The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  7X57R proof loads

7X57R proof loadsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Greetings.... I have been building a single shot break action and am very close to having it ready to shoot. I want to do a proper job of proofing the gun before I deem it serviceable. I am not a reloader, so loading my own proof loads is not an option. I could find someone to do it for me, but was wondering if anyone had a formula or an actual load for proofing this caliber. From what I can find, a load of 30% over normal is appropriate. This comes out to 58,500 for the 7X57R. Thanks in advance, Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | ||

|

| One of Us |

Have no idea as to just what action you are using or other specs, but I would avoid attempting any "proof" loads in the firearm. Have an experienced, qualified gunsmith inspect the finished product, headspace, conditon of bore, mating surfaces, etc. and if he deems the firearm of safe construction, then merely shoot the available factory/commercial loads to begin with and in the event you do begin reloading, follow the manuals for that given cartridge. If not sure as to just how it will perform then, use one of those "lead sled" devices or tie it down in some manner and fire the rifle and position yourself some safe distance away from the firearm. Proof loads and fireing of same would be best left to the professionals in the field and not to be taken lightly. Proper proof loads and their make up is not common knowledge to the public and for good reasons and one of those being that someone would attempt to use that extreme load as something "normal" and you can guess the negative results! Proof loads use a different combo of components, primer(sometimes referred to as the blue pill indicating proof load) lab equipment-strain gauges, pressure sensors, etc. and again, most do not have that sort of facilities. Upon fireing, inspect spent case for pressure signs, or have someone you know to be knowledgeable and if no bad signs, you are good to go. With an "explosion" and pressures in the many thousands of PSI takng place some 2-4 inches from your head, pieces of jagged steel going into orbit is not an experience you want to encounter. Sure others may have their opinions on proof loads, but I would avoid it. Take care. | |||

|

One of Us |

These folks should be able to answer your questions. http://www.hpwhite.com/ _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Good suggestion about H.P. White labs. I just wanted to discourage anyone from using some mythical % increase in load to determine a proof of a firearm. Those folks at HP White will definitely do the right "science." | |||

|

One of Us |

Speaking of proof rounds, I have some actual 22 LR proof rounds from Olin Corp, and those mothers are hot! I don't even know where I got them. Just part of the things one accumulates over the years. _______________________________________________________________________________ This is my rifle, there are many like it but this one is mine. My rifle is my best friend, it is my life. | |||

|

| One of Us |

Thanks for your concern and the link. I planned to strap the action down to a tire, cover it with 1" thick rubber stall mat and use a pull string from behind my bull dozer. I know it is serious stuff. The 30% over normal value is in the ballpark for European proof houses. 58,500 isn't all that hot, but I would rather proof it to be sure it can handle the charge in case I get a hot load sometime int he future and have an accidental proofing experience while holding the gun. Todd Martinez lives less than an hr away, and has agreed to look over the gun for safety. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

Bailey, i've seen the pics you posted of your spectacular firearm on bladeforums. you should post the pics here, as well. these guys would go crazy over them. heath NRA Life Member Gun Control - A theory espoused by some monumentally stupid people; who claim to believe, against all logic and common sense, that a violent predator who ignores the laws prohibiting them from robbing, raping, kidnapping, torturing and killing their fellow human beings will obey a law telling them that they cannot own a gun. | |||

|

| One of Us |

powders act differently at higher pressures. there is NO WAY I would put a 30% overcharged load in a gun I liked. the other way to proof is to lube the cases. without the brass binding against the chamber walls, the bolt-face thrust is increased. IIRC I read about that last in kuhnhausen's mauser book. don't just take my word for it; double check first. | |||

|

| One of Us |

How does one factor in bolt face thrust on a break open action? Just a thought......I think Bailey is on the right track here. I also have a passion for break open singles, hopefully I'll get around to building a best quality sidelock ejector single one day. Nice work Bailey. Steve | |||

|

One of Us |

In a low pressure cartridge, this may be true. In high pressure cartridges this is more likely to reduce bolt face thrust by preventing that 'bound' case from suddenly 'letting go' while under high pressure and slamming into the bolt face with sudden force. Look up suddenly applied loads in engineering text books. I recently witnessed a rifle getting damaged due to excess headspace, to the point that the locking lug recesses peened out to bind the bolt. Yet some of the fired cases had remained bound forward in the chamber. That in spite of it having been lightly lubed. I know this because those cases still had the primers protruding and showed no slip marks on the case body. I believe the danger of oiling a cartridge is haveing some oil flow forward to form a 'wet' ring forward of the chamber which can act as a bore obstruction. Regards 303Guy | |||

|

| One of Us |

you are free to argue the point with mr kuhnhausen. you may also enjoy disputing maj. hatcher's conclusion that lubricated cases caused bolt failures at match events. I suspect that your "sudden impact" theory may not be the best explanation of what happened to the rifle you saw; how could a case cause any stress to a bolt while leaving the primer partially backed out? If I understand your theory, the case grips the chamber, the pressure overwhelms the case's grip, thus slamming the case violently against the bolt with enough force to cause damage. if that had occurred, the primer would be flattened or severely riveted, would it not? and the case head would have been severely deformed. imagine the disparate deformation between soft brass and hard steel, and how much the brass would have to deform to move the steel around. I use brass hammers to strike steel without harming it. the brass does not fare so well. | |||

|

| one of us |

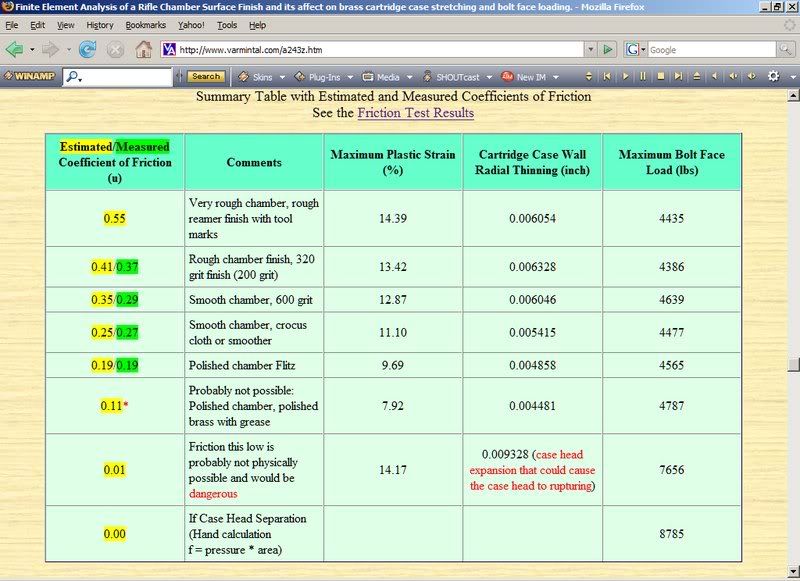

Case grip on the chamber walls is covered by Finite Element Analysis over at Varmint Al's site. It is not nearly as much as you would expect. You don't have to take my word for it. It is all right here Chamber finish and friction These data are for a .243. With real world finishes there is not much difference. It doesn't jump much until mu (coefficient of friction) is nearly zero which is not possible.  | |||

|

One of Us |

True! But, I was unclear. (Thanks for calling me out). Some of the cases remained forward in the chamber while others had failed with the typical 'bright ring'. Others looked normal with the typical 'creap' marks one gets on a fired case. The damage to the rifle would have been caused by the bolt slamming back into the lug recesses - not the case slamming into the bolt face. Case slamming causes bright marks on the case head. The principal of 'suddenly applied' loads is that when the metal under no load is suddenly loaded, the load experienced is nearly double the actual load applied. This is due to minute compression of the materials and small clearance being taken up which gives a momentum factor. This would be significant in a rear locking action. Peening of the lug recesses in a Lee Enfield bears testimony to the magnitude of this effect. Of course the rifle had to start off with excess headspace. Some of those cases that remained forward with the primers still backed out were lubed! Lubing only reduces the friction a small amount and probably does not change bolt face thrust much at all. It does improve case life quite a bit, 'though. My theory on this one is that the case still grips the chamber walls but creaps back progressively over the length of the case body. I have examined several cases with and without lube and radomly picked up on the range and the progressive slip marks are there on unfailed cases and missing on failed cases. Check out Varmint Al's site as ireload2 has kindly quoted. He shows the animated effects of the case firing in the chamber. If I can find something on the subject I shall post it in a new thread. (Even if I find myself wrong!)

Regards 303Guy | |||

|

| One of Us |

I'm still at a loss to understand how a protruding primer can be associated with bolt lug damage. ??? as to the two types of headspace you refer to, hatcher noted the same, and determined one was dangerous (space between the bolt and lugs) and one was much less dangerous (space between the case and bolt face. I always thought that sounded reasonable. | |||

|

One of Us |

The protruding primer was the indicator of excess headspace. That was all. It protruded by about a millimeter! I still have that case. What I found interesting was that a lubed case did not set back to reseat the primer. Another lubed case held tight while the head failed. The damage to the locking lug recesses was as a result of excess headspace, which resulted in the bolt hammering back hard enough to peen the steel. I have no idea why there would be space between the lugs and the recesses. I would have thought the firing pin force would hold the bolt back but apparently not. It is interesting that Hatcher noted it also. delloro, do you recall if he was refering to both systems or just the rear locking system? I should mention that I had warned this young man a few months earlier that he had a serious headspace problem. He continued using the rifle and on this occasion, I was monitoring him. On his next session, the rifle failed in that the bolt started binding. That rifle then went to the "Happy Hunting Grounds"! Now he listens to me. Bailey, I was hoping you would post pictures of your rifle for us. May I suggest 'proofing' your gun by first developing your safe max loads in your rifle then firing a fair number of them in it. The idea is to measure headspace before, during and after to check for change. At the same time checking for cracks and whatever else needs checking. I am refering to loads hotter than what you plan to use but still within the rifle's capability. Just a thought. Is this a brand new action? Manufactured by you? One day I am going to manufacture a falling block 22Hornet. Regards 303Guy | |||

|

| one of us |

The fall of firing pin is stopped by the bolt body or in the case of a Lee Enfield by the bolt head. When the firing pin slams forward it would have a tendency to drive the bolt forward a little. As far as protruding primers go pick up enough fired brass from Lee Enfields, M94 Winchesters and Spanish M93 Mausers and you will find a lot of protruding primers. Some are so bad that they are what I call hammer heads. The primer is actually riveted into a mushroom shape bigger than the primer pocket. When the primer fires it backs out of the case while blowing the case forward due to excess headspace. Then the powder charge fires. The case starts expanding grabbing the chamber walls. The case head is unsupported and the case stretches back toward the bolt. The primer has backed out so far it does not reseat but begins to mushroom against the bolt face as the case stretches back toward the bolt. Luckily the pressure is low because all you have holding the gas pressure in is the .010 wall of the primer cup. | |||

|

One of Us |

Now I understand - thanks for that. That is interesting ireload2. This particular primer shows no sign of flattening or any high pressure. It is just sitting there, protruding. The case with the failed head also shows no primer flattening. Regards 303Guy | |||

|

| One of Us |

Baily. Buy a box of factory 7x57R ammo, test one of those first. Take apart another cartridge and dispose of the powder, then reload the case to the highest pressure you can find in one of the many reloading manuals which list pressures for the 7x57 rimless, seat the bullet again, test that. If all is ok and you still want to test to higher pressures than that's up to you. I think my little test is a good start. Good luck, let us know how you get on. | |||

|

| One of Us |

gotcha. I understand.

he did not differentiate, as I recall. most of the arms he dealt with were front-locking, so that was likely what he had in mind, but I don't see why there would be a difference. in summary, if I recall correctly, he explained that having the brass move was not a problem; when the bolt moved, it was. | |||

|

| One of Us |

Oldun, You outlined what I was thinking of. I will also be taking measurements of the action before and after for any expansion or deformation. also of the case. Thanks!! I will get a loading manual as well. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| one of us |

BB, the 7x57R is a standard European loading and any of the proof houses there could test the gun for you. It would not be cheap and there would be plenty of paper hoops to jump through to get the gun there and back. It might be possible to get one of them to sell you a pair of proof cartridges, but I'd be surprised. The 7x57R is rated at 49 ksi, so you're looking for a proof load of about 61 ksi, of which you'll need to fire two rounds (CIP standards). You might be able to find hot loads "for modern rifles" in some reloading book, but I wouldn't be surprised if such is not available. Full power, CIP spec 7x57 loads will approach 57 ksi, which is close to what you need. Unfortunately, SAAMI doesn't publish a psi spec for this cartridge, so you'd have to seek out European load books. You'd need about 7.5% more pressure than this 57 ksi, and--roughly speaking--this will correspond to about a 2.5% increase in velocity over the max load. If you don't want to invest in a strain gauge, you might use a chronograph as a very crude pressure estimator. Load up to the fps shown in the book as corresponding to 57 ksi and then go for 2.5% more fps. This is all very approximate, of course. However, modern brass and steels can make rifles that will take 65 ksi all day, so you may have some room to spare; there are things I'd try with a Ruger No.1 I'd never try with a T/C Contender carbine. You could use H.P.White's pressure measuring service to develop your own proof loads in 7x57 brass, but this isn't identical in all respects to 7x57R brass, so it's still an approximation. You can find some useful tables and links on this page. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia