The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Shane Thompson Mini Mauser Part 4. Bases and Rings!

Shane Thompson Mini Mauser Part 4. Bases and Rings!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

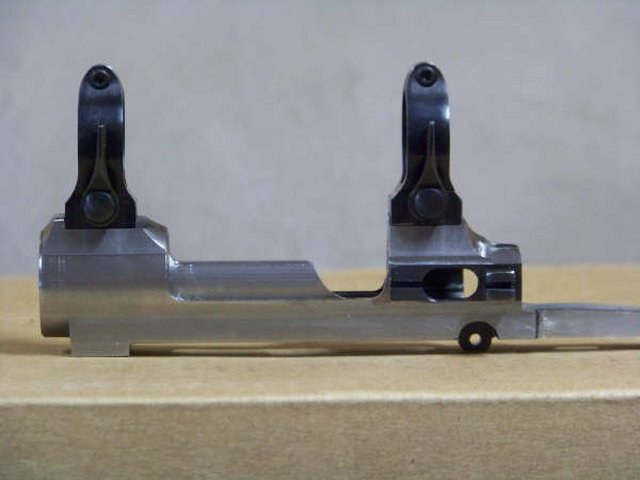

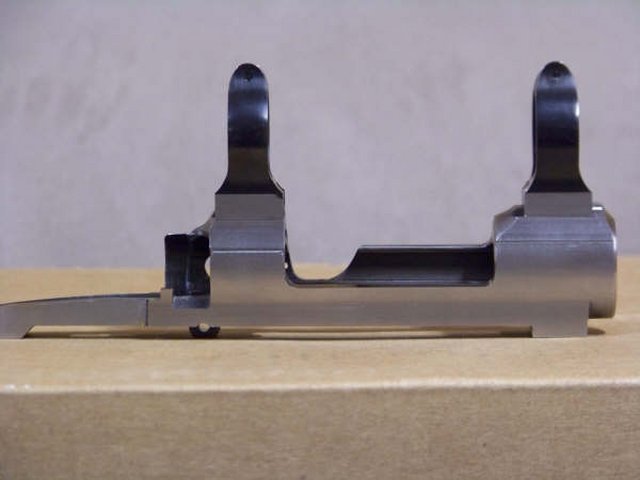

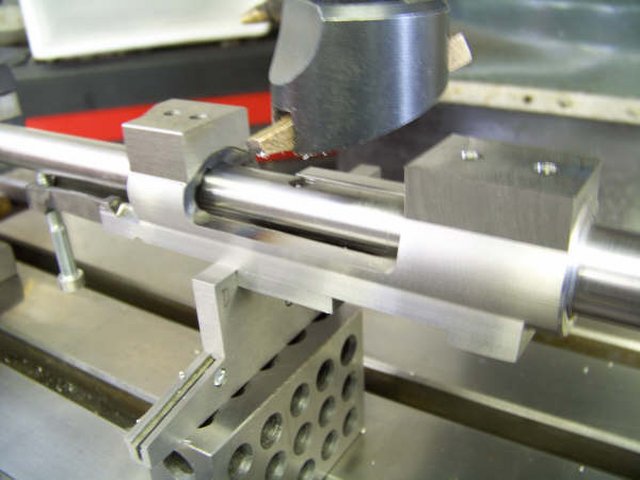

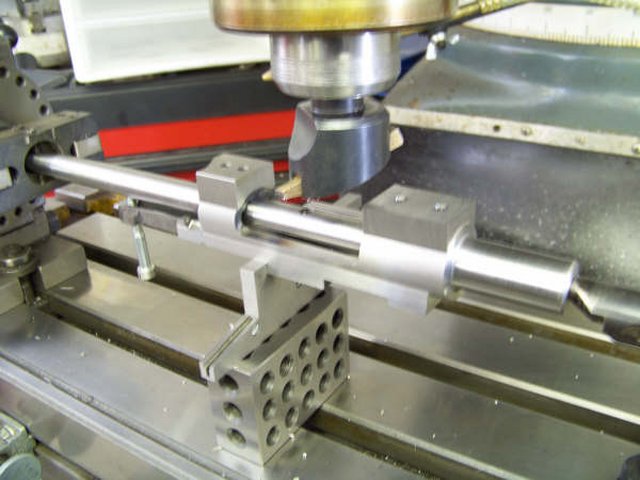

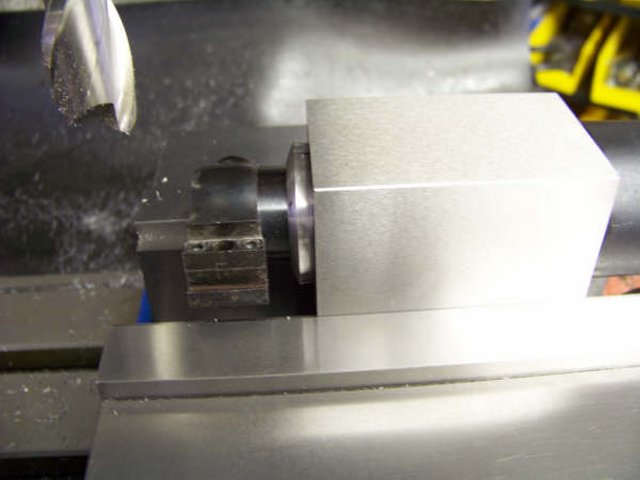

The other thread was getting a little clogged up. For those who didn't see it, go here: Mini Mauser project parts 1 thru 3 Note: The captions are taken directly from Shanes emails. If it say's "I'm doing" That's Shane and not me. 1. flycutting the tops of the base blocks to make them level.   2. one ring smaller and one regular sized. The small one isn't all the way shaped yet.   3. I'm shaping in the other ring.  4. Here I'm finished trueing the ring sides.  5. Some side views showing the action and ring with most of the machine work done and ready for detailing.   6. Bottom view of action all leveled with the safety slot and groove welded and cleaned up.  8. Angled views. These were taken in macro and show some distortion, it makes the rings look like they are twisted.  8. I took these from farther away and just zoomed in, they seem to show less distortion and hopefully give you a better view of what it actually looks like. Commentary: "Hope you like it....I think it rocks. I love the rings scaled down now that it's all done. I reduced them in height a fair bit also. I gotta admit I was a little worried myself at first. Just a note, you'd probably never notice it if I didn't point it out, but the front ring is .030" wider than the rear one. I did this for the optical illusion because the rear bridge and base are so short. I think it worked out real well. They are close enough that without being told you would never notice it. I wouldn't even mention it but I thought you might find it interesting to know the little details that go through the mind of a fruitcake gunmaker. Also didn't want you or someone to see it and think I forgot how to read the dials on my milling machine ha ha. Bolt handle, bolt release, safety and barrel are next, and probably in that order. I took a night off of work yesterday and worked on this until 5 in the morning then several hours again today. I have around five hours in messing with those rings and I haven't even done the spring thing yet. I know you loved them so I won't share my true feelings but there wasn't a true surface on them. They are pretty darn true now though, and damn cute if I do say so myself!! Shane" Absolutely stunning! Notice the details in the bases and the bottom of the action! There is a lot of work there you can't see but I know it's been done. There are cuts for the safety that no longer exist. Yes Shane, I do think it rocks. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | ||

|

| One of Us |

Thanks for the pictures and story of this project. Looks like it will be a wonderful rifle. Nice to contrast the way this project is working out with some of the horror stories we've been seeing here recently. NRA Life Member GOA Life Member Distinguished Rifleman President's Hundred | |||

|

one of us |

Yea, Shane is one of the good guy's. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

Terry, I think you just have above average patience Shane Thompson | |||

|

| One of Us |

Shane and Terry, You guys have a real nice project going. Thanks for the photos. Butch | |||

|

| one of us |

Terry- Another one of your incredible projects; congratulations!!!!! Amazing!!! P.S. Shane, you have a PM! May the wind be in your face and the sun at your back. P. Mark Stark | |||

|

| one of us |

THat will be an awesome rifle when you get her all put together. I love seeing the progress photos you have posted. With all of that set up time for each operation, the total time in the job really goes up. This is why high end customs cost a lot of money. But this one shows they are worth it! | |||

|

| One of Us |

Alway was! Very good stuff, Shane! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Butch, Bent, Marc and others, Thanks for the comments. Yes it takes time liek Marc said. This project has taken extra time because it's difficult for me to guess the right dimensions the first time. I end up setting up and machining then assmebling, only to find out I need to set up and machine a little more to make it look right. I barreled it today but didn't quite get to the quarter rib like I wanted. I'll be gone bear hunting for a week starting Friday so it sets for a while longer. I'll get more pictures to Terry when I get back. I should have taken more pictures of the ring shaping process but there really isn't anything earth shattering there. I have a tendency to take too many pictures now that I have a new camera Shane Thompson | |||

|

one of us |

The man would rather go hunting than work on my rifle. Can you believe that? I'm speechless Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| one of us |

Another thing worth pointing out is what Shane said about playing around with subtle dimensional differences. This is something that happens in both the wood and metal all through the building process, but folks never know about it unless they are told. Just a little more curve here, a little less thickness there, and the end result is an artistically sound rifle. The client will never see the differences unless they are pointed out to them. These small differences must be done by hand. Well, some of the operations need to be done on a machine, but what I am saying is that it is not something you can draw on a computer and plug it into a CNC and leave it at that. THis artistic touch comes from a good eye and a steady hand. It can also be difficult to predict how long this will take to complete. Tinkering back and forth with the slope of a curve or something similar can take a very long time-longer than the actual "meat and potatos" portion of the operation. All of these small touches must work together to for the whole that is the gunmaker's vision. This process cannot be rushed. I often think about Charlston Heston playing Michelangelo when he was painting the Sistene Chapel. The pope was irritated that it was taking so long and regularly asked Michelangelo when the project would be complete. Heston would repeatedly and angrily reply, "When it is finished!" A custom gun is no different. The extra teweaking makes all the difference between a good work of art and a great work of art. I am definitely NOT trying to defend gunmakers who blow schedules and not communicate with the client. I am just trying to explain why schedules can be missed so greatly. A gunmaker needs to figure this into the time estimate and keep the client posted if there will be problems. It is easy for me to say this, but hard to do at times. Hell, it is hard to do most of the time. I have no idea how much time Shane has into that action, but whatever it was, it was worth it! Anyway, estimating the time for the job can be really tough when doing something like this job. Stockwork is usually a lot more predictable than metal work. And "cookie cutter" metal work is fairly easy to estimate. CHambering a barrel, instally a safety, welding a bolt handle, etc, can all be estimated to fall within an fairly narrow range of time for 95% of the jobs. Keeping records of how long each job has taken you in the past is vital for estimateing this. Most folks I know don't keep records. You know, the more I am around custom guns, the more I understand what Steve Hughes is talking about. I started keeping time records on his reccomendation. He always says don't buy a cool new custom action until you can swap cash for a finished product. Boy, had that advice been taken a lot of us could have spared ourselves a lot of heartache over the two custom action fiascos this year! He also reccomends charging by the hour for custom handwork becuase there really is no way to know how long it will take you when you bid the job. Metalsmiths getting behind and then realizing they have lost a lot of money on the job always hurts the schedule (you often have to do small jobs to actually make money before resuming the losing job). Written contracts are another thing Steve reccomends having both parties sign before starting. Wow, would that have been nice to have in many of the heartaches we read about here. Charging a wage you can actually live on is another bit of advice he gives that is often ignored. If more gunmakers did this then they would be under less cash flow pressure and this would greatly help with schudle problems. Sounds like Steve knows his stuff, doesn't it? | |||

|

| One of Us |

I hope Steve Hughes doesnt mind me using this answer to me from a question from another forum, because it will be something i'll do when i get up and running. (almost there)... It got me to thinking just how many hours where really involved and just where i was at on past projects? Thanks for the reply Steve! A very good way to figure out what to charge is to keep a dedicated time log for each project. I started doing this about 25 years ago and can tell to the hour how much time I have in most jobs. A 6x9" steno pad with entries for the date on the left, work accomplished in the middle and time spent for each operation on the right. Compile hours by the page and a running total for the project at the bottom of each sheet. This takes a lot of dicipline, but is really the only way to know how much time is invested. When you have a realistic idea of how much time it takes, you can start to figure how much your time is worth to you. There was over 350 bench hours in this 12 ga. project plus Larry Peters engraving, bore work and metal finishing. _________________________ SDH Another question: Is the ACGG's, Realizing Your Dream: A client's guide to building a custom gun...Worth having and from a builders point , would it be informational to the smith? TC1: Not to highjack your thread,but to agree with the above statement... and add that will be one sweet rifle, with the blank you have for it...Stunning!!! _____________________ Steve Traxson | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Shane Thompson Mini Mauser Part 4. Bases and Rings!

Shane Thompson Mini Mauser Part 4. Bases and Rings!

Visit our on-line store for AR Memorabilia