The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  stock pattern

stock patternGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Gents: Was reading here and got a bit confused: I've seen some posts by fellow members and they mentioned having a pattern finished and then sent off to the duplicator's. First, what is a pattern, why is one made and how? Second, Does the duplicator then make a stock from the pattern using the intended blank and finish it? Thanks! | ||

|

| One of Us |

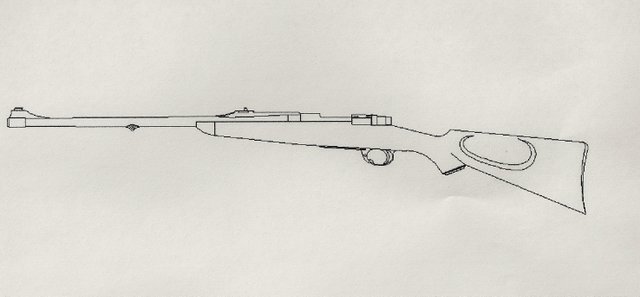

Typically someone may make a stock by hand out of a plain piece of wood, even Poplar, then send it off to a duplicator along with a walnut blank to duplicate. do a search here on duplicator before:   and after:  | |||

|

| One of Us |

These aren't my photos but they will kind of give you an idea of what duplicating looks like.   | |||

|

| One of Us |

Thanks. So, how does one identify someone to make a pattern, and, once done, can a pattern serve as the template for more than one rifle but using different actions? | |||

|

| One of Us |

My friend typically has to dupicate this stock with that inletting. He uses this pattern for the outside and beds it with body putty for that new barreled action and then duplicates it. The $$$ky is the limit. PA Bear Hunter, NRA Benefactor | |||

|

| One of Us |

I've got 3+feet of snow between me and my shop now and it's still snowing & blowing, gusting over 60mph and it's not supposed to let up until evening so I'll try and shed some light on this. If you want a custom stock for a rifle that already has a stock it makes very little sense to use the existing stock for a pattern. A duplicator "simply" duplicates as close as the capabilities of the operator and precision of the machine. The operator can leave extra wood along the toe line for increased drop and this can be shaped by the stockmaker. The cheekpiece may not fit with the lines of the new stock with more drop and the grip may look out of place as well. I don't like using factory stocks as the basis of a new pattern. Rarely is the bottom action flat in the inlet of a factory stock EVER in line with the top line of the stock. Few if any factory stocks have a top line that's remotely flat (try laying one upside down on a table) and usually the barrel/action isn't inletted half way down. Top and bottom inlets can be misaligned a great amount and generous factory inletting helps in assembling. The outside shape of a factory stock is usually not symmetrical and trying to reshape the factory stock to a more custom shape can get quite frustrating because there isn't a single useful datum plane that can be used as a reference. For the amateur stockmaker using a factory stock for a pattern can be very cost effective if you don't count all the time it takes to correct the faults of the factory stock. If I were to do this, I'd start by establishing the top line of the stock EXACTLY with the centerline of the barrel and perfectly flat. Using bondo for this reference plane is NOT I repeat NOT!!! advisable. I would at least use a durable epoxy or better yet graft an oversize piece of wood along the top and then carefully shape it down to where it NEEDS to be. Flatten the top with a jack plane making a good glue joint would work effectively. Next glass the barreled action after insuring the top and bottom inlet are in alignment. Bondo here is not a duplicator's friend as it is very fragile and EVERY imperfection of the inlet will be duplicated by the machine later. I usually don't have the ejection port or bolt notch cut in my patterns as these get very fragile when machining the stock making it harder to make a high quality machine duplicated inlet. I also leave the pattern a little proud around the tang, floormetal and gripcap. Shaping a prepped factory stock to new custom dimensions can be accomplished using bondo on a roughed up surface so it clings well and putting a super glue exoskeleton after the desired shape is attained. Wood or epoxy would be better but bondo works marginally well on the OUTSIDE of the stock if it's hardened with glue and doesn't flake off in shipping or during machining. It usually does to some extent. For my own custom stocks, I like to start with a cad drawing and then machine the profile and inlet exactly where it needs to be. I use laminated cherry to help insure the pattern doesn't later warp. The outside shape is then done by hand while constantly referencing the top line/centerline of the stock. Cast and toe out are easily drawn on the profiled shape and these master lines remain on the stock throughout shaping. Duane Wiebe has an excellent step by step pictorial of stockmaking in the post that's pinned to top of the gunsmithing forum. I learned to make stocks from a blank and I use these methods to make high quality patterns as well as stocks from the blank when necessary. After a good pattern is established, it can be used over and over. Glassing the current project's metalwork into the pattern before duplicating the stock helps speed up the hand inletting process. I never machine a drop in inlet as gaps in the inletting are unacceptable and the only way to make a drop in inlet is to dig a larger inlet like a production stock. Trying to use one pattern for several different inlets, like Mauser, M70, Rem700 or even Rem short to Rem long is not something that can easily and ACCURATELY be accomplished. You would need at least 2 stocks anyway. It would be possible to machine the stock with the desired shape without an inlet a then carefully set it up on a milling machine and machine a different inlet. Most actions have different angles of the tang and different depths from top to bottom and it wouldn't be a simple cheap thing to accomplish. I'm in the process of R&D another gantry for my duplicator. This will have CNC control and I hope to eventually be able to mismatch outside shapes action inlets & different barrel contours. My hope is to multitask, being able to have the machine cutting stocks while I'm busy working on something else in the shop. And if I need to use the duplicator, I'll be able to roll the duplicating gantry back on and duplicate customer patterns as well. Another advantage to converting my machine to a CNC router is keeping the wood dust off the metalworking side of my shop. Here's a few pics of how I build a pattern. If I were to make only one stock like this I would have just made the stock from a blank and not spent the time making this pattern. I've got other miniX projects that will use this pattern.       Figuratively speaking: if you try and duplicate a turd the finished product will look like a turd. | |||

|

| One of Us |

Incredible and informative! | |||

|

| One of Us |

The stock being diplicated in the last pic is going to be a gorgeous finished rifle. Would like to see an update when it is done. I feel the need for a fondle just to see into it's depth's. Someone is going to take an enormous pride in feilding this rifle. Von Gruff. | |||

|

| One of Us |

James, that looks familiar. BTW, I hope you made it back to the house. String a rope taut so you don't get lost. | |||

|

one of us |

Yea, I want to see that bottom one finished too! Terry PS. here's a teaser for ya.  -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

TC, thats just plum mean...You know my thoughts on that stock... _____________________ Steve Traxson | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia