One of Us

| Open the bolt fully and look at the bolt face; you should see the ejector protruding 1/16th through it's slot. If you don't see it, it is either missing, stuck, or broken spring. Remove the bolt and you should be able to make the ejector move a little. If not, see above. |

| | |

One of Us

| I presume you are referring to non ejection of a fired case ? If this action has a receiver mounted ejector I would be checking that to ensure it's not broken and that it slides up through it's slot when the bolt is withdrawn.

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

One of Us

| Pre 64 70s do have a receiver mounted ejector. |

| | |

One of Us

| quote: dpcd

posted 24 January 2021 15:59

Open the bolt fully and look at the bolt face; you should see the ejector protruding 1/16th through it's slot. If you don't see it, it is either missing, stuck, or broken spring. Remove the bolt and you should be able to make the ejector move a little. If not, see above.

Yes, and also, if the ejector has ever been replaced at some stage it needs to be the right one for rifle model. One time I had ejection headaches with a CRF action and sent it off for examination as I couldn't work it out. Ejector got swapped out for the correct type and voila - perfect ejection every time.

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

one of us

| Thank you. Would one of you gentlemen be able to post a photo of what I should be looking for and what it should look like?

Thank you. |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| Just looked through some pics I have but nothing appropriate sorry, and the rifle in question is not handy. Hopefully someone else reading this might come up with some photos. Maybe a Google search might work....???

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

one of us

| No, that is not the bolt from a pre-64 Winchester; that is a Remington bolt.

John Farner

If you haven't, please join the NRA!

|

| | | Posts: 2950 | Location: Corrales, NM, USA | Registered: 07 February 2001 |   IP

IP

|

|

One of Us

| quote: oublegun

posted 24 January 2021 16:38

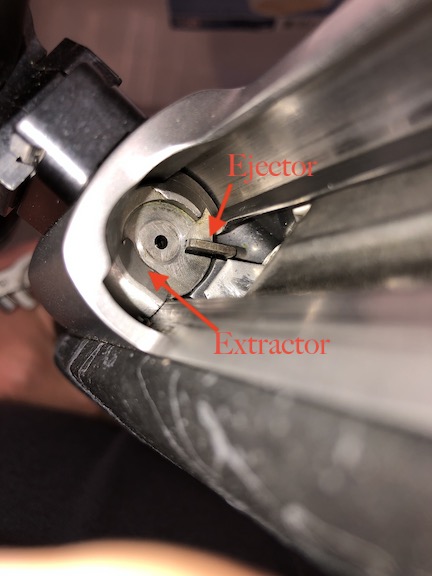

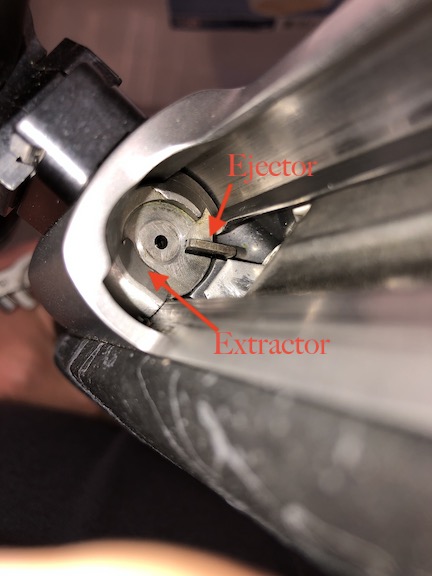

Is this what it should look like?

Your pic is a push feed bolt and not what I was referring to. The CRF bolt, which you rifle should be ( I think ! ) will have a ramp like slot cut along the line of and close to the front end of the bolt, and through the bolt face. When the bolt is pulled back the slot rides over a spring loaded blade-like ejector positioned rearwards inside the receiver. The ejector moves into and along the slot as the bolt moves backwards until the ejector point hits the case base and suddenly pushes ( i.e. ejects ) it from the action.

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

one of us

| I realized that was the wrong bolt face right after I posted it. I have my bolt in hand and see the slot. I can’t figure how it is supposed to work. |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| |

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

One of Us

| Here's my 270. It slings brass across the room...  |

| | |

one of us

| Got it. Now I see how it works and I can see it in my rifle. Now that I know where the parts are and how it is supposed to work I need to figure out why it’s not working. |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| This particular ejector system design is wonderfully simple and even a novice should be able to see if it's basically working, or not. If it's not working a competent gunsmith could probably identify the problem in less than 30 min. so that's always a good move if it comes to that. I'm no expert but have read ejection failure from this action type is sometimes related to how the extractor holds the case against the bolt face. So, if the actual ejector proves to not be the issue it might be time to visit your friendly, local gunsmith. Best of luck. I hope you get it working soon.

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

one of us

| Epilogue: after figuring out how it works (thanks to you) I pressed the ejector up and down and at first it seemed a little sticking but aver playing with a bit I was able to get it working ant it kicked an empty case out several times without a problem. I’m thinking a small drop of oil may be in order.

Thank you again for your help.

Jay Gardner |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

one of us

| quote: I'm no expert but have read ejection failure from this action type is sometimes related to how the extractor holds the case against the bolt face.

m I do believe part of the problem may have been the length of the cartridges and the amount of pressure I had to use to close the action. That would have put a fair amount of tension on the bolt face and the components. |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| Always happy to help a fellow shooter / hunter if I can Jay. I'm glad you got it working. The stickiness may have been from a term of underuse....? and a drop of oil should see you right for a while. If stickiness occurs again sometime later it may be due to a little gunge accummulation in the ejector recess although this is uncommon. If it needs cleaning out an air gun may be sufficient or the whole assembly can be taken out for a thorough clean. Happy shooting.... Grant Wilson

Hunting.... it's not everything, it's the only thing.

|

| | | Posts: 2247 | Location: New Zealand's North Island | Registered: 13 November 2014 |   IP

IP

|

|

one of us

| I’m sorry I misunderstood. Common for dried oil and dirt to gum-up the Winchester ejector and its tiny sprin.

John Farner

If you haven't, please join the NRA!

|

| | | Posts: 2950 | Location: Corrales, NM, USA | Registered: 07 February 2001 |   IP

IP

|

|

one of us

| quote: Originally posted by Toomany Tools:

I’m sorry I misunderstood. Common for dried oil and dirt to gum-up the Winchester ejector and its tiny sprin.

The rifle appears to have been well cared for but it hadn’t been shot for a while and I'm sure there is some dried up gunk and dirt involved. |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| Absolutely not; nothing to do with the ejector; hard closing on reloads is due to making them too long, base to shoulder. Another issue, unrelated to this one.

"I do believe part of the problem may have been the length of the cartridges and the amount of pressure I had to use to close the action. That would have put a fair amount of tension on the bolt face and the components." |

| | |

one of us

| quote: Originally posted by dpcd:

Absolutely not; nothing to do with the ejector; hard closing on reloads is due to making them too long, base to shoulder. Another issue, unrelated to this one.

"I do believe part of the problem may have been the length of the cartridges and the amount of pressure I had to use to close the action. That would have put a fair amount of tension on the bolt face and the components."

I thought the problem was the overall length of the round and the problem might be related to pushing the bullet up against the rifling but you are saying it’s because the overall length of the case. A friend suggested that I get body a die that reforms my cases below the next because they do lengthen over time. Will that solve the problem of a hard closing action? |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| Doublegun, Sounds like some neglect and a dirty case neck area. Tight bolt closing: Clean the chamber neck, throat and shoulder, lug races and bolt end including the back of the lugs and around the ejector with WD-40 and a soft tooth brush and blow it all out with compressed air to see if there is any improvement when you cycle that same unfired round. Repeat 4-5 times. If it improves things, then a fine trace of gun oil will fix it right up. If not, cycle a factory round and compare the feel of the bolt as you close it. Ignore this last one if you already have done this. Extraction: Many feeding/extraction issues can be solved if you slow down and observe. Cycle your unfired round again, no need to close the bolt all the way. As the bolt is near fully retracted, pay close attention to the case rim at the ejector and extractor. Check the inside of the case rim to see if the extractor is "digging in". If so, a qualified gunsmith can relieve the underside of the extractor tip to correct this tightness. If it is fine there, the only thing left to blame is the ejector. The other folks covered this above. Cheers.

