The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Lothar Walther SS barrels ????

Lothar Walther SS barrels ????Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have two LW #1300 stainless barrels. One in .308, and another in .264. Who will chamber and install these barrels for me? Is there something especially difficult about these barrels? Thanks, KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | ||

|

| One of Us |

Easy-peasy, great barrels. 98% of all the barrels I install are Walthers, but I am sure there are good gunsmiths closer to you! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Bent, Thanks for the reply. I have the impression that the use of LW barrels is common in most of Europe and the rest of the world, except the USA. The actual reason is more like speculation to me, but I would like to know more about this. I've read such reference to Shilen, and other US barrel maker's steel "cuts smooth as budder", etc. I'm sure the smooth aspect is true, and important for a machinist, and for the visual effect of having a very smooth chamber, and long tool life, etc. To me it also may be evidence that the steel used is soft, which makes it cut better. In other words, the ease of working the steel is more important than longevity. Short range vision. I've had some gunsmiths tell me they don't want to work with LW SS barrels. They say the steel doesn't cut well because it's tougher, stringy or whatever. To me that translates into longer barrel life. There seems to be no problem from some camps, and a stone wall from others. I just want to learn more about this, and besides, I have two good looking LW barrels that I want to do something with. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| one of us |

I am not a gunsmith so no expert but I did chamber a LW SS barrel recently. I read that they are made from 17-4PH. I don't know if that is a fact. It does not machine as nicely as a Remington SS barrel I rechambered. The gunsmiths here said to use a higher spindle speed for the LW SS which I found was good advice. I used about 100 RPM and if I do another I will probably bump the speed up a bit more. The other thing I learned is to use a sharp reamer. I borrowed a reamer and I could see the flutes were burnished in the body section before I started. That section would not cut cleanly. What happens is that the dull tool work hardens the surface of the steel and then it will not cut cleanly. The chamber is a little rough but it is serviceable. I don't know how it shoots yet since the scope I put on the rifle went haywire and I haven't retested it since the scope repair. It did look like it would shoot. | |||

|

| one of us |

Contact Woody @ Lothar Walther. If memory serves me, lathe speed needs to be run faster to cut properly. Stepchild NRA Life Member | |||

|

one of us |

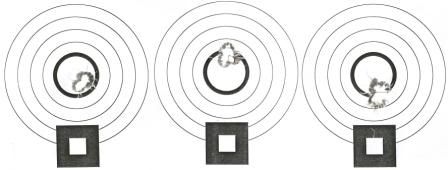

I had my gunsmith install and headspace a LW chambered SS Match bbl. in .308 Win on a (originally in .22-250) shot out Ruger 77 Mk II VT . It was a peach from the very beginning, averaging < .25 MOA with 168 SMK. And as a cherry on the cake, it doesn't copper foul at all.   André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| one of us |

I have several of their barrel in stainless and CM, and they are just great. Oddly enough one of my go to smiths is in PA, who is the first that used a Lothar barrel on one of my projects--but Lothars are produced less than an hour from my home in GA. They have proven to be simply great quality barrels. As to machining them, I would talk to a smith who has used them. JB at Accuflite has a TON of experience with them, he would be worth a phone call to, just tell him Don from GA said give him a buzz. Accuflite I've got 2 6.5x284's that are SCARY accurate with their barrels, and about 6 other rifles with them that just shoot great, and as Andre mentioned, fould very little! | |||

|

| one of us |

I spoke with Woody a couple of years ago and that was what I was told. He explained that their barrels are not re-sulpherized and that leads to longer barrel life. Another thing he told me was that they absolutely will not use a reamer without a "live" pilot. Call the Georgia plant and have a talk with Woody, He's very knowledgable. Good luck. Paul. | |||

|

| one of us |

Excellent barrels, you made the right choice. Lothar Walthers stainless has excellent machining properties. I get extremely smooth chambers useing "tap Magic" as a cutting fluid rather than cutting oil. I cut my chambers at 340 rpm.  Doug Humbarger NRA Life member Tonkin Gulf Yacht Club 72'73. Yankee Station Try to look unimportant. Your enemy might be low on ammo. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Lothar Walther SS barrels ????

Lothar Walther SS barrels ????

Visit our on-line store for AR Memorabilia