The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Hollow ground screwdrivers, correct way?

Hollow ground screwdrivers, correct way?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I recently saw a drawing of how a hollow ground screwdriver was supposed to fit, at least somones idea. In this setup the blade thins down and then flares very slightly at the tip so the blade only contacts the slot walls at the bottom of the slot, negating any chance to bugger the screws. This is not the way the commercially made sets are. The bits on my Brownells set are thinned down and the the sides are parallel and the same width as the slot. | ||

|

| One of Us |

If the screwdriver fits tight and applies torque all the way to the bottom of the slot, what's the problem?. | |||

|

One of Us |

The ones Brownell's sells are ground correctly. The blade has to bear evenly against the full sides of the slot. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

One of Us |

The way it was described in the original post, the flaring of the bottom of the blade doesn't apply the torque uniformly to the slot which is the problem. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

http://www.finegunmaking.com/page16/page16.html Maybe this will help, found it in Custom Rifle section that Steve posted a few days back. _____________________ Steve Traxson | |||

|

| one of us |

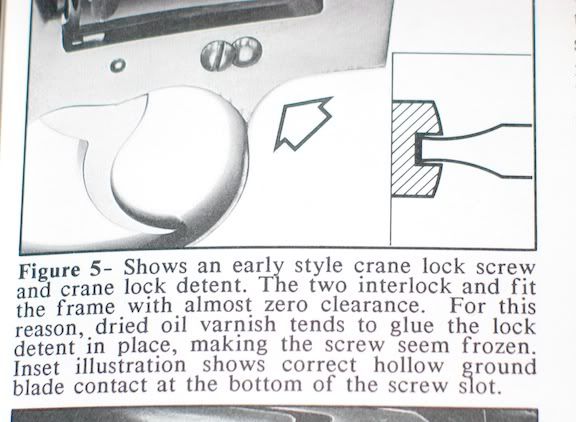

Thanks for referencing Steven's article, very informative. I found where I saw grind I referenced in my initial post, p.24 of Jerry Kuhnhausen's THE COLT DOUBLE ACTION REVOLVERS, vol.1. He is discussing removing the crane lock screw, perhaps it's only meant for that application?  | |||

|

One of Us |

That drawing is an exaggeration. The sides of the blade should be parallel to the slot. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

The copy for that illustration states" Inset illustration shows correct hollow ground blade contact at the bottom of the screw slot". | |||

|

One of Us |

I've probably pulled close to 500 of these Colt yoke screws over the years with nothing but a standard parallel hollow ground bit without encountering a single problem. This configuration would have to be for a single application such as this particular yoke screw. It however is not your typical hollow ground configuration for gun screws. The typical blades are parallel to the slot. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

It's a matter of surface area, a concept that determines how big living things get by the way. The more surface area you have in contact with the slot the less force per area the less chance of deforming rather than loosening the screw. If you grind a driver like the one in Kuhnhausen's book, you could deform the screw at the bottom of the slot, maybe even initiate a crack that pops off half the screw head; something I've seen many times. Spread the force over the largest area and you'll transfer that force more eficiently. Grind the driver, or "turnscrew" for the purist, with parallel surfaces that just fits the slot. John Farner If you haven't, please join the NRA! | |||

|

| one of us |

the brownells set has the changeable tips right? are there any sets that are regular screwdrivers that would be good for the majority of a guys stuff and aren't super expensive? I'd like to use the right screwdrivers on my guns but don't like dealing with bits but don't want to spend a fortune on rosewood handled turn screws. Am I better off just taking my excess stanley and craftsman screwdrivers and grinding them to shape as needed? Red My rule of life prescribed as an absolutely sacred rite smoking cigars and also the drinking of alcohol before, after and if need be during all meals and in the intervals between them. -Winston Churchill | |||

|

| one of us |

Here's pic of a Brownells bit, the short one is most commonly used. The sides of that tip do not look parallel to me. I have had instances where the tip of a bit will fit into a slot about halfway but it will not bottom out because it becomes too wide. I have to use the next smaller width.  | |||

|

One of Us |

Here is what separates the pro from the amateur. If the pro doesn't have a particular blade that fits perfectly, then he will alter the blade to fit the screw he is presently working with. Other than my special thin blade set, I don't have 1 single insert that hasn't been ground, filed or reshaped to a different profile to make it work. Every screw driver bit of mine has had something done to it at some point. The point is to keep the bit as parallel to the slot as you can. The better the blade fits, the less damage you are likely to do. Here's a tip (no pun intended). If you have to go to a smaller blade, wrap the tip of the blade with a piece of masking tape first. It will fill in the voids. I also do this on those "special" occasions to prevent the screwdriver blade from slipping from the slot and skipping across a beautifully finished surface. Adapt, overcome and move on. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| one of us |

Thanks for the words of wisdom Malm, will remember that. | |||

|

| One of Us |

The Magna-Tip bits are ground with the beginning of the flare at a tangent to the centerline. This leaves little or no parallel segment, thus your problem of the blade entering but not bottoming in the slot. Like Westpac, all or almost all of my blades (close to 100, all told) have been reground, and I always form a short parallel segment at the tip before beginning the flare. I used to form the oversize base as described in the book but soon learned NOT to do that. BTW I once wasted my time reading a few of his books but, again, soon learned not to do that (grin). They're OK for beginners but the information was either basic, VERY basic, or else IMO misleading to some degree. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Hollow ground screwdrivers, correct way?

Hollow ground screwdrivers, correct way?

Visit our on-line store for AR Memorabilia