The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Turning Out the "Steps" In a 98K Barrel W/Minimal Stock Removal

Turning Out the "Steps" In a 98K Barrel W/Minimal Stock RemovalGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

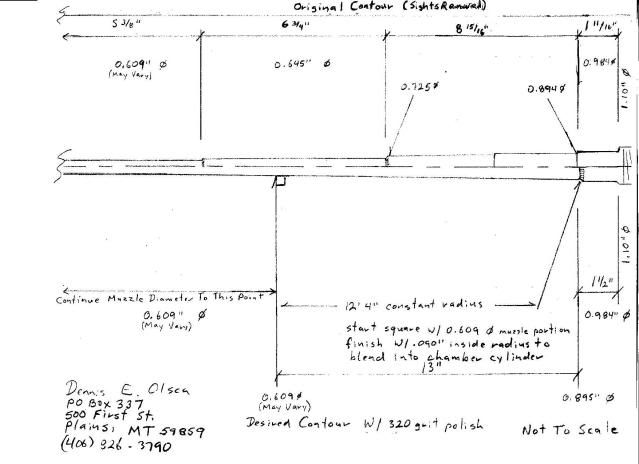

I once had a M98K military barrel turned down to remove the "steps". As it turned out, re-contouring the barrel to a constant taper removed way too much stock & the resulting barrel would walk the shots as it warmed W/consecutive shots. It would eventually settle about 4 " high towards 11 o'clock & then only hold mediocre groups. I could not hold the 1st 3 shots under about 2 1/2" @ 100 yds W/O a complete cool down between shots. I thought long & hard about how to remove those unsightly steps while still leaving the maximum amount of steel on the barrel for stiffness & thermal stability. The answer was not to “taper” the barrel @ all, but to extend the diameter of the cylindrical portion on the muzzle section to the rear to a point where a constant long radius sweep would just clean up the steps. While removing as little metal as possible. I calculated the radius, made a drawing & sent the drawing & barrel to Dennis E Olsen in Plains, MT after discussing the desired results W/him. This is what I ended up with.  After finishing the rifle last fall, I was delighted to find that the barrel would hold zero & shoot sub ½” 3 shot groups W/successive shots W/O any cool down. I have had several people inquire about the drawing & I finally was able to get it scanned so that I could post it here. I’ll explain some of the details later.  The top half (above the drawing centerline) is a rough sketch W/approximate dimensions of the 98K barrel once the sights have been removed. Bellow the centerline is the finished contour sketch. The measurements are taken from the forward edge of the 1.10" shank diameter where it is reduces down W/the radius into the .984" diameter of the chamber cylinder. What you want to have done is continue the muzzle diameter back to 14 1/2" in front of that point & then start the long 12' 4" radius sweep starting square W/the muzzle cylinder back to the .984" diameter chamber cylinder & finish W/a short radius of however you want to finish it out. If the muzzle diameter varies a few thousandths, it doesn't matter as there is some room for this variance. Just continue whatever that muzzle diameter is & use the same radius sweep & starting point. If anyone wants a full sized 11" X 8 1/2" JPEG version of this drawing, PM me your e-mail addy & I will send it to you. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | ||

|

| One of Us |

Real nice. Without that second step it almost looks like a winchester featherweight barrel. | |||

|

| One of Us |

Looking good, excellent soulution. | |||

|

| one of us |

The question regarding the sight locating pin holes has been asked. The way I do it (not sure who told me how, but it was an experienced gunsmith)is to take a drill bit slightly larger in diameter than the hole & clean out the hole W/O deepening it. Then take a piece of drill rod the same diameter as the bit you used & cut pieces slightly longer than the hole depth. Set these pieces of drill rod in RED (271) Loc-Tite & peen them to swell them tightly in the holes. File them flush & they will be extremely difficult if not impossible to locate after finishing. Do this before the barrel is re-contoured. So far I have not had any come loose. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

Very nice looking barrel. I don't know which forum I saw it on but I have recently seen one that was modified by turning 'wedding rings' at each of the steps. I thought it really looked nice. Certainly much easier than the complete taper of the barrel. You would just have to grind a cutting tool and then polish the barrel. SCI Life Member NRA Patron Life Member DRSS | |||

|

| one of us |

A radius of 12'4" is a very difficult measurement for a manual lathe. How did you accomplish this dimension? With an advanced DRO or maybe a CNC equiped lathe? Craftsman | |||

|

| one of us |

To get an answer to those questions you would have to contact Dennis Olsen. All I did was supply him W/a drawing & the barrel to be re-contoured. The turnaround from my home on the Canadian border in northern New York State to Plains, MT & back was just about a week so either Dennis has CNC equipment or he’s one heck of an old school machinist. Since Dennis does not seem to have any internet access, I think the later might be the case. I checked the portion from the chamber cylinder to the barrel band swivel stud W/a 6” machinist’s scale & it is indeed a radius sweep & not a taper. I even notched an old wooden ruler to clear the barrel band & the portion ahead of the barrel band is a radius sweep also. The 1st 7” of the muzzle portion is a cylinder & not a taper either. I measured that W/dial calipers & it remains the same diameter for those 1st 7 5/8” Did Dennis use some set-up her already had that is close to my drawing? Perhaps, but the fact still remains that it is so close to my drawing that I can’t perceive any discrepancy W/the rudimentary measuring devices I have. During my initial phone conversation W/him, Dennis immediately mentioned a “sweep”, so he @ least had a visual idea of what I had in mind. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

one of us |

I believe the correct answer is both. Dennis is very old school, but I believe he has modern equipment. Also, Dennis does have some type of internet access as he(or his wife) have email me several times. I would be willing to bet that Dennis has done similar barrel jobs in the past. I have had him do some odd things and every time I ask him about doing something that I believe is odd his reply is something to the effect: "Yep, I can do that." I get the distinct impression that he has done everything, including the oddest jobs, at least three times. And when I get the work back I am always impressed. Dennis has very good prices and his turnaround is very, very good. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

richj posted that on this forum | |||

|

| One of Us |

Here' you go, I got kcstott to do this for me.  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Turning Out the "Steps" In a 98K Barrel W/Minimal Stock Removal

Turning Out the "Steps" In a 98K Barrel W/Minimal Stock Removal

Visit our on-line store for AR Memorabilia