The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Rear sight base, and secondary recoil lug

Rear sight base, and secondary recoil lugGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

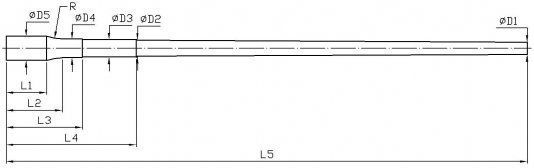

I am looking seriously at the Lothar Walther 5130 Mauser "E" pattern barrel.  It has a level section near the receiver end of the barrel at D3, with a 0.865" diameter. I checked with NECG and found this ring base with a lug and slot for the rear sight blade.  The fly in the soup is that the ring base only goes up to a 0.685" diameter. I seriously doubt that it would be possible to bore the base cylinder section as much as the barre would require. How difficult, or easy would it be to make an appropriately sized cylinder with a secondary recoil lug on it? I could then take an existing rear sight base and solder or have it welded on. Insights and ideas would all be entertained.  | ||

|

| One of Us |

I just dovetail the barrel and fit a recoil lug there and solder it on. Making that sight base would take a lot of time. It would not be possible to make the NECG base fit a larger barrel; not one that big. I make my Oberndorf pattern barrels without the step at their L3 location; I turn the barrels straight to the front step. Why? So you can solder/screw on a rear sight and it looks like you have an integral ring base without actually having one. Or, I can turn the barrel to fit a ring base, should the customer want one. They never do though. | |||

|

| One of Us |

i have a martini cadet with scope rings that are machines much like this. there ain't no way in hell that i want to pay for anything like them. beautiful workmanship but hours and hours to make | |||

|

| One of Us |

I would give NECG a call and see what they actually have for sizes. I have one in the shop that's bored to .985 so I know they have larger sizes than what's on the web. If they don't have one large enough I could make you the part with the express sight integral instead of trying to solder one onto a sleeve with a recoil lug. | |||

|

| One of Us |

| |||

|

| One of Us |

NECG parts are actually made by Recknagel and they do make larger ones; just have to special order from Germany. | |||

|

| One of Us |

Same here. Offset bore in lathe; milled on rotary table. 6-1/2 hours well spent. Then found same thing at Midway............. Doug Wilhelmi NRA Life Member | |||

|

| One of Us |

Damn those bastards and their fancy CNC machines pumping out high tech parts by the dozen. DAMN THEM ALL ! When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years! Rod Henrickson | |||

|

| One of Us |

My sentiments exactly | |||

|

| one of us |

I just looked at the Recknagel catalog, and found the exact iteration that I was looking for. Having a comprehensive catalog beat the heck out of skill and dedication at the mill.   | |||

|

| one of us |

.865" = 21.971mm. By using a 22mm rear sight base, I end up with about 0.001" gap. I can then solder the parts together. Perfect, or pretty darn close to that happy state of affairs. Time to confirm my barrel order, then have NECG order the part for me, along with some magnum cross bolts, and a nice, fancy little wrench for screwing the crossbolt side plates in or out. We live in a golden age of gun parts. Most any need is filled by a fellow with a "Solid works" or other CAD program, and a five Axis CNC machine that is normally not working between 23:00 and 04:50. Pay the boss a nominal fee to use the machine during its normal time, and voila, you have parts that fit well, and have even been through a finite structural analyses.   | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Rear sight base, and secondary recoil lug

Rear sight base, and secondary recoil lug

Visit our on-line store for AR Memorabilia