The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Bolt nose barrel clearance

Bolt nose barrel clearanceGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have a factory bolt action that I'm planning to re-barrel. The bolt is a pretty sloppy fit, and when dry firing the bolt handle jumps and the cross hairs jiggle. With the rifle cocked, I can push down on the shroud at the back of the bolt and watch the front slide up to touch the top of the receiver. Some people sleeve a bolt, or add "bumps", or replace the bolt with an oversize aftermarket piece... What if I just machine the back of the new barrel to be a close fit to the bolt nose? I'm talking axial alignment. I'd leave room in front of the nose and in front of the lugs for dirt. The recess in the barrel would have a taper to start the bolt nose, then it would center up as the bolt is closed. So in effect the front of the bolt is centered in the barrel and the rear is pushed up against the rear bridge by the trigger/cocking piece. Is there any merit to doing this? | ||

|

| One of Us |

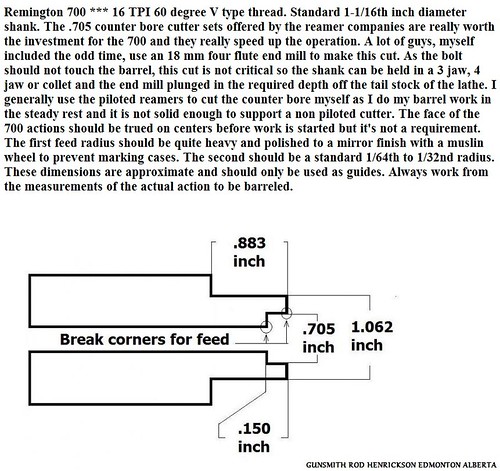

So in Spearchucker's drawing:  The .705 dimension would taper down to the diameter of the bolt nose. | |||

|

| One of Us |

Ok, ask yourself why this isn't being done and isn't recommended... it has been found that contact between the bolt nose and the barrel shank can be detrimental to accuracy. Everybody who fits barrels builds in a .005 to .007" clearance. That let's things fall into "natural" alignment and provides a stress free lockup. Additionally, full contact or pressure here may cause the bolt lugs to gall if some dirt finds its way in. Like trying to chamber a really tight fitting case. Things can go south with just one turn of the bolt. Although the bolt handle "jumps" when it's dry fired, this will stop when a properly fitting case is chambered and fired. In actual shooting, it's a non-problem A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| one of us |

X2, What he said. Although I have never seen proof of accuracy degradation due to bolt contact I would leave a gap as good practice for reliable functioning. bb | |||

|

| One of Us |

Also, when lapping bolt lugs to full contact, this upward pressure from the cocking piece and sear must be compensated for, particularly if the bolt body is a bit loose in the receiver, and often means that a little more material needs to be lapped off the bottom lug in order for there to be even contact with the gun cocked. A lot of little things are at work here. A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| one of us |

You are right but having zero movement means zero tolerances and in my opinion it is not possible to have a reliable mechanism with zero tolerances except maybe in a lab environment under complete control of your surroundings. bb | |||

|

| One of Us |

Correct. There always needs to be some working tolerance and clearance. The extra lapping I refer to is to compensate for the fact that the bolt under pressure from the cocking piece will sit at a very slight upward angle. If the bolt is lapped without the firing pin and cocking piece in place (usual practice) it finds it axial "center" equal to the bolt raceway. When the other parts are installed and the gun goes into actual use, I have often found heavier contact with the bottom locking lug. Hence lapping a bit more here to provide even contact between the two can be done. But this aspect of things is getting a bit off topic here. .. A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| One of Us |

I have heard this theory thousands of times over the last 40 years and many hundreds, possibly thousands of people have actually tried it. All of this trial and error based technology has always come back to one thing. There should be adequate clearance between all parts of the bolt and barrel. Not just for mechanical purposes. Accuracy does seem to suffer if the bolt is allowed to contact the barrel. There are hundreds of theory's as to why this is so and I won't waste anyone's reading time and even dignify it with a theoretical answer. We really don't have a concrete answer as to why it works. It just does and even the manufacturers make a point of leaving space. Many bolt handles do lift on an empty chamber. It is mostly a product of the dry fire stop or shoulder on the firing pin crashing into the bolt. When a case and fresh primer is in place to act as a shock absorber this tendency is reduced dramatically or almost eliminated. My Hall and Shilen action used to do this with general enthusiasm but used to behave quite well on the bench with loaded rounds. As far as the play in the rear bridge. I have seen people leave the rear base screws a touch to long on purpose to minimize that. The simple fact of the mater is that in this instant, trigonometry is your friend. The distance from the bolt face to the rear of the rear bridge on a 700 short action is about 4.600 inches. Assuming that there could be .003 inch play between the bolt and the rear bridge, or .0015 inch per side. The actual deflection over the bolt face on a 308 based case would only be .00015 inch which for argument sake is essentially a non existent number to all put people who do LSD continuously for more than a week straight. When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

Well, I enjoyed the '60's and '70's (I think...) And I even remember some of it.. A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| One of Us |

Then you weren't really there Doug Wilhelmi NRA Life Member | |||

|

| one of us |

When I first started doing my own BR barrel work, around 1977, I typically fitted Remington bolts with zero axial clearance and lapped them in so clearance was minimal. My very best shooting 40X's were done this way. Later on, I started cutting the counterbore with about .005" radial clearance and installed a teflon o-ring to provide alignment. At the rear, I dovetailed inserts into the bolt body to produce "bumps". I use these on other actions as well. It works very well on Model 70's. The concept of lapping lugs with the striker providing the rearward pressure is incorrect because you are producing a misaligned bolt. Remember, the sear/striker interface is exerting no upward pressure once the trigger is pulled. For a short time, I thought using the striker was a good idea but soon learned it was not and abandoned the practise. My latest 40x uses a close fitting counterbore, a separate bolt head, and a close-fitting bolt body. It shoots very well. On a rifle for field use (hunting or varmint) I like about .005"-.010" clearance on the diameter. Regards, Bill | |||

|

| One of Us |

Ought to check-out Benchrest Central. They're building a BR 'tight' 7mm/08 or 284 hunting rig, over there. It's call "tunnel vision". | |||

|

| One of Us |

Thanks for the replies guys! I was sure someone had tried it. I wonder if this partially explains why the howa barrels have a mile of clearance between the bolt and barrel? Maybe the idea is for the bolt to center itself on the case head, with the spring tension from the ejector and cocking piece sort of cancelling. Anyway, I think I'll try it for grins. If accuracy is poor I can open it up and try again (harder to do it the other way...). | |||

|

| One of Us |

I'm lost slivers. I don't find a 7MM or 284 hunting rifle thread. A friend, Jackie Schmidt, was working with a 284 LR competition rifle. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia