The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Go No Go Gauge Question

Go No Go Gauge QuestionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Okay - I checked the headspace on two different 30-06 Enfields I have across three different bolts. I was planning to have one of them rebored (and the neck, throat work) to a 35 whelen. Well, all of them closed easily on the No Go gauge. The bolts were completely dissembled and the ejector/bolt stops removed. On one rifle there was absolute no difference. On the other, there was a difference but is was barely perceptible - maybe like 99.9% the same. All closed easily. i don't have a field gauge. Should I try that next or should I just go with a barrel setback or rebarrel? "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | ||

|

| One of Us |

Well, it looks like another $100 for barrel setback, so probably should just rebarrel. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| One of Us |

I'd buy the field gauge myself. It's not like it will be the only time you ever use it in your lifetime, and it is only a small fraction of the cost of a new barrel or a barrel setback. And one of the foremost authorities on Springfields and "American Enfields", now deceased, and a former officer in charge of many many experimental efforts regarding the '06 and its derivatives, always argued that the "go gauge" for the Springfield '06 cartridge and rifles should be junked anyway. He felt that Armory tests and other data indicated that chambers up to x.x50" inches were perfectly safe and that the x.x46" "no go" gauge should be the "go" gauge. His name was E. C. Crossman, and the better part of a chapter deals with that subject in his book titled "The Book of the Springfield". The modern editions of that book not only have all the work of Crossman repeated from the 1931 first edition, but also have each point therin as viewed by famed gunsmith Roy F. Dunlap in 1951. | |||

|

| One of Us |

I would try a field gauge. Or if you can get your hands on some .003 or .004 precision shim stock. While not prefered, it works. If you are fireforming I might not worry about it. But for the cost of rebarreling... just depends what you want to do with said rifles. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| one of us |

Enfields have angled locking lugs not square like a mauser. You won't feel any resistance until right at the bottom of the bolt travel. If you set the headspace to only close halfway on a nogo guage, it won't close on a go guage either. | |||

|

| One of Us |

Thanks - good feedback. I'll try a field gauge. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| One of Us |

Years ago I had a headspace problem with a M1917 Enfield (never mind why, that's a long story). My solution was to ship it to P.O. Ackley for a rebore to caliber .35 and a rechambering job to .35 Brown Improved Whelen. The .35 B.I.W. is an improved version of the standard .35 Whelen, with a length to shoulder of 2.09". compared to the standard Whelen's length of 1.984". The diameter at the shoulder is .461" compared to .441" for the standard case, and it holds about four more grains of water. Fire forming is done by necking the cases up to .40 caliber and then slowly adjusting the .35 caliber resizer to the point that the bolt barely closes on the loaded case. The result is a very wicked looking cartridge which feeds like a dream through the M1917 action. Of course, you can use the same technique to accomodate a chamber with slichtly excessive headspace, should you not care to go the improved chamber route. | |||

|

| One of Us |

The unique design of the Enfield's lugs has caused problems in the past. When I was in school at Trinidad, I heard urban legends about several of these incidents that had occurred at the Ogden arsenal during WW2. Some of the locals and instructors had worked at and around Ogden during those years and that's all I'll say about that, no names no pack drill, grin. It seems that it's all too easy to slam the Enfield bolt closed on the No-Go gauge with enough force to actually stretch things enough so that the rifle's formerly-OK headspace would then be excessive. Ogden was tasked with returning some of the stored 1917s to service and of course one of the simplest parts of the inspection involved checking headspace. You can see where this is going. The main-most culprit was a well-known gun writer and expert rifleman, almost a local since he was from another Western state close to Utah. At this time he had begun his writing career by authoring several books and many magazine articles, and was trying to help the war effort by working at Ogden. According to the urban legend told to us, he was checking Enfield headspace and had rejected almost 2 dozen straight before he decided to ask someone about the suspiciously-high failure rate...... His name? Elmer Keith. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

One of Us |

Speaking of stretching things... By excess force you mean, in terms of closing the bolt on a no-go gauge, that the force would be something in excess of their proof load? Are you sure??? _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

The no-go gage is .004 longer than the go- gage. The field gage is .015 longer than the go-gage. Put a piece of scotch tape on the no-go base, about .003, and see if it still goes. If not, you are okay...........Tom SCI lifer NRA Patron DRSS DSC | |||

|

| One of Us |

That was the story told to us. I suppose it's possible to compute the force required, if we knew the precise dimensions, angles and surface finish of the lugs. The moment arm leverage of the bolt handle would be easy to compute but there are several other variables. We mustn't forget that the action parts actually do move under firing load, changing dimensions rather dramatically in some cases before returning to their original state. This characteristic is measured by the steel's Modulus of Elasticity, varying with the steel's composition and heat treatment. As long as the Modulus isn't exceeded, the steel will stretch under load and then return to its former dimension. A momentary spike (firing) is less likely to permanently deform the steel whereas a sustained load will sometimes cause problems. Also there is the abrasion of the lugs' final seating, hard surface sliding against hard surface under a hard load and thereby possibly creating more headspace. Like I said, that's the urban legend that was recounted to us. Do I believe that Elmer made a faux pas? Yes. Do I believe that he ruined those rifles? Well, maybe. Regards, Joe __________________________ You can lead a human to logic but you can't make him think. NRA Life since 1976. God bless America! | |||

|

| one of us |

Did you remove the stock? Proper headspace on an Enfield is measured with a feeler gauge between the bolt handle and the receiver -NOT by feel- any differernce between without the gauge and with the gauge is okay. The average is usually somewhere between .002-.004. | |||

|

| One of Us |

Huh? I can't picture at all how this works. Would you please explain? | |||

|

| One of Us |

While a professional G-smith will use one of the go/no-go gauges to do an excellen job in a new/rebarrel job, the easiest way to determine headspace is just by firing a round and measuring with a Hornady headspace gauge then resizing it and subtracting the two. THAT will give you the actual distance from the bolt face to the same points on the shoulder which then can be compared with the standard measurements for your particular case. AND, most importantly in your case, Austin Hunter, is...if you are going to have it rebarreled/rebored/rechambered...WHAT you measure now doesn't mean squat doodly...whoever does the job will "correct" any problems in headspacing by doing the chamber job correctly anyway. Consider the fact that all you're doing, at it's simplest concept, is installing a "NEW" barrel/chamber. There have been 4 gauges actually...no, no-go, field and war(not in use since...). Besides is it also very simple to adjust your sizing die or shell holder to achieve WHATEVER headspace YOU want. I usually just use a case sized in the sizing die I will use in reloading...there is always some springback which allows for my hiccups...the chamber is headspaced as closely as possible to the sized case so I will always have the minimum amount of case sizing for longer case life. I ALWAYS CHECK THE SIZED CASE MEASUREMENTS FIRST THO', just to be sure they are within the SAAMI spec range and hope the numbers fall close to the middle of that range. The subject of "headspace/headspacing" has been covered well on many forums...go online and search or search within just about any gun forum, there is lots of good information and a ton of mis-information. Headspace is headspace, doesn't matter what caliber or cartridge...just that different ways are required to measure, it depending on the cartridge and receiver. Headspace is one of those things that seem to cause sleepless nights for some people...but it is just ONE of the things you need to consider when doing any kind of conversion work. Montea6b...pick up just about ANY rifle, be sure it is empty...wiggle the bolt forward and backward...you will feel "play"...THAT IS HEADSPACE...basically the amount of distance between the bolt nose hitting the barrel face and the bolt lugs hitting the lug abutments...or in some cases the distance between one specific point and another point that is used as "STANDARD MEASURING POINTS/POSITIONS" for that component. In rifles that could/should be ZERO to maybe 0.010", give or take. You need some gap because of dimentional changes due to heating and cooling and to keep the bolt nose from hitting the barrel face which can cause the bolt to lockup tight or mess with accuracy. Now look at where the bolt handle locks into the receiver notch. All you have to do is measure the gap between the bolt handle and the notch wall, with ANY kind of gauge...depending on the amount of distance between the bolt handle and the metal of the receiver notch...just stuff a feeler gauge into the gap increasing the thickness and adding/subtracting blades until it is a gentle slip fit...THAT is the AMOUNT of headspace...then compare it with a measured and subtracted, size and a fired case measured with a Hornady headspace gauge or gauge you made yourself. The two measurements should be very close...and THAT IS THE ACUTAL AMOUNT OF HEADSPACE in THAT rifle. The concept of headspace shouldn't be difficult to understand...it is nothing more than the "gap" distance between the cartridge face and the bolt face...the amount of distance required for "clearances" so that the normal SAAMI tolerances for components will be covered in the manufacturing process of all the components...something to "standardize" the whole process of rifle and ammo making. Tell me JD...WHICH steel part was stressed...the gauge, the bolt lugs, the receiver lug abutments...the rear sight...?? Besides, brass wiggles and squirms, EVERYONE has a different "feel" when measuring with hand held devices and 0.001" is a mighty small amount to measure to begin with...just blowing hot air on a mic can make it wiggle and squirm, so....it ain't no thang, Bro'...and all them Moduluses and Poissons go south the first time you pull the trigger on the first round in a freshly made barrel...the heat and pressures generated by the burning gases blow them other fellers clean ouddadawada. Luck | |||

|

| One of Us |

Foobar - In terms of "match rifle chambering", I think your immediately above post is possibly the best thing you have posted here yet. I'm still thinking over what I would do for hunting rifles in commercially available cartridges though. The way I always chambered my match rifles (and the way several of my friends who were also national champions and/or national record holders chambered theirs) was to as carefully as we could, make a case to the exact dimensions we planned to use for our competition ammo, and use that case as a gauge for the depth of our chambers. By doing that, we could create a cartridge which seemed to best employ the burn rate and amount of the powder we planned to use, at the velocity we also planned to use. That might require shortening or lengthening the length to the shoulder by .010", .017", or whatever. With certain brass, it even required reductions or increases of neck diameter AND length to fit the specific bullets we used. And, of course there is no way a headspace gauge could measure that. That's not what headspace gauges do. So, after the chamber was cut, we would then seat one of the bullets we planned to use in the case to the exact depth we planned to load our match ammo. We would use that dummy round as a gauge for cutting the chamber throat. Though a friend left me a headspace gauge for our nominal cartridge when he died, I never ever used it. I wanted my chamber to fit the exact ammo I'd be shooting, not to fit some gauge which someone else had decided the dimensions for. (I have not made up my mind 100% yet, but I doubt I would use that approach for a hunting rifle which might be sold to someone else upon my own death. There I believe I'd probably go with a standard commercial headspace gauge, so they could safely use any ammo made commercially for that cartridge by any manufacturer.) | |||

|

| One of Us |

WOW!!!! Some of the things you can learn here. I wonder why in the hell they ever invented the headspace gauge? Maybe to measure the distance from the bolt face to the face of the receiver? Ausome and astounding. Jim Kobe 10841 Oxborough Ave So Bloomington MN 55437 952.884.6031 Former Professional member American Custom Gunmakers Guild | |||

|

| One of Us |

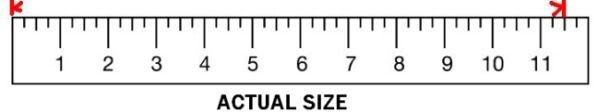

I have to concur, Jim...seems we have a Bureau of Weights and Measures here in the US..For the simple reason that 11 1/2" in New York is the same as 11 1/2" in California. SAAMI...using the standards adopted by the Bureau of Weights and Measures have issued specs on chambers and cartridges so one will interchange safetly with the other. To minimize the importance of a gage is not only foolish,,,just plain ignorant...and dangerous. | |||

|

| One of Us |

The bolt would not close on the field gauge. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| One of Us |

I probably went to TSJC before most on here,1952. We were taught to ALWAYS use a headspace gage but if for some reason one was not available for a particular factory cartridge to use a piece of NEW Remington Ammo as Remington was basically ,at that time I am sure,to the minus side of the standards and Winchester to the Maximum. I am looking at my 30-06 military gages that I have used for the past 57 years for 06 size chambers. It consists of 3 gages as follows: Ord Dept U.S.A. Globe Instrument Co. Inc. Headspace Gage Cal. .30 1.940 C7719 A FCG-18 Ord Dept U.S.A. Globe Instument Co. Inc. Headspace Gage Cal. .30 1.946 C7719 G FCG-18 Ord Dept U.S.A. Ind T & D Co. Inc. Headspace Gage Cal..30 C7719M 1.950 Rev. 5-28-43 Now these were presented to me by an armorer that at the time was building National Match rifle for the U.S.Army. He was building up a demilled action for me to National Match standards. I assume he used similar gages. The 1.940 has a chip in the rim area. They are pretty hard and I rather doubt anyone would compress these gages in any way. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

Duane -- Having lived for quite a few years in California ,I'm not really sure 11 1/2 " in any other state is the same as 11 1/2" in California SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

zimbabwe: I was thought basically the same thing, some 39 years later, a TSJC. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

It should be obvious that personal match rifles, and rifles for the general public using commercial ammunition are two entirely different things. The rifle for the public is made to a standard which has to accept any commercial round fed to it, without the chamber being too big or too small for safety when the round is fired. For that purpose, a headspace gauge set is the means of assuring that happens. It makes the rifle safe in the hands of the public, but the cost in many instances is less than optimum accuracy. But that is NOT the standard for chambering a match rifle which will be using handloads. Match rifles are chambered to dimensions which, in the experience of the shooter or builder, produce the highest accuracy with his components while being safe to use with THOSE SPECIFIC components. The cost in that instance is inability to always operate safely with every odd bit of ammo he stumbles on. To repeat that again, as such, many (most?) match rifles are NOT built to use any random ammo which the shooter happens to come upon. With all rifles shooting handloads, there are two ways to approach the question of safety. One is to build the ammo to fit the rifle, which I think is what Foobar was describing. The other is to build the rifle to fit the ammo, which is what I was describing when I described using a cartridge case and a totally inert loaded round to build and gauge my match rifles. People building guns for the general public really have no choice. They have to build rifles which first and foremost are safe in the hands of the numbest, most nieve, beginner. They pretty much have to use standardized gauges. Match riflemen, especially long experienced ones who build their own rifles, are under no such contraints. They can build what they find works best (within the rules) to win matches. Two different worlds.... | |||

|

| One of Us |

The rifle will either head space or it won't, even that can be remedy'd, one way or the other. But the barrel should be marked as such a wildcat, if it's not a standard chamering, like bore diameter, headspace measurement, and maybe neck diameter. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

One of Us |

FOOBAR, you need to go back to wherever it is you learned about headspace, and demand a refund. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

| |||

|

| One of Us |

Yeah...poor choice on my part | |||

|

| One of Us |

and that was after saying, Headspace is one of those things that seem to cause sleepless nights. All I can say is WOW Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

I hope some of the ideas posted here are just imaginary...If some see real life in the form of a rifle..PLEASE paint the entire rifle blaze orange | |||

|

| One of Us |

Foobar said

That will give you "chamber clearance" and on a rimless cartridge it probably is also "headspace"! Not so on rimmed, semi-rimmed or belted cases! Foobar said [quote] There have been 4 gauges actually...no, no-go, field and war(not in use since...).[quote] My understanding is there are (where) three gauges and it is the “field” that is no longer used. Foobar said [quote] pick up just about ANY rifle, be sure it is empty...wiggle the bolt forward and backward...you will feel "play"...THAT IS HEADSPACE...[quote] I don’t think so! I think that is a sloppy bolt. Headspace is measured from the face of a closed bolt to the face of the chamber cut meant to receive the forward face of the cartridge rim on rimmed/semi-rimmed brass, the forward edge of the belt on belted brass, or a predetermined point on the shoulder on rimless brass. DauneinND-----If you are referring to the Lee Enfield, there are 3 different, exchangeable bolt-pieces (don’t recall the proper name) numbered 1, 2, 3, and you changed them out until you found the one that worked using a set of headspace gauges for the rimmed cartridge. | |||

|

One of Us |

FOOBAR, you should have led with this. Then the rest of would have made sense.

I collect headspace gauges and am in need of a 30-06 "war" gauge to make my collection complete. So if you come a cross a 30-06 "War" headspace gauge, I am definitely interested. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

That's like Jethro Bodine telling Uncle Jed he's got what he wants to be, nerrowed down to, either Brain surgeryin, or Fry cooking Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

GUY'S...There is ALWAYS different ways to approach a problem and different ways to try to explain and SOLVE problems...ALL of which tend to step on SOMEONES TOES and stir someone up and NEVER quite cover ALL the contingencies. Tell you what...why don't any or ALL of you give YOUR definition of headspacing so we can ALL benefit from YOUR CUMULATIVE EXPERTISE. Then EVERYONE can take potshots at your definitions...YOUR CONCEPT DEFINITION, NOT SOMETHING OUT OF A BOOK OR ONLINE...I won't shoot at you...I have other things to do, but I'm always amenable to other forms of information...it will come in handy sometime, somewhere. I might not be a "professional" G-smith, but I've been doing this game as long or longer than some of you, have built MANY rifles that shoot excellent groups, my cases last a minimum of 10 to well over 50 firings and I've had SEVERAL PROFESSIONAL GUNSMITH'S PHUC UP rifles I sent to them for simple rechamber jobs before I got tired of that krap and bought my own lathe/mill... One I've mentioned before, a 338-06, I still shoot that came back to me with "headspace" of 0.022"...all I did was make a horseshoe shim to fit around the case and limit the amount of shoulder set back then bought a Redding Comp Shell holder when they became available. It took an old time REAL G-smith to solve that little problem and HE was the one who taught me all about headspacing and what it was really all about...NOT some definition in a book. I guarantee he would be having some good laughs with all the garbage going around. He and a good amount of others taught me to think for myself and look beyond the people in the ruts. Yes, I understand there are several ways to headspace the various types of cartridges...We were talking about a rimmless cartridge so I confined my comments to that milieu...but knowing and understanding what headspace IS, allowed me to setup a SMLE to shoot both the rimmed 45-70 and the belted mag 458 WM...in the SAME CHAMBER...knowing and understanding headspace was only ONE part of the equasion. As one man said...Don't ask WHY, ask WHY NOT. I tried to put the concept as simply as possible with a few examples...if you disagree or miss-understand, I don't care...DON'T USE THE EXAMPLES OR THE EXPLAINATION...and I'm not sorry either....maybe it flew over your head like a ruptured duck. Maybe Uncle Jed NEEDS to be told "what the hell and why"...did you ever consider that Mad_Jack02...there are thousands of people online that need more than one place to "check the veracity of the statement" and more than one explaination to clearify. AND...Of course ANY attempt at explaining ANY concept is prone to mis-understanding and NO explaination can fully define ALL the parameters and no matter what...EVERY STATEMENT can be picked apart. I made some generalized observations about what I THOUGHT and HAVE LEARNED AND USED in building MY rifles...I DIDN'T SAY ANYTHING ABOUT NOT USING GAUGES...I DID SAY I CHECK MY BUILDS against SAAMI specs. Many of my rifle are wildcats and there ARE NO STANDARD GO,NO/GO gauges...so pray tell...HOW WOULD YOU GO ABOUT HEADSPACING A "NONSTANDARD" WILDCAT...and since my explainations are so bad and I'm dumb...YOU TELL ME HOW TO DO IT!!! I KNOW A COUPLE OF EASY WAYS, but because of my ignorance they MUST BE WRONG...PLEASE...TELL ME. I could chew up and spit out ANY or ALL of the statements many of YOU have made, but all that would serve to do is keep the pot boiling and confuse any newbee even more...there is absolutely NO value in doing that...to me or to ANYONE. I will continue to do this "thing" my way, it doesn't matter if you or anyone thinks my way is wrong...I have no problem in building an accurate shooting rifle...even using "cheap" components. If I didn't make the explaination clear or concise enough, that might be YOUR problem and not mine. Not sure where I read about the "war" gauge, but I think it might have been in one of Ackleys publications...then again, that was years ago and was in reference to that was going on pre WWII and in the arms being readied for the "Lend/Lease" program to go to England. I can't say for certain if it was used by our side or by England. If this is in your area of expertise, then by all means set the record straight. I would like to know for certain...REMEMBER...it doesn't matter WHO wrote the article, then as now, things get messed up, and that "war" gauge might not have actually been "standardized" or they could have been destroyed during or after the need. Heck, who knows for certain WHAT TO BELIEVE in todays world. Luck | |||

|

| One of Us |

this is 11-1/2" in NYC-  .just ask my wife | |||

|

| One of Us |

FOOBAR, I know of no cartridge that has a headspace measurement of .022". Here is a link to Forster's web site http://www.forsterproducts.com/store.asp?pid=24834 and at the bottom their are some visual aids ( pictures ) for those still in question of how and where the measurements are taken. Like Alberta Canuck was saying you can make your chamber fit your brass, or you can make yorr brass fit your chamber, but if it's not in SMMI specs you have a wildcat on your hands, and needs to be stamped as such in my opinion. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

I also have read of the "war" gauge, but do not at this moment recall where. I do also seem to recall that it was in a book by one of the famous old miltary arsenal folk. Whether it exists or not, is totally unimportant to me, but anyone's reference to having read of it is not a fool's fantasy. | |||

|

| One of Us |

I may be wrong, but I was told that for G.I. cartridges you had a field gauge, and may be called a War gauge, meaning, out in the field away from the shop, AT WAR. now I've never seen or herd of a field gauge for any of the off shoots of the parent cartridges? The Go, No-Go, so maybe it's one in the same, still only three. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

Well, that's a perfectly reasonable assumption Jack, but does not apply to the instance I read. The one I read said that arsenal experiments showed that with the brass and anneals in use, there was absolutely no significant risk in using issue ammo in chambers with a headspace up to .050" longer than a field gauge, or even much longer than that. That, of course applied to brass and ammo which would NEVER had been and never would be reloaded. Anyway, for temporary expediting of war production and reduction of rejections based only on headspace, a larger gauge was claimed to have been authorized at at least one production site early in WWII when we were actually teaching new soldiers with broomsticks, as we had no rifles at all for many of them. That is certainly the impression I came away with, even if that is not the exact wording. | |||

|

| One of Us |

See if you can dig that information up, as I'd love to look at it. Extreme Custom Gunsmithing LLC, ecg@wheatstate.com | |||

|

| One of Us |

Sorry, but I am not going to see if I can dig it up. Nothing personal or arrogant intended in that, Jack, I just don't have that kind of time available. My sight is very limited these days, and I have a library here which I estimate at well over 3,000 books on firearms...and that just includes the hard bound ones! Actually, I have more than three rooms full of them, if one includes the soft-bound material....much of which (both hard and soft) is still packed from our move 20 months ago. Obviously, not nearly that number are by old arsenal hands, but then it might have been written by someone else. IF I happen across it again, though, I will definitely cite it, and folks can then look it up for themselves. | |||

|

| One of Us |

Greetings, Alberta Canuck: Just want to make this observation...the firing pin protrusion is generally accepted as around .060 (OK with that?) Now it you have .050 excess headspace, I THINK a system 98 extractor would hold the case up against the bolt face enough for ignition. Wonder what would happend in a 700 Remington or Garand, etc. with the ejector pluger pushing the case deep into the chamber...my guess it would not fire...but if it did, I'd bet a Big Mac there's be a case head seperation. My personal conclusion is that .050 excess is WAY out of the loop of responsible and safe shooting...again...paint that rifle blaze orange so that I will not sit next to that rifle at the range | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia