The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Please comment on lug engagement (pics)

Please comment on lug engagement (pics)Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

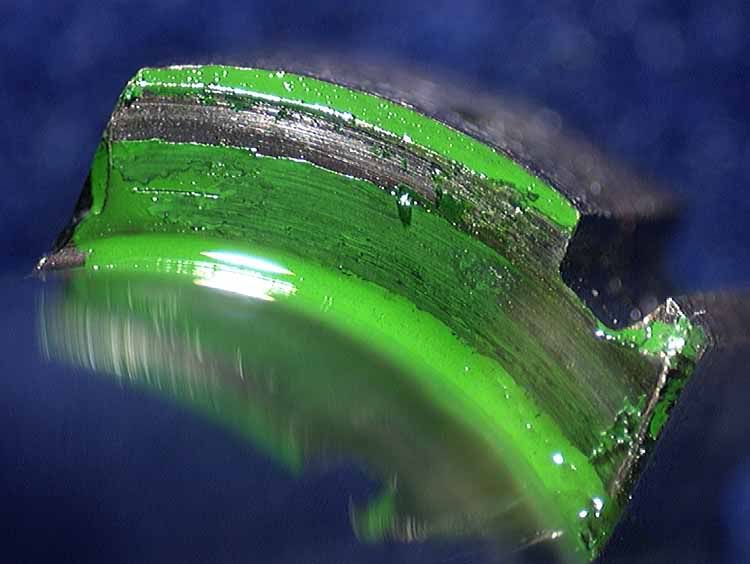

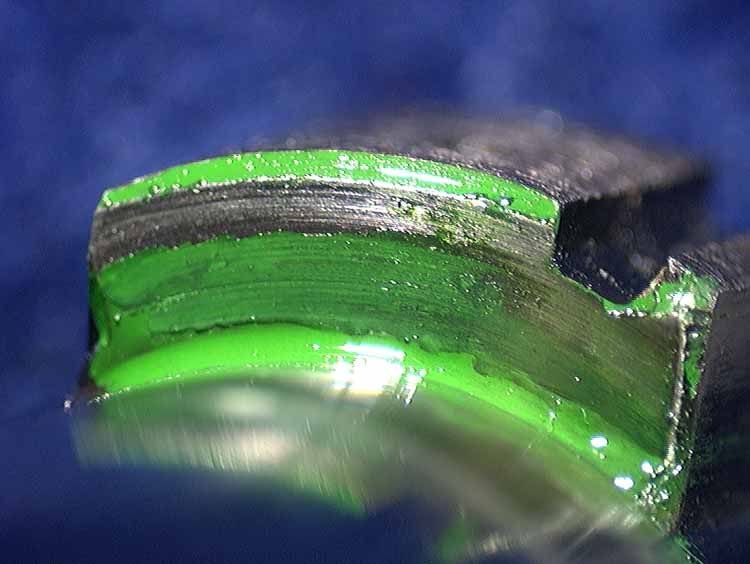

The rifle is a Remington 700 stainless synthetic that I am pretty attached too. I am in a quandry about doing some work to the rifle as it is a good shooter. It does foul in about 40 shots and is difficult to get all the copper out. The bolt close of this rifle has always been a little stiff. It "feels" like the lug has to overcome a hump on at the initial engagement with the recess. It will squeek if not well lubed. I inked the rear of the lugs with green so it would show in the photos. I tried blue Dykem and got similar results, but it did not photo well. I worked the bolt half a dozen times keeping some rearward pressure on the bolt. The results are in the photos below. The right lug will show more engagement than the left. I can see a ring on the outer surface of the right lug on one working of the bolt. Note how the engagement is not full on the lug surface, but more of a ring around it. It does seem to engage rully aound this ring however. I have to plead ignorance and wonder if this is normal. Does 90% contact mean 90% contact around the circumference or 90% of the ENTIRE lug surface. Is this rifle a good candidate for trueing? Would you just lap it? It shoots really well. I have decided to not lap it myself, as I have read enough to concern me about increasing headspace. I would greatly appreciate any comments!    | ||

|

| <9.3x62> |

This is pretty typical lug-bearing on most factory remchestgers, I've actually seen worse. Lapping is suppose to smooth this out, but it may also slightly change the bolt face's alignment with the bore and/or headspacing. I usually do all three truing tasks at once, not just one at a time. You may be able to smooth this up a bit. However, if it shoot wells, I'd probably just leave it as is... As for your fouling bore - try the Tubbs polish system http://www.midwayusa.com/esearch.exe/search?TabID=0&cat...+to+Begin+Search.y=0 It will usually improve accuracy and DOES decrease fouling substantially. Only $27 - a really bargain... | ||

|

one of us |

If you have designs on rebarreling, go ahead and get the action trued. It won't cost that much more in the grand scheme of things and you'll probably end up with an even more accurate rifle. And, you could lap the lugs if you liked and there are many tools and lapping compounds available for this. But, if you do lap them, you may end up increasing headspace and needing the barrel set back a bit to re-establish tight headspacing. Rebarreling to a premium barrel is never a bad idea but it is an added cost to the overall rifle. You just have to decided which way you want to go - leave it or have it trued and rebarreled. Jason "Chance favors the prepared mind." | |||

|

| One of Us |

Did you do that with or without the firing pin assembly installed? Butch | |||

|

| One of Us |

I did it with it in. Will it make a difference? | |||

|

| One of Us |

Yes it will make a difference. The cocking piece pushes the bolt up in the rear and the top lug is then off the upper lug abuttment. The bolt is loose in the back of the receiver causing this. Harold Vaughn said in his book that they should be lapped with the firing pin assembly and spring installed as that is the way it is when you cock the bolt before firing. Butch | |||

|

| One of Us |

In your case it wouldn't make much difference as your bolt don't have much surface contact. In theory the Remington bolt would be a little tilted with the cocking piece lifting the rear of the bolt. I wouldn't do anything to correct it unless you rebarrel at a later date. | |||

|

| One of Us |

What do you expect? It's a Remington | |||

|

| one of us |

metalman29! When you check the lugs for contact you have to press the bolt forward on closing and when the bolt i fully closed you release the forward pressure and move it up and down a few deg. This will tell you how much contact area you have. If you turn the bolt 90 deg. you will get a false indication! You only need a small high spot in one place in the reciver to get marks like in your first picture! I find a candle the best help to check for lug contact. It´s easy to blacken the lugs and fast to wipe off. It´s hard to tell if the action will clean up easy, but since you plan to let a gunsmith fix this he would tell you what to expect. Personally I like to remove the barrel when lapping lugs. It´s really hard to get the lapping compound out if the barrel is still on the action........ It´s also a good thing to inspect the surfaces inside the action. It´s not unusual to find ruff surfaces in Remington recivers..... It´s possible to get a good lug contact on 99,9% of the Remingtons though! It only takes a bit more time Good luck with your rifle! _____________________________________________ The bitter taste of poor quality stays in the mouth far longer than the sweet taste of the low price! | |||

|

| One of Us |

Yes, I was aware of this. I "tried" to keep forward pressure when engaging the lugs initally and disengaing finally. I also tried to keep rearward pressure when working the the lugs. I never let the lugs disengage during the 1/2 dozen workings. I tried to simulate a writeup I had read by Reid Coffied in shotgun news, with the exception of disassembling the bolt (I honestly didn't this it would make a huge difference. But, it is highly likely I screwed up Is this what one would expect to see and a factory Remchester? Did I screw it up enough not to get a useful reading? | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Please comment on lug engagement (pics)

Please comment on lug engagement (pics)

Visit our on-line store for AR Memorabilia