Life itself is a gift. Live it up if you can.

|

| | | Posts: 5459 | Location: Near Hershey PA | Registered: 12 October 2012 |   IP

IP

|

|

One of Us

| I don't agree;

I see this all the time; it is not the bullet, nor a dirty neck, or anything but the cases not being sized enough, base to shoulder. Make sure your die is against the shell holder and the ram cams over a little.

Ejection problems are not related to the above; I already told you what to do there.

If sizing the brass fully does not work, try another make of die. I assume your cases are not too long, OAL.

Question; how does it close on factory ammo? |

| | |

one of us

| quote: Originally posted by dpcd:

Question; how does it close on factory ammo?

I’ll let you know as soon as I can find some factory ammo. But in the meantime the action has no problem closing and ejecting the brass from the rounds I fired yesterday. Is that n cause the brass has been fire formed in the chamber when I shot them yesterday? |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

One of Us

| Receiver mounted, spring-loaded ejectors will gum up. It is their weakness. Just keep the action clean and properly lubricated, and all will be well. As for hard closing, poorly sized brass will always be the culprit. After you fire it, you've effectively resized it.

Mike

Wilderness is my cathedral, and hunting is my prayer.

|

| | |

one of us

| So how can I effectively resize the ~ 100 rounds I have loaded? |

| | | Posts: 886 | Location: Michigan | Registered: 17 March 2003 |   IP

IP

|

|

one of us

| You’ll have to pull the bullets, dump he powder and full-length resize after you remove the de-capper from your resizing die.

John Farner

If you haven't, please join the NRA!

|

| | | Posts: 2950 | Location: Corrales, NM, USA | Registered: 07 February 2001 |   IP

IP

|

|

One of Us

| Right and lesson learned here; Never load ammo until you make sure the sized brass will fit into the chamber. Your chamber is the gauge. |

| | |

One of Us

| excuse me for hijacking thread her , but I have new 300 RCM and some once fired brass I bought. I full leingth resized it in RCBS dies and it is a tight crush closing bolt. I suppose I need to find some factory ammo first, but how would I go about selecting another sizeing die? are some known to be smaller/ larger? only options are hornady and forster |

| | |

One of Us

| Happens; and no way to tell which die is going to be smaller; they have relatively huge tolerances. But, first take some of your brass and size it again, making sure the ram cams over when the shell holder hits the die; hard. Milk the case into the die 3 or 4 times. Brass is very ductile and will spring back.

Then try another die if that doesn't work. |

| | |

One of Us

| Do what I said before you alter the shell holder. Sometimes the brass needs to be convinced to stay back. |

| | |

One of Us

| will get some new factory ammo first to have a bench mark. Will look on Gun Broker. thanks guys! |

| | |

One of Us

| So true dpcd, and.... Nothing beats brand new brass, no sizing necessary. quote: Originally posted by dpcd:

Right and lesson learned here; Never load ammo until you make sure the sized brass will fit into the chamber. Your chamber is the gauge.

Life itself is a gift. Live it up if you can.

|

| | | Posts: 5459 | Location: Near Hershey PA | Registered: 12 October 2012 |   IP

IP

|

|

One of Us

| First try resizing like I described; 4 times for each case, up and down, with a lot of cam on the ram. If you don't know what I mean, PM me and we can talk.

That technique has a 99.9% probability of success. |

| | |

One of Us

| Have you ever tried it? I have. Brass fired in another rifle sometimes needs convincing to stay shaped. And make sure you have the shell holder bumped against the die, super hard. You are not the first reloader to need this technique.

Of course, in some cases, (situations) the die and chamber are not compatible; I have had those too. But try the thing that does not alter any steel, first. |

| | |

One of Us

| You don't understand the process. Come over and I'll show you. It is very fast.

As I said, if it doesn't work, then alter something. And I have lathe turned both dies and shell holders to do just that. But it is rarely needed.

But so far, we don't actually know what the OP's problem is, he has not come back with any more information. If I had the rifle you would know in 5 minutes. |

| | |

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Case not ejecting

Case not ejecting