The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  rechambering - grinding recoil lug instead of setting barrel back?

rechambering - grinding recoil lug instead of setting barrel back?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I would like to rechamber my 7mm-08 to 7SAUM. it seems the 7SAUM would need another 0.065" of depth to get a proper chambering. Being as little as it is, would it be easier to grind/mill the recoil lug instead of intervening on the threads? | ||

|

| One of Us |

If were talking Remington 700, your recoil lug will end up being less than 1/8" thick (if were talking 'factory' recoil lug/barrel bracket)and you'll be 'intervening on the threads' to get the now thinner lug (barrel bracket) 'squeezed' between the action and barrel, you will run out of threads . You will have some serious work ahead of you making a rifle , original set-up for 7mm/08 Rem. feed that 7MM SAUM. IMO, more trouble than what it's worth. And, if you could ever get it accomplished, the strength of the recoil lug (barrel bracket) will have been compromised. | |||

|

| One of Us |

Don't understand the question, If a rechamber is desired, why cut the recoil lug? For this conversion, why would you not just deepen the chamber? I guess I don't understand this. If going to a longer cartridge you need to deepen the chamber. It probably won't feed anyway. Sorry, but I am confused. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

I hadn't bothered to look, but SAAMI says the case length for both the 7mm/08 Rem and the 7mm SAUM is 2.035" -.020. Rechambering a factory barrel is rarely worth the effort or the cost. | |||

|

| One of Us |

You will never have a flat lug if you try to grind the standard M700 lug. Plus you will make a too thin lug even thinner, yes they will bend under recoil. The M700 lug is junk anyway, this is why we replace it with a nice thicker lug. No flies on a 7mm08, fooling with the SAUM is generally a waste of time and invites feeding problems as Jim mentioned. And as Jim says I think you have the operation backward. | |||

|

| One of Us |

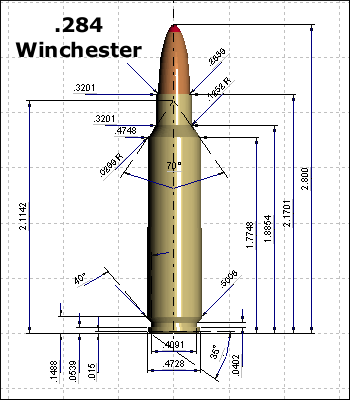

The SAUM is also a magnum bolt face. Check out the 284 Win. That's a bigger 7mm that uses the 308 bolt. | |||

|

| One of Us |

I am trying to understand this topic. If you are rechambering the barrel anyway what is so difficult about setting the barrel back a little bit. The barrel will have to be headspaced which might require some setback to get it right. Dennis Life member NRA | |||

|

| One of Us |

Maybe trying to do it without a lathe: T-handle on the reamer. Guarantees a non concentric chamber/throat. | |||

|

| one of us |

OK; the barrel is a custom - Krieger with just a couple of hundred rounds through it. My idea of grinding the lug was because I didn't want to have to cut anymore of the shank, because it is already a featherweight profile. Aslo, the lug is a custom, thicker lug. However, once you have it set up and dialed in, I realized that taking a few though off the threads and shoulder isn't going to be a problem. The same rifle comes from the factory chambered in both 7mm-08 and 7saum in this same action and model (Titanium), so feeding should not present a huge problem. Yes, the bolt face will need to be opened up, but I got this with a 1:8.5 twist to shoot heaver bullets and it just hasn't satisfied me in either accuracy or oomph. It is getting a brake and new stock and hopefully will find it's final configuration. The barrel has been gathering dust for years since I had it pulled, so I'm not really risking much. Best I can tell, the 7saum is: 0.0216" shorter at the bottom of the shoulder 0.0268" shorter at the top of the shoulder 0.0107" shorter over case length So it should only need 0.0268 taken off the stub in order to headspace properly, right? | |||

|

| One of Us |

Should be something around that number. Dennis Life member NRA | |||

|

| One of Us |

Looks to me like a 284 reamer would clean out a 708 chamber. No need to mess with the lug or threads or bolt face. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  rechambering - grinding recoil lug instead of setting barrel back?

rechambering - grinding recoil lug instead of setting barrel back?

Visit our on-line store for AR Memorabilia