized footer on my test arrows. The footer left a definite impression on the OSB. ABS 315 grain Ashby penetration:  The Ashby had some chipping on one edge about halfway back that was originally masked by the splinters. SteelForce 300 grain single bevel:  The SteelForce edge was very slightly burred along its full length. Nothing that 2-3 strokes on a stone wouldn't fix. Abowyer 270 grain single bevel:  The edge of the Abowyer head was essentially untouched by its third trip through the OSB. You can see the pressed wood where my oversized footer stopped the penetration. Then I fired a 180 grain original GK-Silver Flame at the OSB, and it blew through, in spite of being 120/135 grains lighter!  The GK penetrated in spite of hitting the previously embedded SteelForce on the way in. The edge of the GK was damaged, but the ferrule was still true.  In the spirit of fairness I fired the GK again at a clean spot in the OSB. It also blew through, even with the damaged edge. I have no explanation for why the GK performed so well, with a double bevel and a 180 grains - but I like it! It'll tip my elk arrow this year. I then fired the GK at the angle iron. The tip buried into the iron before breaking off. The arrow also broke at the back of the footer. A dimple in the back edge of the aluminum footer makes me think the arrow broke here due to hitting the side of the angle iron as has happened before. But it could be that the shaft actually flexed enough to break there without help. If so it'd be the first arrow that broke without help. The ferrule appears to still be straight, even though the head was well and truly trashed.  To DO: trash a VPA, an Abowyer and SteelForce on the angle iron. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Hi Don. I love the way that you test your broad heads. By shooting them into a wet medium you are actually imitating what would happen in an animal more closely than in a dry plank. Bones are wet and therefore you get less penetration. I have done similar tests with a lot of BH's and still the GK came out on top for penetration and durability. Regards. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

Hi, Fritz. The GK was very impressive. I've got 8 left, and will not fire any more at the angle iron! The surviving edge on the GK is still perfectly razor sharp, and the ferrule seems true - it is certainly still straight enough for good penetration which is what I'm looking for on the angle-iron test. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I have used some heads that were better than the GK's in one aspect or another but never in more than one. Overall I have yet to see a head that compete with a GK in all facets. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| One of Us |

I agree with your suspicion about the effect of the dampness. I've seen wet target media make quite a difference! I once had a shooting session interrupted by a heavy rain storm. I left my bag target out in the downpour and it got thoroughly soaked. It rained through the night and didn't let up until morning. My first shot at the soaked target and the arrow literally bounced off! Three follow up shots did the same thing. When I went to retrieve my arrows, I lay the target down and squeeze as much water out as I could. Arrows didn't bounce off after that but they didn't penetrate nearly as much as when the target was dry. My theory is the water spreads the effect of an impact over a larger area than if the same media was dry. The lighter GK performance is interesting. Perhaps 180gr is the sweet spot weight for your setup? | |||

|

| one of us |

the big guy its called hydrolic displacement happens with guns as well as bows.. for every action theres a opposite reaction. | |||

|

| One of Us |

[/QUOTE] I really don't like how parts of these BHs have broken off. The steel seems to brittle to me. I am a big fan of GK broadheads and I know for sure what head I would use for a buff. I recommend you to test out the 210gr SilverFlame from GK. It has the same shape as the 180gr you tested , but with a all solid blade, so no holes and should be stronger. | |||

|

| one of us |

When I last checked GK was out of the 210 and did not know when they'd get more in. I agree the GK 210 would be a better buff head than the 180s. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

As I understand, do they have the 210 grain in stock and you can buy it directly from them online if you are interested. http://www.german-kinetics.com/ | |||

|

| one of us |

Thanks for both the advice and link, Norwegianwoods, I think I will wait a bit. JCHB says Vantage Point Archery will have a single-bevel design in the next few weeks. I think it may be worth the wait. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

The range was busy today, could not make sparks. So I tried to track down why my groups have opened up. I think the culprit is me and the Axis ST 300 arrows I have been mistreating. Turns out that about half of my arrows are now showing to be severely under-spined for the 390-440 grain total tip weight I have been shooting with them. My initial testing showed they were OK, in spite of the fact they are only rated for about 250 grains. I think they were marginally under-spined when I started, and after bouncing off the angle iron a few times some of them now have literally 4" right tears, when some still shoot bullet holes. I hate to throw visually and flex-test perfect arrows away, but I don't know how else to protect myself from incipient failures. You can bet I will be wearing a full-length arm guard from now out. I will try to see if a static spine test will reveal the weakness. Gotta figure out a practical way to do this. Maybe I should start using the freakin' expensive Gold Tip Kinetic Pro 200s that I bought for the real deal. They are rated for the load - barely. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Hey Don Been watching from the distance, very nice work, I would recommend another arrow you may wanna try is the Carbon Express Pile Driver, very tough, and in my opinion a better arrow than the Axis, and about the same price point. Matt Simply, Elegant but always approachable | |||

|

| one of us |

I've used Carbon Express arrows with good results before. These look pretty good, but a spine of .300 is the stiffest they show. From here on out when I buy arrows for this project they'll have to be 200 or better. Not a big selection. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

