The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  James Anderson begins stocking the Mini Mauser. UPDATE 3/17 try pattern begins

James Anderson begins stocking the Mini Mauser. UPDATE 3/17 try pattern beginsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

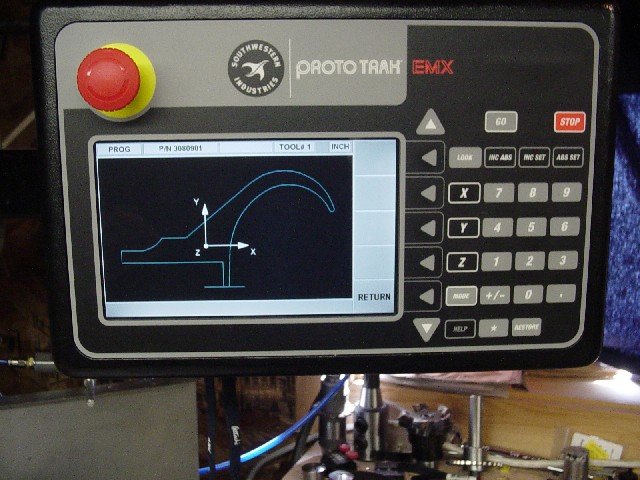

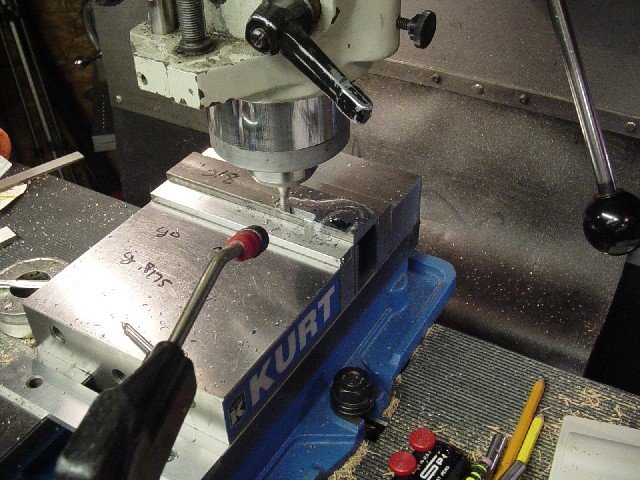

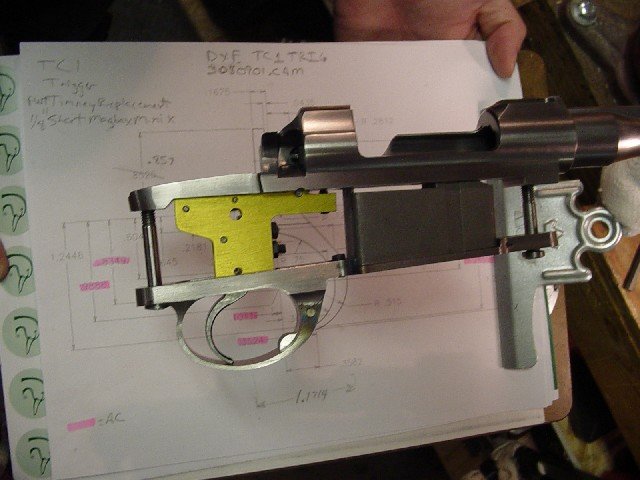

I just got some pictures from James Anderson. These are of some changes to the magazine box and trigger fitment. These are a real treat. The bolt handle and 3-position are the the last things to be done and the metal is finished I believe. We're going over the final stock dimensions tomorrow and then the pattern goes into production. James has been very kind to share the progress of this rifle with us. If you ever have a desire for that once in a lifetime gun please keep him in mind. Below are a series of pictures were the magazine is depth is reduced to scale the rifle down. Since changing one thing always' effects another, a new trigger shoe is cut for the Timney trigger. This is a nice upgrade because it give a custom fit inside the the bow. James Anderson: "Heres a few pics to pass the time. After milling the 1/8" off the height of the grip came down to what my Mex Mauser pattern is. The stock MiniX is a little too thick. My unmilled miniX holds 7 down. It looks like it too. I'll be able to trim your stock to a much more pleasing line with this modification." "Setting the mag box to mill off 1/8" "  "Finished mlling"  "Here's some more pics. The Timney trigger was way too long for the little miniX bow especially with the shorter mag box. zeroing the stock"  "Cad verifying the program"  "rough milling"    Finished part  Basicly the before and after photo's Notice how much better the trigger fits now and whille the depth doesn't look to be much, when you cover it with wood it'll be significant.   Thanks again James, this made my day. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | ||

|

| One of Us |

Nice work and project, keep the pictures coming. Thank you James for taking the time to take pictures. | |||

|

| One of Us |

Beautiful work James! Terry I am very jealous and I know you are anxious to get it back into your hands. Butch | |||

