The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Update 3-25-08 Shane Thompson Mini Mauser. PART 3 BARREL CONTOUR!!!!

Update 3-25-08 Shane Thompson Mini Mauser. PART 3 BARREL CONTOUR!!!!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

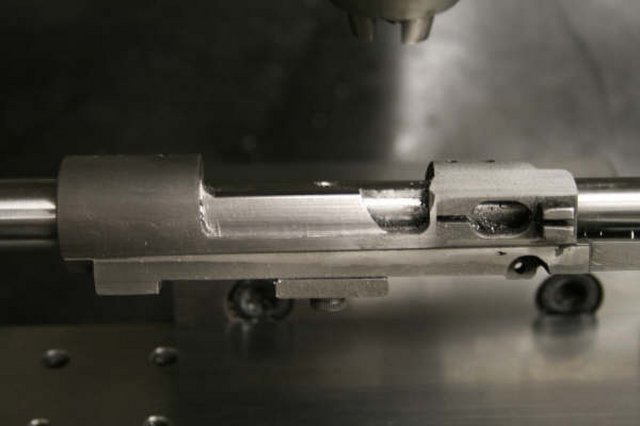

UPDATE 3-25-08 New pics on the bottom. Barrel contour begins. I'm so excited! A few years ago I talked Shane Thompson into building a little Mini Mauser barreled action. The job started off rather modest, just a new bolt handle, safety and barrel. Then, and I'm not sure how this happened but it morphed into a full blown custom barreled action. It took a little while long longer than I had expected it would befor the project got started but we stayed in touch the whole time and I feel like I've made a friend in the process of getting the rifle built. This is going to be a very neat little rifle when finished. Here are the specs: Charles Daly Mini Mauser action with New bolt handle. 3-position safety. Custom scope bases. Timney feather weight trigger. James Anderson custom bottom metal. Shilen 1-9" twist custom contoured barrel chambered in .223 Remington. Custom quarter rib, barrel sling swivel and front sight base. After this is all done it's going to James Anderson (AKA gunmaker) to be stocked. It's a long story how this came about seeing as both men are completely capable of taking the job from start to finish, but that's how it worked out and I'm very happy with the arrangment. I asked Shane for some pictures of the project while it's "in the works." Shane knows I hang out here and has graciously agreed to let me post his pictures here and share the progress with everybody. What's already happened in this series of pictures blows my mind. Shane is a member here and posts on occasion. With two jobs and a big family he doesn't get to hang out much like some of us, but he might chime in here before this is over with. He say's the project should be completed over the next few weeks. As I get pictures I'll edit the title with a new date. Without further a adue Here it is in the jig before the "magic" happens.  A picture of the jig. Shane said he has lots of hours in this alone because the action is so small it won't fit in the normal stuff.  SURFACE GRINDING The next 3 are of the "billboard" and all that Yugoslavian goodness coming off    OK, IMO the next few pictures are what sets the man apart from most others in his trade. I wish I could say I even thought of it. Neither of us liked the beveled piece on the left side of the action so Shane decided to give it the G33/40 look! This is soooo cool! We talked about putting lightning cuts in the receiver, but it's not necessary and I don't think it's going to happen. Is this a treat or what?!      Here is a scraping tool Shane had to make from a 60deg cutter.  The right side of the tang has a detent for the trigger safety. This will no longer be needed and is being welded up. Since Mr. Anderson is going to stock the rifle Shane isn't going to do much with the tang.  Well, this is what we have for our first session. Is this fun or what? I'm not sure which direction he's going in next. It'll be a treat to see. Terry   -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | ||

|

| One of Us |

And I thought my miniX was unique. Looks pretty slick | |||

|

one of us |

Seeing the one you did planted the seed Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Terry What a damn shame to take away all of those beautiful markings on that action. What kind of 3 position are you putting on it? | |||

|

one of us |

The safety is a Dakota. The G33/40 thing with the thumb cut is a new idea. One of those Satterlee's would have looked good with it don't ya think? Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Did James and you pick out a stick of wood yet? | |||

|

one of us |

Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

This is the one I've been wanting to see for a while now. Great to see the photos Terry. It's going to be one bloody nice looking rifle. cheers, - stu | |||

|

| One of Us |

Did anyone else wonder why he had the end mill in a Jacob's chuck????? Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

One of Us |

I noticed it, but I often use my keyless chuck for small, fast milling jobs where heavy material removal, great precision and delicate setups aren't required. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Hey Terry, It is looking very good! Keep the photos coming. Butch | |||

|

| One of Us |

I would say they would die with a smile on their face... Neat project! _____________________ Steve Traxson | |||

|

| One of Us |

Westpac your right on the money, laziness on my part when doing light milling, and it just doesn't matter. My old machine shop instructor would have kicked me in the backside, but fortunately he wasn't around Next phase will be filling the bolt lock slot in the bottom of the receiver. Since the original trigger won't be there the slot doesn't need to be there. Then I'll finish grinding out the receiver side rails and bottom. I've got the scope material set aside and I'll start fitting them shortly. A smart man would have welded and filled and then did all of the grinding but somehow I got a little off of sequence. It's been a fun project to work on....I think Terry is just excited because wer're so far ahead of schedule Shane Thompson | |||

|

| one of us |

Terry- About the time I think to myself, "There's no way he can top that," you come along and do just that. Incredible project; what caliber? .223 or .222? Oooops, I did not read the original specs, .223!! Ought to be a great turkey gun, too!!! May the wind be in your face and the sun at your back. P. Mark Stark | |||

|

| One of Us |

Terry, that is really going to look sharp. The thumb cut was a nice touch. BTW, were those available in left hand? | |||

|

| one of us |

Chic, My left hand Charles Daly mini is with Jim Dubell right now. Just waiting for a new 3-P safety - and its turn in his queue. cheers, - stu | |||

|

| One of Us |

Shane -- Beautiful work, m' friend. Can you describe how you made the shaping tool and how its used for this operation? Many thanks. -- Brian/ale | |||

|

| one of us |

Just slightly off-topic, my granddaughter (left handed) twisted Grandpa around her finger and got his Charles Daly mini. Now Grandpa needs another lefty action for himself. Anyone know where one is available? Even would get a bbl'd action if I could find one. Email me. .395 Family Member DRSS, po' boy member Political correctness is nothing but liberal enforced censorship | |||

|

one of us |

Yea, the lefties show up on gunbroker sometimes. I don't think Remington is offering the new ones in left hand though. -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

tc1 is correct. a fellow in new york has a standing auction for the left handed mini action on gun broker. just type in left handed mauser and it will come up. if anyone is interested i still have 1 custom bottom metal available that was offered for sale here a few years ago made by gunmaker. | |||

|

| One Of Us |

| |||

|

| One of Us |

aleaddict, The shaping tool was made from the shank of a broken 60 degree dovetail cutter. I save broken endmills for special uses like this. They are of the proper heat treat and material already so they work great. I just ground a radius on the bottom to match the radius of the side of the action. I then ground a little relief on the bottom and then ground off half of the diameter on the face of the tool. Most of the machining work was completed with an endmill. Then I locked the spindle in back gear so it wouldn't rotate while scraping. I then used the scraping tool to scrape in the acute angle at the bottom of the rail cut. I cut about .002" depth each pass. Then lightly scraped off the milling machine marks. When doing this it leaves a little metal bunched up at the end of the scrape, you can see this in the picture, I now have to go in with chisels and files and clean up the corner where this metal is bunched up. I hope this makes sense. I had to go back and stage the picture, instead of showing the actual work, or it would have been more clear. Shane Thompson | |||

|

| One of Us |

New Guy, I'll be sending this to you for final polish Shane Thompson | |||

|

| one of us |

Shane, Super Work! Very clever and most original.  Aut vincere aut mori | |||

|

| one of us |

VERY nice indeed. Excellent out of the box thinking!  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

one of us |

Shane sent some new pictures. Tang clean up     And now for the really cool ones Hubba hubba hubba     Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Yep when you realize that the receiver ring OD is about 1 1/8" & the scope rings ID is 1" it looks out of balance.  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| One of Us |

You guys do great work. Keep it comin' ! ! | |||

|

| One of Us |

Terry, I got the new (faster twist) barrel in yesterday. I'll be making chips again shortly. Shane Thompson | |||

|

one of us |

Can't wait to see it go on with all the custom stuff you have planned for it! What you've done so far is amazing. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Amen to that. Terry, where did you find that amazing piece of wood and would you mind giving us some discussion on your wood choice. Thanks, May the wind be in your face and the sun at your back. P. Mark Stark | |||

|

one of us |

Hey Mark, I bought that piece of wood second hand from JJS another member here. When the Silver-Lining Scholarship Rifle needed a blank Jim stepped up to the plate an took care of it. He ordered it from Denli Walnut. At one time Denli had some nice wood, but I haven't seen much there in a long time. While he ordered that one he also ordered 2 more for himself and 1 for me. I found one I really wanted from Adam Freeman over at Luxus for my project and sold mine to you. One of the two Jim bought he decided not to use for his project. He knew I really liked that blank and offered it to me and here we are. From left to right. The 1st is the one that will be used for the mini mauser. The 2nd is the blank that was used on the Silver-Lining Scholarship Rifle. The 3rd blank can probably be bought if anyone wants it. It's an amazing piece of wood. The 4th is the one I sold you.  Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

It warms my heart to see another quarter sawn man. | |||

|

| One of Us |

Very nice, Shane! Good to see you are producing! Do you have any plans for the boltstopper? It looks a bit overseized...? Keep us updated, thanks, Terry! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Bent, My reproducing has slowed down my producing I'm thinking on he bolt stop, I'll do something, but options are a little limited. Shane Thompson | |||

|

one of us |

The barrel contour begins. Shane filled me in on whats going on here with captions. cutting true centers.   roughing in shank dia contour.  my offset boring head. It’s an R8 arbor cut to a morse 3 taper to fit my tailstock. The gouge in the middle is what’s left of the keyway from the R8 arbor.  beginning to taper  roughing in contour at breech end of barrel   barrel is at final contour and I’m ready to cut the Radius.  the radius is cut     Pretty cool stuff Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

It keeps you yong!! Here is a pic of a stopper I slimmed down many years ago for my .22-250 on a shortened M98. I am restoring it now, so I snapped a pic - maybe you get some inspiration. There are plenty of threads in the plate itself, so the raised lump under the screwhead is not neseccary on a custom rig at all - mine has worked well for 15 years.  Cheers, Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Wow, Looks like pure fun to me. I really like the thumb cut. nice job. Timan | |||

|

| One of Us |

Bent, Thanks for the pics, it looks real nice. Always good to have food for thought. Stuart, Thanks, it's been a fun project. Shane Thompson | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Update 3-25-08 Shane Thompson Mini Mauser. PART 3 BARREL CONTOUR!!!!

Update 3-25-08 Shane Thompson Mini Mauser. PART 3 BARREL CONTOUR!!!!

Visit our on-line store for AR Memorabilia