They do go to a 450..13 grains an inch and a spline of .300 This is only with the pile drivers Simply, Elegant but always approachable | |||

|

| one of us |

Yeah, the Carbon express arrows are weird that the biggest number is the stiffest spine. Most other makers just use the spine in the name. My Gold Tip's get to a much stiffer 200 spine, and I just found out I need it. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

WooHoo! I've found a manufacturer to make my custom broadhead design.  More in a few weeks, I hope! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

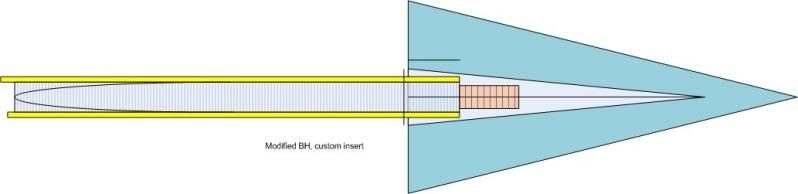

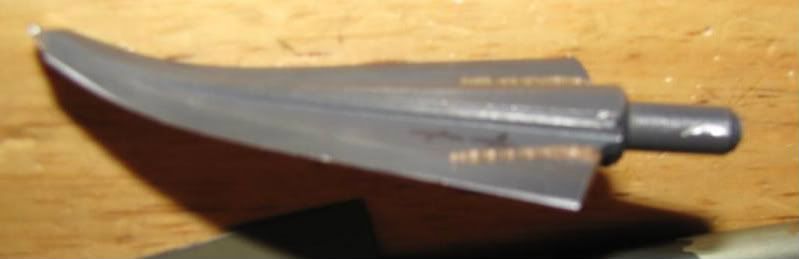

The manufacturer has added a few wrinkles of his own, and has sworn me to silence on blade details until he gets any patent and trademark stuff done. They don't let any grass grow under their feet, so I am expecting the finished product around the end of the month. The head should be around 275 grains and the insert/footer around 100 grains. The ID of the broadhead internal ferrule will be .3135 so that any Axis ST/GoldTip Kinetic-sized arrow can be externally footed with a 20xx aluminum arrow to mate. My estimates are that this internal ferrule design yields an assembly about 4x stronger than the normal external ferrule. To say that I am excited is an understatement! The cone on the head that forms the ferrule reaches .375 diameter about half an inch forward of the rear face. This makes the taper a little steeper/fatter than other designs, but I think the ultimate strength is worth it. I just cannot picture this thing breaking on anything less than my angle iron. The .3135 ferrule ID allows you to make total arrow weights from 550 to 1250 grains (including the head), with spines from 400 to 100. I don't pretend to know what bow could shoot this head at 400 spine! This lets the trad guys use it with a lighter arrow and an aluminum insert for 550 gr arrows that reach the true 30% ultra extreme FOC that was Ashby's goal. My Cape Buff arrow will probably be a Gold Tip Big Game 200 Kinetic Pro with a short 2014 external footer, and come in around 750 grains and 27% FOC. The 200 spine arrow with external footer is just barely adequate for my 73# 101st Airborne, according to pjwatson05 of aarcherytalk, who ran some calculations for me. For all you elephant hunters, you could full-length sleeve the GTBG200KP with a 2014, add the 8 GPI weight tube from threerivers and get a 1250 grain arrow with an FOC of 15%, and a spine sufficient even for a 100 pound compound bow. (You could even look for some sort of 'weight tube' that adds to the spine.) You could probably find some sort of metal tape to "foot" an FMJ DG 250 out to fit, but I don't think the spine would be sufficient even for my 73# 101st Airborne. If this catches on, maybe Easton will make a 150 spine FMJ with a .3125 OD. I am NOT going to be any kind of partner/employee/part-owner in this. I make nothing on the deal, and paid full price (plus development cost) to buy mine. It took some stubborn-ness on my part to get them made. If you are interested in buying any of these after you see them you will have to wait and ask the manufacturer. I am not going to get into the middle of this. If anybody wants to "pay me back" for getting the design in play, fund the development of the custom 275 gr practice head. My wallet is skinny! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Sounds very interesting Don_G. Very much looking forward to see photos of that head and see how it performs in your tests | |||

|

| One of Us |

Don have you played with "stu's arrow calculator?" It's an excel based program and calculates all kinds of stuff.. total arrow weight, gpi, foc, potential speed, etc. It's mostly for trad bows but might probe useful for the compounders. | |||

