The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Modifying a rear open sight

Modifying a rear open sightGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I recently acquired a really fine Mannlicher Schoenaur Model 1956 in .270 Win. I want to shoot it with the open sights it is equipped with, a two leaf folding rear and bead front. However, with all of the ammunition I've tried it it shoots about 6" high (for me) at 50 yards, and more at 100. One solution would be to put a taller front sight on it, but I doubt such is available for this out-of-print edition. Is it practical to lower the fixed blade of the rear sight by deepening the notch and milling off about .045" from the top flat of the rear sight? Other suggestions (besides handloading down to about 1500 fps | ||

|

| One of Us |

Put the rear sight in the mill and chop it if you have room, or taller front sight. If it's a 2 piece front sight you might be able to get a new blade. You would have to post a picture of the front sight. The best way is to change the front, if possible. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| one of us |

| |||

|

| One of Us |

The blade looks like a standard 3/8ths dovetail. If you check with your local gunplumber he will probably have a taller one in his junk box that will match the (antiquity) of what you have. If your dovetail is smaller he should be able to modify a sight to fit it for whatever his minimum is. There is no point in bastardizing the rear sight when you can simply change the front. Besides, modifying the rear sight is permanent and if you go to far - - - - - - - - When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

I built a calculator and have it somewhere on my computer. Tell me the distance between the sights and how much you want to move the POI at what distance and I can tell you how much taller the front sight needs to be. Mike Legistine actu quod scripsi? Never under estimate the internet community's ability to reply to your post with their personal rant about their tangentially related, single occurrence issue.  What I have learned on AR, since 2001: 1. The proper answer to: Where is the best place in town to get a steak dinner? is…You should go to Mel's Diner and get the fried chicken. 2. Big game animals can tell the difference between .015 of an inch in diameter, 15 grains of bullet weight, and 150 fps. 3. There is a difference in the performance of two identical projectiles launched at the same velocity if they came from different cartridges. 4. While a double rifle is the perfect DGR, every 375HH bolt gun needs to be modified to carry at least 5 down. 5. While a floor plate and detachable box magazine both use a mechanical latch, only the floor plate latch is reliable. Disregard the fact that every modern military rifle uses a detachable box magazine. 6. The Remington 700 is unreliable regardless of the fact it is the basis of the USMC M40 sniper rifle for 40+ years with no changes to the receiver or extractor and is the choice of more military and law enforcement sniper units than any other rifle. 7. PF actions are not suitable for a DGR and it is irrelevant that the M1, M14, M16, & AK47 which were designed for hunting men that can shoot back are all PF actions. 8. 95 deg F in Africa is different than 95 deg F in TX or CA and that is why you must worry about ammunition temperature in Africa (even though most safaris take place in winter) but not in TX or in CA. 9. The size of a ding in a gun's finish doesn't matter, what matters is whether it’s a safe ding or not. 10. 1 in a row is a trend, 2 in a row is statistically significant, and 3 in a row is an irrefutable fact. 11. Never buy a WSM or RCM cartridge for a safari rifle or your go to rifle in the USA because if they lose your ammo you can't find replacement ammo but don't worry 280 Rem, 338-06, 35 Whelen, and all Weatherby cartridges abound in Africa and back country stores. 12. A well hit animal can run 75 yds. in the open and suddenly drop with no initial blood trail, but the one I shot from 200 yds. away that ran 10 yds. and disappeared into a thicket and was not found was lost because the bullet penciled thru. I am 100% certain of this even though I have no physical evidence. 13. A 300 Win Mag is a 500 yard elk cartridge but a 308 Win is not a 300 yard elk cartridge even though the same bullet is travelling at the same velocity at those respective distances. | |||

|

| one of us |

Thanks for the suggestion spearchucker. I'll see if I can measure the dovetail. I was guessing that the Steyr from Austria would have a metric dovetail, but perhaps it is something that can be matched. Mike, six inches at 50 yards is equal to about .048" with a sight radius of 14.5 inches. You can check it against your tables, but unless I've done something squirrely with the math that should be pretty close: 50 yards = 1800 inches. Six inches divided by 1800 = .00333 x 14.5 = .04833, or just under 1/20th of an inch. | |||

