The Accurate Reloading Forums

Duane Wiebe 300H&H work photo's

Duane Wiebe 300H&H work photo's

Duane is currently building a 300H&H for me on a mauser action. Duane is very good about sending work photo's (the best form of communication there is). Here are a few of those photo's of the metal work. Duane can chime in and give you any details. I hope you all enjoy the photo's as much as I do.

Here is the barreled action.

Top action is the 300H&H, middle action is a Granite Mtn 404, bottom action is the Satterlee 416 Rigby.

Installing new bolt handle

Custom talley bases.

Milling the rear sight

Finished rear sight

Installing and squaring the rear sight to the action.

Front sight profile was re-shaped.

Installing the front sight.

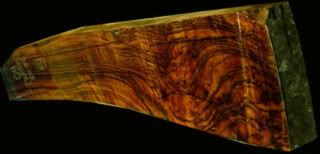

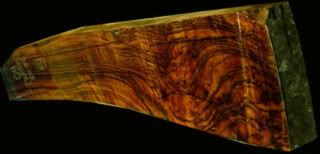

Going to use this blank.

After band sawing - middle blank is for the 300H&H.

Laying out the measurements for inletting the action.

Inletting.

Installing recoil pad with widows peak.

Left Side

Right side.

After tinting stock with red oil.

Sanding stock with rottenstone and stock oil to both fill and polish the wood. Each application leaves a very thin coat of finish......need to do this 20-25 times.

Duane will be shooting in the iron sights next.

Checkering layout.

All of these little parts were blued, while waiting on the engraving.

Scrollcutter did the engraving.....I didn't want a lot as this will be a working gun.

Here is one with the Swarovski scope

15 May 2008, 22:15

FAST996Mike,

All 3 actions are nice looking. I do like Stu's a little better,but I'm biased as you know.

Roger

"A long life, and the good sense to live it." ...Quintis Arrius

375H&H,404J,416DAK,458AFR,416RIG,450RIG,505GIB

Avatar: Gregory Peck & Susan Hayward in Africa

NRA member

:::SIGH::: absolutely gorgeous Mike

Love the caliber too! jorge

USN (ret)

DRSS Verney-Carron 450NE

Cogswell & Harrison 375 Fl NE

Sabatti Big Five 375 FL Magnum NE

DSC Life Member

NRA Life Member

15 May 2008, 23:18

500grainsThe man is a genius.

That is going to be something special. Keep the pictures coming.

Terry

--------------------------------------------

Well, other than that Mrs. Lincoln, how was the play?

MHC,

How about it, are going to have Duane extend those tangs? Thanks for sharing and sure would be nice to turn Duane lose on all that iron.

Many Thanks

HBH

16 May 2008, 08:45

butchlambertYou are one lucky feller! I don't think the other 2 receivers have anything on yours.

Butch

16 May 2008, 16:40

Marc_StokeldDuane-

nice work as usual. I noticed that you soldered on the rear site and you Loc-Tited the sling swivel on the Searcy rifle. I was just curious which method you chocse for different applications.

Thanks again for posting the pics. You set a high bar for hacks like me.

They are addictive. That's quite the line up.

Timan

17 May 2008, 04:24

Duane Wiebequote:

Originally posted by Marc_Stokeld:

Duane-

nice work as usual. I noticed that you soldered on the rear site and you Loc-Tited the sling swivel on the Searcy rifle. I was just curious which method you chocse for different applications.

Thanks again for posting the pics. You set a high bar for hacks like me.

Well...read the tea leaves, test the wind...you know..all that scientific stuff! On this project, I soldered everything. Loctite can be VERY effective. I once had to remove a loc tited swivel band that I had originally. installed.....couldn't do it! had to turn it off on the lathe. Lot has to do with the fit. Installing sights, leaves little room for error. If it's not exactly right and loc tite was used...you're screwed! With solder, you can adjust, then light up the torch and finish the job Like to hear how others feel about all this

17 May 2008, 07:49

D HumbargerDuane,

The problem with silver soldering (for me at least) is that when soldering metals of different thickness together ( barrel bands, sight bands which are thin etc to barrels which are thick ) they heat up very differently. Thin=fast, thick=slower. Any special tricks to address this issue to make the solder flow where you want it to.

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

17 May 2008, 19:58

Duane Wiebequote:

Originally posted by D Humbarger:

Duane,

The problem with silver soldering (for me at least) is that when soldering metals of different thickness together ( barrel bands, sight bands which are thin etc to barrels which are thick ) they heat up very differently. Thin=fast, thick=slower. Any special tricks to address this issue to make the solder flow where you want it to.

Unless you're going to caustic blue, silvcesolder usually is not necessary for ramps, bases, etc. I use a 'productr xcalled "sta brite" a silver bearing solder ( 6 percent)but have lately tried the "force 44(4 percent) which is much easier to work with. I tin the barrel, using steel wool to spread out and make a nice even coat. flux again and then flux the inside of the band real well. Clamp in place and heat evenly until the solder flows into the joint, applying as much as it will take...of course, don't overheat. I use a "Presto lite" acetylene torch such as you see plumbers use. The flame on hand held bottles sputters at exactly the wrong time if the bottle is inverted or almost any position except straight up

17 May 2008, 21:25

Jim KobeDitto on the Force 44 solder. The only problem I have with it is cleaning up the overrun stuff. Usually use the soapstone sticks to keep it from spreading too far.

I quit using silver solder a long time ago. It takes way too much heat to make it flow to do sights on a barrel.

As for bluing, I don't have a problem with caustic bluing with this solder. It will stand up to the bluing temperature.

Jim Kobe

10841 Oxborough Ave So

Bloomington MN 55437

952.884.6031

Professional member American Custom Gunmakers Guild

18 May 2008, 01:54

Duane WiebeJim: I've heard that! Does the action of the salts themselves deteriorate the joint? I'm pretty sure temp iself would not

18 May 2008, 05:50

D HumbargerDuane

quote:

Presto lite" acetylene torch

Which tip do you use?

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

19 May 2008, 06:01

gunmakerDuane

What kind of flux do you use?

Do you degrease your steel wool before using it for tinning?

quote:

Originally posted by HBH:

MHC,

How about it, are going to have Duane extend those tangs? Thanks for sharing and sure would be nice to turn Duane lose on all that iron.

Many Thanks

HBH

HBH,

No, I will not have extended tangs installed on this rifle. I want to keep the weight down.

I also posted a photo of the wood blank we will use.

20 May 2008, 05:00

Duane WiebeLets see....I use the big tip...don't even know where the small tip lives. I don't bother degreasing...but it sure wouldn't hurt!

The Flux with Force 44 is the one I use...I also squirt a bit on the steel wool...really makes a nice flow.

After you're done, wash well in hot running water and scrub with SOS pads...this stuff is really caustic!

Tip: Have a fan taking away the fumes

20 May 2008, 18:40

Jim Kobequote:

Originally posted by Duane Wiebe:

Jim: I've heard that! Does the action of the salts themselves deteriorate the joint? I'm pretty sure temp iself would not

I thought that I had replied to this but...

I have not noticed any deterioration of the joint.

Jim Kobe

10841 Oxborough Ave So

Bloomington MN 55437

952.884.6031

Professional member American Custom Gunmakers Guild

21 May 2008, 03:14

Gun toterMHC,

Nice!

I am sitting here thinking about PM you to invite you on a hunt when that gun is completed.

And one great gunmaker,

Purdey and H&H (and whoever else you want to insert here) over the pond can take a back seat to that gun when it is finished.

Helluva stick of Turkish too.

Amen

I love my Avatar Too Fellas.

quote:

Originally posted by Gun toter:

MHC,

Nice!

I am sitting here thinking about PM you to invite you on a hunt when that gun is completed.

And one great gunmaker,

Purdey and H&H (and whoever else you want to insert here) over the pond can take a back seat to that gun when it is finished.

Helluva stick of Turkish too.

Amen

Where are we going?

21 May 2008, 07:53

Gun toterHow close are you going to be to that 300 H&H when its done.

Its gonna have a huge bearing on our location!

I love my Avatar Too Fellas.

MHC,

Good God Man, there you go using common sense again. Sorry I just got a case of the Jones for extended tangs Duane has teased us with recently. Those sure will make nice litter mates for the Mrs's 7 x 57.

Looks like a super nice blank!

Many Thanks

HBH

22 May 2008, 08:23

ForrestBAt least we know Duane is pleased with the way the Scholarship Rifle raffle turned out.

______________________________

"Truth is the daughter of time."

Francis Bacon

23 May 2008, 06:13

aleaddictI would really like to know how you reshaped the ramp of the front sight. It looks seamless.

-- Brian

quote:

Wow, I want that top blank!

02 July 2008, 01:14

MHC_TXupdated with more photo's 7/1/2008

02 July 2008, 01:51

CAS IIOh, my. That is incredible.

02 July 2008, 02:29

Austin Hunter"That's one bad, mofo shooting stick." Shaft

"Evil is powerless if the good are unafraid" -- Ronald Reagan

"Ignorance of The People gives strength to totalitarians."

Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness.

02 July 2008, 04:35

30 Caliber Mag FanMHC_TX-

That is one incredible project!!! Great caliber, my favorite of all the .30 caliber magnums.

Gorgeous stock, in-fricken-credible to be more precise.

What bolt handle was used on your action?

May the wind be in your face and the sun at your back.

P. Mark Stark

02 July 2008, 18:40

MHC_TXquote:

Originally posted by 30 Caliber Mag Fan:

What bolt handle was used on your action?

I'm not sure - maybe Duane will see this and give us the answer.

I did go with a 25" barrel length.

02 July 2008, 20:05

srtraxMr. Wiebe;

I noticed in the bolt picture that the fixture looks to be fixed.

Are you set on a certain angle that the bolt handle should sweep away from the bolt body, and if so what is the degrees from center of bolt to the extended bolt handle? Hope i'm clear and understandable on this question...

_____________________

Steve Traxson

02 July 2008, 22:06

ClaymanThat's great progress on a very nice rifle! I love that he sends photos of the progress; that's the mark of a truly honest and dedicated 'smith. You'll have to show us some pictures when it's all said and done!

_____________________________________________________

No safe queens!

03 July 2008, 07:12

Duane Wiebe[QUOTE]Originally posted by srtrax:

Mr. Wiebe;

I noticed in the bolt picture that the fixture looks to be fixed.

Are you set on a certain angle that the bolt handle should sweep away from the bolt body, and if so what is the degrees from center of bolt to the extended bolt handle? Hope i'm clear and understandable on this question...Yes your question is very clear..my answer probably won't be...I haven't measured the angle, but I like to nestle the bolt knob JUST above the bottom line of the stock and leave enough room btwn the stock and knob to comfortably get the heel of the hand for a reliable purchase...maybe about an inch? I had these handles made up, but the knob itself is Half Moon/QUOTE]

03 July 2008, 20:47

srtraxMr. Wiebe;

Thank you for your reply, and i do understand your answer. Looking at the bolt pictures, and the side view of rifle picture gives me a good idea what you are saying. I built rifles a few years back, but got side tracked. I built what some would call OLD SCHOOL rifles with the swept back bolt handle, but the straight down look is really growing on me. Going to make a go at it again, putting shop together. Using a Brownells copy of their bolt jig and never really liked it. Anyway, Again...Thanks for the input, may come up with a rig of my own.

While i'm at it, let me say... Nice Work, hope to see more of it!!! Enjoy

_____________________

Steve Traxson

03 July 2008, 20:54

srtraxMHC_TX;

Thanks for sharring photos with us, Damn fine rifle your getting there...Enjoy!

_____________________

Steve Traxson

Everytime I see Mr. Wiebe's work I am just amazed. Absolutely stunning.

Ken....

"The trouble with our liberal friends is not that they are ignorant, but that they know so much that isn't so. " - Ronald Reagan

04 July 2008, 05:17

Duane WiebeNow...that's a jig! A work of art in itself. Mine is similar in application....see the spud with a locating pin in it for cocking notch?

That is kind of the basic requirement, just hold the knob in position for welding The bolt shanks I had made up go into a "square" near the weld...saves a heap of time building up weld, then milling off excess..for me anyway!

04 July 2008, 18:28

srtraxThanks 22WRF;

That makes me want to do the "JIG"

I like the way the bolt handle itself slides in a dovetail/groove...Good idea!

But with all that metal, where is the heat sink...

Thanks guys you've been a big help!

MHC_TX; Didnt step over the bounds of highjacking i hope, here to learn something new and did...Again THANKS for starting this post!

_____________________

Steve Traxson