The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Nitre Blueing In the Kitchen Oven

Nitre Blueing In the Kitchen OvenGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

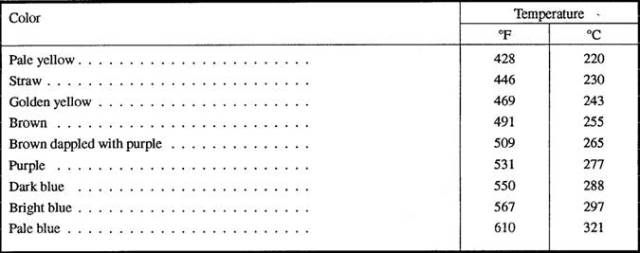

Well, perhaps a better discription would be Nitre Coloring W/O salts. I wanted to color some action parts that were hardened & didn't want to bring them up to the temperatures that achieve the "blue" color W/nitre bluing salts. Since the melting temperature of potasium nitrate is higher then "straw", I have had a hard time getting anything less than "dark blue" W/the salts. Besides, I wanted something other than blue for contrast. I pre-heateed the oven to 440*F (according to the temperature readout on the range) After polishing the extractor, cocking piece & the bolt release spring, I popped them into the oven on a clean cookie sheet. I chose the 440*F setting as it would be a little lower than the temperature desired. (if the readout was accurate) I figured that I could always up the temperature a bit until I achieved the color desire if neccessary. (it wasn't) I used this chart.  After about 20 minutes, the color had come to a nice dark straw color. Here is a shot of the extractor, you can also catch a glimpse of the cocking piece. NOTE: the parts have a film of oil on them W/some streaks & flecks of dust in the film. The flash really exagerated the dust. I didn't notice the streaks/dust W/my naked eye.  A better shot of the cocking piece. The end (only the last 1/4") of the firing pin was nitre blued in salts for contrast.  Here is another shot that shows the extractor as well as the bolt stop spring as it looks when installed in the rust blued bolt stop.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | ||

|

| one of us |

Very Cool! Is the color permanent, barring wear? I actually have a bolt stop spring that color, I wondered how it got that way, if I popped it in an oven at 550 would it make it darker or once the color is there that's it? Red My rule of life prescribed as an absolutely sacred rite smoking cigars and also the drinking of alcohol before, after and if need be during all meals and in the intervals between them. -Winston Churchill | |||

|

| one of us |

The colors should be permanent just like salt nitre blueing, but nitre blueing does not wear well so it should not be used for parts that will get a lot of hand wear. The colors are progressive. (see the chart) You can go up in temperature to the next color phase, but to "back up" you would have to polish the metal back to bright & start over. 550*F will give you "dark blue". I have to watch when using hot nitre blueing salts as it is very easy to get the "bight blue" or "pale blue" if I leave the parts in too long. I dip the parts up & down while watching the color develope. The "oven" method should give better control. If you want the dark blue, set the oven @ about 450*F, leave the parts in for several minutes until the color either stops progressing or come to the level you want. If the color progression stops before the level you want, look @ the chart to estimate the actual temperature of your particular oven. Then you can adjust the additional temperature by the amount of *F that will bring the color you are seeking. If you go too far, polish back to bright & try again @ a lower temperature setting. I'm going to try some screws later & try to get the "dark blue". It looks like my oven is running about 30-40* hotter than the setting so I will probably start @ about 475*F & adjust upward. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

At what temperature does spring steel start to lose its "spring" ? | |||

|

| One of Us |

Nice job. How about a pic of the action all together? | |||

|

| One of Us |

Around 600 to 750 degrees F depending on the carbon content of the steel produces a good spring. Anything above this and the spring starts to weaken www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| one of us |

This is exactly why I did not want to use potasium nitrate salts to color the hardened parts. In the oven I was able to acheive temperature coloring @ temperatures below the melting point of the salts. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

If you buy good quality, commercial nitre blue salts, there is not a problem with temperature. In fact, I use nitre blue to draw out springs, as the heat range it works in is just about ideal for that purpose. Now the guys trying to cheap out by using tree stump remover may not be able to use nitre blue effectively at low temperatures, but Brownells salts will. I personally know they work well in the 500 degree range for spring drawing out. Here's the info from the Brownells tech sheet on their salts: 5) TEMPERATURE CONTROL OF THE NitreBlue BLUING BATH - The working temperature range of NitreBlue Bluing Bath is from 300° F. to 900° F. Although the Bluing Bath is molten at about 275° F., color changes in the steel will not take place until the Bluing Bath reaches approximately 450° F. For best results, the NitreBlue Bluing Bath should usually operate at 600° F. to 650° F. when blue color is wanted on the parts. Below 600° F., the parts may never completely change color to blue. At higher temperatures, the color change is so rapid you will have difficulty bluing irregular parts, such as triggers, hammers, etc. Remember, bath temperature is a major contributor to the color the part will turn, and you will need to operate the Bluing Bath below 600° F. to get the yellows. CAUTION: Do not allow the bath to heat higher than 900° F, because the NitreBlue Bluing Salts will break down chemically. dave | |||

|

| one of us |

Unfortunately I will not be able to post the competely finished action as the receiver/barrel still need to be rust blued & deer season is upon me. Everything but the receiver/barrel has been rust blued or color tempered so after some finish bedding in the stock I will cold blue the receiver/barrel & post pictures. NOTE: The temperatures quoted are the settings that read out on my oven & are not the actual oven temperatures. From the results, it seems obvious that my oven display reads about 40-50*F lower than the actual oven temperature. The extractor, bolt stop spring & cocking piece I did previously came out a bit darker than I wanted (brown) so yesterday I polished them back to bright & re-did them. I also polished all of the screws that needed to be blue & placed all of the parts regardless of color desired into a (preheated) glass casserole dish. Since my oven seems to be about 40-50*F hotter than indicated, I started out setting the oven @ 400*F. After about 45 minutes at that setting I was not getting any results so & upped the setting to 410*F. Within about 15 minutes I got a beautiful golden yellow color on all of the parts. I then removed the extractor/stop spring/cocking piece from the dish. I left the screws in the dish & upped the setting to 500*F. About 1/2 hour later the screws were a deep purple color & didn't seem to want to kick over to the blue. I raised the setting to 510*F & after another 20 minutes @ the higher setting, the color kicked over to dark blue. I left the parts a little longer to make sure the color was consistant before removing from the oven. This is a much easier albeit longer process than using the salts. Once you have the proper oven setting figured out parts can be left in until all have reached the desired color regardless of shape or size. If you want to try this I would suggest that you start out setting your oven about 50*F lower than the color temperture chart & slowly work up in 10*F increments. If you do go beyond the temperature/color desired, just polish the parts back to bright, set the temperature lower & have another go @ it. You will need to leave the parts in the pre-heated oven for some time during the initial heat cycle (45-60 minutes?) until the color is fully developed. It only takes about 10 minutes to achieve the 10*F incremental changes though. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Here are some (crappy) pictures of the parts I temper heat colored last night. This shows the gold color of the extractor but does not do it justice.  Another shot of the extractor. You can also see the "blue" of the rear mount windage screw.  These 2 shots show the "gold" coloring on the stop spring as well as the "blue" rear mount windage screw.   A better shot of the windage screws showing the color. (& dust)  This one really brings out the "gold" on the cocking piece.  Finally, some PIX of the guard screws. For some reason, the light refraction does not show the color of the locking screws well.    The front reciever ring had some forging flaws that required me to take about .015" from the left side so I also reduced the right side a like amount. I am going to skin the sides of the ring W/bedding compound to close the gap that now exists between the wood & metal on each side of the front receiver ring. Since this will require a minute amount of bedding compound, I have waited until I have another action ready to bed so I can mix a larger batch & will get that done today. I got lucky on all of the action screws & they all "clocked" W/O any modifications. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

how high a grit do you polish to first? My rule of life prescribed as an absolutely sacred rite smoking cigars and also the drinking of alcohol before, after and if need be during all meals and in the intervals between them. -Winston Churchill | |||

|

| One of Us |

Is there actually any nitre involved in this oven process? | |||

|

| One of Us |

Montea Like he said it was done in his kitchen oven. No Potassium nitrate needed. And just an FYI all the potassium nitrate does is control the temperature at which the metal is heated. It does nothing other then carry the heat to the part to be colored. Unlike Hot caustic salts that chemically react with the steel to provide a black oxide finish www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| one of us |

I take it to 400 grit & then hit it W/a cloth buffing wheel & emory stick. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

As kcscott pointed out, the salts have nothing to do W/the actual coloring, they are just used to carry the heat. The coloring is a result of oxidation of the surface of the metal as it reaches certain tempertures. These colors have been used for years to determine the amount of tempering when drawing out the hardness of heat treated parts after they have been quenched. The salts would be a lot faster, but my Lee Production Pot varied too much as the themostat kicked on & off & the melting temperature of pure potasiaum nitrate is 633*F so anything less than the temperature for purple or blue was not possible. The Brownell's Nitre Blueing Salts must have other compounds to have such a low working temperatuure. For the average "bubba" home gunsmith, paying $70 or more for nitre blueing salts & then setting up a controled heat source would be cost prohibitive. Yes having a set-up like that would be much faster but (just about) everyone has an oven & W/a little experimentation one can achieve a wide variety of colors W/no cash outlay other than some gas or electricity used in the oven. This method is perfect for the "hobby" gunsmith that wants to add some subtle finishing touches to the gun. I have a junk floorplate that I can polish out & take through the various stages of color. If I get time I will post PIX of the color progression through the various tempertures. BTW: The heat/color chart in the 1st post is something that kcscott posted in another of my threads. Thanks scott for that contribution to this experiment. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

Wildcat Anything I can do to help out and return the favors and business I've received here. www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| One of Us |

I'd be curious to see how this holds up. If you plan on hunting a lot I would recommend staying away from/not nitre blue, doesn't last worth a shit. Even furniture screws lose their lustre quickly- looks nice at first but pure crap after just a few years. I wouldn't do it again. But if you're building a rifle for show and tell and won't get used it'll be alright. Well I guess the good thing is you can always re-nitre your parts just before hunting season like re-warming leftovers. There are two types of people in the world: those that get things done and those who make excuses. There are no others. | |||

|

| one of us |

Being aware of the wear issue I didn't do any large pieces or those that would get constant contact such as the safety or floorplate release levers. As you pointed out, it will be a simple matter of popping the parts into the oven @ a pre-determined temperature setting occasionally to spruce up the color. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Nitre Blueing In the Kitchen Oven

Nitre Blueing In the Kitchen Oven

Visit our on-line store for AR Memorabilia