The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Single Shot Rifles

Single Shot Rifles  group from encore 30-06

group from encore 30-06Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

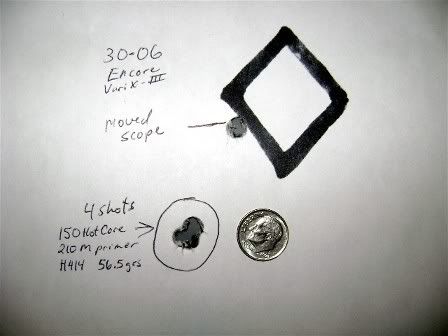

I have been fooling with encores since they came out and have pretty much figured out how to get them to shoot. I swapped scopes on my 30-06 encore rifle and shot a group. It usualy is under 1/2" but this is its best to date. .211" for a 4 shot group. reflex264  | ||

|

| one of us |

OK, you can't leave us hanging like that, LOL. What type of barrel(Factory? length, finish, forend type, hanger bar? etc. etc.) Great groups by the way. almost got the dime, better luck next time. LOL. Thanks for any info. Steve E...... NRA Patron Life Member GOA Life Member North American Hunting Club Life Member USAF Veteran | |||

|

| One of Us |

The barrel is a factory stock barrel. I use a VVG hanger on my .264 but not on the 06. I took a factory synthetic forend and cut the ribs out with a Wizard grinder. I cut the excess plastic at the front boss so that it wouldn't contact the barrel either. I glued #8 steel washers to the tops of the bosses and used high tack permetex on top of them. Once dry it formed a micro bed. Now I can tighten the screws enough to keep the forend from moving and not string shots. I worked out a loading method for encores using info from Bellm and some of my own ingenuity and have all of mine shooting very good. Looks to me like TC would fix the forend problem to keep every one from haivng to modify them. Here is a post on from another forum about how I load for the encores. reflex264 Loading for the bottleneck Encores To start with Encores are a very interesting gun. A great concept that has its flaws. Yep as much as I love them they are not perfect. Just fact. Some of you that used to post on huntertalk will remember the endless threads about Encore problems on the single shot forums. Accuracy is relative. If you are happy with a high-velocity centerfire rifle that shoots 3" groups at 100 yards this thread probably doesn't apply to you. I have a feeling that most of you like myself ask much more from your rifles. Before going too far we must first examine the design/ contruction problems associated with the Encore. To start with TC in an effort to simplify barrel interchange ability fits Encore frames and barrels on a jig. This would be fine and dandy except for the amount of permissable slop need to ensure production rifles don't have to be fitted. The jigs are set up as go/no go. In most instances the fit is close enough to provide resonable accuracy with factory ammo. In some cases you can get extremes from the barrel and frame and have a real problem. I have heard of them being loose enough so that factory ammo would not go off because the firing pin did not contact the primer enough. Others borderine on being too loose from the breech face to the rear of the case head. This is a real problem. I have two Encores that have extreme amounts of slop in this dept. In the most extreme cases the rifles should be sent back to TC for a fix but in the cases where they determine that the fit is acceptable you have a couple of options. Trade it or make it work. To understand these guns the first lesson to earn is they DO NOT HEADSPACE. They clearence instead. TC's design for interchanability allows slop to make them work. What they consider acceptable varies but after sending some back to them and actualy measuring the amount of clearence they though was OK I think I have it figured out pretty good. Lets take the example of my 30-06 Pistol. With some help from Mike Bellm I got it shooting and then worked out a method for sizing the brass that closes the sometimes huge gap in clearance. Step 1. Shoot some factory ammo in the gun. 20 rounds is a good number. Step 2. Remove the extractor from the barrel and reassemble the gun. Step 3. Attempt to close the action (not hard) on the fired case. If it will close easily do the following: close the action with the fired case in the chamber with a sheet of note book paper in between the breech face and the rear of the case. If you can pull it out with very light resistence your gun is fine. If not go to step 4. Step 4. Using the 20 fired cases install a full length sizing die in your press and a shell holder for the cartridge to be loaded. Use a feeler gauge and for the first attempt use the .015" gauge. Make sure that the die is not bottomed out on the press. Raise the ram to TDC. Insert the feeler gauge in between the shell holder and gently screw the die down until it makes contact with the feeler gauge then screw down the locknut and tighten it up so the die is held firm being careful not to loose your measurement. Now insert the first fired case and size it. Insert it into the chamber and gently close the action. The action should not close on this case. If it does send it back to TC. Using this same case (re-lube it) using the next feeler size down size it once again in the same manner. repeat this operation with a new piece of the fired brass until the action closes. On the first time that the action closes take note of which gauge you used. In the case of my 30-06 pistol it takes a full .013"!!!!!! Now back up the gauge that is .001" smaller and reset the die. Size a case using this die. Insert it into the chamber and close it on a piece of typing paper. If it closes you are there. Take note of this feeler gauge size and each time you size brass for the particular gun set up the sizer using that gauge. The end result on my 30-06 pistol took groups from slightly over 2" at 100 yards all the way down to .5" for 5 shot groups. In the case of the .264 rifle once I solved some other issues the sizing of the brass took groups from 2" to .25"!!!!!!!! It is time consuming but worth it. reflex264 | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Single Shot Rifles

Single Shot Rifles  group from encore 30-06

group from encore 30-06

Visit our on-line store for AR Memorabilia