The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Single Shot Rifles

Single Shot Rifles  Ruger#1 in 300 Win Magnum shots climb on barrel heating

Ruger#1 in 300 Win Magnum shots climb on barrel heatingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Anyone see this in their rifle? I mean there is only vertical no horizontal degradation in accuracy. Seems repeatable. I am now waiting up to 5 mins between shots (barrel cooling) to keep 3/4" accuracy at 100yrds. This seems to work, but I wounder what is going on????? | ||

|

| one of us |

Vertical stringing is often a bedding problem. Since #1s sometime have bedding problems I'd look at that. There also may be stresses in the barrel which cause the barrel to bend as it heats up . | |||

|

| one of us |

If you lean on the butt stock with your face while shooting it can cause the same thing. Try gripping the fore end with your hand and putting your hand on the front bag. You will feel how much pressure your face is putting on the rifle. Then you can minimize the pressure while maintaining a uniform grip much like a field hold. | |||

|

One of Us |

When working with my brother in laws rifle a .270 1B, I took off the forearm and carefully rested the little bit of the front reciever on a rest. Tis way I learned that it was the forearm which needed to be glassed. Major pain, but for a unter, if you know where the first round is going... the rest is easy.  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | |||

|

| One of Us |

By all means pull the rib and make sure that it is not in a tight bind on the studs. I had a 375 Holland that would walk 6" in four shots. After filing the stud holes just a smidge oblong it settled in very well. J | |||

|

One of Us |

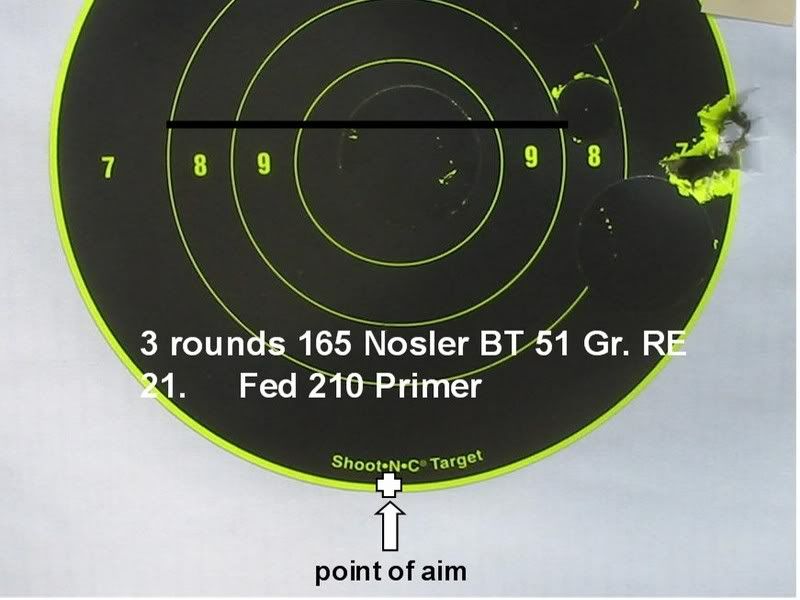

Bedding may indeed be a problem. There are a number of ways to approach this problem, but about the easiest and most effective I have found to date is one I learned from members on the Yahoo No. 1 rifle group. "e-mail ruger-1@yahoogroups.com" It is facetiously referred to as the "Miller Magic Rubber Thingy". What it consist of is a chunk of truck innertube rubber, cut to fit in the barrel channel at the forend tip, about 3/4" long and wide enough to wrap up the sides of the barrel, but not wide enough to protrude above the sides of the barrel channel. I was told it should be "red truck innertube rubber", which is what I happened to have and I used it. I have a No. 1B in .30/'06 that was only shooting into 1.5-2 MOA, which is not nearly as good as the rest of my Ruger SS rifles do. After installing the "thingy", I got three 3-shot groups under 1" @ 100 yards when I tested it. This is the best of them. I will test the gun further with other ammo to see if it is an all-round remedy!  There are other things that could be done, such as installation of the Hicks Accurizer device, but I would try the "Thingy" first-it is better, IMO, than the use of a rubber washer under the forend screw-(an Elmer Keith innovation). You might consider posting your inquiry via e-mail to the No. 1 Group. "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| one of us |

The fore end hanger on a #1 looks strong but is pretty springy and to top it off it has a hammer spring mounted in it. Boing........ Not a very good vibration dampener. But I was wondering Why does the inner tube have to come off of a red truck? Reminds me of the movie "Used Cars". | |||

|

One of Us |

The rubber must be red. I don't believe it matters what color the truck is that it came from. But I don't know for sure! At least, it does not have to be installed at midnight of a the full moon! Nor is eye of newt nor toe of frog involved....... "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| one of us |

I had some V shaped aluminum pieces made and used them to glass bed the end of the forearm, they really worked well...Jack Belk made some adjustable ones that were even better. Also, glass bedding the forend tight, screw the etcheon up until the wood is at half the barrel. be sure and lightly glass the end where it butts into the action. Most No. 1's can be made to shoot very well indeed if you tinker with them.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Agreed! The theory of vertical stringing in No.1 rifles is pretty simple, but because it is theory, it may not be the whole truth in every instance. Basically the theory is this: A long thin tube of steel beomes less rigid as it heats. That being the case, gravity pulls it down more when warm. If one end is supported (by an action for instance) pulling the other end down further puts the barrel in stronger contact with the wood of the forend. As rifle barrels commonly shoot AWAY from the point of contact with the stock, that would cause the shots to string upward. Well, that's the theory, anyway. Now for relief from the problem: There are two major possible routes to navigate. One is to make sure the barrel has no contact with the stock regardless how far gravity may cause it to droop. That's the approach which results in the popularity of "free-floating" barrels. Both the "Keith" and the "Rubber Thingy" approaches move the forend away from the "hanger, so the forend is also farther away from the barrel. Being farther away from the barrel, the forend is less likely to touch the barrel, no matter how much it "droops". The other major approach is to put the forend in such strong contact with the barrel at all times that any decreased stiffness and more sag/contact of the barrel with stock are superflous and insignificant. That is commonly done in bolt rifles by putting a "bump" or "bumps' in the bottom front of the barrel channel, creating a pressure contact between barrel and forend. In Rugers that may work, but what works best in my experience is to drill a small hole in the front of the forend hanger, and thread it for about a 5/32" machine screw. Then put a screw in the hole & turn the screw in far enough that it strongly contacts the barrel. It creates a "pressure point" between the hanger and the bottom of the barrel. Using a "lock nut" or "loktite" will keep it in adjustment. The nice thing about this approach is that the pressure is adjustable by turning the screw, so one can experiment with different amounts of pressure. There are lots of other ways to relieve pressure or to create pressure, whichever the shooter wants to do. Anyway, as Ray says, with a little fussing, they can often be made to shoot very well indeed. Best wishes and good luck. P.S. Vibrations are "damped", not "dampened". | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Single Shot Rifles

Single Shot Rifles  Ruger#1 in 300 Win Magnum shots climb on barrel heating

Ruger#1 in 300 Win Magnum shots climb on barrel heating

Visit our on-line store for AR Memorabilia