|

| one of us |

Norwegionwoods, Thanks for your interest. I'm like a kid waiting for Christmas! Chef, I have played with it a bit, but it does not work for predicting the spine required for compound bows, nor the dynamic spine of an arrow, and that is what I need most. I have all the FOC , energy and momentum equations, but spine escapes me. I never was any good at dynamics. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don it does indeed calculate the dynamic spine for the arrow. It also works if you're adding an aluminum footing, which I really like. If the arrow shows weak it's easy to add a footing to increase the spine. You're right that it won't work for the spine required for a compound though. Maybe you should switch to a nice custom longbow, it would look a lot nicer in your trophy photos | |||

|

| one of us |

I'll have to try again - I could never get that to work. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Well, I spent a frustrating couple of hours getting the calculator to work on Win7/EXCEL 2010. After I got it to work I can't figure out how to use the results. As you said, it is made for trad bows. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Sorry if I was short, chef. I played with Stu's calc and it says that the Dauntless broadhead would be properly spined for a 53# trad bow using an Axis ST 340 at a BOP of 29.25 with a normal aluminum HIT insert with a 1/2" set screw forming a light-weight Dauntless internal footer and a 2.5" external footer made from a 2016 Easton aluminum arrow. The three layers formed by the external footer/carbon shaft/internal footer will extend about 1/2" into the broadhead, making a very strong assembly. I forgot to weigh the insert/set screw before I glued it in. In a few weeks I hope to show you a pic of the broadhead. Right now here's the business end of the assembled shaft.  If you want more weight, you could do the same thing with a brass 100 grain insert from threerivers. For more strength and weight you could use a steel Dauntless internal footer. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Nice! Using a high grade set screw in that manner will be very strong and tough. The screw will be much tougher than if it was simply machined on the end of the broadhead. Suggestion: You might want to check the consistency of the balance points of the entire assemblies. Measure the distance from nock end to balance point. It doesn't take much difference to affect the dynamic spine of the arrow. | |||

|

| one of us |

Good advice. I am getting set up to measure static spine today, and will check weight and balance of all the assembled arrows. I will be using a 100 grain one-piece custom steel footer, unless they have production problems, in which case I'll be using a custom steel footer with internal threads and a set screw. The screw should never see much stress at all. The head-to-shaft junction is pretty much always in compression, so the shaft will take all the stresses. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Looks great! Have you done any testing with nanook heads? Tom Addleman tom@dirtnapgear.com | |||

|

| one of us |

Nope, and none planned. I tested the ABS Ashby heads and did not like the results. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

I had an expensive trip to the range today. Every arrow I shot broke when it hit the angle iron/target/skin that I had set up. These arrows all had a single 2016 aluminum footer 2.5" long on them, to match the common ferrule diameter. I made a frame and stretched an old towel over it and placed that 6 inches from the target. Then I taped the angle iron to the target. The idea was that the towel would act like the skin of a critter and keep the shaft from slapping the angle iron. This did not work so well... The first shot was the Abowyer Brown Bear (mine weigh 270 grains.) The head hit the iron and skidded off as always. The head hit so that bending force was in the plane of the blade - the blade is hardest to bend this way. The blade bowed very slightly and the ferrule bent at the back of the broadhead. The shaft broke about 9" back of the head, where it slapped the iron. There are several scrape marks on the shaft where it slid along the edge. The head buried about 8" into the Black Hole target. The Abowyer head behaved very well in this test.  The next head tested was the SteelForce 300 gr single-bevel. This head came off the ferrule, inside the target. It came off right through the locking ring. Penetration into the target was about 4 inches. The ferrule was bent at a severe angle.  The last half inch of the SteelForce tip curled.  The VPA 300 grain Penetrator also curled at the tip. (About the last .7 inches.)  (The shiny tracks on the blade are where I drilled the head out of the OSB in a previous test.) The curve in the head caused a curving track in the target. The head penetrated 10 inches into the target before the shaft broke off due to the sideways pressure. The body of the ferrule is still straight, but the threads broke off. This is where the shaft broke as well. This is the first total failure of one of these footed shafts. The forces due to the curving path must have been tremendous - the head wound up travelling at right angles to the flight path. I was very impressed that the ferrule did not bend. I suspect very strongly that the threads broke after the reinforced shaft gave up the ghost.  You can see in the photo that the end of the shaft essentially disentegrated: there was aluminum and carbon fiber shrapnel in the "wound channel." The head almost exited the side of the target. All in all I was impressed with the metallurgy of both the Abowyer and VPA heads. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don, you're going to spend all your safari money on arrowheads at this rate!! I doubt there is anything that will resist that kind of impact...but it's fun to hear about it!! Better your money than mine | |||

|

| one of us |

Yeah, it is expensive, but I'm near the end. I have no more production single-bevel heads to try. I will of course have to sacrifice at least one of my custom single-bevel "Dauntless" broadheads on the angle iron. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  Cape Buffalo Arrow for 2012

Cape Buffalo Arrow for 2012

Visit our on-line store for AR Memorabilia