|

| One of Us |

Your calcs are correct Mike Legistine actu quod scripsi? Never under estimate the internet community's ability to reply to your post with their personal rant about their tangentially related, single occurrence issue.  What I have learned on AR, since 2001: 1. The proper answer to: Where is the best place in town to get a steak dinner? is…You should go to Mel's Diner and get the fried chicken. 2. Big game animals can tell the difference between .015 of an inch in diameter, 15 grains of bullet weight, and 150 fps. 3. There is a difference in the performance of two identical projectiles launched at the same velocity if they came from different cartridges. 4. While a double rifle is the perfect DGR, every 375HH bolt gun needs to be modified to carry at least 5 down. 5. While a floor plate and detachable box magazine both use a mechanical latch, only the floor plate latch is reliable. Disregard the fact that every modern military rifle uses a detachable box magazine. 6. The Remington 700 is unreliable regardless of the fact it is the basis of the USMC M40 sniper rifle for 40+ years with no changes to the receiver or extractor and is the choice of more military and law enforcement sniper units than any other rifle. 7. PF actions are not suitable for a DGR and it is irrelevant that the M1, M14, M16, & AK47 which were designed for hunting men that can shoot back are all PF actions. 8. 95 deg F in Africa is different than 95 deg F in TX or CA and that is why you must worry about ammunition temperature in Africa (even though most safaris take place in winter) but not in TX or in CA. 9. The size of a ding in a gun's finish doesn't matter, what matters is whether it’s a safe ding or not. 10. 1 in a row is a trend, 2 in a row is statistically significant, and 3 in a row is an irrefutable fact. 11. Never buy a WSM or RCM cartridge for a safari rifle or your go to rifle in the USA because if they lose your ammo you can't find replacement ammo but don't worry 280 Rem, 338-06, 35 Whelen, and all Weatherby cartridges abound in Africa and back country stores. 12. A well hit animal can run 75 yds. in the open and suddenly drop with no initial blood trail, but the one I shot from 200 yds. away that ran 10 yds. and disappeared into a thicket and was not found was lost because the bullet penciled thru. I am 100% certain of this even though I have no physical evidence. 13. A 300 Win Mag is a 500 yard elk cartridge but a 308 Win is not a 300 yard elk cartridge even though the same bullet is travelling at the same velocity at those respective distances. | |||

|

| One of Us |

It's very easy to take an American, wide dovetail sight, put it into the mill and make a smaller, European dovetail sight. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Prechtl or NECG may have what you need. | |||

|

| One of Us |

It was years ago on a MS 1905 but I recall that with minimum of fitting a standard Williams/Marbles insert went right into the dovetail on the ramp. They don't have the same teardrop shape and character of the original but they fit. I would not modify the rear sight blades. | |||

|

| one of us |

I use a 3 corner file with one egde file smooth to fit a sight, What you have there is a piece of cake to do..I would order a blank sight from Brownell and cut and file it to needed specs.. I have some plastic front sights I got from brownell that have nothches in them. About $6.00 for a pack of 6 or 12 as I recall. I install one of them and sight the gun in with them and then mic the platic sight and cut the new front sight to the same specs. Its easy, fast and zero will be exact.Usually best to deal with the front sight on a collectable gun such as yours.. Your gun looks like a standard dovetail, so if you trust the math ( I don't as a rule) just purchase a nice NECG or Redfield, or Lyman.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

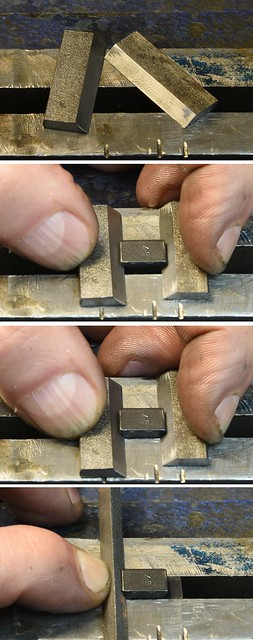

All this talk of different dovetail sizes reminded me of a post I made on another site awhile back as to how to use a smooth jaw vise as a file guide so that only the foot of the dovetail is cut and is kept square. Safe sided dovetail files do work after a fashion but they will eventually either dive or climb depending on where the teeth end on the edge of the file. The sure way to keep everything square and neat is to use a file guide. The two little planer blades are used to align the flat on the sight to the flats of the hardened vise jaws. Simply press them together and slightly down against the dovetail and tighten the vise. The novelty of them is that the sight can be filed and then put back into the vise time and time again as you cut. The file will simply skate over the hardened jaws. It's a very cheap and foolproof filing guide and I have used this method a lot when the mills are occupied with something else.  Sight File Guide by Rod Henrickson, on Flickr Sight File Guide by Rod Henrickson, on FlickrWhen I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| one of us |

Thanks for the advice, guys. I found an unused front sight blade on a Marlin which looked just the right height. It fit a bit loosely in the M-S dovetail, but just a little peening tightened it up nicely. Gun now groups about an inch high at 50 and dead on at 100. Still drifting the sight back and forth trying to get the windage where I want it, but it is now down to about 2 inches left, so the tiniest of movements should put it where I want it to be. | |||

|

| One of Us |

That's damned smart! | |||

|

| One of Us |

Thank you. Now I know how to deal with something that has been a problem in the past. You've fulfilled my goal of learning something new every day. | |||

|

| One of Us |

The blades will work fine if you only have to remove a little bit of metal. They should never allow you to cut anywhere but on the dove tail. If you go in and out of the vise too many times they will loose accuracy because they follow your cut after that. Not the existing dove tail and they may raise up the sight in the female side or sight ramp. If you have to make a large cut, you can use 2, #31 drill bit shanks. If the sight is not machined, if it is cast or sintered the warped material in the dovetail may not give you a true reference to your vise jaws with the drill shanks. Drill bits work but you want to take a flat edge and scrape it across it to make sure that you don't end up with the sight .001 or more high in the vise. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Scroll way, way down this page and the calculations are there: http://www.rifleman.org.uk/PH_Service_sights.htm | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia