The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Stock Finish Questions

Stock Finish QuestionsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I read Les Brooks' tutorial on stock making and followed his guidelines on applying the finish. He said he uses spray urethane as a grain filler and that he sprays on a few good coats, lets it dry for 5 days and then cuts that finish back to the wood with mineral spirits. After he gets the grain filled he then applies a tru-oil finish. My question is if you've got urethane filling the grain of the wood, how does the tru-oil penetrate? Seems kinda backwards to me. I've been working on my M77 stock and have it coated with 2 good coats of the spray urethane and it looks pretty darned good but there are a few areas that need a little more fill. Can I stop once I get the grain filled to my desire and forgo the tru-oil? | ||

|

| one of us |

Tru-Oil is a type of polyurethane that also contains some BLO. You can accelerate the process by 1st applying a thinned coat of Tru-Oil, then following with successive coats of full strength, each right before the previous coat dries and is still tacky. When the pores are filled, mist the stock with turpentine or mineral spirits, then strike off the excess finish with the edge of a credit card cross-grain. This will fill the pores. Let that dry until hard and sand to smooth. This eliminates a huge amount of sanding. Apply a final topcoat of Tru-Oil. You can also do the same thing with the poly spray. | |||

|

| One of Us |

What do you thin the Tru-oil with, mineral spirits? | |||

|

| one of us |

Yes, that is correct. Usually 1st coat is 50:50. Turpentine works too and smells better.

| |||

|

| one of us |

This is a somewhat controversial opinion, but oils never really fill pores in the majority of wood stocks. They also don't need to soak into the wood. In your case the urethane sealed the wood and the oil just sits on top of the urethane to give a specific look. If you like the look of the finish with just the urethane, then adding oil doesn't do anything, except change the look. I finish my stocks with epoxy and then apply oil over that to get the look I want. The epoxy fully seals the wood, and the oil just sits on top of it. Use enough gun... Shoot 'till it's dead, especially if it bites. | |||

|

| One of Us |

Will wiping the dried finish down with the mineral spirits knock the gloss off the finish w/o streaking it? I like the look of it now after I just added a couple more coats of the spray urethane but its got just a tad too much shine. | |||

|

| one of us |

I use the stock polish that comes with the tru-oil kit to knock the shine off. Most of the directions you read say to use "rotten stone" to knock the shine down, but I still haven't figured out what rotten stone is. Use enough gun... Shoot 'till it's dead, especially if it bites. | |||

|

| One of Us |

rotten stone is pumice | |||

|

| One of Us |

Well, sort of. Actually, rotten stone is a finer grade of pumice . | |||

|

| one of us |

Stock finish can be several different types of materials. The ways to apply the sealer varies by whether it is sprayed or hand rubbed. Most people like to have the pours filled smooth with the surface of the wood. The way to get this smooth is to cut back down to the wood surface with steel wool or by using a wet or dry sand paper with a solution to keep the finish from filling the paper too quickly. The grain of the wood will probably need a couple of coats of a filler before it will be smooth enough to apply a top finish. You can buy a finish for high gloss or a dull finish. I use an Auto Rubbing Compound to get a dull finish by cutting back the top finish after it has dried for a week or two. If you are planning to cut back to make a smoother finish you will need maybe four or five top coats to build up enough finish to cut back. Johnsons floor wax can be applied to the stock after you are finished with the rubbing compound. I have used lacquer, boiled linseed oil, poly urethanes, and epoxy spray finish on gun stocks. Spraying the above finishes can be very dangerous for explosions as well as filling up the lungs with the particles. Pick a method and stay with it until you are satisfied with the results. Only you know what type of finish you like. I started out using the Geo. Brothers Lin-Speed oil in 1957 and I still like that finish. Similar oils are available today, but they are not the same formula. The newer formula’s will dry quicker. Custom stock makers have their own ideas of a finish. Some think they have the best kept secrets on finishes. Any finish will require you to practice until you have it perfected. The purpose of the sealer is to seal the wood. | |||

|

| One of Us |

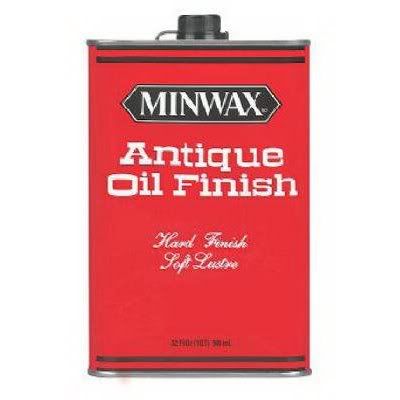

If you want a satin almost flat urethane finish , Min-Wax Spar urethane Satin is the ticket ! Brownell's Pro-Custom aerosol in satin is just a tad glossier but doesn't cure quite as hard as Spar urethane , Both look good . Don't forget to have your Liberals spayed or neutered ! | |||

|

| One of Us |

Thats what I'm using now, the MinWax Helmsman satin clear but its just a tad to shiney. Might do the rubbing compound trick after it dries for a few more days. | |||

|

| one of us |

Here's what I use.  After a good build-up & partial grain fill, I sand W/wet-or-dry paper using turpentine to wet/lubricate it. The slurrry fills the pores quite nicely. I used to use Tru-Oil but this works much quicker & is much more durable. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Rottenstone is actually powdered limestone.

| |||

|

| One of Us |

[QUOTE]Originally posted by Bobster: Rottenstone is actually powdered limestone. [QUOTE] Good to know, I stand corrected. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia