The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  best rockwell hardness for break action

best rockwell hardness for break actionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I am getting close to heat treating time. My action is made from 4140. I was wondering what the best hardness would be. I will be using a digitally controlled salt bath for austenitizing and quenching, so I have no problem hitting the numbers exactly. My best guess would be 40RC, but I don't kow if that is correct or not. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | ||

|

| one of us |

I was thinking around 40 just as a swag. I guess 38-42 would be fine. Can you tell us more about the action? Did you make a break action your self? | |||

|

| One of Us |

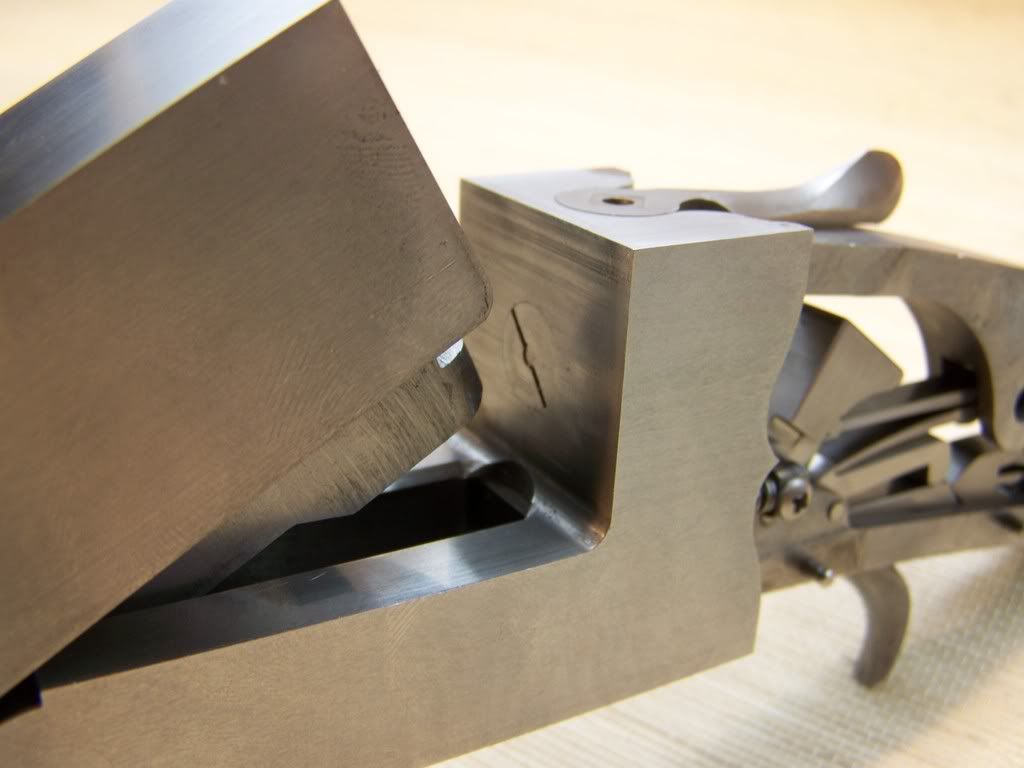

Yes, here are a few pics of the action. I have a thread in the single shot forum named "ejector or extractor" that has more info and pics. It's all my own design, but really nothing new...It will be chambered in 7X75R for the first barrel, and I plan to make a second barrel in 22 hornet.    Thanks for the info. I am going to make it on the harder side as I like the slicker feel. Since I am not putting too much pressure on it with the calibers I selected, I don't think there would be any problems. I can always draw it a little softer if I learn otherwise. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

It seems from my limited data collection that crappy guns are RC25 and good guns are RC47. And I have some in between. My stress analysis and experiment ion with break actions leads me to believe the hardness of your action will not matter. I analyzed a handi rifle in 45/70 and then validated the calculation when I overloaded it until the brass flowed. I can't tell for sure from the pics, but my guess is that you are even better. Here is a chart: http://www.varmintal.com/arock.htm Gun are even harder to blow up than calculations would indicate, possibly because the peak pressure passes quickly. If we can push .080" thick RC47 chamber wall 40sw cartridges until the primer falls out, then 69ksi steel is fine for chamber walls .25" thick. Have you looked at Walter B. Mueller's 41 page book on building a single shot action? He goes through the calculations. | |||

|

| one of us |

As tough as 4140 is I suspect you don't need any heat treat. You action is massive and has nice filet radii. I think all heat treat might do is warp it. How hard is it now? High 20s to low 30s? | |||

|

| One of Us |

The receiver is cut from a block of pre-heat treated 4140 fro die shoes. It is at 30-31 rc. The thing is that it is sticky and wants to adhere to itself. In speaking with the manager at crucible steel in Dallas ( Scott Devanna), he indicated a little higher hardness would make it less prone to adhesive wear. I plan to engrave it poot out of it, so I don't want to go too hard. 40-42 would be a good balance. I just wanted to see if the ballpark was right. I will run a stress relief cycle or two before I HT it to minimize warping. Plus, using salt baths helps with this as well. A lot of people have said the action looks massive. It really isn't all that big. 1.9" tall and 1.3" wide and 8" overall from the hinge including the tang. I just tried to leave the beef where it was important. I borrowed proportions from 20 ga. shotgun actions I could measure. A good friend is encouraging me to make a third barrel in 450/400. I am just not sure it is right for a big bore. Sure would be fun to have a big bore though. What do y'all think of the caliber? If any of you have a CAD program, I would be happy to forward my drawing. It is still in progress as I will end up with a complete 3D model of each part. This one being the prototype has some variations from the drawing right now. I designed it to be made as a double with minimal modification. My next one will be a small bore double. Maybe a .17 hmr....that would be hell on the local squirrel population :-) I am not one to push the limits, so I am looking at chamber pressures of 45,000 or less. There are plenty of choices, and once the action has proven itself durable with time, I may try a .375 flanged or H&H. Any suggestions or input is more than welcome, so please fire away if you see something I overlooked. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

You mean that steel rubbing on steel of the same hardness are both galling? | |||

|

| One of Us |

Yes, the tendency is there. Although none of the parts have any galling, I have enough experience to know what it feels like when the potential for galling is there. I did make a couple of drill alignment tools from the same block with a tight fit, and they REALLY wanted to stick. I have used different steels for the lock parts and top lever, and it helps to have dissimilar steels. I am most concerned with the monoblock interaction with the receiver. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

The only galling I have ever seen in a gun was in a Cricket 22 rimfire for children. The bolt body and firing pin galled. That had big side loads and spring loading. I can't imagine your mono block and receiver having as much trouble. Is is starting to gall now? Put some polish and lube on it? | |||

|

| One of Us |

There isn't any galling yet, but what I am anticipating is the possibility of some of the parts moving when proofing, and if the tendency to gall is there, I want to remove it before I have to use a hammer and punch to loosen a stuck part. What I am noticing is the parts are burnishing in with each other, but this is not under a load. I've made hundreds of folding knives, and even some hardened steels will gall with a load on them, even oiled. I can feel it before it actually happens in the way the parts want to stick. The only solution that works with consistency is to polish the surfaces and make sure the HT is right. I just don't want to waste my 100 plus hours on this thing because I didn't HT the parts. I spoke with Bill Hein last year and he indicated that his actions get nice and slick in the low to mid 40's. I just wanted to bounce that hardness off a few others in light of the fact that my action is not a bolt gun, and if that could make a difference. I really want this rifle to be as good as I can make it. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| one of us |

I Rockwell tested a Remington M700 bolt on the locking lugs and they are supposed to be 4140. It was 42 RC. In spite of the heat treat I have galled M700 locking lugs slightly by closing a dry bolt on a tight case. So you have to keep it lubricated on areas that have high surface loads. Your stress relief is a good idea but quenching a hot part with an odd shape still stresses it from the differential shrinkage that occurs as it cools. To minimize galling you want the hardness to differ some between the mating parts. From the photo some of your cold weld/sticky/galling tendency is coming from the tool marks. Polishing them so the surface texture lay is parallel to the relative motion of the parts will help. | |||

|

| One of Us |

Thanks for the info on the hardness. 42 is my target hardness. I agree that some of the sticky feel is due to unpolished parts. I will certainly get them nice and shiney :-) The inherent stress of heat treating is the reason I am going to use salt baths. While you can't remove all the stress from the process, marquenching in salt greatly reduces it. I am also going to play with a test piece to see what a piece of 4140 with a bainite grain structure would behave like. Bainite is the second form of hardened steel, martensite being the first. Bainite is formed by leaving the steel in between the martensite start and martensite stop temperatures for several hours. It is a little less hard than martensite but is MUCH tougher. I have seen knife blades of bainite do some incredible feats like being bent 90 degrees one direction, then back 90 degrees the other direction several times before finally breaking. The blades were all around 56-57 rc and made from 1084, 5160 and L-6. It will be interesting to see what 4140 does. Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

For what its worth, 41-46 would be a good range. Most actions of this type would be slightly oversized, heat treated, and finish ground to final dimensions. Looks like an ambitious project, send pics when all is done... John | |||

|

| one of us |

There has been much hype about bainite with knives and fortunately that hype has just about disappeared ! I've spent a lot of time on knife making forums to dispel the myths.The difference is not 'MUCH' better and consiering the HT proceedure needed it's not worth the effort except for special cases.Marquenching is much more appropriate to reduce warping and a hardness of HRc 42 is an excellent choice !! | |||

|

| One of Us |

Hi it dependes to the kind of steel you would use. low end 40 HRC and upp to 48 HRC,but you can surface harden to upp 60 HRC for giving a good wearing restance to the action and receiver (very shallow around 0,1-0,2 mm deep ) regards yes Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy; its inherent virtue is the equal sharing of misery. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  best rockwell hardness for break action

best rockwell hardness for break action

Visit our on-line store for AR Memorabilia