The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  Steam vs water

Steam vs waterGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Here my old stainless tank, roll of stainless came out of the AA jet shop at Kennedy, 4x4x40, I think, about 3 gallons. Imagine it sitting on a blue Garcia double burner propane camp stove, took forever to boil outside. Going to build me one of those steamers (not the bamboo type)  | ||

|

| One of Us |

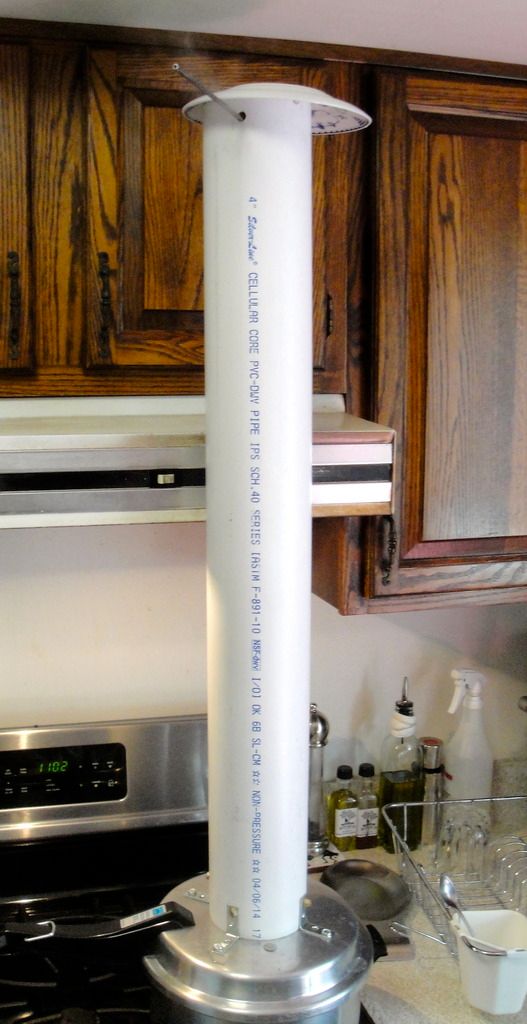

Steaming is the only way to go. Very efficient to me. Made my steamer from a piece of pvc and an old turkey broiler. It's ugly but works. I will make a better one soon. Society of Intolerant Old Men. Rifle Slut Division. | |||

|

| one of us |

I promote cellular core PVC but you know, if you have access to 3-6 inch inside diameter bamboo, that would make a nifty steam pipe also. Just have to knock out the thin membranes between sections. Steam is beautiful for rust blueing. Clean and low volume. No issue with water quality. Bob www.rustblue.com | |||

|

| One of Us |

bamboo is for dumplings | |||

|

| One of Us |

Dumplings, indeed. I much prefer mine deep fried. As for rust bluing, stream is the only way to go, for several reasons I have outlined here. I was converted by Bobster, and will never boil a tank of water again. I can boil a quart of water in an electric tea boiler in 3 minutes and pour that into my pressure cooker (no pressure involved; I used that for the lock on lid), and boil that on the stove. FAR quicker than the long tank idea. Bamboo? Go to Lowes and get a piece of PVC pipe. They do not carry bamboo tubes. | |||

|

| one of us |

[/IMG] [/IMG]Only way to go and for less than $50 to set up Picture shows the material and equipment | |||

|

| one of us |

| |||

|

| one of us |

| |||

|

| One of Us |

I love the hand drill in the vice! Never would have thought of that. I've never tried the steam method but would like to give it a try. This may be a stupid question, but if the pvc pipe holds the barrel or barreled action how do you steam the smaller parts (btm metal, trigger, etc.)? Also is there an outlet on the top of the pipe so the steam passes through or is that sealed off? | |||

|

| One of Us |

Les Very nice set up | |||

|

| One of Us |

You hang the parts from a rod which you put through the pic pipe at the top; I put a piece of foil on the top to keep the steam in but you do not want to seal it off; you want hot steam to pass up through the pipe at all times. I steam for ten minutes. I used the pressure cooker because of the locking lid; there are 5 big holes drilled in the lid to let the steam up; no pressure involved. I see I used a saucer on this one; I don't do that now for fear it might fall off. Total cost; $12; I took the pressure cooker from my wife as she no longer used it.  | |||

|

| One of Us |

IF the two of you set this up in the backwoods you could be on an episode a reality TV about the moonshiners :-) | |||

|

| one of us |

For small stuff use a large stock pot and stretch a length of iron wire across the top between the handles. Hang the parts on hooks. Cover with foil and steam for 10 minutes. Pieces like bottom metal you can hang in the pipe. I have several lengths of pipe I can use to handle different sized work. A 48 in length for barreled actions down to 18 inches for bottom metal.

| |||

|

| One of Us |

Thanks DPCD and Bobster. I'll be giving this a try. Did I see somewhere that water quality isn't an issue when steaming? As in can I use tap water instead of distilled? | |||

|

| One of Us |

I hang all small parts on a strand of wire, vertically, and on hooks from the cross bar; plenty of room for one Mauser. I use Mississippi River water. Which is what we get from the tap. | |||

|

| One of Us |

Great! Thanks for all the tips. Looking forward to not cussing at the wind every time I try to boil water outside. | |||

|

| one of us |

I use a tea strainer of stainless steel to hold all the small parts , screws, etc. The middle of the pipe has a coupler so I can reduce the height down for a better working area. Larger parts were hung with wire from the middle section and a cap was placed over the top with enough holds to allow the flow of steam to come out. The stainless steel tea pot spout has an auto water hose fitted into the bottom area and a electric hot plate does the rest. The drill is a 3/8 in. variable and it needs to turn about 400 rpm's and the stainless wire brush is from Brownell's. My early days for rust bluing was the tank of distilled water and long gas burner. My first try was in 1960 and I had the drug store make up the solution of Baker's #1 formula. When I went to TSJC in 1961 my instructor Louie Mrace assigned me a project to write up a research paper on hot water bluing. I wish I saved a copy. The steam method is quick and easy to use, so make up equipment and get started. | |||

|

| One of Us |

Les Are you making anymore custom stocks? | |||

|

| one of us |

I don't plan to make anymore stocks at this time. Old AGE is catching up with me. I know that it is time to quit and I reject requests for me to work on any guns except for myself. Bobster has a good site for anyone wanting to learn the steam method. I didn't try this type bluing until a few months ago. It is by far the best way for me and I can store this method in the basement of my 5th Wheel. I have used steam to blue spots on rifles and shotguns. I used a block 1X3X5 aluminum and heated this up very hot with the torch. I used a towel wet of several thickness over on the rust solution and hold the aluminum to the towel to create the steam. You can patch up a spot to match the rest of the gun. It will take a few times to get the right amount of color. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia