The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Life Hack #2 Threaded Cups for QD sling swivel

Life Hack #2 Threaded Cups for QD sling swivelGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I, as a rule don't like sling swivel attachments that stick out of the bottom of the buttstock, and the bottom of the fore end. The flush mounted cups for holding quick detachable sling swivels have always appealed to me. The problem is that those cups are listed under frou, frou in Brownells,and they are built like a shot glass (eg, there is not outward development to help lock the cup into the stock, be it wood, wood laminate, or heavy fiberglass, kevlar, aramid, or carbon fiber (Teflon and tupperware need not apply. A solution came from the forward thinking team at McMillan. They produce cups that are smooth on the inside, and heavily threaded on the outside. These cups can be held through a strong mechanical lock. courtesy of the threads on the outside.  Tomorrow I will post a picture wherein I drill the hole with a 1/2" forstner bit to the correct depth. That will be displayed on my Mitutoyo analog depth gauge that displays depth with numbers. The Best of both worlds. Then I will Tap the hole 9/16 - 18. Pretty sturdy stuff. Marine Tex and Acra weld with black die will feature strongly, ha, ha, ha.  | ||

|

| One of Us |

Those are Grovtec heavy duty QD sling swivel cups. Grovtec make them in a few different flavors for a variety of rifle/stock makers, including McMillan. Were I to do it all again I'd get the cups that have limited travel so that slings can't twist around and make a mess. Otherwise they're very nice pieces of kit. | |||

|

| one of us |

Thank you jpl, Yes, they come in 360 degree swivel and 90 degree swivel. I bought 10 of the 90 degree swivel so I don't hang myself walking down the bunny trail. Thanks for the info on Grovtec. I will follow up on that lead. I need to order a new Forstner drill bit. They are cheaper from McMillan than on Flea Bay. McMillan sells both types of swivels. I did get a carbide 1/2" Forstner bit from McMaster Carr for $14.50. Also picked up a 7/8" Forstner bit in carbide for drilling holes for mercury recoil reducers. I'll be drilling through laminated stocks, and figured HSS would dull up on me too quickly.  | |||

|

| one of us |

I mixed a little black Acra dye in with the acra weld to get the correct color to blend in with the stock. I had one are in the fore end where there was only 1/4" thickness to try and support the threaded cup. I will get a piece of hardwood cut to fit the space, and use some 1/8" brass drill rod to anchor it in place. Installing the threaded cup will also help pull the new piece of wood into the stock structure. ONLY use WOOD Glue for joining two pieces of wood. If you use epoxy, the piece of wood will delaminate in three years or so. We still need old Bossie's hooves to hold it all together.Here is a link for the GrovTec flush cup installation tool: http://www.grovtec.com/catalog...n-tool-gthm-262-207/  | |||

|

| one of us |

Here is a link to the official GrovTec installation video: https://www.youtube.com/watch?v=dSl5bahOEDo  | |||

|

| one of us |

Here is where you can get the installation tool: http://www.midwestgunworks.com/page/mgwi/prod/GTHM262  | |||

|

| One of Us |

Like you I didn't want stuff hanging off my stock when I didn't have a bipod installed, so I recessed a hollowed out piece of magnesium for a bipod rail and combo flushcup. I used epoxy and it's doing fine so far 6 years later. This rifle has had three 7mm WSM barrels and over 2300 rounds shot through it and dragged all over the place and it's still all tight. I don't think you really need to glue the flushcup in. In my case, there's a bit of friction just screwing them in. Mind you I only ran the tap in as far as was necessary to bottom the cup out in the magnesium/wood while leaving it ±.015" proud so the swivel would rub on steel and not wood. The cup themselves have enough thread engagement to hold at least 90lb per cup in plain jane walnut. I tested it with a bucket of scrap iron, a scale and the QD swivel...    | |||

|

| one of us |

That is a very slick, and well thought out installation you made. When I looked through the GrovTec video, it showed using just a dab of epoxy on the threads. By running the 9/16-18 UNC tap into the hole, it made installing the cup an order of magnitude easier. Again, I am very impressed with what you did, and how long it has held up.   | |||

|

| One of Us |

This is my match rifle. I cut my teeth gunsmithing on it when I had more tools and time available to me than money. It isn't perfect, but so far it's been "bullet proof." The latest barrel is a 7mm WSSM wildcat which helps cut down on barrel erosion and component cost at the local matches now that 7WSM brass is so hard to find.  | |||

|

| one of us |

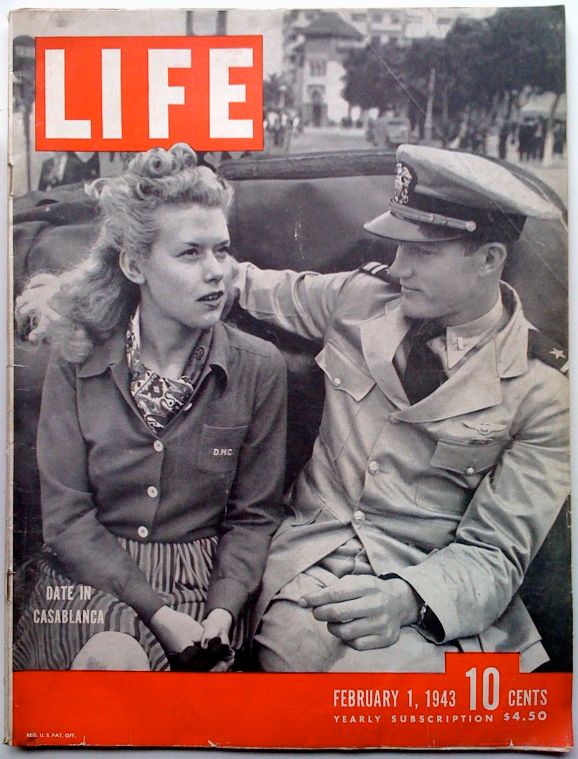

I really like that rifle. I have become Nothing like a uniform on a date:   | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Life Hack #2 Threaded Cups for QD sling swivel

Life Hack #2 Threaded Cups for QD sling swivel

Visit our on-line store for AR Memorabilia