The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Standard Depth M98 Magzine Belted Mag Capacity

Standard Depth M98 Magzine Belted Mag CapacityGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

What is the maximum belted mag capacity of a standard depth M98 action? I get 3 rounds down in my 7mm Mag FN Mauser and 3 rounds down in my 458 WM Whitworth Mauser. However, I remember when I converted my 9.3x57 to 9.3x62, I had to file and thin down the sides of the magazine to get 5 rounds down for the '62 like I had for '57. Can a standard depth mag be widened (to the correct geometry) to fit 4 belted mags down? I remember seeing Phil's original 404 that had the sides of the mag removed at the factory to hold 4 404 jeffery rounds down in a standard depth mag. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | ||

|

| one of us |

Look how much you had to file the magazine walls for a cartridge that us only .006" larger in diameter. A belted magnum case is another .060" larger. Short answer is no amount of filing will allow you to get four rounds to stack properly in a factory bottom metal unit. Aftermarket units like Wiebe's are a good bit wider to fit 4.  Aut vincere aut mori | |||

|

| One of Us |

I wondered if his would fit 4; his site says it does. My stock is already inletted for a FN commercial bottom, would have to check his pattern, probably fine. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| one of us |

I went thru this a couple of months ago. Have a friend who bought one of those 1909 Arg rifles that had been imported and rechambered to 30-06. Shot terrible, no wonder. Any way wound up converting the action/guard to a 300 Win Mag. Machined .015" from the inside of each side of the guard, up to just past the shoulder of the Win Mag case. Then tapered that cut up into the messed up front end inside of the guard. They did a number on it, so I silver soldered a piece of 1/8" 1018 mild to what was left of the front of the box, and recut the inside to clean up the messed up inside. Also at the same time I cut .050" from the inside of the rear tab, this way I could open the length of the inside of the guard to 3.50" Then as the body taper of the Win Mag is wrong for the now modified guard, I had to spread out the guard at the shoulder area for the wider Win Mag case, this is needed to allow the cases to stack/lay inside the guard flat and level. OK so now I can get 4 rounds in the box BUT nothing else fits. So I make a new floor plate with a .160 deep recess ( Pocket Floor Plate ) this allows the spring and follower to drop lower and get the 4 rounds, follower and spring all in the guard and rails of the receiver. Now On to recutting the feed rails of the receiver a little wider to match the modified guard and wider case, and to clean up the messed up feed ramp from the 30-06 conversion. Then as it was an 1909 Arg I sent the receiver off to be re heat treated. Now the Shilen barrel has come in and I need to finish the job. So yes you can get 4 rounds in a standard guard BUT it takes a lot of work and you need to be able to use a milling machine, and a file properly to do it. 3 rounds no problem, but that 4th round is a total different cat. J Wisner | |||

|

| One of Us |

[QUOTE]Originally posted by Austin Hunter: Good news is my mag is long enough already (3.4" inside length) and wide enough at the rear for 4 458 rounds. The problem is the front and the angle of the sides. I need about .865" inside width at 3.4". The outside mag here is .80". So I'd have to completely remove the sides and allow the stock to form the sides of the magazine like Phil's 404 (see below), but keep the front. I'm willing to give it a shot. I have several wider followers as well I can use. If it doesn't work, I'll get a new bottom from Duane that I know will work. https://www.flickr.com/photos/...n/dateposted-public/ "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| One of Us |

My 404 bottom metal holds four down with as standard thickness floorplate IF the rails are properly configured. That will also allow enough compression to load a 5th up the spout. With the optional cavity plate, (.150 deeper) gives PLENTY of room | |||

|

| One of Us |

Academic question here. If someone wanted to make a custom "Rigby" / "coffin" floorplate to add an extra .374 H&H case based round in military or FN/Interarms/Zastava bottom metal how much deeper would it need to be? Is it possible to add that extra round with a floorplate before the follower would drop below the bottom metal to floor plate seam and potentially catch? | |||

|

| One of Us |

I offer a "Rigby" floorplate, but will not do a retrofit. | |||

|

| One of Us |

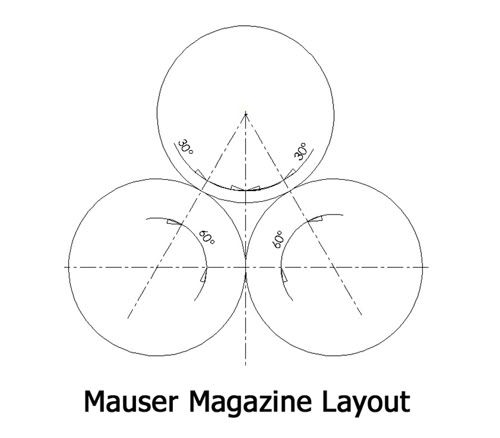

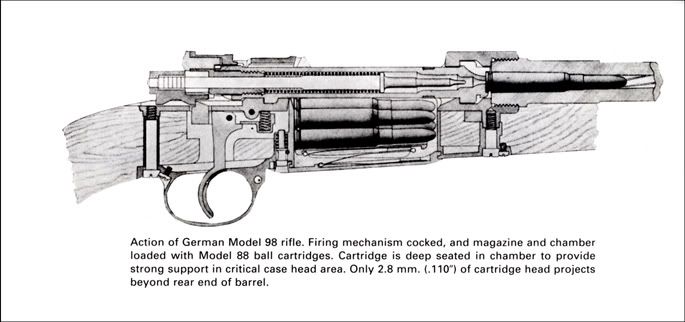

This is an artical I have C&P from another forum so the authorship is by Tileyman of Australia I originally wrote this article for our club magazine, pulled together from a few sources including Ludwig Olsen's Mauser Bolt Rifles and De Haas' Bolt Action Rifles... hope you find it useful! Many thousands of Mauser 98’s have been rebarrelled to a multitude of modern cartridges very different to the original 7.92mm German military chambering. While some of these conversions feed reliably from the magazine, many do not! The fault often lies with the magazine and follower profile if it is left unaltered from the original layout. Paul Mauser was a gifted firearms designer who carefully designed each magazine of his M98 rifles for a particular cartridge. Box and follower dimensions were predicated on case dimensions... Paul figured that a staggered column would enable more cartridges to fit into a given magazine well than a single vertically stacked column. In order to feed correctly from a staggered magazine, each cartridge needed support... from the magazine box on one side and a cartridge or the follower on the other side and underneath. With a stacking angle of 30 degrees, three stacked cartridges in contact would form the corners of an equilateral triangle:  By multiplying the Cosine of 30 degrees ((0.866) by the case head diameter, then adding the diameter to the product of the equation, the correct magazine box width could be determined. For example, a 9.3x62mm case measures 11.95mm across the rim. So 0.866 x 11.95 = 10.35 +11.95 = 22.3mm Theoretically, that is the correct inside rear magazine box width for any cartridge deriving from the 9.3x62mm case. However, all cartridges taper, and so must the magazine. The same formula yields the proper box width at the point of shoulder contact: The shoulder diameter is 11.45mm So 0.866 x 11.45 = 9.92 + 11.45 = 21.4mm A magazine box for a 9.3x62mm cartridge must therefore theoretically taper from 22.3mm to 21.4mm. Adding an extra 0.07mm ( 0.003") or so for dirty or oversized cases makes practical sense. So a practical magazine box for the 9.3x62mm cartridge would taper from 22.4mm to 21.5mm A magazine box designed for one cartridge works for others ONLY with the same identical front and rear diameters and the same span between them. Triangles between cartridge centrelines get steep when the box is too narrow, and rounds tend to cross-stack. Paul Mauser also relieved the box sides slightly, from just ahead of the cartridge base to just behind the shoulder, so there would be no increase in friction between the case body and the box wall. He lavished equal attention on the magazine follower, which on an original M98 mirrors the box taper. The width of its lower shelf matches that of the case, with a 61 degree step between the upper and the lower shelf.  The top shelf is high enough to touch the next-to-last cartridge without lifting it off the last round in the stack (its half a diameter above the lower shelf at base and shoulder) The follower has a slope to follow case taper and keep the cartridges level in the box. Side clearance of the follower to box is also critical. Followers should be about 1.5mm (0.060") narrower than their boxes so they can wriggle a bit... especially important for the last cartridge. A magazine follower for our 9.3x62mm example cartridge must therefore theoretically taper from 20.8mm to 19.9mm. A magazine follower to fit the practical box above would taper from 20.9mm to 20.0mm Floor plates that have been machined to hold the magazine spring tightly won't feed properly either... the springs are supposed to shimmy back and forth! If the spring can't shuffle a bit as the bolt strips a round, it twists and the follower tips or ends up sideways... sometimes both! Follower length is not as critical, but one that is too short will tend to 'dive' in the magazine box and cause misfeeds. Many temperamental-feeding custom rifles have had some attempt at magazine alterations, often made on trial and error rather than based on sound engineering principles. Getting a custom M98 rifle to feed flawlessly with a new chambering is the mark of a top-notch gunsmith who fully understands the ‘elegant simplicity’ of Paul Mauser’s original design.  | |||

|

| One of Us |

Great info there Von Gruff, thanks. | |||

|

| One of Us |

Thanks - good info! My big bore days may be over after my neck surgery, so this project may not start. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Standard Depth M98 Magzine Belted Mag Capacity

Standard Depth M98 Magzine Belted Mag Capacity

Visit our on-line store for AR Memorabilia