The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  James Anderson does it again!!!!

James Anderson does it again!!!!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

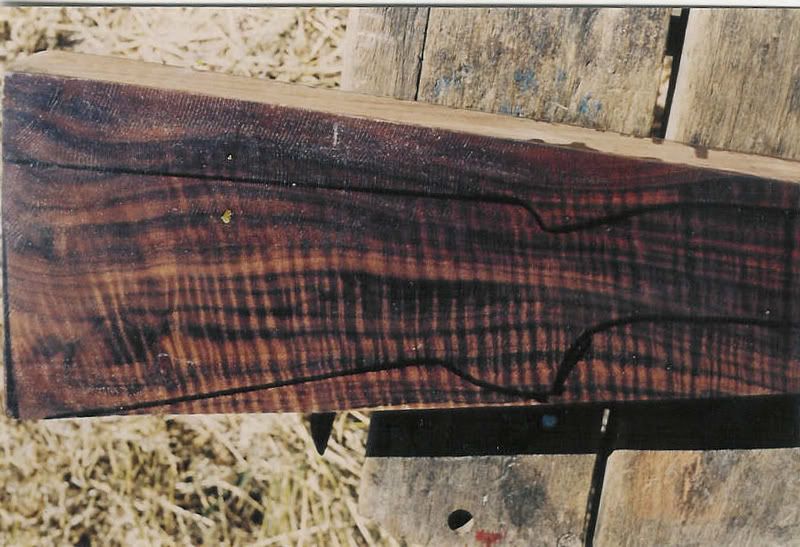

Several years ago my Dad and I decided we wanted to build a matching pair of rifles. But at the same time we wanted them to each still be unique. The intent was that after they were built we would hunt with them and enjoy them and then when it came time for Dad to pass on his guns we would pass these rifles on to my boys. That way they would each have something special that was done by Dad and Grandpa together. Well, over the last few years this project has taken several turns and changes. The original plan was to use a pair of Winchester M70 Classic actions and chamber them in 300 WM. Since we wanted them to be a little different from each other I chose to use stainless. Well, the action and caliber are about the only thing that has stayed the same. Long story short - following the recommendation of ForrestB I went to James Anderson for some help. He was kind enough to take on the project despite his already full plate. I sent him the parts I had and asked him to work his magic. I already had the CM barrel, it was a Badger and cut in the same octagon contour as the Winchester Custom Shop. James looked it over and recommended re-cutting the funky Custom Shop octagon into something a little lighter that was more elegant. James selected a stainless Half Moon barrel for my rifle and turned both barrels into very classy and graceful octagon barrels. He also gave the tangs his “cloverleaf†treatment and also welded up the bolt release and checkered them. The stocks will be done by Dean Zollinger in a classic pattern with an open grip and slim and trim overall. Mine will have an incredible stick of English and Dad’s a piece of tiger striped claro. Both stocks will have Fisher 2 screw grip caps, red Decelorator pads, and Wiebe inlet swivel bases. Bottom metal is Blackburn. The CM M70 will be rust blued and the stainless M70 will be finished to a satin finish. In order for the swivel bases and grip cap to match the stainless of the stainless rifle they will be coated to match by Robar. For rings and bases both rifles will be getting Warne Premier lever QD rings and bases in the same finish as the rifles. Scopes will be Leupold 3.5x10 with the same finish as the rifles also. I realize I have left out a lot of the steps that happened to make these rifles come into being but you get the idea. I have to say that without the help of Forrest and the great work of James that these rifles would have been mere half attempts at being custom rifles. Thanks to the help (usually meaning a smack aside my melon) and impeccable taste of Forrest and the incredible talent and skill of James and I really learned a lot about what separates a great custom rifle from being just another nice rifle with this project. I will you posted on the rifles progress and hopefully have some more photos to share with you soon. I can’t begin to recommend James Anderson enough. His work is impeccable, prices fair, and he works very hard to complete the work in the time promised. And one thing that really impressed me, on top of the quality of his work, was that his communication with me about the project was always timely and he kept me very well updated with the progress of the work. If you are considering having work done then James is the man to talk to.        William Berger True courage is being scared to death but saddling up anyway. - John Wayne The courageous may not live forever, but the timid do not live at all. | ||

|

| One of Us |

You are a lucky man and to be able to share it with your Father is very special. I hope to have some metal work to Jim soon. Butch | |||

|

| One of Us |

Thanks for the plug Bill. I hope you get the chance to hunt with your father and these two rifles next season. Keep your head down for now! | |||

|

| one of us |

Great work and a great idea Bill, be sure to show us the finished guns and maybe a picture of the boys too. best, Rob | |||

|

| one of us |

VERY nice! Great project that will be cherished and used for generations. John There are those that do, those that dream, and those that only read about it and then post their "expertise" on AR! | |||

|

one of us |

Very nice, your English blank is right up my alley can't wait to see the finished product. ______________________ Always remember you're unique, just like everyone else. | |||

|

| one of us |

What a great project ... and coming along BEAUTIFULLY!!!!! Congratulations indeed Mike -------------- DRSS, Womper's Club, NRA Life Member/Charter Member NRA Golden Eagles ... Knifemaker, http://www.mstarling.com | |||

|

| One of Us |

When I die I want to come back as a machinist. I have met so many amazing gunmakers/machinists in my life and I still marvel at the ability of those folks to take something to plain as metal and wood and make them into works of art. I love it. _Baxter | |||

|

| one of us |

+ 1! | |||

|

one of us |

Very nice. I love the tang treatment, nice touch. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

one of us |

Thanks everyone for the nice comments on the rifles. This pair of rifles has been a long time dream for Dad and I. And finally they are becoming a reality. Dean Zollinger has promised to have them completed by the time I get home from this deployment in February. They are going to be a great welcome home present!!!!! I already have a hunt planned for mine to get it broken in!!! I cant begin to tell you how much I appreciate the talent of James Anderson. He really did an outstanding job and turned what would have just been a nice barreled acion into somthing very classy. William Berger True courage is being scared to death but saddling up anyway. - John Wayne The courageous may not live forever, but the timid do not live at all. | |||

|

| One of Us |

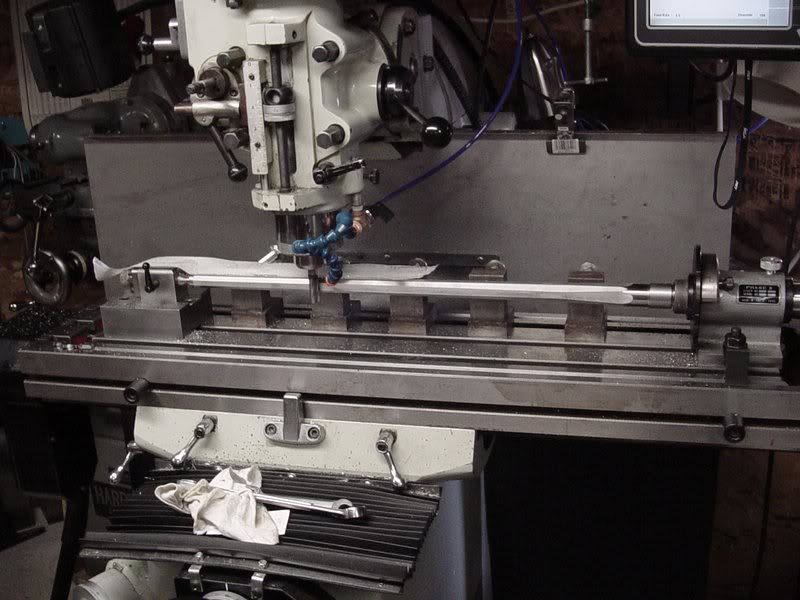

Mr. Anderson; Thank you for the phtos of your set up on the mill. I like the suport blocks you have made up for the milling operation. I need to make up something myself to make life a little easier when doing this type of project. Can't see complete set up because of masking tape, are you wanting to keep the cat in the bag or is it possiable to get a photo of the backing plates/blocks? One more question...Was the barrel done with just the roughing end mill and what size did you use for this project. Yes i know, I'm being nosey but Hey thats just me! Thanks! Nice work and a nice finish /very well done...Octs add a lot of class to a rifle. _____________________ Steve Traxson | |||

|

| One of Us |

The first milling pic shows the tape off the first 2 supports. They're just a chunk of steel with a 1/2-13 threaded hole through. I welded a foot on the chunk to bolt it down with. The headstock, tailstock, and supports are all keyed on the bottom to make setup go quick. I use a 1/2" roughing mill first and then finish with the sharpest carbide mill I've got. I'm milling 2 arcs on the barrel in the picture. It's swamped a little. If you don't have CNC then a 3" shell mill would work and the keys in the head and tailstock would not be needed. The control gets lied to for the rougher dia so it leaves enough for a good finish cut. Blanks are turned down before milling. The tape keeps the chips from vibrating between the barrel and the 1/2" carriage bolt. I cut opposite sides kind of like tightening lug nuts to relieve the stress a little more evenly. My ideas are from John Pell in Trinidad, I just added the CNC part to generate the arcs with smaller tooling. The climb milling leaves a great finish as well. | |||

|

| One of Us |

Thank you for your answer!!! Nice equiptment and set-up... Enjoyed seeing your work. _____________________ Steve Traxson | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  James Anderson does it again!!!!

James Anderson does it again!!!!

Visit our on-line store for AR Memorabilia