The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Gunsmithing

Gunsmithing  308 SMLE with large chamber

308 SMLE with large chamberGo  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

Hi guys, I need some advise. I have a customers gun here, it's one of the Ishapore(?) SMLE in .308 that is splitting cases near the web. I took a chamber cast and it is .478" at the base. The shoulder is also at 1.615" instead of 1.560". He said that it is really bad with Win ammo. I checked some factory cases and the win is .465, RP is .469" at the base. I think that Nuemrich has replacement barrels or could I pull the barrel, trim a couple of threads off and rechamber? I've never pulled a barrel on a SMLE before, is there anything to look out for? TIA | ||

|

one of us |

do they make replacement bolt heads to take up an additional .050"?? I think I'll try to make a new piece for my action wrench to fit the lug and give it a go. The neck part of the chamber was tapered from .350 to .347" also. What were they going for, maximum easy chambering? | |||

|

| One of Us |

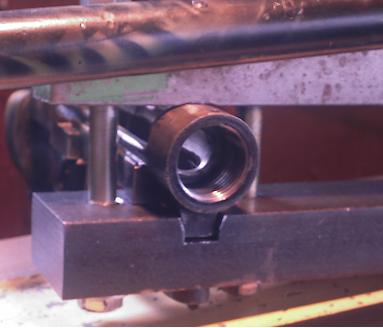

For what its worth I made this for removing SMLE barrels. I used a piece of 1018 cold finish 1/2 inch thick by 1 3/4 X 2 1/2. drilled a hole just a bit larger that the receiver and milled out a slot for the upper guard screw projection on the bottom of the receiver ring. Add an 15 inch cresent wrench and a sharp rap on the wrench with a dead blow hammer and the barrel should screw right off. I have used this to change a number of barrels. Hope this helps  I have also tighened up the head space on a SMLE by silver soldering a piece of shim stock on the bolt head and cutting it to size in the lathe, (British armorer recommendation). Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | |||

|

one of us |

Excellent, thanks for the info and pics. | |||

|

one of us |

would anyone happen to have the thread measurements for the barrel shank handy? I'm wondering if maybe I could just trim 1 threads worth off of the barrel to get the headspace back where it should be? | |||

|

| one of us |

14 Threads per Inch. One revolution is somewhere around .071. I doubt you have that much headspace. You will need a reamer. Rojelio | |||

|

| One of Us |

I got an Ihsy covered in grease for $75 through ShotgunNews 10 years ago. I put on a FAC steel scope mount and took it to the range, once. It shot one type of ammo well. I was not too impressed. I would spend my time on Mausers or Ruger #1s. I would throw a bad Ishy in the trash. But if you drive to Seattle, you can use my .308 reamer in one of my lathes. | |||

|

one of us |

If I measured right it is .055", so I can probably set it back one thread and then just ream it a little by hand until it closes over a Go gauge. Soldering a shim onto the bolt face sounds like a much quicker way to go. I'll see which way the customer wants to go. | |||

|

One of Us |

Would that be 'hard' lead solder or silver solder? I am told silver solder can be had in varying melting points. Weren't the 308 chambered SMLE's chambered 'generously' to keep pressure down to SMLE levels? Just a question - I always thought only No.4's were chambered in 308? Regards 303Guy | |||

|

one of us |

I have some Silver solder from Brownells. I'd have to check to see what the temp range and strength is, but yes they do come in different temps and strengths. I hadn't heard of the generous chamber idea, but it sounds reasonable. Maybe Weatherby style freebore would have worked better for keeping the pressure down? It probably wouldn't have a problem with military brass being thicker and closer to the chamber dimensions. The end of the chamber is .478", which is also right at the extractor groove of the cases. I measured the base of some different cases. Win .465" RP .469" Military range pickup: WCC .469" LC .470" O O .470" OFV .470" FNM .471" MF .472" NNY .473" He'd probably be fine if he only shot military or Remington ammo. I would like to decrease the excessive headspace though. | |||

|

| One of Us |

I have built some tooling for soldering shims to No4 bolt faces for 303 Brit. The base of some 6.5x55 brass is bigger. Walking into my reloading area, I measure: NNY .480" RP .474" S&B .473" Win .472" PMC .472" | |||

|

one of us |

could you take some pics of your bolt face shim tools and post them here or email to idahobronco@aol.com ? I think the 7x57 and 8x57 cases were originally slightly larger than the 30-06. They were close enough that they just got lumped in with the 06 family of cases. TIA Glenn. | |||

|

| One of Us |

Info dump on the way. The bolt head is screwed into a fixture that acts as a heat sink and/or water bath during soldering. A wire pulls down the shim through the firing pin hole. A weight is put on the wire. When the torch melts the solder, the shim will go flat on the bolt head. There is a problem with keeping the hole in the shim perfectly aligned with the hole in the bolt head. Cutting firing pin holes from the rear is a pain. If I were to do it again, I might use an Aluminum plug to pull down or a centering bushing on the hole. It would force the hole alignment. The fixture can also be used to hold the bolt head in the lathe to trim the shim after soldering. Of cutting the shim off and starting over Dunlap talks about firing pins in his 1950 book on page 155:

What does it all mean? Shims are easy. Firing pin holes are hard. | |||

|

one of us |

Well, I finally got it finished and sent home. I made a piece for my action wrench that has a groove for the under lug, but it also fits tight against the flats on the bottom of the action.  With a couple of hits from a 5lb sledge, it let loose and turned off easy. I made a tapered aluminum bushing to fit the SMLE barrel taper for my home brewed barrel vise.  I went to Harbour Frieght and found this set of carbide cutters for makeing joints in wood? Anyway, it wasn't very much $ and came with several different sizes. I used the 1/4" one and ran it in slow to recut the extractor groove. It worked great. With the barrel back on, I ran the reamer by hand and checked often with the Go gauge so I could get a tight chamber. I rented a reamer and gauges from www.reamerrentals.com When the bolt closed on the Go gauge, I tried a dummy round it and it was very hard to get the bolt closed. I tried some different factory rounds and it still closed very hard.(So why did I go to the effort of useing a Go gauge?). I ran the reamer in a few more times till the bolt just closed over a factory round with light pressure. I test fired a couple of rem and winchester rounds with no case splitting. Before I pulled the barrel, the bolt would close easily on the No-Go gauge. One note on the barrel steel, I used a center punch made from 1/4" lathe tool stock to make a mark on the barrel and it dulled the point of the punch. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia