The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Firelapping?

Firelapping?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have a Martini 303 sporter with a rough bore. It currently groups about 5 inches at 100 yds. Rather than replace the barrel I'd like to try firelapping to improve accuracy. Kits are available in the common calibers but not 303. I know the basic principle but need a few details. Do you use jacketed or cast bullets? What grits to start with a rough bore? Any thoughts are appreciated. Thanks. | ||

|

One of Us |

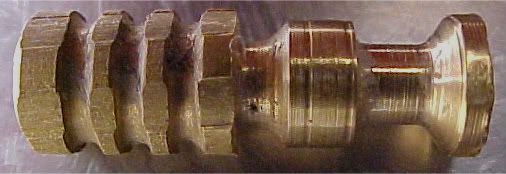

I have done it. I made up some brass bullets to force the grit into the lands where there was hard scale. I got that out and there was some well defined rifling! Rough but there. One rifle is now shooting very well - the other I don't know yet. The good shooting one had scale in the grooves which was damaging cast bullets causing them to leak and flame cut. That stopped. I used medium grit grinding paste. Not to say I would recommend the medium grit. I doesn't polish the bore exactly but doesn't seem to destroy it either. Here's a pic of one - not the best one. The idea is that the front bit bore rides to keep the 'bullet' true and the grit is contained in the grooves inside the neck. The exposed groove had lube in it (not the big void - that just puts the front bit far enough out). The first band to engage the rifling is supposed to ensure the 'bullet' is following the rifling before the grit hits it.  Regards 303Guy | |||

|

| One of Us |

I firelapped a 25-06. I used 120 grain bullets. I smeared lapping compound on a piece of steel plate, and used a smaller steel plate to roll the bullets in the compound. I loaded with starting loads, and shot a few, cleaning in between. Jason | |||

|

| One of Us |

I might suggest an easier approach take a cleaning rod swivel handle type and a slightly over bore mop impregnate it with lapping ,polishing compound or silicon carbide grit ( Which ever you prefer ) Now just start at the chamber and stroke , allowing mop to follow bore lands break out on muzzle end remove mop repeat , 10 - 20 -30 times . I prefer the Hard muslin mops . Clean out bore with a decent solvent when finished . I see no reason to clean before ones done lapping . Other than using a Dry Mop to have a look see . I often use a little solvent in my compound seems to speed up the process . BOL | |||

|

One of Us |

This is what the fire-lapping 'bullet' is supposed to look like. The front band bore-rides, the second just begins to engage the rifling, the third fully engages followed by the grit grooves and the final two bands are over groove size but fit the throat.  This gets the scale out that can be left behind by normal hand-lapping. This gets the scale out that can be left behind by normal hand-lapping. For polishing, it's best to ask the cast bullet shooters over on "Cast Boolit.com". But I dare say that after using one or two of my fire-lapping 'bullets' the method described by Doc224/375 would be just fine too. The first one I showed was used in a bore that had been lapped by a gunsmith. (I'm sure he would have prefered to scrap that barrel! It might still come to that). It made undefined rifling well defined. That's the one that is still to be range tested. By the way, sometimes - just sometimes, the pitting and roughness in a bore can be turned to good use by holding lubricant which actually prevents copper fouling. So there is hope! You might have to recrown the muzzle though - maybe even take off a little. You won't believe how rough a certain 22LR bore was that I cleaned out enough to remove the sharp edges of the pits and now still shoots quiet well without leading. Regards 303Guy | |||

|

| one of us |

That's an interesting 'bullet' from 303 guy, but I would simply look at the Neco kit, a lot of places carry it, including Midway, and just use some inexpensive bullets and embed the various grits as per instructions and go through the process---I have used the Tubbs Final Finish system on a LOT of rifles, and have always had at least positive results, sometimes amazing results. I don't know if they offer it in a 303 cal though. If they do I'd go that route, if not, the Neco as mentioned. Good luck! | |||

|

One of Us |

I do agree with Fish30114. My system is a bit drastic for a drastic bore. I shall be looking into the Neco system myself. Regards 303Guy | |||

|

| One of Us |

i have a friend who has done it on a couple of rifles, he's sold on the idea because it worked well for him | |||