|

| one of us |

Jim, As usual, great work!  Aut vincere aut mori | |||

|

| One of Us |

The trigger is still a little thick. I still need to hand file contour a radius to the front where your finger goes. It'll look more like a shotgun style trigger after final shaping. Now that the trigger and mag box are modified, I can get the grip pull and length of pull established on the pattern. Terry's got a thing for stocks with some drop in them so I get to build a new pattern from a blank. | |||

|

| One of Us |

Hi Terry, James, nice project! About the magazine, what am I missing since the reducing was not made in the flat, bottom end? Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

one of us |

Hi Bent, I'm not sure. If James doesn't see your question I'll find out and PM you. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Bent, The way I am assuming it was done (and perceive from the picture as well) the entire magazine is inside the block of wood with a wooden insert inside it. Cheers, Number 10 | |||

|

one of us |

I just looked at another Mini Mauser magazine I have. I'm sure the reason is because there is a screw tap attached to the bottom that you can't do without.  Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Ah, thanks Terry! I still wonder if that one could not be altered easier than Andersons milling operation, but I am sure he has a good explanation and hope he responds here in the thread! Gerry, thanks, but I think you are missing my point. Cheers, Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Bent If it didn't have the screw tab, I would have just scribed the bottom and used my belt grinder. Then welded the little tabs back on that hold the box to the floormetal rails. Tig welding on sheet metal isn't my forte so I thought it easier to mill the fixture using the Prototrak. The close fit pocket holds the mag box square. The plug in the middle is the same 5 line pocket program where I lied to the control about the cutter diameter to offset the cut the thickness of the sheet metal box. When you shorten a standard 98 magazine, don't you mill off the top as well? | |||

|

| one of us |

Great work - thanks for sharing. | |||

|

| One of Us |

James excellet work as usual Terry another project to keep everyone entertained and possibly a little envious. Excellent all around Gentlemen!! Michael J | |||

|

| One of Us |

James, I hope you did not take my question as critisism, I was just qurious. The pics do not tell the whole story, and I have not worked on a minimauser. To compare it to a M98 is in my opinion a bit unfair, as it is two completely different things. We all have our different fortes, I would have opted for cutting the tab off and welded it back on, but I am not the wiz in a mill as you seem to bee. To each his own, everything indicateds that the job and result is superb. Thanks for shearing. Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

James - What model of Timney trigger is that? I don't find one on their website for the Mini MKX. If a standard Mauser trigger, what has to be done to fit it? "I ask, sir, what is the Militia? It is the whole people. To disarm the people is the best and most effective way to enslave them" - George Mason, co-author of the Second Amendment during the Virginia convention to ratify the Constitution | |||

|

one of us |

Hi Masterifleman, that is a regular Timney M98 featherweight trigger. They bolt right in. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Looks like that should really trim the rifle down to a proper scale. Did oyu have to trim down the trigger housing itself (the yellow anadized aluminum part)? How long is the barrel on the rifle, and what is the diameter at the muzzle? WHat will be the length of pull? On th emagazine/wood fixture, did you mill out the female part and then the male from a seperate piece of wood? At first glance I was like "how did he make such a thin *%(*^%! cut in that wood!?!" | |||

|

one of us |

Hi Marc, the barrel is 20" and .550 at the muzzle. The trigger housing was left standard (I remember this from a conversasion with James.) The length of pull was decided today and will be 14". The stock will have about 1 1/2" of drop and will be an English stalker style. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

one of us |

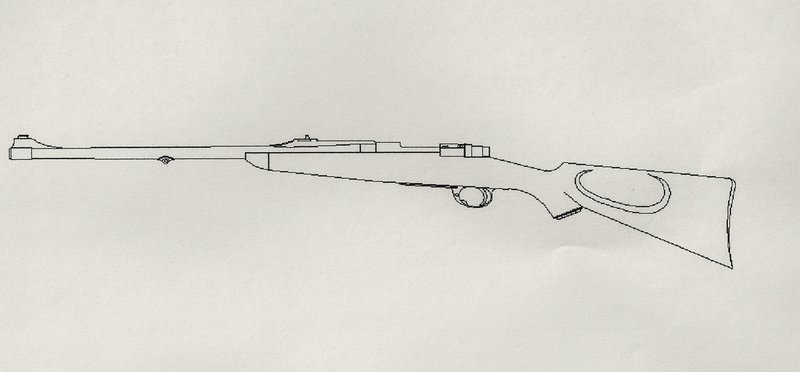

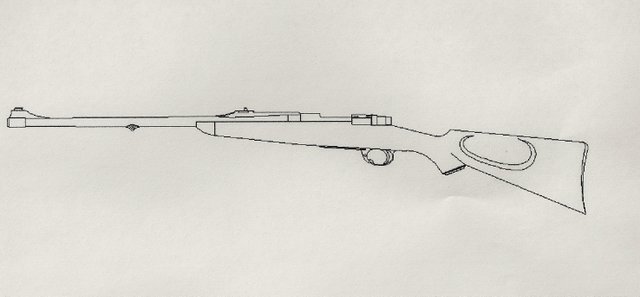

Final stock design agreed on and CAD drawing rendered.    The wood chips are about to start flying Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

