The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Converting FN "push-button" bottom metal to a hinged system..?

Converting FN "push-button" bottom metal to a hinged system..?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

All, I was wondering about the practicalities of converting the standard FN bottom metal with the detachable floorplate to a hinged variety. I seem to recall seeing some pics/discussion of this, but could not find it. The question is two fold, I suppose. A. Realizing that anything can be done at a cost, is it reasonably feasible from an effort perspective? B. Is is generally cost prohibitive for a consumer (non-machinist/gunsmith) to go this route, and to stick with something that is commercially available? Any thoughts or opinions..? TIA Bob | ||

|

| One of Us |

I have done it in the past but would not do it again. Way too much work laborwise to be cost effective. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

If you do it yourself and screw it up you could always buy the bottom metal anyway. Hope Don doesn't mind. I bought one of his bottom levers but have not converted one myself. http://www.mausercentral.com/howtotips.htm | |||

|

| One of Us |

If you do it you would have to put a release button in the triggerguard or use a lever on the floorplate. You would also have to mill out a spot for the floorplate pivot to rest and then drill a hole for the pin that holds it in place. Or you can cut the triggerguard off and weld on a new one such as the ones shown in the photo and then put on a straddle floorplate such as the one in the photo.  | |||

|

| One of Us |

I've done several of them, but as Jim Kobe said earlier it's not cost effective unless you just have an odd guard and are trying to match the inletting or you just want a project. Here's one i did for a friend, the stock was inlet for the swede guard which is wider, so going commercial wasn't an option. Don  | |||

|

| One of Us |

It can be done various ways. The best way is if you had a mill and your own mig welder, but you can do it all with a file or a dremel tool and a file. You need to weld a piece of key stock to the front/bottom of the floorplate for a hinge and mill/grind/file to shape. Then you need to mill/grind/file out a recess for that part into the forward tang of the trigger guard assembly. The release can be as simple as removing the existing release mechanism and welding those openings up and then drilling a 1/4" hole in an angle similar to a model 70 Winchester's release button, and then making a release button from a 1/4" rod. You mill/grind/file half way through the front portion of the rod; this serves two functions, one is to provide a stop for the cross roll pin to retain the spring loaded rod into the front of the guard bow and it also is the surface that holds the floorplate closed. You may or may not need to bevel the front for it to work smoothly. PA Bear Hunter, NRA Benefactor | |||

|

| One of Us |

Okay, you guys have convinced me that it is not worth the effort. I suppose I need to decide whether or not I can live with the detachable floorplate or not. I really didn't want to spend big bucks on decent hinged bottom metal, so my options are kinds limited. By the way, nice work Don! I wish i had half your talent! Bob | |||

|

| One of Us |

I think it depends on how nice of a rifle you want and how long you are going to keep it. It certainly would be worth the effort if you are going to keep the gun for a long time and you want something nicer than what you already have. | |||

|

| one of us |

I've done a few where I make a hinge plate which is welded or silver soldered to the floorplate. I mill a slot for the pin. The original FN release button is retained. In use, the button is pushed and the plate pushed to the rear as always (the slot in the hinge allows it to move rearward)then pivoted down on the hinge. It's a decent system and reasonably easy to do. Sorry, I don't have any pictures. Regards, Bill | |||

|

one of us |

I like this option best! That looks nice Don. Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

| One of Us |

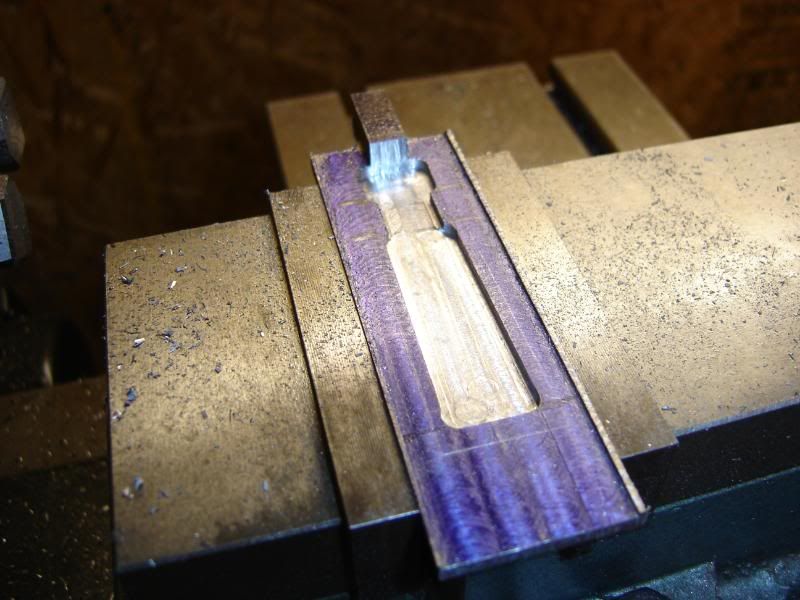

A couple of 1903 hinged jobs in my shop now. One is a straddle adapted from a Win 70 and the other is like the sliding Mauser example mentioned in another post but not shown. The hinge tongue has an elongated slot for the hinge pin, allowing the floorplate to slide to the rear when the latch button is pressed hard enough to move the spring-loaded latch. The button is captive within the floorplate and will be engraved or checkered, depending. I apologize for the unpolished appearance but these are still under construction. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| One of Us |

Thanks, Terry that one I had to make the floorplate from scratch. Did'nt turn out too bad I did some miscalculations when I bought the bar stock and it didn't end up being thick enough to make the boss around the lever hole to keep it from turning backwards,so I had to do that with the latch. Don    | |||

|

| One of Us |

Hard to tell from the pic, did you have to build up the front of the bow do make enough room for the latch on the one with the in-the-bow release? Don | |||

|

| one of us |

I wonder if it would be possible to buy complete 1909 Argentine magazine and guard bottom metal, or late/current commercial hinged bottom metal, and file and fiddle with it to fit the existing inletting. | |||

|

| One of Us |

Yes Don, I had to add a small amount (~1/16") to the bottom, to mate up with the slightly-short M70 straddle plate. If I was a better welder I might have added more filler up higher so that I could use a larger hinge pin and a longer latch lever. I may yet do that anyway, before it's all over.  Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Converting FN "push-button" bottom metal to a hinged system..?

Converting FN "push-button" bottom metal to a hinged system..?

Visit our on-line store for AR Memorabilia