17 December 2014, 17:35

wildcat junkie1898 Krag Barreled Action Question

I would like to have a flat recessed crown done on my 1898 Krag. I believe it was one of the CMP/NRA versions that were cut down 22" in the late '20s

The Barreled action looks like it would be impossible to chuck up in a lathe W/O removing the receiver from the barrel.

For various reasons I want to avoid taking the barrel/receiver apart.

Is there an easy way to do a flat recessed crown W/O doing that?

I have a local machinist that, although not a gunsmith, he is capable. I would like to have some input before I take it to him.

17 December 2014, 17:45

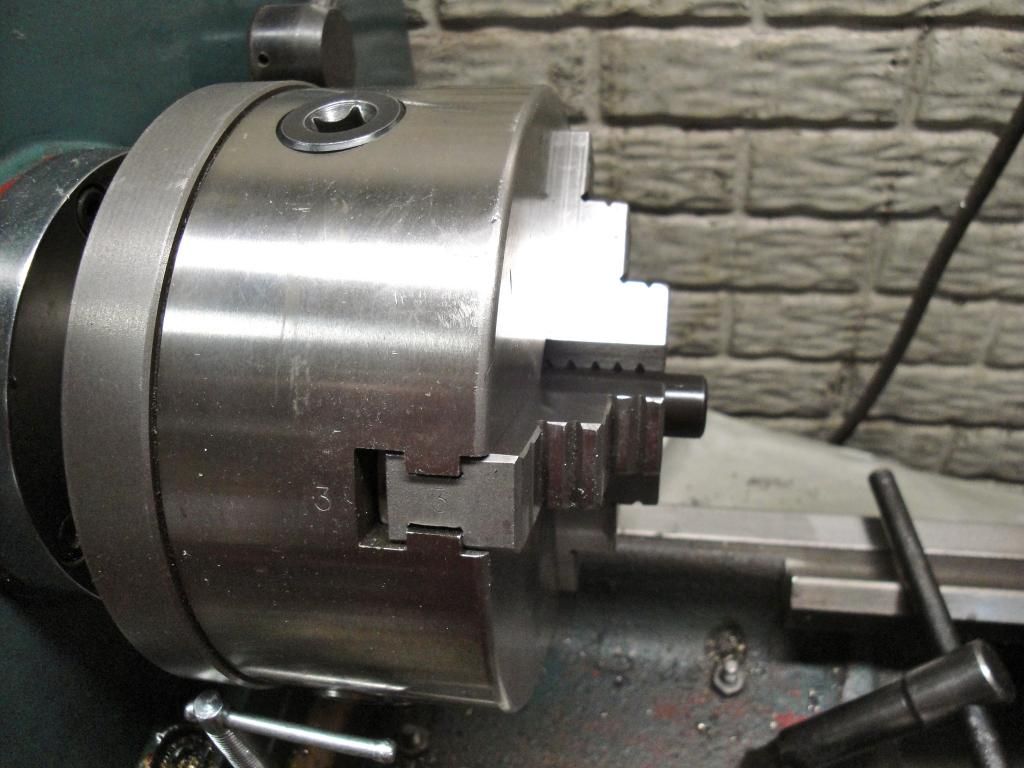

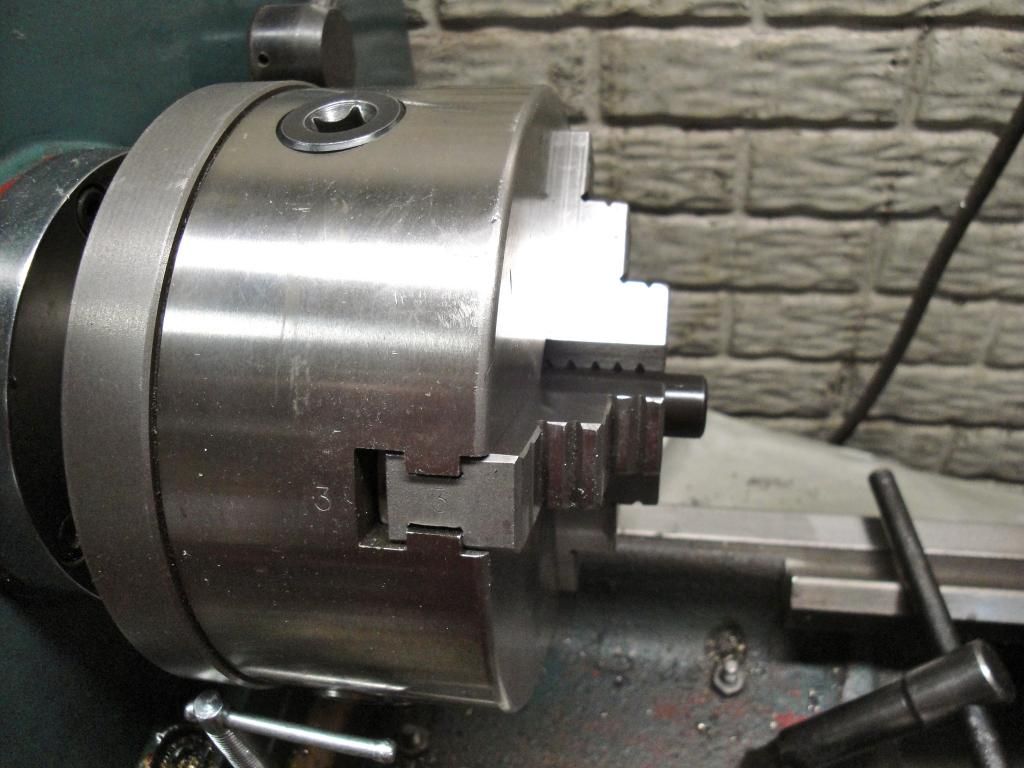

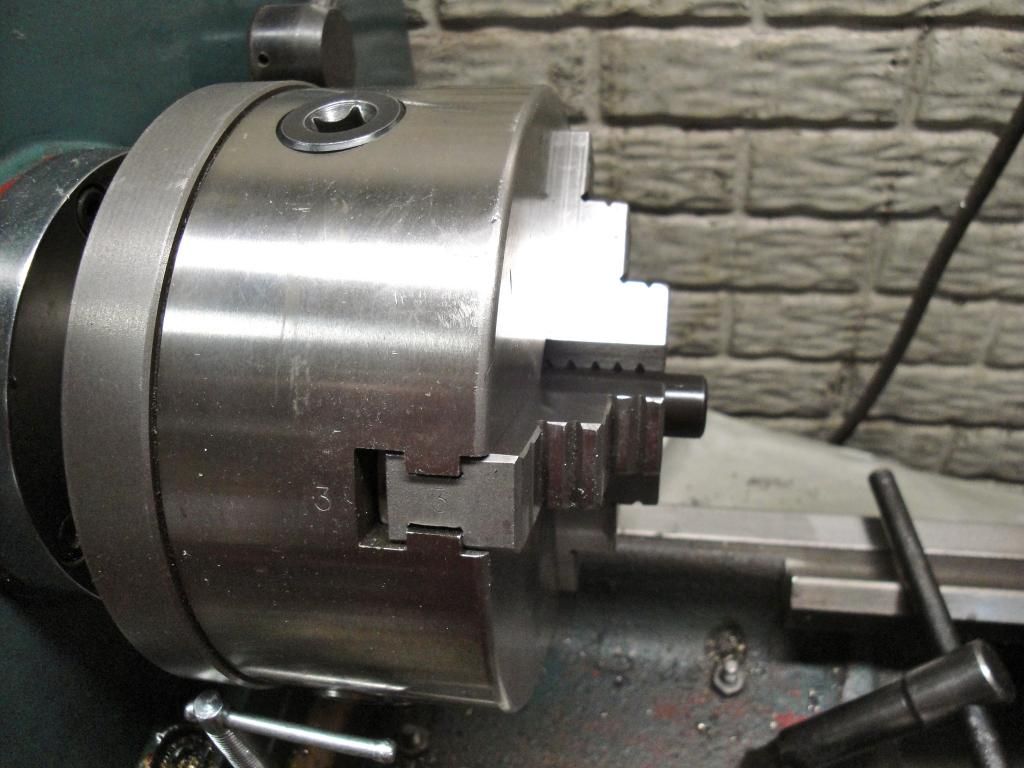

Jim KobeNot sure! Have not had a Krag barrel in the shop lately, but. I think it would have to fit through the headstock and have a spider on the outboard end, I think 22" would fit in mine.

17 December 2014, 17:52

Toomany ToolsThere's various tooling available to do the job adequately without a lathe. For revolvers I use piloted reamer that works quite well, and it would work the same on a rifle.

17 December 2014, 18:43

wildcat junkiequote:

Originally posted by Jim Kobe:

Not sure! Have not had a Krag barrel in the shop lately, but. I think it would have to fit through the headstock and have a spider on the outboard end, I think 22" would fit in mine.

Hi Jim: The problem's not the barrel, but the big box magazine hanging off the right side of the receiver.

17 December 2014, 19:01

GrenadierThe CMP Custom Shop might be able to do that for you.

http://thecmp.org/cmp_sales/custom-gunsmithing/17 December 2014, 19:58

JTEXPacific Tool and Guage makes piloted crown cutting tools that do not require the use of a lathe.

.

17 December 2014, 20:22

dpcdThis is an easy job but not all lathes will take a 22 inch barrel with receiver. If you do not trust your 3 jaw, then center it up in a 4 but for a flat crown, it will be fine. Those hand job tools cost more than actually machining it.

Don't spin it too fast or you will get some serious vibration.

19 December 2014, 07:06

wildcat junkiequote:

Originally posted by dpcd:

This is an easy job but not all lathes will take a 22 inch barrel with receiver. If you do not trust your 3 jaw, then center it up in a 4 but for a flat crown, it will be fine. Those hand job tools cost more than actually machining it.

Don't spin it too fast or you will get some serious vibration.

Thanks, that's exactly the kind of input I was looking for.

21 December 2014, 18:59

Toomany ToolsIn certain circumstances I like the hand-jobs,

but pulling the barrel and indicating the bore in a four-jaw chuck will produce the best results.