tc1 congrats, excellent looking rig. Rich | |||

|

| One of Us |

That is so sweeeeeeet! | |||

|

| one of us |

WHat scope is going on it? I am putting a 3-9 Leupold Compact on the little L461 I am building right now. Think it will be the best scale for my rifle. Just my point of view, but I think a 1.5-5 Leupold would look best on your rifle, but the 5X would be too low for me on a .223. ANyway, i was just curious about your scope plans! | |||

|

| One of Us |

Terry, Hope you are heading towards full recovery! I am really looking forward to seeing this rifle come to life...I am sure it will be very special....and I am looking forward to putting my hands on it soon Possibly we can head to the Memphis Sport Shooting facility for a few test rounds...may be you will let me pull the trigger Best, jjs | |||

|

| One of Us |

What are you going to do with the bolt handle? The only easy day is yesterday! | |||

|

one of us |

Marc, I've got that exact scope sitting in a box Jim, I'm still in a little pain but heailing up well. You will get some trigger time, Just bring the Hoffman. HA! Pegleg, here is another handle James just did for me on another Mini Mauser. It's from the Halfmoon rifle shop. The next one I think is going to be slightly longer.  Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Terry- Will this be chambered in 223? This is going to turn out great! The only easy day is yesterday! | |||

|

one of us |

yes, .223 Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Will the stock have a steel butt plate and grip cap? So Sweeeeet! I have a mini-mauser that I would like to do similar things to and chamber it in a .222 The only easy day is yesterday! | |||

|

one of us |

Yes, It's going to have a trapdoor buttplate and he was going to do a trapdoor gripcap but decided it wouldn't scale properly so we had to let that go. James is going to turn one of his own for this project. Give James a call about yours. That's what this is all about. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Terry / James; Now this is what makes this forum special... Again Thanks to both of you! Hope more will jump on the bandwagon. The figure in the wood on the cad drawing is a little plain don't ya think! Enjoy _____________________ Steve Traxson | |||

|

| one of us |

Terry/James, Thanks for posting all the details on yor mini-Mauser project. I recently bought the one Trez Hensley sold in the AR Classified Section. The action is in Duane Wiebe's shop right now, it will also be a .223. | |||

|

| One of Us |

Best guess on final weight? Can't wait to see with stock complete. | |||

|

one of us |

I wouldn't venture a guess on weight. I'm sure it'll be light enough. Balance is my only real concern. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

one of us |

Wow! Nice work, as usual, James. Terry, you must be a proud papa....lol Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

one of us |

From the CAD  To the 3D version  A few small details and it'll on it's way to me. It's inletted for a factory barreled action at the moment. Mainly because I have one just like it. I can put my factory barreled action in this "try" stock and fingure print it for a few day's while the other barreled action doesn't have to make the trip across the country. Then if anything needs changed James can do that before nice blank goes under the knife. This is going to be a VERY nice Mini Mauser! Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Not sure what is going on with the stock making. Did James rig up his duplicator to operate off a 3D cad program??? | |||

|

one of us |

Yep, you tell him what you want, he draws it, you discuss, make changes and agree, then it becomes reality. Pretty cool stuff. I've been truly blessed to be able to work with two fine gunsmiths on this project. Shane Thompson and James Anderson are both at the top of their game and it shows. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

one of us |

Just a few pics of the pattern coming together. This is what keeps me hooked     Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

I machined the stock on my milling machine starting with the profile that I'd drawn in CAD. Then I machined the inlet. My mill only has CNC power on the X & Y. After that, I just rounded off the corners using a bandsaw as much as possible then used planes, chisels and files. After the bandsaw, I was wishing I could try Duane's Tasmanian Beaver to melt away everything that didn't look like a stock. My other MiniX pattern has very little drop and a 1/8" taller mag box. I'm kind of interested in using this new pattern for my own miniX. It has a quarter rib as well could use more drop. As for the 3D stuff.... I've been thinking about converting my duplicator to a CNC router. The biggest problem is that I don't want to lose the flexibility of being able to instantly copy something. Since my duplicating gantry rolls on DualVee bearings, I could just make a new servo powered gantry and pull the duplicating gantry off in a minute by removing just 2 screws. When using the duplicating gantry, the CNC one would be rolled all the way back and just turned off. The rails are 6' long so there would be enough room to do normal stock duplicating even with 2 "cars" on the track. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  James Anderson begins stocking the Mini Mauser. UPDATE 3/17 try pattern begins

James Anderson begins stocking the Mini Mauser. UPDATE 3/17 try pattern begins

Visit our on-line store for AR Memorabilia