The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Best way to install a secondary barrel lug

Best way to install a secondary barrel lugGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I started a model 70 claasic project in a 458 African chambering,it is more powerful then the 458WM. I ordered a Lilja barrel last month in stainless. From what I have read most think a secondary lug is needed on a 458 and up. Tubbs makes a .375 thick stainless lug, what would be the best way to affix this to the stainless barrel. Thanks http://www.davidtubb.com/overs...-lug-stainless-steel "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | ||

|

| One of Us |

Dovetail it in. I usually DT and solder them on. I like a mechanical interface instead of just solder. | |||

|

| one of us |

Ditto. John Farner If you haven't, please join the NRA! | |||

|

| One of Us |

The last 458 Lott, that I did on a SS M70 Classic, I dovetailed the barrel and had a friend TIG the lug in. NRA Patron Life Member Benefactor Level | |||

|

| One of Us |

The Tubb lug is made for a Remington style use where the barrel goes through the recoil lug. It's a waste of money for you in this instance. Let your gunsmith use a piece of stainless barstock and shape it to be dovetailed and soldered into the bottom of your barrel. "Peace is that brief glorious moment in history when everybody stands around reloading". | |||

|

One of Us |

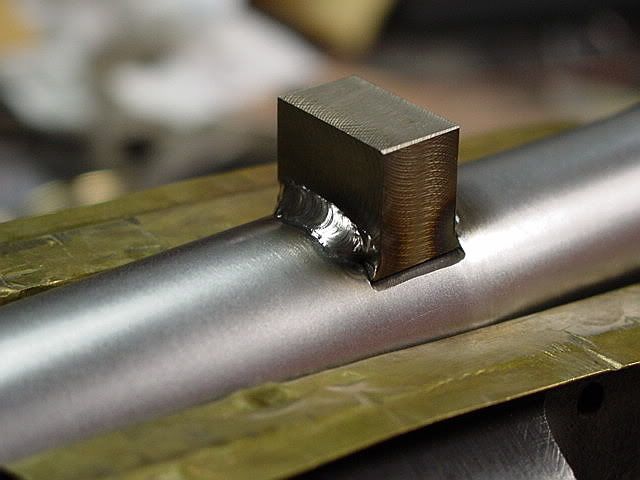

This is on a .585 NYATI and is both dovetailed and TIG'd. The person who installed the original use solder and screws. That lasted a couple of rounds.  _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Do you think TIG welding is better than soldering with HI-TEMP HI-FORCE 44™ SOLDER? The TIG would get pretty hot I would guess. No doubt the welding would be better. Just wondering. Btw nice work there. "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

| One of Us |

Westpac PM sent "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

One of Us |

Thanks, but I'm not accepting any new work at the present time. I have some local contracts and a pretty heavy backlog I need to attend to before I resume taking on new projects. As far as TIG vs Force 44 solder goes, I don't know. With proper forethought, preparation and technique, TIG welding the lug as I've done isn't going to hurt anything. I chose to use the TIG because I didn't want there to be any doubts about it's permanence. Perhaps a little bit of overkill. Good luck. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Can I use 304 stainless bar stock with 416 stainless? 416 is martensitic so I am wondering what stainless to use including what type rod...ER309,ER310?? "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

One of Us |

Can't tell you on the use of 304 stainless for the lug, but the fill rod I use is 1/16" M316L. Perhaps Mete will chime in, he's a metallurgist. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Thanks.... "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

| One of Us |

416 is not generally considered weldable if you do a search on it. It can be though. The best procedure is to preheat to 300-350F, TIG it fast (i.e. minimize the heat from welding) with a 309, 309L, 316L, or 321 filler, and wrap it with a fire blanket to cool slowly. Minimum heat to limit the heat affected zone should be used. Although, the method most commonly used is to just TIG weld it with a 309 filler and not worry about the preheat and slow cool. The 300 series rod will take up the stress in the weld and keep it from cracking. To answer a previous question, solder will never beat a properly done weld. Jeremy I am a metallurgist, by the way, and this came out of the Hobart pocket guide to welding. I love that booklet. | |||

|

| One of Us |

With all due respect I think we are entering dangerous territory here. As Farbedo points out, 416 is not generally considered weldable but with correct pre & post heat it should be alright... Same with 4140, weldable, but with precautions. I just wouldn't call it worlds best practice on a barrel though. | |||

|

| One of Us |

Will probably be the last large bore 416 barrel I order. There's a couple of welders in town that specialise in welding stainless,I will go talk to them before I have the barrel dovetailed. The classic action has a lug on the front,but I would just feel better with the secondary lug. "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

| One of Us |

Good point. I didn't stress that this is a non-trivial procedure. A good shop will be able to steer you straight. Although, for a 458 of most flavors it isn't needed. Proper inletting, bedding and cross bolting is enough to keep everything together. If it is a choice between messing up a barrel, or not adding the lug, again, it isn't needed. IMHO. My Lott is a single lug setup. Many are. Jeremy | |||

|

| new member |

IF AVAILABLE IN YOUR AREA TRY TO WELD YOUR BARREL LUG BY LASER WELDING. LASER WELDING PUTS FAR LESS HEAT INTO THE METAL COMPARED TO OTHER TYPES OF WELDING. | |||

|

| One of Us |

I talked to a welder today that has experience in stainless. He said that to weld the 304 lug to the dovetailed 416 barrel would be no problem. He can preheat so the filler would puddle and flow well. His only concern is that he had never welded on a barrel before and wanted to know at what temp would damage the barrel. "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

One of Us |

A lay person runs a bigger risk of damage, silver soldering or brazing things to a barrel. With good foot control, a skilled person with a TIG machine can come in, hit it, and be out of it before IT knows what happened. You can pack that section of the bore with an anti scale, heat control paste if you're worried. I would recommend it, and, I would also recommend wrapping wet rags around the area to help keep things cool. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Lets keep in mind here that the term "weldability" is subjective to say the least. The weldability of steel is usually referenced to a structural code of some sort to keep some iron worker from swapping in a chunk when he is not supposed to. I've welded on stainless for years in the injection mold industry and maybe the stresses are different but I can tell you 416 will weld just fine without preheat, typical stainless fillers will also work just fin as well. 4140 is also a metal I've welded on for years and it is one of the best metals to weld. In the mold shop we have a grade of steel called P20 which is a modified 4140 with a smaller grain structure for polishing. This material welds absolutely beautifully with just minor prep. Keep in mind we never preheated a section unless it was deemed necessary to prevent warping or deformation of the part. That said this is a barrel and every step possible should be taken to preserve the condition of the barrel. So I would pre heat the barrel to 350, weld it, then post heat it and let cool slowly. Obviously I'd also back gas the bore to prevent sugaring of the weld area (HAZ) for those so inclined. www.KLStottlemyer.com Deport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK | |||

|

| One of Us |

Thanks everybody....very informative. "A long life, and the good sense to live it." ...Quintis Arrius 375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB Avatar: Gregory Peck & Susan Hayward in Africa NRA member | |||

|

| One of Us |

A different approach: When you have the barrel profiled, leave a knot on the barrel where you want the lug, then mill it off on top, or use it for a sight boss like a pre-64 model 70. I did a barrel like this, left a 2 1/2 inch long section, and milled to an integral express sight base on the top. The bottom was left as a secondary recoil lug and bedded into the stock. McGowen will contour a barrel like this; that's who I had do it. dave | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Best way to install a secondary barrel lug

Best way to install a secondary barrel lug

Visit our on-line store for AR Memorabilia