|

| One of Us |

BJA105, Your method is what I had in mind, what grit did you use? Thanks for the ideas 303Guy and Fish, I;ll try them if the other doesn't work. | |||

|

| one of us |

The Wheeler kit, from Midway has worked very well for me on several marginal barrels. Some have improved a bit, others dramatically! Mark "Greatness without Grace is mere Vanity" - Hank the Cowdog | |||

|

| One of Us |

I used a cast bullet and filled the exposed lube groove and in front of the driving band with Autosol and shot of about 30 of themin a play session. Helped with copper fouling. New barrel though so might not work as well with an older one. Von Gruff. | |||

|

| One of Us |

I used fine valve lapping compound from an auto parts store. Jason | |||

|

| One of Us |

I do the JB Bore Paste scrub for all barrels that aren't lapped when you get them, 100 strokes with a tight fitting patch loaded with JB. It works. I'm having a hard time getting my arms aound the fire lapping routine. Don | |||

|

| One of Us |

Several caveats: Full loads with cast bullets will often obturate the bullet into the throat, wearing that area too much. Use jacketed bullets or VERY light loads with cast, just enough to clear the muzzle when fired. With a rough bore I suggest you begin with 220 grit (rough), only a few rounds before inspection. When you see noticable progress then it's time to clean thoroughly and go to the next grit level, 320-400. Ditto the noticable progress with the finer grit, will probably take a few more rounds to make a difference, maybe 5-10. Then clean again and go to the next level, etc. Stop after the finest grit you can find, probably 1200 or so (J-B, bore shine, etc), and by this time you should be shooting 10-15 rounds with each grit. Discard the brass cartridge cases you used with the lapping compound, the compound will adhere to the inside of the necks and lap your dies. The process works well, just go slow and clean often. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

If you have not already done so I would slug the bore. You will probably find that on these older rifles it may be even 317". No amount of firelapping will correct that. But a bigger diameter bullet will. | |||

|

| One of Us |

How many rounds have you fired through the rifle? Just shooting 100 to 200 rounds with cleaning every 5 shots may improve your bore's condition. Before you start down this trail you might want to slug your bore to find out it's diameter. Check it at the muzzle and at the breech. Also push a soft lead slug though it to determine if there are any tight or loose spots. If you have any doubts push several sinkers or buckshot through to see if you get the same results each time. A tight spot might have to be lapped out by hand. Loose spots may go away if the entire barrel is lapped out some. You may find you have a trumpet shaped bore eg one that is larger at the muzzle than at the breech. If not too extreme you may be able lap the rear half of the barrel to improve this condition. If it is extreme you may not be able to do much with it. Basically what I am suggesting is that you check your barrel and determine as much about the size and consistency of the bore diameter before you start. It may require that you lap it in some manner and then use cast bullets of the proper size. In some cases you may have to acquire the next large jacketed bullet and size them to work in your bore. | |||

|

| One of Us |

Gentlemen, Thank you very much for the suggestions. I have slugged the bore and it is .312 and seems of consistant diameter. I will, however double check in that I was not looking for this aspect of it's condition. Again, to all Thanks. | |||

|

One of Us |

Only .312 Mmmm.... sounds like there is hope there! I have a pretty badly rust damaged barrel which I have fire-lapped and this has removed the scale and exposed definable rifling. I plan to bore this one out to 375 but I am now thinking that before I do that I should fire-lapp it to see what can be achieved. If I do that I would machine up some bullets for testing (or make a cast bullet mould) to suite whatever bore and groove dimensions I end up with. This is an operation I could pull off in the next week or two. (Especially if someone is interested in the results!) Regards 303Guy | |||

|

One of Us |

I came up with the grooved brass fire-lapping bullet after having problems with the abrasive getting into the chamber or throat. My arrangement allows me to keep the abrasive unside the case neck. But be warned. Brass is quite hard and needs enough propellant to drive it into the rifling with the abrasive. (I won't go into how I know but I did figure out a way of removing the stuck thing from the leade!) Regards 303Guy | |||

|

| One of Us |

I had my mould made so the long nose section was bore riding.I figured this was only a superficial lapping with very fine compound so did not think it would wear the throat although your point is well taken. Von Gruff. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia