The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Other Topics

Other Topics  Black Powder

Black Powder  Cannon

CannonGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Some years ago a buddy and I turned out some cannon tubes from drawn over mandrel, seamless, high pressure steam pipe. 1" bore. It shoots 3 oz cannon ball lead sinkers, behind about 500 gr. (35 mm film can) of Fg. But mostly I shoot paper wadded blanks -- 4th of July and stuff. Cloud of smoke the size of a school bus. I had this tube mounted on a funky carriage made from John Deere pallets and fence hardware. No trunnions, and so the tube was secured to "bed" with U bolts. (first photo) Recently we welded up some trunnions. Now I'm roughing out "cheeks" from some 1" red oak salvaged from an old desk. A lot of hand tool, chisel and rasp work. I used a drill press to form the trunnion recesses in the cheeks -- but they needed to be enlarged and fitted by hand. We have some work ahead of us, but I have all the parts, hardware now. It's coming along. Old Cannon --  Same tube, new cheeks, trunnions --    | ||

|

| One of Us |

| |||

|

| One of Us |

Lengthened the elevation rails for the quoin. 1/2" mild steel angle iron, secured with countersunk wood screws. Inset the rail on the axel journals. Quoins (elevation wedge) are hard geometry. They need to be steep enough to elevate, but not so steep that they impinge on the cascabel (breech end knob). Replaced the cheek ring hardware with heavier stainless. Retained the 1/4" washers. Trunnion caps are mild steel strap, 1/8" X 1" -- cold forged shaped over a mandrel. The trick is to get them a tight radius, the same size, straight. Also, the more they're beat on, the more they "work harden." From the radius to the flat is a lot of beating, shaping. Caps are secured with 5/16" X 1 1/2" stainless lag screws. 1/4" washers are the same as on the cheek rings. Painted high temp stove black -- flat black. Wood is finished with linseed oil and Minwax finish, floor wax. I didn't keep track of my time. Does running to the hardware store count on the clock? 500 gr. Fg, paper wad. Even with the wheels wedged with "hauser" it rolls back 10'. BOOM!    Oh yeah -- "vital stats" 15.5" length 9.5" width 6" heigth 22.2 lbs. unloaded | |||

|

| one of us |

Its a beaut, but it looks like it would jump up and bitch slap who ever touches it off. | |||

|

| One of Us |

C Cell battery or 3 oz lead ball over 500 gr. of Fg and it's potent. But mostly I like to shoot blank salutes. At a 4th of July picnic on the coast in WA ("Where REAL fireworks are still legal.") We had neighbors on either side of us shooting off rockets, M-80's, mortars, etc. I touched off this pup . . . Neighbors on both sides come through the hedge . . . "What was that, and where can I get one?" | |||

|

| one of us |

Zedo: Very nice work. Is your DOM tube fitted inside a larger sleeve? Any idea on the range of one of those C cells? There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

Tube -- 1" dia. bore 3/4" wall DOM. It's solid stock. I found a length about 3' out in the steel yard in Gladstone, Oregon (Since yer a local.) Seamless -- The boys at GreyBeard Outdoors http://www.go2gbo.com/forums/index.php give me some grief because according to the "cannon rules" the breech needs to be the same thickness as the bore diameter. (One inch wall over one inch bore) Well . . . yeah, sure for a casting. But this is a forging. Black powder, short bore, not much back pressure. Should have a pin in the breech plug and welded too, but the plug specs were drawn up by a Structural Eng. and we've attempted to blow the plug out in a second tube. (1200 gr. black powder and a shot of Clays Smokeless with 4 1" lead ball. Plug didn't budge, no stress in the tube (Cyrogenic and Xrays -- and tests I don't understand) No clue on range, but when we bungied the first barrels to pallets, the barrel (about 20 lbs) would slam into the 2 X 4 and break them. Makes a hell of a hole in heavy planks! Mostly it sits on the coffee table. | |||

|

| one of us |

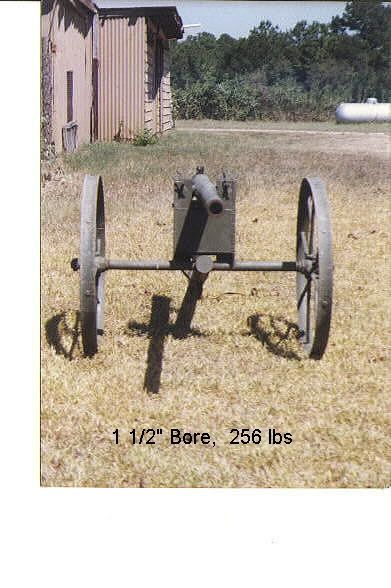

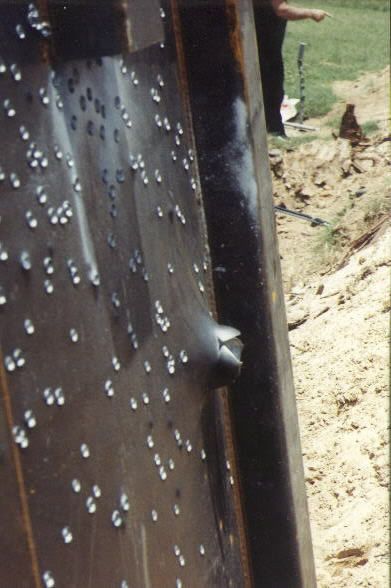

Here is my "toy". Specs: wt. 256 Lbs 1 1/2" bore 6' barrel load: shot 1lb 12oz, powder 2 1/2oz. recoils ~5' usually fired with winged musket caps and cannon lock.  1/4" plate steel @ 100yds.  three consecutive shots @ 200yds  ...and it is foo big to keep in the house. Keith IGNORE YOUR RIGHTS AND THEY'LL GO AWAY!!! ------------------------------------ We Band of Bubbas & STC Hunting Club, The Whomper Club | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia