The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Color case hardening Mauser actions.

Color case hardening Mauser actions.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

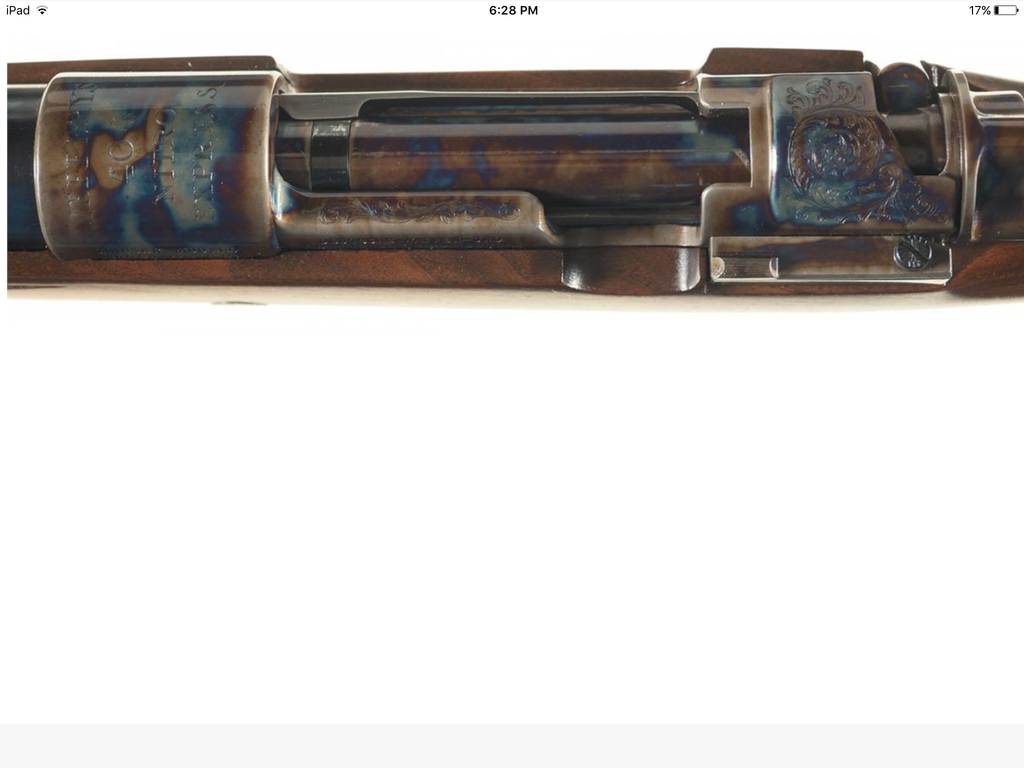

Just curious. Ralph Martini has a lot of his Mauser actions CCH'd by a fellow named Oskar Kob in Novascotia, Canada. These include 1909 Argentines, Oberndorf commercial sporters etc. Many are magnums, such as 300 and 338 Win. I've heard rumour that doing a proper job of color case hardening a Mauser borders on witch craft, and the opinion of some is that no CCH process imparts enough strength to a Mauser action to handle anything but low pressure and low bolt thrust Mauser rounds, such as 8x57 and the like. I would like to hear some informed opinions, pro and con, about CCH Mauser actions. Some people like the look, and some don't. That's irrelevant to my query. I just want to know if it's safe, and how much risk is there for catastrophic warpage. Thanks BTW, I believe I heard Turnbull quite CCH Mausers partly due to warpage problems. I don't know who did this 1909 Argentine, but I like it:  Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | ||

|

| One of Us |

To counteract warping, "blocks" are built to hold the 'part' during quench. The "block" is close fitting and for a Mauser '98 that means making one for each action. The "block" fits both the raceway and the threads and takes time to make properly, raising the cost. The 'hardness' imparted will depend on the steel, the carbon bearing medium it is 'packed' in, the time the crucible (with the part) is in the oven, and the temp of the 'part' when quenched. The higher the temp the part is, when quenched, the higher the 'hardness' of the 'case' and the more tendency there is to warping. The liability of heat treating a rifle receiver would be very high, as 'common sense' becomes less common. | |||

|

| One of Us |

I'll be interested to see where this thread goes. I've been advised that the depth of color case is so shallow as to make it decorative only. Or...if a heat treatable steels are color case, the quench will make the entire part brittle..and of course, cannot be tempered without losing the color. I am one of those that do like the looks! | |||

|

| One of Us |

Strength wise, it is an identical process to what the Mauser went through at the factory. If done correctly, it imparts a 0.015-0.035" case, and the action is plenty strong. No different than the re-hardening done at a modern heat treater. The process differences are the quench is done in highly aerated water to oxidize the surface and produce the pretty colors. In the CCH process, the charcoal mix is a blend of wood, bone, leather, cigar ashes, an old shoe, and two wine corks. Or whatever mix works and produces the colors you are after. Different mixes favor different color pallets. When the factory did it, they more than likely just used one charcoal type that was locally available and just dumped the batch in a water tank. Warpage was likely either reworked, or ignored (the bolt isn't exactly tight fitting). Time at temp dictates the case depth, and is very predictable. Fick's law of diffusion is how you calculate depth, but that is another discussion. An hour at 1550F is about right. Warpage can be minimized, but could always happen. Brace the action as Slivers describes, and anneal it prior to CCH. This takes stress out of it and gives you a proper starting point. If doing one at a time, the orientation the action hits the water can warp it. Ideally, it should drop straight in end first so the contraction in the metal from quenching is not off the centerline axis. Once in the water, all bets are off, but highly aerated water should quench evenly. I will make one correction to the comment Slivers makes. Temp doesn't affect final case hardness. As long as it enters the water as austenite (i.e. it is hot enough), it will reach max hardness for the carbon content of the case. That said, hot enough changes with the carbon content of the steel and case, so you do have to know a little something about the iron/carbon phase diagram. Temp will change case depth (hotter equals faster diffusion of carbon into the surface), and as noted, can increase the tendency to warp. Jeremy | |||

|

| One of Us |

I'm relying that you have had experience or plenty of study..So...it would be pretty important that the action be made of a mild steel in the first place? i.e. Quenching at 1550 on say...a M-70 would be inappropriate? Say a contract 98 has been case hardened (pretty safe bet) Would that no mean there is already carbon introduced. Now you want color,,,that mean more carbon? Is that OK? Re heat treating a Mauser by most authoritative firms is a case hardening..again it's OK to introduce the additional carbon? Maybe I'm overthinking this | |||

|

| One of Us |

When Turnbull CCHs modern alloy steel like 4140, it is NOT by introducing more carbon into it as that is not needed; the color is decorative only; there is no "case" hardness to it. He knows how to regulate the process so it does not become brittle. So, he can color any type of metal; I do not know if he still does bolt actions, but he knows how to, safely. I have sent him plenty of Ruger revolver frames, and other single shot frames made from 8620, and wrought iron; He does all of them very well. The hardness does not come from more carbon; it is from the quenching water; it has to have oxygen mixed into it; look at the original Marlin video; they stir the water before quenching. And the part must not come in contact with air; it must go from the carbon monoxide atmosphere of the crucible directly into the water. Now, when Blanchard re hardens Mausers, and I just got 6 of them back from them, there is no color; actually the surface is a rough gray. They heat them to a very high temp first to remove all the carbon, and then re-introduce a controlled amount into the steel, quench, and draw to get the desired case hardness. | |||

|

| One of Us |

I probably didn't state the 'hardness' correctly, farbedo is correct case depth will increase with the 'higher' heat. I'm not totally convinced that the colors come from oxidation. I've got different colors with different charcoals and different blends of charcoal. Oxidation may be part of it, but different charcoals have an influence, too IMO. I'm a believer that different hardness can and has occurred. On some originally CCH rifle actions the surface is so hard a good file will glide right off. Others can readily be cut with a file, even though the 'case' is apparent. Leather tanned using the process that includes chromium is to be avoided according to the instructor that taught the NRA Summer Gunsmithing Class that I took in 2004 to "get my feet wet" with the process. Learned a lot, but learned even more by doing and reading whatever I could find on the subject, and then trying what I'd read (if I hadn't tried it already). There's just not much in depth reading material available. CCH can only be done in the traditional manner to low carbon steel. 1018 colors beautifully as does 8620, chrome moly steels turn an ugly gray as do many other alloys. How Turnbull manages to color them, is not known and he's not telling. Parts that are already case hardened need to be annealed before re-treatment, an excellent time to polish as they're 'soft'. I have seen polishing make a difference in colors and coverage. Not polished enough can be seen in surface finish, polished to too fine of a finish may influence coverage. After taking the NRA class I tried many different charcoals, methods of packing in the crucible, and degrees of polishing as I was in a position (money wise) to have a heat treat oven built (Paragon Kiln in Mesquite, TX). I built the other things needed, crucibles, tools for handling HOT crucibles, a quench tank and aerator and catch basket to retrieve the part(s). I only start the oven occasionally, now. Everyone wants a discount or to "help". I've CCH a couple of Mauser '98s for myself, but as I mentioned, common sense is none too common today and Bubba is sure he can load that .30/06 to RUM levels and get away with it. | |||

|

| One of Us |

Yes, Turnbull somehow, can color any type of steel from wrought iron (not steel) to 4140 and everything in between, producing the same super colors; and I have never had any warpage there, maybe I am lucky. . Of course, he ain't telling how he figured it out. | |||

|

| One of Us |

Mr. Wiebe, I am a steel metallurgist (we metallurgists specialize by metal) by trade, and deal with heat treat shops fairly regularly. Yes, appropriate steel is a per-requisite. Medium plain carbon, or an alloy specifically designed for the task like 8620. Coloring can be done on higher alloy steels as DPCD notes, but you are just coloring, not adding carbon. It still has to end up being properly heat treated in the end. The coloring can be done in the tempering step if you go hot enough to get the oxides you want. No idea how Turnbull does it. Heat treating alloys like 4130 or 4340 should follow the guidelines of a maker. Crucible, Timken or Carpenter offer recipes to heat treat most any alloy they make as data sheets for free. As for re-hardening, adding more carbon doesn't hurt anything. The process itself has a built in throttle. Meaning, getting the normal case depth takes an hour. Getting twice that depth takes more like 4 hours. The carbon is in a gradient from about 0.95% at the very surface degrading to the base metal carbon level as you move into the part. Re-hardening just adds a little to the areas where the case is already deep, and corrects the areas where it is thin. Kind of a nice phenomenon for our purposes. Thin case areas can accept carbon more readily than thick case areas because there is already max carbon there and it has to move out of the way before new can be introduced. Slivers, Thank you for the reply. I agree with you on the differences with different charcoals or additives. In my experience I noted the mechanism is that different charcoals add new/different elements to the steel surface. Some as films on top of the steel, some as elements diffused into the steel like the carbon. There are a scant few nitrides formed also since air is mostly nitrogen, but nitrogen isn't as reactive. Remember the tempering charts where you heated to a straw color, purple, or a blue color? Different elements oxidize at different temps and to different colors. Even iron will oxidize to different colors at different temps. The thickness of the part (heat mass) and how fast or slow an area cools is what gives the color changes. Curiosity got me and I took some parts I did to work to look at on the scanning electron microscope. Jeremy | |||

|

| One of Us |

DPCD, Are you sure Blanchard decarbs before they re-harden? Not arguing, just being curious. I have never used them. Seems like a waste of time to me. That said, my experience is mostly with gears and drivetrain components. The shops I work with anneal, and then hit it again in the carburizng furnace after the parts are reworked in some fashion. Jeremy | |||

|

| One of Us |

I talked to them before I sent them. Your method might be what they do. | |||

|

| one of us |

I'm a retired metallurgist and started out with Timken and learned a few things about case hardening ! I have to agree with farbedo. I had a fine rolling block reproduction of 8620 with Turnbull CCH -gorgeous !! Doing a Mauser without warping need a good knowledge of the process , especially quenching. But there are a number of ways to do that. My Mauser was done while I was at CST .Spotty hardness gave me reason to do it .No deer has complained ! | |||

|

| One of Us |

Farebo and others...I really thank you for this insight. AS for Turnbull's coloring...I have found there actually is a case..pretty easy to go through with not much polishing with 320. I think I remember correctly is that he describes his case "A few microns thick" | |||

|

| One of Us |

Yes, thanks to all for the comments! Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

Oskar Kob http://www.oldguns.ca/restoration-services.html Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

Ironically, in the past when "hardening" ment case hardening in the traditional manner that produced colors, the colors were polished off on some higher grade firearms. The colors were just a by-product of the hardening process and not always desired. | |||

|

| one of us |

I had been looking into this as well, Mr. Turnbull puts some very specific requirements on the guns. From his website: He will only do the following (the modern rifles have to be NIB): Dakota Cooper Mauser Ruger #1 Kimber bolt actions They will not do: Winchester Model 70 Savage Remington 700 Ruger 77 Am looking to have him do the bolt shroud or safety - not sure which, rings, and bottom metal for a Model 70 I have. Had hoped for the receiver, but will take what I can get. Strange to me they do Mausers given the differences in models, metallurgy, etc. but not the more modern rifles. ______________________ Ken A society grows great when old men plant trees whose shade they know they shall never sit in. --- Greek Proverb | |||

|

| One of Us |

I suspect that Turnbull's would not CCH a pre-war Mauser action, and that what he has posted on his website may be a misprint, as I know he had stopped doing mausers. He may have recently figured out how to do them to his satisfaction. I don't know. I believe the Granite Mountain Arms actions are made from 8620, and CCH very well, but a prewar action might be more problematic. Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

This 404's colours look less natural, somehow, but I like it!  Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

Parts color case hardened in the past showed colors that were much more subdued. The 'color' wasn't the goal, a hard 'skin' on the part was. | |||

|

| One of Us |

True, and a lacquer is applied over many CCH jobs, such as those pictured to both protect the finish and make the colors "pop". Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

I've coated quit a few pieces that I've CCH with backing liquor,myself. It makes it 'shine', but adds no color. It protects from UV light, also,, as the 'colors' fade quit readily when exposed to UV. IMO, many of the pieces we see CCH today are down right gaudy and not true representations of what was originally produced when CCH was the way to make a part 'hard'. | |||

|

| One of Us |

The before and after laquer treatment pictures that I've seen shows that the laquer treatment brightens the colors, which is what I mean by making the colors "pop". I had a Turnbull SAA clone that had a lacquered CCH frame. It was something to behold, if you like the bright colors (I do!). I liken it, somewhat, to putting oil on a gunstock blank to show the grain and mineral streaking. Not quite as a dramatic effect, but it helps anyway. Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| One of Us |

You do occasionally run across pre war "Guild" Mausers that are colored. A more subdued color than most today but it has been done forever. I really like the looks of a colored Mauser. | |||

|

| One of Us |

True. I would like to see one that was put away for the last 100 years without seeing any UV rays. Teddy Roosevelts 1886, in 45-90, still has the most spectacular CCH. Some folks say Turnbull and others CCH is more colourful than original guns. Having seen some originals that have been kept mostly out of the light for three generations, I'd say Turnbull's CCH results are pretty accurate. https://m.youtube.com/watch?v=_6rkmY_p5KQ Matt FISH!! Heed the words of Winston Smith in Orwell's 1984: "Every record has been destroyed or falsified, every book rewritten, every picture has been repainted, every statue and street building has been renamed, every date has been altered. And the process is continuing day by day and minute by minute. History has stopped. Nothing exists except an endless present in which the Party is always right." | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Color case hardening Mauser actions.

Color case hardening Mauser actions.

Visit our on-line store for AR Memorabilia